|

Author

|

Topic: GS1200 Blower Motor Connections

|

Paul Adsett

Film God

Posts: 5003

From: USA

Registered: Jun 2003

|

posted September 26, 2019 07:25 PM

posted September 26, 2019 07:25 PM

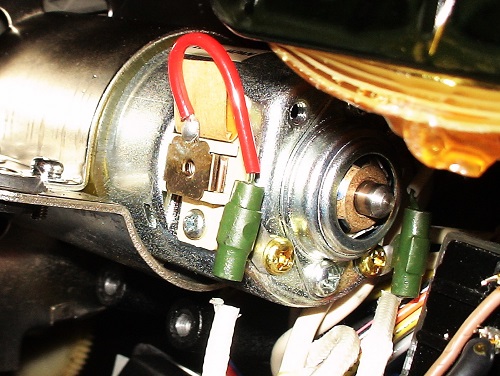

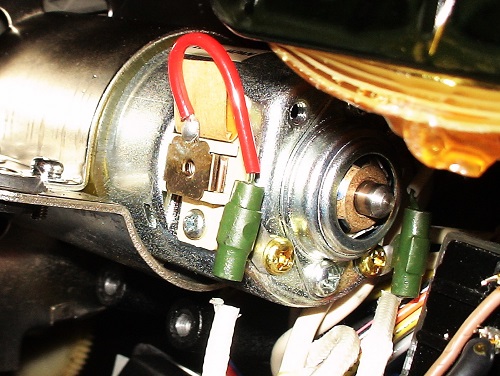

Well, talk about cascading system failures, I now find that I have broken off one of the main blower motor leads, which may or may not explain why the blower motor is not running! ![[Big Grin]](biggrin.gif)

Anyway the question for Leon and anybody else is "what are those two green things spliced into both leads going to the motor brushes? Are they just there for stress relief/support of the wires, or are they something more sinister? Can I just ignore them if I connect a new wire up directly from the relay to the motor? The existing motor wire is extremely fragile,no wonder it broke off.

--------------------

The best of all worlds- 8mm, super 8mm, 9.5mm, and HD Digital Projection,

Elmo GS1200 f1.0 2-blade

Eumig S938 Stereo f1.0 Ektar

Panasonic PT-AE4000U digital pj

| IP: Logged

|

|

|

|

Phil Murat

Jedi Master Film Handler

Posts: 671

From: Villeneuve St Georges, France

Registered: Dec 2015

|

posted September 27, 2019 02:20 AM

posted September 27, 2019 02:20 AM

Hello Paul,

Green Cylinders :

It looks to be "Coils" ("Selfs" ?) installed in a serial path to increase motor performances or decrease arcing at brushes areas.

To be confirm.

Could you record "R" for these coils ? (Normaly "R" value is very low, may be below 10 OHMS, depending on lenght of coil wire).

"Selfs" can be found on Electronical Components Market. However, due to numerous configurations (Torus, Cylinder, With or Without core, Wire section, etc....), you need to find out some datas to determine Self Class.

Otherwise, may be (in order to save existing coil) it is possible you roll out a portion of copper wire from the fail green coil and simply renew soldering to link it to motor terminal....

[ September 27, 2019, 03:33 AM: Message edited by: Phil Murat ]

| IP: Logged

|

|

|

|

Phil Murat

Jedi Master Film Handler

Posts: 671

From: Villeneuve St Georges, France

Registered: Dec 2015

|

posted September 27, 2019 10:43 AM

posted September 27, 2019 10:43 AM

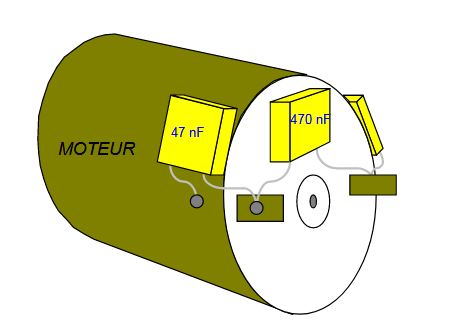

You are right Paul, "inductor" is the right name :

[URL=INDUCTOR for sale]https://fr.aliexpress.com/item/32812559693.html?spm=a2g0o.productlist.0.0.2aa31f65bOzAyL&algo_pvid=41ee612c-c24f-4a1b-aab6-8e40e7c0cdc5&algo_expid=41ee612c-c24f-4a1b-aab6-8e40 e7c0cdc5-14&btsid=064984b8-f905-40c8-b373-e344bf316b4d&ws_ab_test=searchweb0_0,searchweb201602_1,searchweb201603_52[/URL]

Bypassing failed inductor will increase arcing condition, so that arcing could be observed on relay contact diminishing relay life.

Also , unwanted extra noises can be reported on sound.

May be 3 capacitors could replace both inductors (unpolarized capacitor fitted on motor terminals,1 in // installation + 2 links beetween shell and terminals ), but I have no idea of capacitor value, and it is better to get wiring diagram before to make any change.

Here is an exemple for a small filtering system which works pretty good for small motors (scale models , etc...).

To be efficient, it is recommended to get capacitors terminals shorter as possible...

| IP: Logged

|

|

|

|

|

|

|

|

Paul Adsett

Film God

Posts: 5003

From: USA

Registered: Jun 2003

|

posted September 27, 2019 05:28 PM

posted September 27, 2019 05:28 PM

Thanks Phil, Mark, Leon, and Maurice for all the helpful advice. Right now my GS1200 has ended up on life support in the ICU following what was thought to be a minor problem with the take up not rotating. Amazing how these GS1200 jobs can rapidly escalate in terms of complexity and cost.

Anyway my next question is how critical are the specs for those inductors. Will any RF Choke with say a few microhenries of inductance (a few turns on a ferrite core) do the job, or does it have to be 'tuned' as in an LCR resonant circuit, in other words does it has to be a specific value of inductance to suppress arcing at the brushes and relay contacts?

UPDATE

I was able to solder the lead from the relay back onto the green inductor, albeit a very weak solder joint it at least makes the connection good enough to test the equipment. Anyway one of the main fuses blows immediately on turning on the main power switch and everything is shut down except for a couple of lights. None of the motors are running.

[ September 27, 2019, 07:50 PM: Message edited by: Paul Adsett ]

--------------------

The best of all worlds- 8mm, super 8mm, 9.5mm, and HD Digital Projection,

Elmo GS1200 f1.0 2-blade

Eumig S938 Stereo f1.0 Ektar

Panasonic PT-AE4000U digital pj

| IP: Logged

|

|

Phil Murat

Jedi Master Film Handler

Posts: 671

From: Villeneuve St Georges, France

Registered: Dec 2015

|

posted September 28, 2019 06:15 AM

posted September 28, 2019 06:15 AM

Hi Paul,

I am not specialist in Electronic systems but I don't think that filters generaly used to cut noises due to motor arcing are built as resonant circuit RLC more often used in radio system and tuned up for a specific frequency.

I assume in our case the idea is only to damp or absorb what happens in brushes area.

Concerning fuse burnt, I suggest you to investigate around power supply (after bridge rectifier).

If a transistor (power regulator) has failed, it is necessary to find out origine of defect (miscelaneous short circuit and/or failed big capacitor, etc.....) before to replace it.

Did you test the Fan motor with a seperate power supply ? (Motor has to be fully unplugged to do that)

Do you have schematic or wiring diagram for your machine ?

An other idea :

Reviewing your picture, it appears broken wire is linked to a Red one on motor (Normally Positive current).

So if this broken wire has incidentally hit shell of motor, this could result in a big short cut which could heavily damaged the power governor circuit just before....

[ September 28, 2019, 09:19 AM: Message edited by: Phil Murat ]

| IP: Logged

|

|

|

|

Phil Murat

Jedi Master Film Handler

Posts: 671

From: Villeneuve St Georges, France

Registered: Dec 2015

|

posted September 29, 2019 01:54 PM

posted September 29, 2019 01:54 PM

Hi Paul,

Yes , my feeling is the issue is around one of the power supply stages too.

Could you tell me if bottoms of Big "blue" caps are perfectly flat (idem for black ones next to these ones) ?

Anyway , I suggest you to replace them in a same time you renew bridge rectifiers.

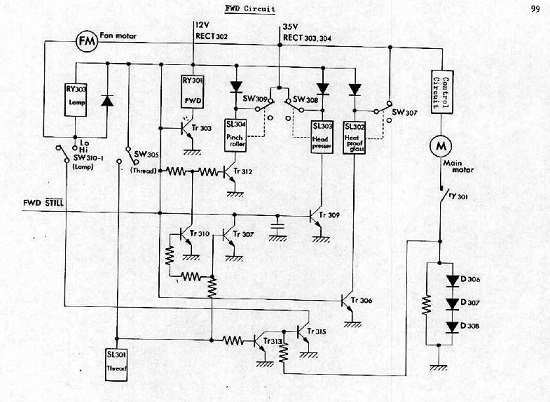

But, at this time, I have a problem to find out a "Datasheet" for voltage regulators (4) D330 just below flywheel,Some of them appears in P99.

- what is the fuse which breaks ?

- Does it breaks when you power on the machine or only when you play forward?

To follow

NB

Have you got this schematic ?

[ September 30, 2019, 04:09 AM: Message edited by: Phil Murat ]

| IP: Logged

|

|

Paul Adsett

Film God

Posts: 5003

From: USA

Registered: Jun 2003

|

posted September 29, 2019 04:02 PM

posted September 29, 2019 04:02 PM

Hi Phil, thanks so much for taking your time to try and helpme out - much appreciated.

Ok so the blue caps all look visually like new, all flat bottoms as far as I can see without removing them.

The fuse that is blowing is one of the 3 amp fuses on the board attached to the main transformer. There are two 3.0 amp fuses which are oriented vertically and it is the one on the left looking into the back of the projector.

This fuse blows instantly when the main power switch is turned on.

The lamp is still going into its preheat mode and the amplifiers

signal level meters still light up, but that's about it. None of the motors are getting power.

What is the operating voltage of the fan motor?

[ September 29, 2019, 07:36 PM: Message edited by: Paul Adsett ]

--------------------

The best of all worlds- 8mm, super 8mm, 9.5mm, and HD Digital Projection,

Elmo GS1200 f1.0 2-blade

Eumig S938 Stereo f1.0 Ektar

Panasonic PT-AE4000U digital pj

| IP: Logged

|

|

Phil Murat

Jedi Master Film Handler

Posts: 671

From: Villeneuve St Georges, France

Registered: Dec 2015

|

posted September 30, 2019 03:54 AM

posted September 30, 2019 03:54 AM

Hi Paul,

Your first idea to replace RY303 seems to be a very good way.

If you have no spare available at this time, try to remove it and save (this is just to make troubleshooting) by soaking it using a powerfull contact cleaner (choose cleaner-lubricating too). you can manage a small hole in crystal shell to insert the spray pipe. the idea is to get inner contacts free and clear from all oxyde you can. Then test relay outside with a small battery (max 12V) observing contacts motion and their good position (contacts have to swith all together).

Moreover, test (and insure you) Fan Motor works properly with a 12V battery (disconnect motor from machine of course)

Fan Motor works under 35V at full power and just around under 12V when idling (Lamp Off / Preheating) and actuating flywheel.

4 RECTIFIER stages:

A) +35V powers Fan, Main Motor (via governor), Amplifier (Vertical Fuse 3A) :

To renew 35V power stage you need 1 Rectifier 1B2C1 (RECT 303) + 1 Rectifier 1B2Z1 (RECT 304) + 1 Capacitor 2200µF/50V (C317)

B) +35V Amplifier (Vertical Fuse 3A) :

1 Rectifier 1B2C1 (RECT 305) + Rectifier 1B2Z1 (RECT 306) + 1 Capacitor 4700µF/50V (C318)

C) +12V Amplifier , Miscellaneous (Relays, etc...)(Fuse 5A) :

1 Bridge S4VB20 (RECT 302) + 1 Capacitor 4700µF/16V (C316)

D) +5V T/U & Rwd Motors (Fuse 5A) :

1 Bridge SIRB20 (RECT 301)

(In case some references are no more supplied , you can install an equivalent)

1B2C1 - 1B2Z1 DATASHEET

NPN transistors which are following works in the Logic Schema p99 (transistors don't like short circuit) :

TR303 / TR307 / TR 310 / TR313 = 2SC945

TR306 / TR309 / TR312 / TR315 = 2SD330 (Installed below Flywheel, taged D330)

D330 :

2SD330

2SC945 :

2SC945

As necessary Both references are still available for few money (Ebay or anyplace else).

Let us know ...

[ September 30, 2019, 08:49 AM: Message edited by: Phil Murat ]

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

Phil Murat

Jedi Master Film Handler

Posts: 671

From: Villeneuve St Georges, France

Registered: Dec 2015

|

posted October 03, 2019 01:42 AM

posted October 03, 2019 01:42 AM

Hi Paul,

Very High probability you found out "issue root" ![[Wink]](wink.gif) : :

Upon some research in forums backgrounds from my side (German Forums too) some GS1200 owners have reported this typical problem (35V fuse burnt due to failed "Governor").

Often time , when "Governor" board fails, it generates a short-circuit on 35V power supply.

I/C UPC1002C fitted on "Governor" Board is probably out of order due to poor caps around.

Also it can be an aging failure which shows up for machines which have accumulated many working hours.

UPC1002C is an I/C "NEC" component, a bit difficult to get , but still available (minimum price around 5Eur in China) .

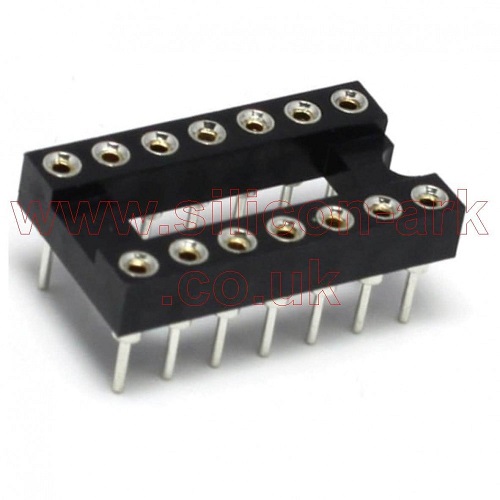

In case "Governor" refurbishment option is choosen :

A) To remove UPC1002C, it can be more confortable to cut pins before and to desolder each pin by each one in order to limit stress of board.

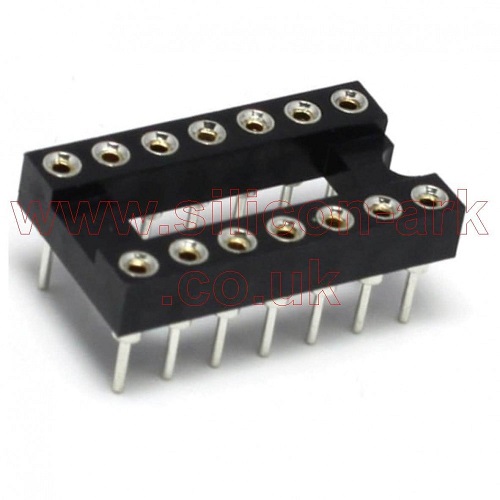

B) Install 14 pins DIL socket on board first then simply clip new IC on socket.(This minor modification allows fast future installation/removal of I/C)

Pay particular attention during socket and I/C : Do not reverse their position

C) Suggest to replace all caps and small transistors as an corrective action package.

14 PINS DIL SOCKET Suggested :

[ October 03, 2019, 05:56 AM: Message edited by: Phil Murat ]

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

UBBFriend: Email this page to someone!

UBBFriend: Email this page to someone!

Printer-friendly view of this topic

Printer-friendly view of this topic

![[Big Grin]](biggrin.gif)

![[Smile]](smile.gif)

![[Roll Eyes]](rolleyes.gif)

![[Wink]](wink.gif) :

: