|

Author

|

Topic: Advice on Elmo K100 wanted

|

Martin Davey

Film Handler

Posts: 94

From: Southampton UK

Registered: Dec 2011

|

posted February 04, 2012 03:09 AM

posted February 04, 2012 03:09 AM

I have recently obtained an Elmo K-100 SM and I was hoping members could answer a few questions for me please.

The main, larger belt failed after a few mins. It snapped. I think it was not a correct belt in that it did not have either a square or round profile. Instead it was very flat in profile being 5mm x half a mm and quite weak,much like an elastic band.

I presume that a more normal round (profile) belt is required? The length of the belt was 48cms which gives a circumference of 15.3cm approx. If anyone knows the exact specification of belt please could they let me know.

I was going to purchase a belt from www.bearingstation.co.uk, as mentioned in a previous thread (o rings for £1.20) a short time ago. Their site lists two types of O ring, Nitrile and Viton, but I have no idea which type I should order.

In the 5 mins it was operational I found threading quite difficult. Does the machine like stiff leaders? I was tempted to load it in to the slot sideways to reach the opened gate.

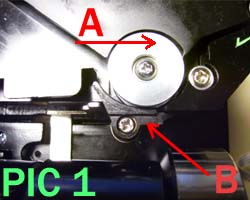

PIC 1.The roller 'A' has no sprockets but I presume throughout operation of the machine it should be turning in the direction of play?

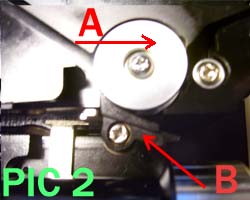

On the bottom left of the roller is a guide 'B'. Is the first position correct for the 'off' position (pic1), and the position in PIC 2 correct for threading? And should the guide return to the first position (pic1) when in projection/lamp on mode? I wondered if the film threading action was being blocked by this.

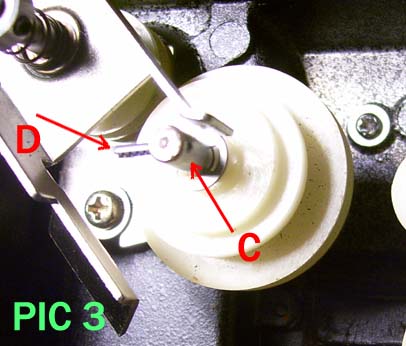

PIC 3. Looking at this same roller from the motor side I see that it is driven by the larger belt (and in the printed diagram in the machine). Turning this roller by hand, from the motor side turns the roller fairly easily but some times a small shaft 'C' projecting out of the main roller axle hits, and locks against a small flat piece of metal 'D'. Is this action cancelled when the machine is running at a proper speed, rather than a 'hand turn' speed? I wondered if the weak belt had snapped on this action.

Thanks in advance for any info members may have.

| IP: Logged

|

|

|

|

|

|

|

|

|

UBBFriend: Email this page to someone!

UBBFriend: Email this page to someone!

Printer-friendly view of this topic

Printer-friendly view of this topic

UBBFriend: Email this page to someone!

UBBFriend: Email this page to someone!

Printer-friendly view of this topic

Printer-friendly view of this topic