|

Author

|

Topic: Beaulieu Take-Up Problem.

|

Rob Young.

Phenomenal Film Handler

Posts: 1633

From: Cheshire, U.K.

Registered: Dec 2003

|

posted March 10, 2015 03:01 AM

posted March 10, 2015 03:01 AM

Well my Beaulieu is throwing it's latest tantrum. ![[Roll Eyes]](rolleyes.gif)

A couple of months ago, when switching to forward, the take-up spool refused to move. Switching to reverse then forward a couple of times and hey-presto, all was well again. I assumed it was the old washer in the arm wearing out, but when I dissembled it later, all was fine.

Anyway, I did a quick check in the back of the machine also and all looked fine, so I put it back together and it ran happily for the last couple of months.

Then on Saturday, during a show for friends (why do they always do this during a real show ![[Confused]](confused.gif) ![[Roll Eyes]](rolleyes.gif) ![[Big Grin]](biggrin.gif) ) the same problem. ) the same problem.

A couple of reels ran fine, but then no response from the take-up arm. Switching from reverse to forward several times and finally (with a little clunk) the take-up mechanism started to work again and is now fine.

It must be a problem with the clutch not re-engaging following rewinding I guess? I've had a quick look at the service manual and couldn't see anything obvious.

Any one else had this problem? Someone tell me there is a really easy fix!! ![[Big Grin]](biggrin.gif) ![[Smile]](smile.gif) ![[Smile]](smile.gif)

One for our resident Beaulieu expert, Andrew, me thinks.

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Andrew Woodcock

Film God

Posts: 7477

From: Manchester Uk

Registered: Aug 2012

|

posted March 12, 2015 05:57 AM

posted March 12, 2015 05:57 AM

Had another look into this for you this morning Rob.

The only linkages that come from the main switch cam shaft, control the sound head section mechanical movement and the floating roller movement around the capstan drive roller area. That is it.

No linkages are utilised for spindle movements.

With the rear cover removed on my machine, I placed the machine into forward and reverse projection modes on the master switch.

All that changes is the rotation of all gears and the take up reel drive belt. Everything turns in both modes while ever the motor is turning.

So how then does the machine know only to turn the take up spindle in forward mode while leaving front arm spindle stationary and vice versa in reverse I hear you ask?

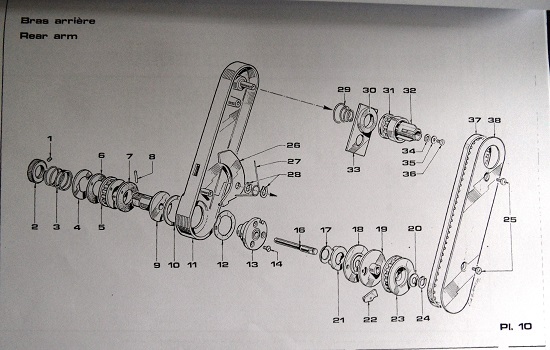

Simply that each arm has a ratchet mechanism built into the gearing at the lower end of each arm.. see drawings below.

This one way clutch or ratchet mechanism simply allows the spindles to be only engaged with the drive only ever in the direction that each of the spindles will ever turn or be driven.

In the opposite direction, the lower gear is still turning away as normal but the ratchet mechanism or one way clutch, simply rides over the ratcheting drive points.

Conclusion:

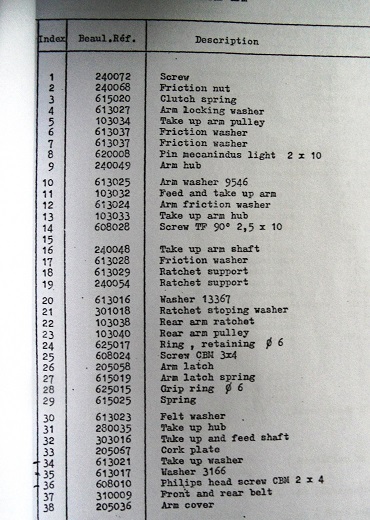

If, with the rear cover removed, you observe all gears and take up belt turning in both directions as you switch the master switch from forward to reverse, then the only other reason why the spindle cannot turn is either because the ratchet drive key (item 22 on page 10 of the service manual) is not engaging correctly with the ratchet drive wheel or there is wear to the ratchet drive wheel or the internal arm belt (item 37 on page 10) is either worn, loose or snapped.

Please refer to drawings below in your manual :

[ March 13, 2015, 12:40 AM: Message edited by: Andrew Woodcock ]

--------------------

"C'mon Baggy..Get with the beat"

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rob Young.

Phenomenal Film Handler

Posts: 1633

From: Cheshire, U.K.

Registered: Dec 2003

|

posted March 23, 2015 02:10 PM

posted March 23, 2015 02:10 PM

Hi Paul, I'll take some photos tomorrow if I get the chance to make it clearer, but basically, the actual ratchet is fine. The problem is that on the back of the ratchet part, there is a small "prong" or pin, which fits into the hole on part 18.

When part 18 rotates in reverse, it pushes the pin to move the ratchet out of the way, and then when running in forward, it pushes it to engage and drive the take-up.

The pin on the back of the ratchet shouldn't really, I suppose move away form the hole on part 18, but it clearly has, as there are wear marks on part 18 (the disc) and this has basically filed down the pin.

Hope all this makes any sense! ![[Roll Eyes]](rolleyes.gif) ![[Smile]](smile.gif)

The slippage may be down to grease, or lack of pressure form the spring (part 17) but once re-engaged, the hole in the disc (part 18) should drive the pin, and thus keep the ratchet in a fully engaged and locked position.

But now that the pin has worn down (by fractions of mm!) it has become temperamental.

The ratchet part is finished in black and you can compare the wear by looking at the front arm ratchet which is fine, compared to the rear arm ratchet which has a worn silver tip to the pin and is (under a magnifying glass!) shorter.

I fear the only resolve is to re-engineer the whole ratchet (part 22), or somehow replace the pin (which may be engineering micro-surgery!!)

| IP: Logged

|

|

|

|

Paul Browning

Phenomenal Film Handler

Posts: 1006

From: West Midlands United Kingdom

Registered: Aug 2011

|

posted March 23, 2015 02:48 PM

posted March 23, 2015 02:48 PM

Hello Rob, so can we get the pin out ?, when you say micro surgery, are you talking about a pin with a diameter of say, a few mm's, or the is this a dimple pressed through the material from behind ?. Making a pin will not prove a problem rob, I have access to material harder than any metal your likely to encounter, that includes, hardened tool steels, tungsten carbide stainless steel, but this will need to be fixed somehow, maybe an araldite will do, or industrial super glue. The down side is that it will ware out the part it comes into contact with !!!!, so these are sometimes designed to ware out the replaceable part, ie the pin, but perhaps your right, and it may need a redesign. Lets have a look at the pictures rob, I'm we can cure this, we are the "A" TEAM OF FORUMS after all.

| IP: Logged

|

|

|

UBBFriend: Email this page to someone!

UBBFriend: Email this page to someone!

Printer-friendly view of this topic

Printer-friendly view of this topic

![[Roll Eyes]](rolleyes.gif)

![[Confused]](confused.gif)

![[Big Grin]](biggrin.gif) ) the same problem.

) the same problem.![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Frown]](frown.gif)