|

Author

|

Topic: Sankyo sound 600 motor problems repair

|

Phil Murat

Jedi Master Film Handler

Posts: 671

From: Villeneuve St Georges, France

Registered: Dec 2015

|

posted October 02, 2016 01:01 AM

posted October 02, 2016 01:01 AM

Hello Janice,

A) There is a high probability original TR Power is in good condition.

The breakdown design T° is around 150 °C , if you feel casing "extremly" hot, means T° is around 70°C. This is a bit too much and needs to be pull down.

B) I am not surprised considering T1 condition. If you find a capacitor fitted next to TR1 , it could be profitable to replace it (a faulty capacitor could be the "hiden" issue)

C) 5v or 6V are just the "breakdown" limit for these Power TR Base.

Normal operating voltage when regulating is around 0,6v for our case.

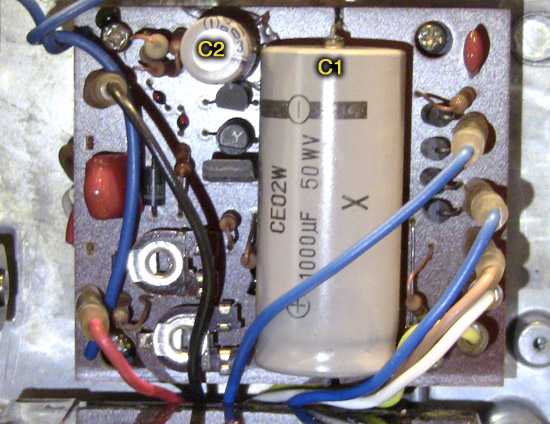

The Max Voltage limit is around 50V : You can measure Voltage "going in" from Big Capacitor Pins (1000 µf / 50V).

NTE152 looks a bit stronger, However , once installed, the 18/24 Adustable Resistors could need to be trim again.

IMPORTANT:

Some "vintage" TR are difficult to find and can be replaced by an "Equivalent" item. if overall limits are the same, however "response" curves could be different.

I have experienced this situation as I faced a similar failure for a BEAULIEU : I had to reinstall the same TR reference because régulation wasn't responding correctly.....

For exemple : If installing NTE152 makes the motor running to High (for any 18/24 setting) , you could be induced to compensate by adding a small resistor (may be 10 K) just before PIN 1.

As a primary experience, if original TR works properly, I suggest to keep it.

Let us know

[ October 02, 2016, 04:33 AM: Message edited by: Phil Murat ]

| IP: Logged

|

|

|

|

Phil Murat

Jedi Master Film Handler

Posts: 671

From: Villeneuve St Georges, France

Registered: Dec 2015

|

posted October 03, 2016 02:08 AM

posted October 03, 2016 02:08 AM

Hi Janice,

Due to this new picture I can see an other "small" TR (TR3, "half moon" shape) very next to C2 too. It probably works with T1 and T2, so, normally the thinking is identical for this TR.

C2: If 6,3 V is not available , you can choose 10 , 16, or 25v as well, it doesn't matter. (You just need "room" enough to fit it properly)

"New Generation" Capacitors are smaller than old ones for same value, so you can upgrade to a higher Voltage Limit at your conveniance.

POTs : Probability both pots to fail together and in a same time is very low.....

[ October 03, 2016, 04:20 AM: Message edited by: Phil Murat ]

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Phil Murat

Jedi Master Film Handler

Posts: 671

From: Villeneuve St Georges, France

Registered: Dec 2015

|

posted October 10, 2016 03:16 AM

posted October 10, 2016 03:16 AM

Hello Janice,

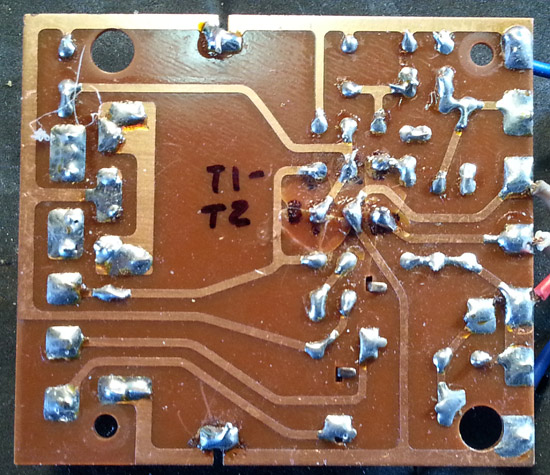

I understand you get problem with PCB material during T2 installation.

These former PCB's are fragile as this is not Epoxy Reinforced with Fiber matérial : It can crack easily and may be due to the age, tracks can stick out if overheated.

I met exactly these typical problems when working on my projectors.

So, don't be afraid too much, there is a high probability you can fix it anyway , making "Bridges" for the damaged tracks (small portion of wire and "Top off" concerned area with Tin).

As necessary, for exemple, pick up portion of wire from spare resistors.

Could you put here a picture for the Coper Tracks Side?

This is a precision work wich requires a magnifying lens (x3 approx) on stand.

Also I use a Headlamp (LEDLENSER are very good) and a precision soldering iron (narrow tip, 15W).

As necessary too, to extract Tin from tracks, you can use a Hand Depress Pump or Coper Mesh dependind on the configuration.

Standard Drills size for PCB holes are 0,8mm (sometimes 0,6mm for tiny components)

Remember also if T1 has failed it is important to find out the failure root. Otherwise installing a new one without solving the cause can lead it to fail again.

Courrage !!

NB:

Plan "B" :

In case nothing works and spare PCB hard to find, I think it is possible to "Clone" the former PCB.

That needs time but you can find a dedicated "Freeware" on the Web to carry out the drawing (professionnal result).

This is a simple lay PCB. Big advantage is you can get it in Epoxy material (more professionnal)for few USD.....

| IP: Logged

|

|

|

|

Phil Murat

Jedi Master Film Handler

Posts: 671

From: Villeneuve St Georges, France

Registered: Dec 2015

|

posted October 10, 2016 04:29 AM

posted October 10, 2016 04:29 AM

Hi Andrew,

I have started to make a simple board for a small power card as a primary experience, as you kwow , I am still working on an Embeded "Frequencemeter" for my Beaulieu's :

2 devices (and their Infrared probes) are almost ready to install inside rear cover .

Now,I just need to pick up a little power from big transformer inside Beaulieu 708(I mean Lamp Coil) and to adapt voltage to Frequencemeter (Power consumption estimated is 0,3 A, approx)..... ![[Wink]](wink.gif)

However the "first juice" for my PCB power is not very good looking, right now, because I met problem during printing drawing on the PCB

![[Roll Eyes]](rolleyes.gif)

To follow

| IP: Logged

|

|

|

|

|

|

Phil Murat

Jedi Master Film Handler

Posts: 671

From: Villeneuve St Georges, France

Registered: Dec 2015

|

posted October 11, 2016 02:07 AM

posted October 11, 2016 02:07 AM

Hello Janice,

At first sight, the tracks overall condition looks OK. There are minor damages, anyway bridges are properly done.

Observing PCB through side tracks is helpful to anticipate complementary checks for other components :

Could you check what happens when the "white bloc" fitted on steel bracket (and blue wired) is disconnected from PCB)?

-Observe effect as speed motor change for exemple.

If speed decrease, check "Pots" for efficiency.

-There is a high probability this is a Interference-Suppression Capacitor , however do not let motor running a long time when capacitor disconnected.

Let us know....

Moreother, a good news is this circuit is not too much sophisticated.

If you like attempting a "cloning" experience , try that (This is in French language , but quite a "basic" use anyway) :

TCI DOWNLOAD FREEWARE

This is a "Lightweight" software (331ko). "Framework" Microsoft installation is prerequisite.

TCI.exe is compacted. Upon first time lauching it expenses in different files. The total size is around 1 MO once expended !!

Have a great fun !

As a first Test , making any drawing you want, you can select the drawing with the mouse, make "Copy" (Rh "Clic" if I remember)

and Paste in a "Word" page (for exemple). After that, Change picture from "Red" Color to Dark Black 100%, adjust the picture size to get the truth size (as a try and test procedure).....this is almost ready to transfer on a PCB !!!

[ October 11, 2016, 09:16 AM: Message edited by: Phil Murat ]

| IP: Logged

|

|

|

|

|

|

|

|

|

|

Phil Murat

Jedi Master Film Handler

Posts: 671

From: Villeneuve St Georges, France

Registered: Dec 2015

|

posted October 12, 2016 01:28 AM

posted October 12, 2016 01:28 AM

Hello Janice,

This is a Happy news !!!!!

"DOUBLE" CHAMPAGNE!!!

Troubleshooting is often time an "Exciting Game of Patience"

Very Good Job !!!, you are a chief (In France, we are also used to say "Respect" or "Chapeau")

There is a high probability the Power TR T° is right now much better , as current crossing it is properly calibrated now.

The Heatsink plate is offering a good size. Normally , T° around 40° is a reasonnable and acceptable estimation.......

Let us know !!

NB

In case in the future you need to work anymore "classical" PCB, check for the Iron power. 15w is enough for soldering tiny tracks and sensible components too. (associated to an Iron Narrow tip)

Moreover , remember : 5 seconds is the max time allowed for soldering many Electronic components without getting them to fail out.

If you are still interested in PCB "Reverse Engineering" take a look for that :

EASY EDA Tutorial

This is in English language and looks........very powerful

I have never used it , but, nothing to install or download, EASY EDA only works with any Web Navigator

[ October 12, 2016, 04:03 AM: Message edited by: Phil Murat ]

| IP: Logged

|

|

|

|

Jase Serre

Junior

Posts: 1

From: Phoenix, AZ, USA

Registered: Jan 2017

|

posted January 25, 2017 09:01 AM

posted January 25, 2017 09:01 AM

Hi everyone...i am a new user here. As per my knowledge problem is an Electrolytic capacitors which had dried out and makes a short circuit. Considering age of the projector, and cheapness of this components, very easy to find too, don't try to test it and renew directly.If capacitor original voltage is not available, choose upper rate, just the Capacitor size increase.

low cost pcb assembly

[ April 19, 2017, 03:39 PM: Message edited by: Jase Serre ]

| IP: Logged

|

|

|

|

|

|

|

UBBFriend: Email this page to someone!

UBBFriend: Email this page to someone!

Printer-friendly view of this topic

Printer-friendly view of this topic

![[Smile]](smile.gif) Turns out this is a Silicon Controlled Rectifier (SCR). The label says FOR2B. It's a TO-92 package. I'm having a tough time cross referencing this SCR to find an equivalent.

Turns out this is a Silicon Controlled Rectifier (SCR). The label says FOR2B. It's a TO-92 package. I'm having a tough time cross referencing this SCR to find an equivalent.![[Frown]](frown.gif) . At least I didn't blow anything up... everything ran fine ... except still can't adjust the speed.

. At least I didn't blow anything up... everything ran fine ... except still can't adjust the speed.

![[Mad]](mad.gif) After this fiasco the motor will not turn on now.

After this fiasco the motor will not turn on now.![[Wink]](wink.gif)

![[Roll Eyes]](rolleyes.gif)

![[Big Grin]](biggrin.gif)