This is topic GS/ST Metal Input Guides in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=001885

Posted by Kevin Faulkner (Member # 6) on May 10, 2006, 05:25 PM:

FFR in Geramny have got for sale some metal input guides for the GS and ST 600,160 & 180 etc machines. I'm going to try to order one and see how they perform.

Take a look here: http://www.ffr-film.de/Katalog/index.htm

Scroll down to: ELMO S8 Zubehör

Now scroll down the great collection of parts etc for the GS and you will see the metal input guides ![[Smile]](smile.gif)

Kev.

Posted by Paul Adsett (Member # 25) on May 10, 2006, 07:44 PM:

Very interesting Kev. Looks like they will supply an HTI conversion, and what is that weird single bladed shutter all about?

Posted by Adrian Winchester (Member # 248) on May 10, 2006, 07:54 PM:

Looks like a good idea, although at around £50 + postage, I wonder if they are made of platinum!

Posted by Jan Bister (Member # 332) on May 11, 2006, 12:01 AM:

Paul, that's not really a single-bladed shutter... You're supposed to put three of these together to build your own switchable 2/3-blade shutter. ![[Smile]](smile.gif) Does look weird at first, though!

Does look weird at first, though!

Posted by Kevin Faulkner (Member # 6) on May 11, 2006, 01:02 AM:

Yes Jan it does look a little strange. They certainly have some interesting stuff. Notice they sell Wurker tape patches ![[Smile]](smile.gif) and yes it does look like they do their own HTI conversion sync pulse units.

and yes it does look like they do their own HTI conversion sync pulse units.

Certainly a site to bookmark ![[Smile]](smile.gif)

Kev.

Posted by Antoine Orsero (Member # 41) on May 11, 2006, 04:58 AM:

Thank you very much Kevin!

Very interesting:

Motorregelplatine GS1200

Best.- Nr.:

Stück / €

- Motorreglerpatine des ELMO GS1200.

- Wir liefer Typ II kompatibel zu allen GS1200

and

Speed Messer

Best.- Nr.:

Stück / €

Dieses kleine Messgerät ermöglicht die Messung der Bildfrequenz des Projektors. Sie halten ihn an das Objektiv und können die Frequenz in Hz ablesen

Antoine

Posted by Ricky Daniels (Member # 95) on May 11, 2006, 05:12 AM:

Kevin,

What a great website, thanks for the link ![[Smile]](smile.gif)

Rick

Posted by Jan Bister (Member # 332) on May 11, 2006, 09:19 AM:

Oh, yes, I bookmarked the site as soon as I noticed the Wurker splices. ![[Big Grin]](biggrin.gif) What more, they even appear to have ESS sync modules (much like Pedro's box) for both PAL and NTSC frequencies. One does 18/24fps, and the other does 16-2/3 and 25fps, all with quartz precision. !!!

What more, they even appear to have ESS sync modules (much like Pedro's box) for both PAL and NTSC frequencies. One does 18/24fps, and the other does 16-2/3 and 25fps, all with quartz precision. !!!

Posted by Dimitrios Kremalis (Member # 272) on May 11, 2006, 09:35 AM:

Jan,

They don't offer NTSC boxes. The 18/24fps box is mainly for filmers, while the other is to synchronize with vintage silent movies at 16-2/3 and PAL at 25fps.

Posted by Kevin Faulkner (Member # 6) on May 11, 2006, 05:08 PM:

Yes true NTSC should run at 23.97 FPS and not 24. I think the .97 is right?

I think it's great that this company are supporting us GS owners so well. I emailed them today about the guides and had some really good email exchanges with them. Very knowledgeable, helpful and friendly.

I think they will probably sell quite a few of those guides now and lets face it Metal will not wear like that plastic does.

Kev.

Posted by Paul Adsett (Member # 25) on May 11, 2006, 06:38 PM:

But will metal guides eliminate the film scratch problems on the GS1200?

Posted by Adrian Winchester (Member # 248) on May 11, 2006, 06:40 PM:

"I think it's great that this company are supporting us GS owners so well."

I bet some of the executives at Elmo would find it amazing and thought-provoking to know how many new products are being sold today, in connection with a projector that they stopped making around 20 years ago!

"But will metal guides eliminate the film scratch problems on the GS1200?"

I suppose it's probably the best guide to have in metal, although I have a GS with extra rollers added to both this guide and the one above it, and I've never had problems with scratches.

Posted by Paul Adsett (Member # 25) on May 11, 2006, 06:56 PM:

Hi Adrian,

Where did you get the GS1200 guides with rollers?

Posted by Adrian Winchester (Member # 248) on May 11, 2006, 07:19 PM:

Hi Paul,

Mine were modified around the time I got my first GS in 1989, by Dave Locke, who is well known in the UK for specialised services regarding GSs. I'd better not imply that he still offers this now, though, without checking with him.

Posted by Jan Bister (Member # 332) on May 11, 2006, 10:01 PM:

Dimitrios/Kevin: oops! You're right, 24fps is not true NTSC - 23.970fps is. Nonetheless, I would imagine that the 16/25fps box is usable for syncing with PAL DVDs since they're transferred at 25fps, and the sound is accordingly a bit faster. As far as the 16 2/3fps speed is concerned, I believe that's for the transfer/capture of 18fps home movies to PAL video (three interlaced fields to one super-8 frame).

Posted by Kevin Faulkner (Member # 6) on May 16, 2006, 05:14 PM:

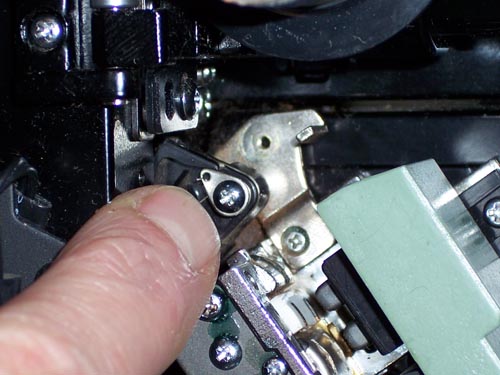

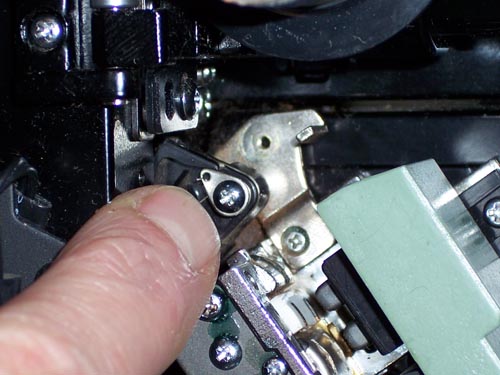

Modifying these guides is quite straight forward with a little time and patience. I have modded the first sprocket guide on my GS as for me I think this one is the worst for wear and its wear you cant see to easily.

The input guide can be removed very easily and checked. Its even possible to use the GS without the input guide although it does make threading a little more difficult.

I do have one of the new Metal guides on it's way to me from Germany and will report on my findings as soon as it arrives.

Kev.

[ May 18, 2006, 04:20 PM: Message edited by: Kevin Faulkner ]

Posted by John Clancy (Member # 49) on May 17, 2006, 02:54 AM:

Wouldn't the GS look fantastic if all those green film path guides could be replaced with chrome versions?

I'm looking forward to hearing your opinion of the replacement guide Kevin.

Posted by Kevin Faulkner (Member # 6) on May 17, 2006, 03:25 AM:

FFR Have been selling these on eBay and now have another one on offer.

http://cgi.ebay.co.uk/ws/eBayISAPI.dll?ViewItem&item=9727486347&ssPageName=ADME:B:SS:UK:1

John, if its here in time I'll bring it along to the BFCC for you and Keith to have a look at.

Kev.

Posted by Joerg Niggemann (Member # 611) on May 17, 2006, 04:49 AM:

Hi all,

this is my first posting on this forum. My name is Joerg, I live in Taunusstein, Germany and got my first defective GS1200 some weeks ago from ebay. Searching for information about the GS, I found this great forum and got the manual from the download section (thanks Kevin!). After 2 weeks of work and replacing the claw with a new one, the GS is running smooth and silent now and I'm very satisfied with the performance.

Since my way to FFR Film is about 5 minutes, I got the metal input guide there. It's a nice piece of work and fits perfectly to the GS. After about 2 hours running time, the metal looks like "polished" where it is in contact with the film edges, but I think this is quite normal.

I'm still waiting for the original input guide to return from Wittner's "modification"...

Joerg

Posted by Kevin Faulkner (Member # 6) on May 17, 2006, 05:35 AM:

Hi Joerg,

Welcome to the forum. Thats interesting that you are not far from FFR and have been able to try the new guide. Yes the film will polish the guide like it does on the plastic original but as long as it does not wear away then we are onto a winner.

Great to hear that you have managed to change the claw on your GS did you change the shutter blade to a 2 blade while you had it stripped down? FFR also sell the 2 blade shutters.

Anyway enjoy the forum and lets hope we hear more form you in the future.

Kev.

Posted by Joerg Niggemann (Member # 611) on May 17, 2006, 06:20 AM:

Kevin,

no I didn't change the shutter. I really thought about that, but my good old "home movies" should also run on the GS at 18fps. For the future, I will get into a conflict when going for my first cinemascope feature with the need for more light. I think the only solution will be a second GS 1200 with 2 blade shutter :-).

Joerg

Posted by Adrian Winchester (Member # 248) on May 17, 2006, 09:49 AM:

Deleted

[ May 17, 2006, 07:29 PM: Message edited by: Adrian Winchester ]

Posted by Kevin Faulkner (Member # 6) on May 17, 2006, 04:08 PM:

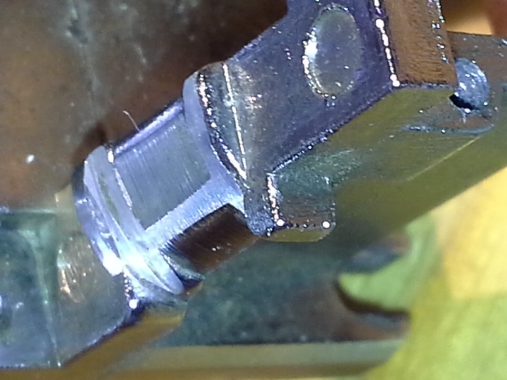

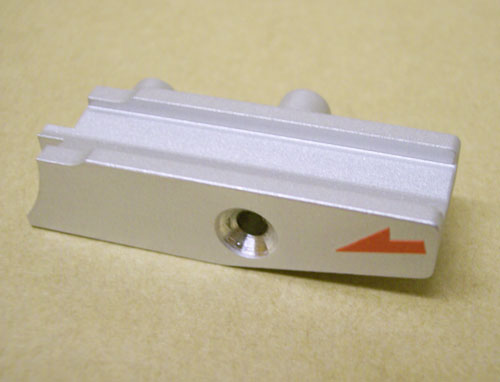

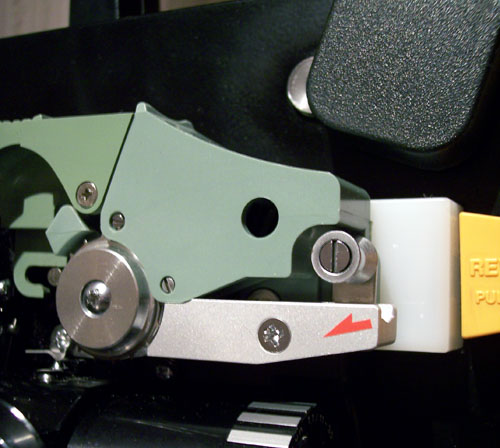

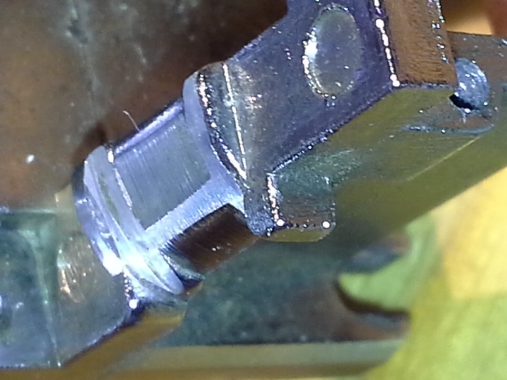

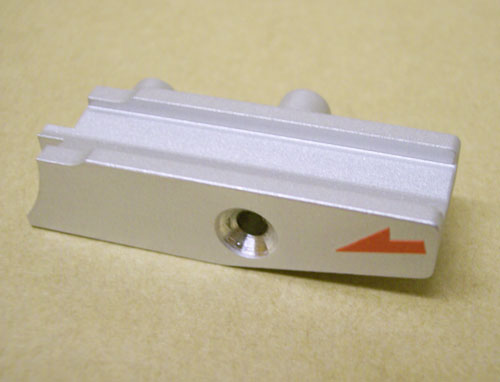

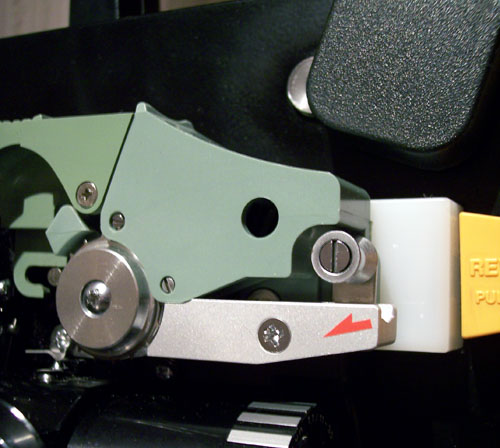

Pleased to say that I have mine now. It's like looking at the original Elmo input guide except that it's made from ally...cast ally at that I think.

It's exactly the same as the original as if it came out of the same mould's except its not hollow like the original.

It fitted straight onto the GS xenon without any fiddling about and worked a treat. I'm not sure but I think it makes the machine run quieter at the top sprocket and thats probably because the film is not vibrating against the plastic input guide but a more rigid and securely fitted metal guide.

I think FFR have to be congratulated where this guide is concerned and I would certainly say to others that they shouldnt hesitate in getting one even at the cost of £50 GBP. Lets face it with inflation etc thats probably what the cost of a new plastic one from Elmo would cost if they were still made.

I have included a couple of pics of the guide so that you can hopefully see how exact to the original they are. Excuse the colour but I had to take them with articfical light to cut down flare etc which I would otherwsie have got with flash.

So there we have it...new input guides for the GS1200, ST600, ST180. These will not fit the ST1200 or 800 range of machines.

Kev

Posted by Adrian Winchester (Member # 248) on May 17, 2006, 07:26 PM:

Wow, that looks so impressive that I won't even 'nit pick' about it not having the little arrow on the side!

Posted by Kevin Faulkner (Member # 6) on May 18, 2006, 04:24 PM:

Adrian, Especially for you. I had a few sheets of Vinyl self adhesive arrows cut out at work today. ![[Smile]](smile.gif)

So if you or anyone else gets one of these you can now have an arrow.

Kev.

Posted by Adrian Winchester (Member # 248) on May 18, 2006, 06:53 PM:

![[Big Grin]](biggrin.gif) Superb... and perhaps invaluable if anyone, disorientated due to the lack of an arrow, forgets where to thread the film.

Superb... and perhaps invaluable if anyone, disorientated due to the lack of an arrow, forgets where to thread the film.

Posted by Michael De Angelis (Member # 91) on May 18, 2006, 10:48 PM:

Kev,

This is remarkable.

I wonder if it would help

to have a roller placed

on the end of the guide,

in the similar method

to the modification on

the plastic guides?

Michael

Posted by Kevin Faulkner (Member # 6) on May 19, 2006, 01:04 AM:

Yes I wondered that too Michael. Although metal would have to be cut away at least this one is solid so there wouldnt be the need to glue plastic at the rear etc for something to screw into.

I think though that the wear on this guide will be much slower than with the green plastic so hopefully there would be no need for the roller.

Maybe be a second as a spare would see the life of the machine out.

Kev.

Posted by Tony Milman (Member # 7) on May 19, 2006, 01:05 AM:

Kev,

Couldn't you have painted it green as well ![[Big Grin]](biggrin.gif) ....

....

Now then, will you be selling your old modified guide ![[Wink]](wink.gif)

Posted by Kevin Faulkner (Member # 6) on May 19, 2006, 01:12 AM:

I didnt get round to ever doing the mod on the input guide but was thinking about getting it done very soon.....then this came along ![[Smile]](smile.gif)

See you at the BFCC with one unmodded green input guide ![[Wink]](wink.gif) and no your not having that 1st sprocket guide off my machine

and no your not having that 1st sprocket guide off my machine ![[Big Grin]](biggrin.gif)

Kev.

Posted by Tony Milman (Member # 7) on May 19, 2006, 01:55 AM:

Kevin,

What is the story behind whoever went to the trouble to make this guide and do youknow if they have plans to do any other pieces of the GS ?

Posted by Kevin Faulkner (Member # 6) on May 19, 2006, 04:25 AM:

Tony, More Later ![[Wink]](wink.gif)

Kev.

Posted by Joerg Niggemann (Member # 611) on May 25, 2006, 04:45 AM:

Kevin, I just "modded" the first sprocket guide of my GS according to your photo. Great idea and it works!

Jörg

Posted by Kevin Faulkner (Member # 6) on May 25, 2006, 05:50 AM:

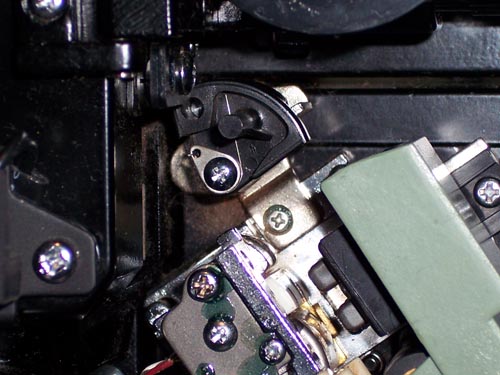

Joerg...Great news. It certainly removes the possibility of scratching at the exit of the guide. The other points where the GS can wear and scratch is the bottom black tensioner which can be removed and reshaped or replaced with a roler assay from a ST1200HD, and the entrance to the sound head where the small rubber roller pushes down onto the film prior to going through the heads.

Bill Parsons sent me a picture of a GS with very severe wear at this point and at the moment there is no way to solve this except to remove the rubber roller to stop this wear from happening. This can only be done on the later machines where the loop goes back towards the lamphouse. It cant be removed on the forward loop early machines as this roller is vital to shape the loop before it goes into the heads.

The head block holder assay is no longer available but I wonder if thin strips of teflon plastic could be stuck over the worn areas. I will put a picture here of that part showing wear tonight when I get home.

This small roller is there to smooth out the intermittant motion of the film before getting to the heads. The ST600 has exactly the same layout as the later GS's and doesnt have a roller which is why it seems to be ok without on the later GS's.

Kev.

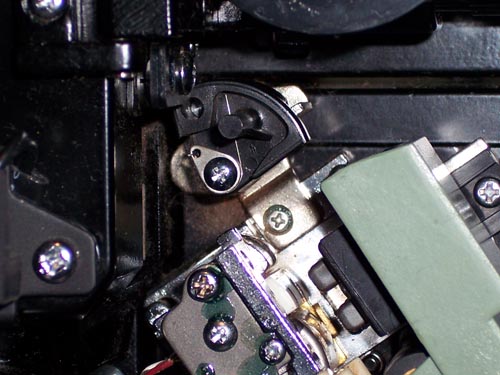

Posted by Joerg Niggemann (Member # 611) on May 25, 2006, 03:11 PM:

Kevin, I found some wear at the points you mentioned on my GS, but I think there's some time left until it will cause scratch. I wonder if the head block holder assay of the ST1200 will fit to the GS1200. Having a look at my "spare part ST", it seemed to me that there is no difference. The ST has no rubber roller at the entrance to the sound heads and so there is no wear at that point.

Jörg

Posted by Kevin Faulkner (Member # 6) on May 27, 2006, 12:39 PM:

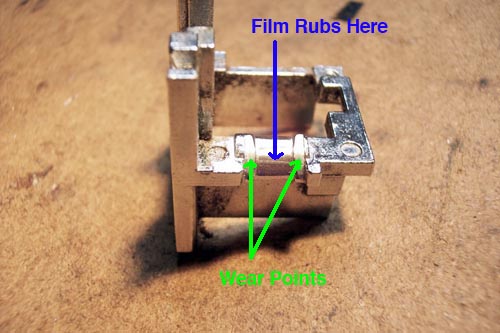

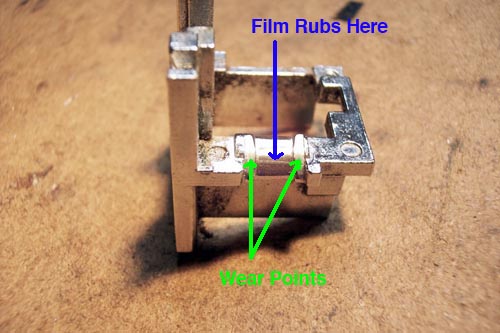

Here is the picture Bill Parsons sent me showing the exact points of wear at the entrance to the head block. This I think seems to be more of a problem on the GS because of the rubber roller pressing the film onto these two points which due to the abrasive stripe wears the metal away then allowing the film to rub in the centre.

I have now removed the roller assay on my GS and it seems at present to not give rise to clicking on the soundtrack. This can only be removed on the later machines with the backward loop. If anyone else want to give this a try you will be able to see the mounting screw once you move the plastic loop restorer back out of the way. Beware there is a small coil spring and brass bush. I would suggest laying the machine on its back so these items dont fall out all over the place.

Kev.

Posted by Mark Norton (Member # 165) on May 29, 2006, 06:01 AM:

Kev,

My first GS1200 had worn badly in this area, [and everywhere else] at first I tried to build the worn shoulders back up, this didn't work as the film seemed to skate around over the sound head. I finally with a small cut down needle file slowly and carefully filed down the metal in between. I did this with the sound head in the machine but removed the head presser assembly etc for access. I filled off a good 1.5 to 2mm and this worked well.

Another point of wear in this area can come from the green guide that folds back after the film has been threaded. If the bottom loop before the sound head is formed too big this wears the guide and can lead to scratched films.

Posted by Kevin Faulkner (Member # 6) on May 29, 2006, 06:54 AM:

Mark, The film should never touch that fold back guide when running correctly. If it does then it would suggest that the bottom film tensioner is coming up too high which makes the loop bigger. The only time the film should come into contact with the guide is during threading.

Kev.

Posted by Mark Norton (Member # 165) on May 29, 2006, 11:06 AM:

Yes that's right Kev and with a roller mod {from ST 1200}instead of the black plastic tensioner I think there is even less chance of this occuring. It's easy to see if the tensioner is not set up correctly as it will show up as wear on the guide. Anything that has the potential to scratch the film after the gate is the worst because you only find out about it the second time you run a print.

Posted by Kevin Faulkner (Member # 6) on May 29, 2006, 12:38 PM:

I agree. Kev.

Posted by Joerg Niggemann (Member # 611) on June 01, 2006, 01:01 PM:

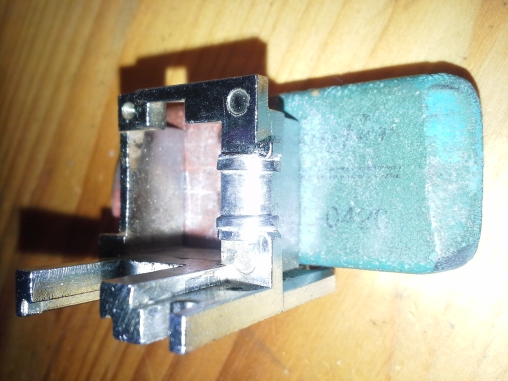

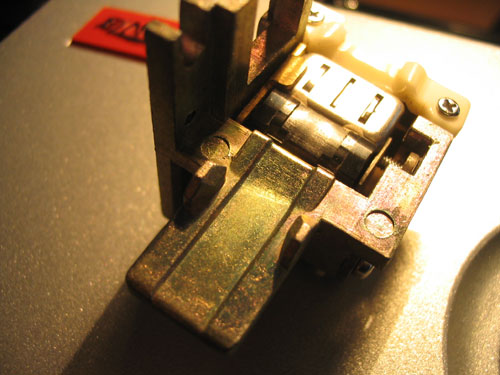

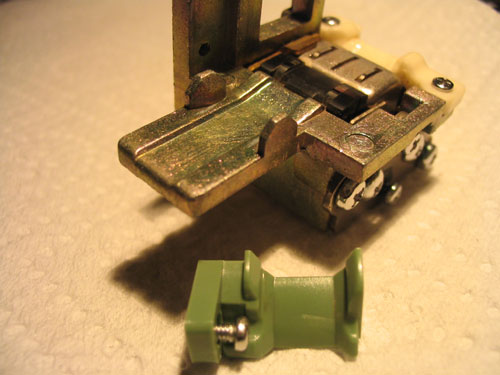

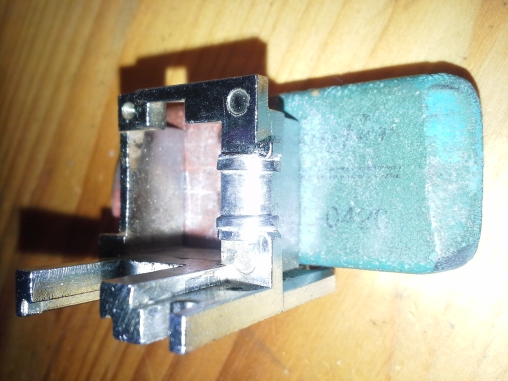

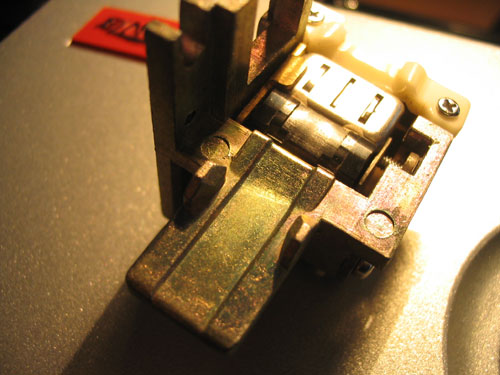

Here are some pictures showing the older version of the sound head assay. The first picture of my GS1200 shows wear points at the entrance to the sound head area, caused by the rubber roller pressing the film down to the metal part. The second one shows the same part taken from an ST1200 without any wear at that point. The ST uses a green plastic part to guide the film into the sound head area instead of a rubber roller. I'm about to replace the original part by the one of the ST1200. Hopefully this will work and last for another 20 years for my GS1200...

Joerg

Posted by Dimitrios Kremalis (Member # 272) on June 01, 2006, 02:08 PM:

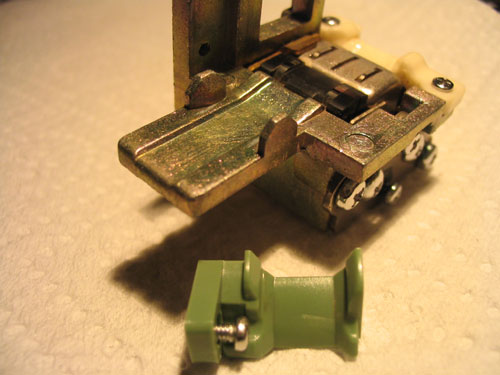

Joerg, can you please post a foto of the green plastic part the ST uses, that can be also used with the GS?

Posted by Joerg Niggemann (Member # 611) on June 01, 2006, 03:02 PM:

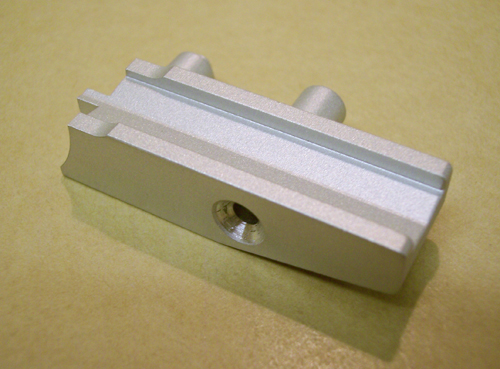

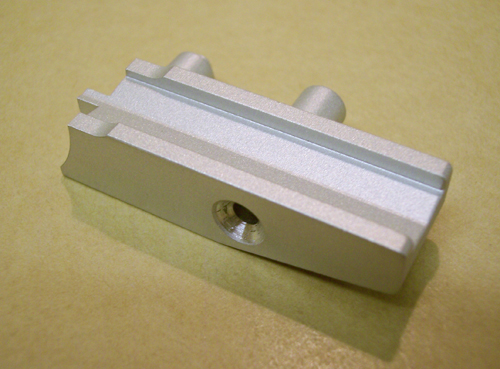

Dimitrios, here it is...

Joerg

Posted by Dimitrios Kremalis (Member # 272) on June 01, 2006, 03:12 PM:

Thank you very much!

Looks like a nice replacement if it doesn't change the loop.

Posted by Kevin Faulkner (Member # 6) on June 01, 2006, 04:26 PM:

That is exactly the part that Elmo would give you if you complained about loss of loop on optical prints with the forward loop machines and yes its the rubber roller which causes that very problem. However that palstic part instead of the roller will increase the clicking noise on loud pasages of sound breaking through but I think a little more noise is better than a lot of wear on a part which is no longer available.

You cant put that part on the ver3 back loop machines but you can do what I have done in my pictures and remove the roller assay. So far I have had no problems or increase in intermittent noise coming through on loud sounds.

Kev.

Posted by Ugo Grassi (Member # 139) on June 02, 2006, 08:14 AM:

Dimitrios...

on your GS I already modify that point to avoid scratches. ![[Wink]](wink.gif)

Now there are two thin edges of teflon....

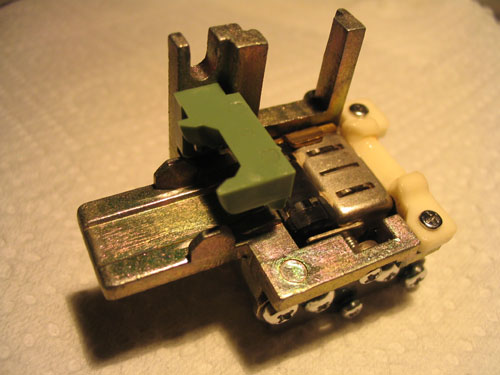

Posted by Thomas Knappstein (Member # 6134) on November 25, 2017, 10:35 AM:

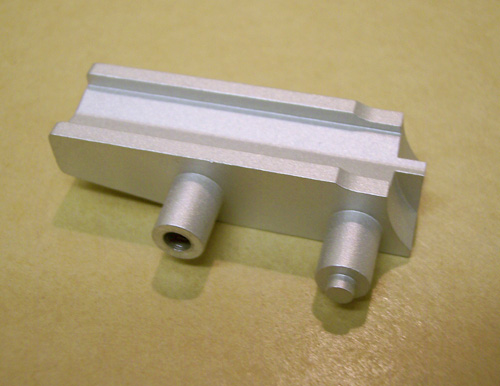

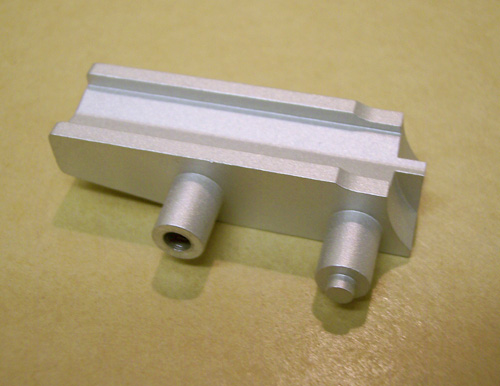

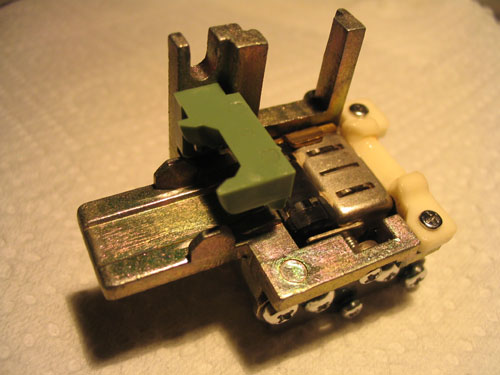

Hello!

I had this Problem too. I took one old worn out Side Guide from the Aperture Plate of an ST1200. Then cutting them with a small Proxxon Cutting Disc and fixed them on the Soundhead Unit.

Here are two Pictures before and after repairing this Part.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Smile]](smile.gif)

![[Smile]](smile.gif) Does look weird at first, though!

Does look weird at first, though!

![[Smile]](smile.gif) and yes it does look like they do their own HTI conversion sync pulse units.

and yes it does look like they do their own HTI conversion sync pulse units.![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Big Grin]](biggrin.gif) What more, they even appear to have ESS sync modules (much like Pedro's box) for both PAL and NTSC frequencies. One does 18/24fps, and the other does 16-2/3 and 25fps, all with quartz precision. !!!

What more, they even appear to have ESS sync modules (much like Pedro's box) for both PAL and NTSC frequencies. One does 18/24fps, and the other does 16-2/3 and 25fps, all with quartz precision. !!!

![[Smile]](smile.gif)

![[Big Grin]](biggrin.gif) Superb... and perhaps invaluable if anyone, disorientated due to the lack of an arrow, forgets where to thread the film.

Superb... and perhaps invaluable if anyone, disorientated due to the lack of an arrow, forgets where to thread the film.

![[Big Grin]](biggrin.gif) ....

....![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif) and no your not having that 1st sprocket guide off my machine

and no your not having that 1st sprocket guide off my machine ![[Big Grin]](biggrin.gif)

![[Wink]](wink.gif)

![[Wink]](wink.gif)