This is topic Elmo GS1200 Xenon Fan problem in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=002359

Posted by Clive Carmock (Member # 347) on December 23, 2006, 02:47 PM:

I wonder if anyone here can offer advice. We were just watching a newly purchased feature print of Oh Mr Porter when the exhaust blower ont he projecter started to make a noise as if the fan blades were rubbing against somethign and then the fan stopped altogether.

Naturally I haven't run the machine in this state apart from a few seconds to test various functions. Turning on the power brings on the amplifier but no blower. The Xenon lamp strikes perfectly. Forward/reverse works correctly as does rewind.

I wonder if anyoen can give me some tips on finding the fan motor etc and the fan itself. I am happy to take the machien apart to try to repair. I am wondering if something is obstructing the fan which jammed and either the motor has burned out or blown an internal fuse?

It was in this 'noisy rubbing' state for no more than 10 seconds.

I do know the ESS switch had been knocked as that wasn't in the correct position initially.

Any help appreciated.

Regards

CLive

Posted by Andrew Wilson (Member # 538) on December 25, 2006, 12:08 PM:

Hello Clive.W

Posted by Andrew Wilson (Member # 538) on December 25, 2006, 12:10 PM:

Hello Clive.Welcome to the forum.Asked Kevin Faulkner;he's your man,with reguard that fan problem.Andy.

Posted by Steven Sigel (Member # 21) on December 25, 2006, 12:43 PM:

My guess is that the fan hung up on something and then the belt snapped.

First off -- DO NOT run the projector with the lamp struck for any length of time without fixing this, the xenon machines need the extra cooling.

If you take the back of the case off, you should be able to see the fan and determine if the belt is snapped - in which case you'll need to replace it. Then you'll need to figure out what the fan is hitting (alternately, the bearing in the fan might be shot, in which case, you'll need to replace that, or the entire fan).

Posted by Clive Carmock (Member # 347) on December 25, 2006, 06:20 PM:

Thanks Steven. When I get back home I'll take the back off and have aproper look. I don't think it's a belt though in this case since if I turn the power on to the machine I hear a click from the speaker as the amplifier starts but there is not even a motor sound from the fan motor itself.

I wonder if the motors are each protected by a fuse that might have gone.

I wonder also if the ESS switch having been knocked could have caused a problem.

You are right about the lamp and not leaving it running - I just struck that for a few seconds to confirm what was/wasn't working on the machine. The only think not working is the cooling fan which seems totaly dead.

Hopefully this can be fixed as apart from that this has always been a great machine.

Regards

Clive

Posted by Steven Sigel (Member # 21) on December 25, 2006, 10:28 PM:

Hi Clive,

The fact that the motor works isn't terribly relevant. The GS-1200 has separate motors and belts for everything. I haven't had one apart in years, so I don't remember for sure, but I do know that the 16mm equivalent machine has a belt driven fan in the back, so it may well be...

Not sure what an ESS switch is so I can't tell if it might have anything to do with it.

Posted by Kevin Faulkner (Member # 6) on December 26, 2006, 06:45 AM:

The fan on the GS is direct drive on the motor so there is nothing to snap.

To be quite honest I cant think what would cause it to make a noise and then stop unless one of the motor brushes has disintegrated and the brass contact had started to rub the motor armature.

I would double check first that the rubber roller which forms part of the drive for the flywheel hasnt perhaps fallen to pieces and jammed the motor.

Very strange one indeed but then I have also seen a strnage one this week with the GS from Andrew Wilson. He had the situation where he couldnt form the loop on his machine at all.

When I stripped down the machine I found that one of the shutter springs had snapped so the claw wasnt protruding through the gate to pull the film down. This is the first time I have seen this problem on an Elmo and lets hope it's the last.

Kev.

Posted by Clive Carmock (Member # 347) on January 02, 2007, 05:03 PM:

I know this sounds bad - btu due to things over Christmas etc I haven't had chance to whip the back of my GS1200 yet. However Kev if the motor is shot do you know if I'm likely to get a replacement fan motor for the Xenon model? Failing that I guess I need to look for one of those specialise motor rebuild places, thats if the motor has gone of course.

Posted by Clive Carmock (Member # 347) on January 03, 2007, 02:57 PM:

Well I have finally had chance to take the GS1200 apart and found the fault.

The reason the fan isnt runnign is not a motor problem thats just fine. What has happened is that the fan itself, which is made of plastic, has cracked in falf and 'opened' up slightly on it's shaft and is catching on the inside of the metal cylinder into which it fits.

Now my options are - replace the fan baldes (does anyone know if I am likely to find this as a spare part at all?) or try to take it apart and use strong glue liek araldite to glue it back together again.

It looks tricky to get out so if anyone has any ideas they'd be very wlecome! Apart from this the machine is in perfect condition.

Regards

Clive

Posted by Ugo Grassi (Member # 139) on January 03, 2007, 05:28 PM:

To find this spare part is hard and if you find it, it will be surely expensive!

May you post a photo of the defect? you can send it me via mail too...

At least if you disassemble the hole fan I may try to fix it. Of course you have to send it to me...

Posted by Clive Carmock (Member # 347) on January 04, 2007, 02:58 PM:

Hi Ugo I'll try to get a picture of it in situ, however it looks hard to get the part out - I need to spend a bit more time examining it. Kevin might have some tips for me at which parts I need to remove to get the fan out.

Thanks for your kind offer. I probably could use some good epoxy resin glue such as Araldite to glue it together again if I can get it out.

basically there is a crack right the way across the circular plastic part which has then 'opened up' on the spindle and is hitting part of the metal can as the fan rotates. It had clearly got jammed particularly hard which made me suspect the motor originally. I was able to free it by hand and then the fan motor runs fine again except the fan makes a terrible noise as it spins hitting the metal, so I haven't run it for more than a couple of seconds. At least the motor is OK.

The fan on the Xenon version of the machine is more powerful than the standard version so I assume the fan blades are different and it's not just that it spins faster on that model.

I guess finding scrapped GS1200 Xenons to get a fan from will be nigh impossible so if I can't get hold of this as a spare part then I think the best option is repair with good strong glue.

Clive

Posted by Ugo Grassi (Member # 139) on January 04, 2007, 07:24 PM:

No. The fan is the same. The difference is in the supply vultage.

In these days I'm refurbishing a xenon machine with a supplementary tlittle transformer which works togheter that one main. Kevin says the latest version had this device. The fan works really fast, faster then my Xenon that - probably - is like your.

Just for your curiosity... that little yellow thing is the no standard transformer for the fan. On this machine the fan seems an airplane engine. Oh...the first time I switched on this Xenon GS it flyed away...

[ January 05, 2007, 03:57 AM: Message edited by: Ugo Grassi ]

Posted by Clive Carmock (Member # 347) on January 05, 2007, 04:12 PM:

Hi Ugo,

Yes my machien has a circuit board with a relay int he area you have the yellow transformer shown. Kevin hadn't seen that before - and I don't think we managed to conclusively work out what it was.

Do you know the best way to start to remove the fan assembly from the machine so I can look to repair it?

Regards

Clive

Posted by Kevin Faulkner (Member # 6) on January 05, 2007, 04:31 PM:

Clive this is not any easy quick job to do. You have to remove all items infront of the fan such as the High Tension unit & the small board with the relay on it.

The fan motor is fixed to the main frame with 4 screws. Once these have been undone the whole fan assay should come free as one unit.

Round the edge of the fan which can be seen in that picture are 4 lugs which you need to pull up so that you can remove the end plate and at that point you will need to release the grub screws to remove the fan blade assay. In your case the fan blade assay will probably fall off. Araldite seems like a good idea to me but you will obviously have to keep the whole of that under pressure to keep the gap closed while it dries. Maybe some wire wrapped round it will work. Once its glued it will be worth putting some more glue over the join to give it some more strength.

I don't know of anywhere supplying these fans although it may just be possible that Wittners in Germany might have one. I think they have broken down some machines to use as spares.

I'm sure though that you will be able to do a fix on this without too much trouble.

Ugo correct when he says that the whole fan and motor assay are the same as in the std GS. The xenon has a higher voltage applied to the fan to give it more power (and noise). From your description on the added transformer and associated electronics I would think that Elmo have built in some form of control circuitry for the fan but without see the machine or circuit diagram it's difficult to say.

If you need any further help then do email me and we can talk it through on the phone. I don't live a million miles from you so can help if need be.

Kev.

Posted by David Pannell (Member # 300) on January 05, 2007, 05:10 PM:

May I enter a word of caution here, please?

Whilst I am not familiar with the construction of this particular fan blade assembly and the actual type of plastic used, but please be aware that Araldite, - in any of its forms, - will not stick any of the so called "greasy" types of plastic. These are usually the "" 'thenes", ie. alkathene, polythene, etc. etc. In fact it is my understanding that no glue exists which is effective on these plastics.

Posted by Ugo Grassi (Member # 139) on January 05, 2007, 05:57 PM:

quote:

Yes my machien has a circuit board with a relay int he area you have the yellow transformer shown

A board with a relay? there??

So you have another different version of Xenon machine...

Normally the relay in the Xenon is under the igniter. The igniter is the white box you can see in the left of my photo.

Clive... I think you have a job for the Royal Mail. To send your GS to Kevin is the easier way.

Otherwise I can post here some photos about the disassembling of the fan in the Xenon.

Posted by Kevin Faulkner (Member # 6) on January 05, 2007, 06:29 PM:

Ugo, The relal board I was talking about is the one on the igniter.

With that extra transformer, Clive has an extra board which has an IC mounted on it which I suspect is some form of fan control?

I'm happy for Clive to ship the machine to me or he could bring it along if he wishes.

David, Good point you make there.

Kev.

Posted by Ugo Grassi (Member # 139) on January 07, 2007, 04:11 AM:

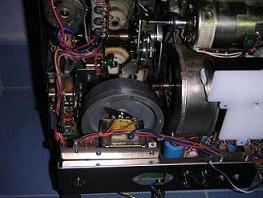

that are the insides of the Xenon in my hands. The first is the Xenon I refurbished, the second is mine.

Xenon with supplementary trasformer

my Xenon

Posted by Bill Parsons (Member # 244) on January 07, 2007, 04:30 AM:

As a point of interest I thought you may like to know that during the production run of the Xenon GS1200 it was decided the lamp cooling was not sufficient, two things were done, one was to fit an extra transformer to increase the voltage to the fan motor, the other was a different fan, the fans in the later production machines are not the same, they have cupped blades, in my experience it is these fans that tend to break or sometimes shatter! I have managed to glue them with bostick ‘plastic glue’ and as Kevin suggested if it has cracked on the collar reinforce it with some wire.

Regards, Bill

Posted by Kevin Faulkner (Member # 6) on January 07, 2007, 05:35 AM:

Thats very interesting info Bill. Having cupped blades would certainly add stress to the fan I would think.

I'm surprised that Elmo thought the original cooling was insufficient as my machine is really quite cool in use and you can certainly touch the metal parts round the lamp house minutes after the lamp is switched off.

Bill, Do these modded machines sound very noisy? Maybe that increased supply voltage is a bit OTT.

Posted by Bill Parsons (Member # 244) on January 07, 2007, 05:45 AM:

Yes Kevin these machines are much noisier, not unlike an aircraft taking off (slight exaggeration) I have a mark 1 machine the cooling seems ok to me, but in the Elmo tech bulletin I have somewhere it appears they thought the cooling was insufficient.

Bill.

Posted by Kevin Faulkner (Member # 6) on January 07, 2007, 05:56 AM:

Bill, Mine is a late machine and I have just checked it and can see that it also has the cupped blades but no added transformer. I have turned the fan by hand and can't see any breaks round the edge. I wonder if the fans last better without the added transformer to increase the voltage/speed? and therefore the stress. Maybe it would be better to remove the transformer and wire it back the way they were originally?

Here is a picture sent to me by Clive of his broken fan for those interested in seeing what had happened.

Posted by Ugo Grassi (Member # 139) on January 07, 2007, 05:58 AM:

Elmo tech report???

uhhhhhh I want it! Please Bill send me a copy

ugo(point)grassi(at)email(point)it

![[Smile]](smile.gif)

Posted by Bill Parsons (Member # 244) on January 07, 2007, 06:31 AM:

Kevin, I have only encountered about 5 of these fans broken in all my years of servicing these machines, maybe you would be best with the extra cooling rather than reducing the speed, Elmo seemed to think the lamps would last longer this way!

Ugo I will try and find my Elmo tech bulletins, I have several somewhere, but have not been able to find a lot of things after having my new workshop last year.

Bill.

Posted by Dimitrios Kremalis (Member # 272) on January 07, 2007, 08:36 AM:

So Bill your final word is not to remove the additional transformer and wire it back despite the much increased noise and additional stress to the fan? Is there any proof (e.g. comparison test) on the prolonged lamp life?

Posted by Kevin Faulkner (Member # 6) on January 07, 2007, 08:41 AM:

Bill, I too would like to read those bulletins if you manage to find them. It would be interesting to see what Elmo had to say about this.

When you consider people like Keith Wilton who has used his Early machine for years I wonder if there really is any advantage to the extra forced cooling.

Kev.

Posted by David Pannell (Member # 300) on January 07, 2007, 09:26 AM:

Ouch!! ![[Eek!]](eek.gif)

That fan looks pretty horrendous. I am sure one would need to be extremely careful not to upset the balance when repairing one of these. Otherwise it would knock the fan motor bearings out in very short order, to say nothing of an annoying out-of-balance vibration!

Still, I expect you've got all that covered, Kev! ![[Cool]](cool.gif)

Posted by Kevin Faulkner (Member # 6) on January 07, 2007, 10:06 AM:

David,

Clive has now repaired it and did use some wire round the middle. He has now run the machine again and all seemed ok.

My only concern is that it may go again and wonder of the reduced voltage to the fan would help give less stress. I dont think there is an issue with the cooling really with the lower voltage as Bill says even the early machines seem to be ok where cooling is concerned. Maybe it would be an issue if the machines were used for very long periods of time with not much downtime between shows but for most of us that wouldn't be an issue.

Posted by David Pannell (Member # 300) on January 07, 2007, 10:48 AM:

I think I tend to agree with you, Kevin.

I should like to know the original voltage rating of the fan motor, and the percent voltage increase, before passing judgement, however.

If the motor were to be over-volted, it would run hotter itself and have a shorter life. Heat is the killer of all electrical insulation - but I'm sure you know that. It is a very interesting situation if indeed Elmo did increase the supply to the fan motor. Is it in fact the same motor, or did Elmo change the motor to a higher speed one requiring a different voltage? I find it difficult to believe that any company would simply increase the volts just to make a motor run faster - very bad practice and poor electrical knowledge!

How say you?

Posted by Kevin Faulkner (Member # 6) on January 07, 2007, 10:55 AM:

Yes that would certainly be a worry but you will probably find that the original was being under run. Never the less the motor would produce more heat ![[Frown]](frown.gif) and that could as you say be a killer.

and that could as you say be a killer.

Kev.

Posted by Bill Parsons (Member # 244) on January 07, 2007, 11:09 AM:

Dimitrious, no my final word is not to leave the transformer in, it’s worth trying with the lower voltage it comes off the 30v rail, it usually runs at about 32v I think, it’s just that the lamps don’t come cheap!

David, the voltage was increased to about 40v going on memory the motors were rated at 50v, Elmo usually used well rated motors, the main drive motor as you know works on a voltage increase to run between 18 & 24fps, I have never seen a faulty fan motor due to extra voltage, just the fans.

Bill

[ January 08, 2007, 07:21 AM: Message edited by: Bill Parsons ]

Posted by David Pannell (Member # 300) on January 07, 2007, 11:12 AM:

Are we saying that the transformer now supplies the motor with the correct operating voltage? If so, then clearly that's OK, but it does seem a bit strange that the motor was underrun in the first place - why???

I'd be very interested if the technical bulletin becomes available. It's just a bit difficult to understand their philosophy if this is the case.

I want to talk to their design engineer!!! ![[Big Grin]](biggrin.gif)

Posted by Bill Parsons (Member # 244) on January 07, 2007, 01:16 PM:

Posted by Kevin Faulkner (Member # 6) on January 07, 2007, 01:21 PM:

Wouldn't we all. We would then get then to design the final GS with all the things we want and guides which don't wear.

Bill, With them increasing the running speed of the motor does it not effect the the drive to the flywheel ie it could get to fast?

I think that it might just be worth dropping the voltage back to the normal 29V tapping on the main transformer which might just take a bit more stress of the fan blades.

Another thought Bill is that the blades on my Xenon look more like a polythene plastic as its very shiny but on the GS std I have stripped down at present the plastic looks different. It's very dull in it's finish.

I wonder if that blade of Clive's just split like that nylon type plastic is prone to.

Anyway at least he's now got it back together and working.

Kev.

Posted by Graham Sinden (Member # 431) on January 07, 2007, 01:22 PM:

It would be a nice idea if any Technical Bullitins from any maker (e.g. Eumig, Elmo etc.) could be scanned and placed in the Manuals section of the forum.

Posted by Bill Parsons (Member # 244) on January 07, 2007, 01:30 PM:

Kevin, yes as you say the flywheel does run faster in the idle mode, but this does not appear to cause any problems, you could have a point with the type of plastic that the fans are made of, the correct material should not break.

Bill.

Posted by David Pannell (Member # 300) on January 08, 2007, 05:38 AM:

Thanks for your explanation of the motor rating, Bill. Makes sense - up to a point. ![[Wink]](wink.gif)

Posted by Clive Carmock (Member # 347) on January 08, 2007, 03:28 PM:

As Kevin mentioned I have managed to get the fan glued back together again.

It was still held fasdt to the spindle even in that 'open' state. I used a couple of bands if wire around the edge and twisted that to tighten it up to close the gap.

As Kev suggested I put some araldite on the top surface of the fan across the crack to provide extra support. I did use a small blade to 'rough' the surface a little to give the glue a better surface to key into. And of course cleaned the plastic with alcohol to de-grease it first.

The araldite has set hard and is holding the fan togetehr very well.

I did wonder about vibration, but can't detect any when the fan runs.

My GS 1200 is like the one Ugo is repairing, with the transformer mounted close to the flywheel.

In a while I will measure the voltage across the running fan motor and post my findings here.

I would desrcibe the fan noise from this machine rather like a Jet engine, and much louder than my Standard GS1200 (which is a Mk1 version)

So far I have run a few shorts since repairing the machine and it's holding it's own so far.

Regards

Clive

Edited - just measured the voltage on the fan motor - 44.6V

[ January 08, 2007, 04:36 PM: Message edited by: Clive Carmock ]

Posted by Kevin Faulkner (Member # 6) on January 09, 2007, 01:30 AM:

On my Xenon without the extra transformer the voltage is about 33Volts DC. At that voltage mine is loud enough so I can imagine what its like at 45V!

Kev.

Posted by Ugo Grassi (Member # 139) on January 09, 2007, 01:27 PM:

On the little transformer there is the output value: 6,3 volt. So I assume when the fan is working the whole vultage is less 39 v.

Posted by Alan Rik (Member # 73) on January 09, 2007, 02:48 PM:

I had 3 Xenon machines and to my ears they all sounded like a mini jet taking off compared to a regular Halogen GS.

Posted by Kevin Faulkner (Member # 6) on January 09, 2007, 06:18 PM:

I have to say that I am considering modifying my machine so that when the lamp is not struck it throttles back to a lower speed. Something like the std GS does but maybe with some delay to give the lamp time to cool down.

I find the noise a real pain when the machine is in idle mode.

Posted by Lars Pettersson (Member # 762) on March 26, 2007, 01:53 PM:

Hello everyone!

This is probably a bit "old hat" but as I posted in the buy/sell Forum, I have plenty of ELMO spares, mostly for the ST series. I think there are something like 20-30 fans in there. None with cupped blades though.

Best Wishes

Lars

Posted by Clive Carmock (Member # 347) on June 09, 2012, 04:32 PM:

Sorry to ressurect an old thread, but my GS1200 Xenon is sick again. I am suspecting the fan again. I was settling down to watching an Optical feature this evening of Rising Damp to replace my 16mm copy that has turned totally red.

About 600 ft into the first 1200ft reel the machine started to make a screeching noise. I immediately shut it off.

I find that with the power on, but the mechanism not running the screeching noise is there.

So I am suspecting the fan unit again - either my old repair on the fan blade unit has failed and it is rubbing against somethign again, or the fan motor bearign have gone.

I need to spend soem time stripping it down again, but wondered if anyone knew of a source of spare fan motors or fan blades?

Posted by Clive Carmock (Member # 347) on June 17, 2012, 12:39 PM:

Following on from my post. I have now removed the fan and fan motor from the projector. The fan motor itself seems fine - it wasn't turning quite as freely as you'd expect but a few drops of light oil on the bearings either end fixed that and now it rotates very freely.

However the plastic fan blade unit is at fault again. I think the heat from the machine over time has softened the epoxy resin glue I used and the crack opened up a little more. I see the beginnings of a second crack at 90 degrees to the first one now. So I suspect this particular fan blade will be of no use.

The good news is that I doubt whether I will need a new fan motor, but will need a new fan blade unit for it. If anyoen knows of a supply of them, or alternatively of a scrap machine being used for spares I'd be interested in buying the fan from it.

Did the GS1200 share fan assemblies with any of the other Elmo machines? If so I can keep a look out for those as well.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Smile]](smile.gif)

![[Eek!]](eek.gif)

![[Cool]](cool.gif)

![[Frown]](frown.gif) and that could as you say be a killer.

and that could as you say be a killer.![[Big Grin]](biggrin.gif)

![[Wink]](wink.gif)