This is topic Restoring the Rubber Shutter Wheel Surface on Elmo ST-1200 (and other tales!) in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=010066

Posted by Steve Klare (Member # 12) on July 01, 2015, 06:08 PM:

I’ve never been happy with the idea of running the Elmo ST-1200 without the rubber surface on the shutter wheel. Let’s face it: for profit companies don’t put in added costs when they don’t need to. Putting that belt in there meant an extra part for Elmo, an extra assembly process to glue it on the wheel and extra assembly time while the wheels sat with the adhesive setting up. If they didn’t really need it they would have designed the machine without it and kept the difference as profit.

-but unfortunately we live in the Senior Years of Super-8, and all over the place rubber eyepieces on cameras and belts on projectors are reverting to the goo they started out as, and we have situations like this “belt” (I actually like to call it a “tire”, but whatever…) where it’s basically fate that it melted years ago and the only possible solution is to clean up the mess and run on the metal underneath (…or is it?!)

This arrangement is the Achilles Heel of what is an otherwise excellent projector. It is one wheel riding on the edge of another bigger wheel: no gearing, no stretched belt, just a spring for tension on a rocker of uncertain location trying to press the two wheels together for traction: like something the Flintstones would have used!

-then we remove that rubber surface: just like driving your car around on the rims!

I hatched an idea last winter of taking an ordinary rubber band, stretching it around the wheel surface and tacking it down. I grabbed a few bands and opened up the back of the machine. The shutter wheel is narrower than any of the bands I had, and I don’t have the patience to sit and split a rubber band in half!

Putting a new tire on that wheel went on the back burner, but a few weeks later circumstances forced my hand.

Mid-March my ST-1200 started to act like it had a flat tire. I took off the back and found the motor pulley was no longer pulley shaped! It was cracked and distorted. Five years after I got it, and for the first time, I had to take my ST-1200HD out of service. I put a semi-retired Eumig 800 in its place and the show went on.

I tore the ST-1200 down and took the old pulley out to do some measurements. For a while it became a bin full of parts up on the dresser in the spare room. (At low moments I was afraid I’d created a parts machine!)

I thought finding a replacement pulley would be easy! Turns out this pulley defies many standards that off the shelf ones conform too: the diameter was a little odd, but more importantly the shaft diameter is larger than usual for pulleys this small. I considered getting a standard one and having it bored out, but a hole this large would not leave enough hub material to be sturdy.

-so I went on a quest for a good original Elmo pulley, and that added on another six weeks.

(We’re getting to the good part soon, stay with me...)

After all this fuss, there was no way I was re-assembling this machine with the original belts!

I went to my favorite E-bay seller, isellprojectorbelts (His real name is “Mark”), and I looked at what he had for ST-1200HD. I wanted the two belt set, because I don’t really care about the footage counter. Yet I looked at the five belt set, and saw it described like this:

“1 Square Upper Take Up Belt, 1 Small Square Motor Belt, 1 Tiny Counter Belt, 1 Large Square Motor Belt, 1 Flat Shutter Wheel Belt.”

………Shutter Wheel Belt???!!!

I asked Mark about it and it turned out to be exactly what I’d hoped: a replacement for the missing rubber surface. (!)

Mark was of the opinion anybody who is reasonably mechanically inclined could handle this job. I once changed a car from drum brakes to disk: I took his challenge! (I get in more trouble this way…)

This could be a nasty job. The shutter wheel is narrow, the belt is springy and prone to diving off in one place when you are holding it in another, the space to thread this thing around the shutter is confined and the visibility is awful. I fought it for about fifteen minutes, and started to wonder if driving on the rim was really all that bad!

-yet there IS a way!

First thing is to remove the two screws holding the rocker/roller assembly to the chassis, set it aside and get some room to work. Second is you need a way around the fact that the ideal way to put this band (…belt?, tire?) on the wheel would be to stretch it out in all directions and place it all on the entire edge at once, because you really can’t do this with the wheel still installed in the machine.

-You need an army of little “hands” to hold it in place while you mount it!

I found the smallest Ty-Wraps (cable ties) we had in the house. I laid the belt on the shutter wheel edge and snugged it down. This took care of only one point on the edge, so I rotated the wheel part of a turn and did it again. This held the belt in place everywhere between those two points. I did it again and again until there was a last segment I stretched into place and I was done! (…at least with THIS!) I put the buckles of the ty-wraps inside the shutter apertures to fit inside the tight confines of the chassis. (It barely helped.)

Mark told me that adhesives between the belt and wheel are optional. Given the difficulty of doing this I didn’t want to risk having to do it again, so I took that option.

Janice Glesser recommended Eclectic Products E-6000 adhesive:

E-6000

This was available locally so I gave it a shot. This cement has a narrow applicator tube which allows just a small amount to be applied exactly where you need it. Another nice thing is it is heat resistant (remember: this wheel rotates through the lamp house) and it cures to a pliable consistency. Anything that hardens fully is liable to become brittle and flake away from being pounded by the drive roller 24 times per second for maybe thousands of hours. If I have to redo this someday, this cement should also be easier to scrape off the wheel edge than something like cyanoacrylate (Crazy Glue).

I cemented the belt to the wheel at about 8 points around the circumference. I lifted the belt, placed the cement on both surfaces, held them apart two minutes and then pressed down and smoothed the spot. I let them cure for a while and then clipped off the Ty-wraps. The recommended full cure time was 24 to 72 hours: I erred on the side of caution, especially this first time.

I restored the machine to barely operable condition and ran the transport for one minute. After I stopped I looked at the belt and found in a couple of spots where the distance between the patches of cement was too far. The belt had curved over the edge of the wheel and was now hanging from the adjacent cemented spots. I have to respectfully disagree with Mark here: the cement is mandatory. My belt would have twanged off the wheel for certain without it!

I applied cement in the middle of the problem areas and let it cure, then tried again for another minute. I repeated these steps until it stayed completely in place. I nudged the belt all the way around the wheel looking for loose sections: it was solid.

I ran it an hour: OK. I reassembled fully and tried a 200 footer: OK. 400 Foot: OK. 600 Foot, 800 Foot, 1200 Foot: All OK.

-I felt quite contented by the time I finished up that night, and not just because I had a victory beer!

Lately I’ve been operating the machine in normal service (many 1200 footers this week...). I just inspect the shutter wheel before I start (It’s visible from the lamp side, and you can see the whole thing if you turn the inching knob.)

-Eventually I won’t even do this. It’s looking good and I’m more and more confident with it.

I am now getting a full 24 FPS out of this machine with almost no time to full speed: something it has actually never done since I bought it in the first place.

Do I think the restored shutter surface is what did it?

-Surprisingly, not entirely.

It seems this machine had a problem all along that only now do I understand. It used to be when I started up cold there was a really irritating squealing sound I always thought was the rollers slipping on each other. It really was my lower belt slipping on the motor pulley and it continued until the lube heated up a little and the slippage stopped. The consequence is that the belt was actually wearing the pulley: cutting the nylon sheave deeper and deeper. In a few places it actually wore through the bottom of the sheave.

As a result, the effective diameter of the pulley was getting smaller and smaller and the maximum possible speed was falling too. It was doing the best it could under the circumstances, but if I wore the pulley down just 10% I was now below 22 FPS! The squealing stopped last Fall when I figured out a proper lubricant and cleaned and greased the cam tank, worm gear and other things, but the damage was already done.

-it was as if I was driving around with undersized tires and wondering why I was having trouble keeping up with traffic!

Moral: If your ST-1200 is running slow, and especially it it’s making this nasty sound: check out your motor pulley!

I think the restoration of the shutter wheel has helped get to 24 FPS and does get there sooner. It also helps quiet the machine: It muffles the wheel rolling with the drive roller. I also believe that when the rubber was removed the original owner didn’t re-adjust the contact pressure and that contributed to slippage. Without changing the adjustment the traction wheel on wheel is noticeably better.

-So I do recommend doing this, and if I get another ST-1200 without the rubber in place I would certainly do it again. At the very least I know the machine is now operating the way it was designed to, and besides: the second one should be easier.

If you are interested: Search on E-bay for “Super 8, Elmo ST-1200HD, Projector Belts, 5 Belt Set”.

Posted by Barry Fritz (Member # 1865) on July 01, 2015, 06:37 PM:

Great job and nice write-up Steve. It appears there is a writer inside of you wanting to get out!

I have dealt with Mark McWilliams often over the years. If he is selling a multi-belt set on Ebay, and you don't need all the belts, contact him. He has sold individual belts to me. Even if he doesn't list your belt on Ebay, contact him. You'll need to know the size belt you need, but he most likely will be able to help you. Also, as is illustrated in Steve's comment, Mark is not an expert on projectors and their repair. He sells only belts and doubtless has acquired some knowledge about various projectors over the years, but don't take his word as gospel.

Posted by Janice Glesser (Member # 2758) on July 02, 2015, 12:07 AM:

Excellent Steve. Sounds like your ST1200 is running better than ever. For now I've opted to leave the shutter wheel belt off... but I will give it a try in the near future.

Steve you wrote:

quote:

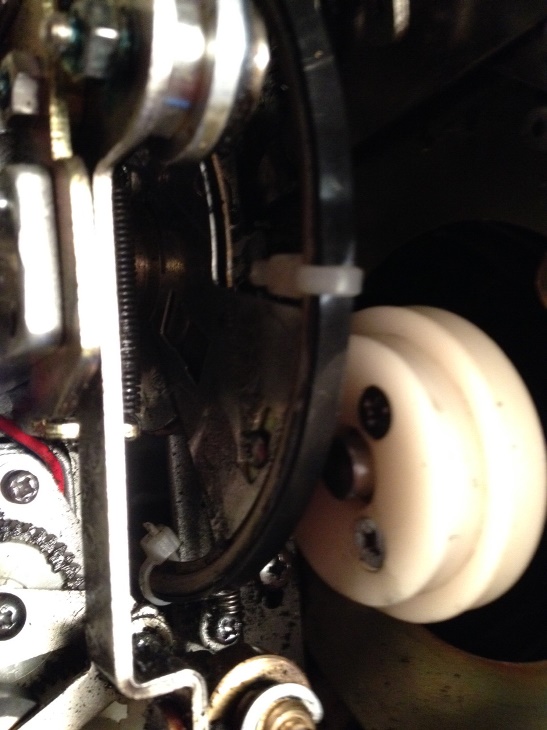

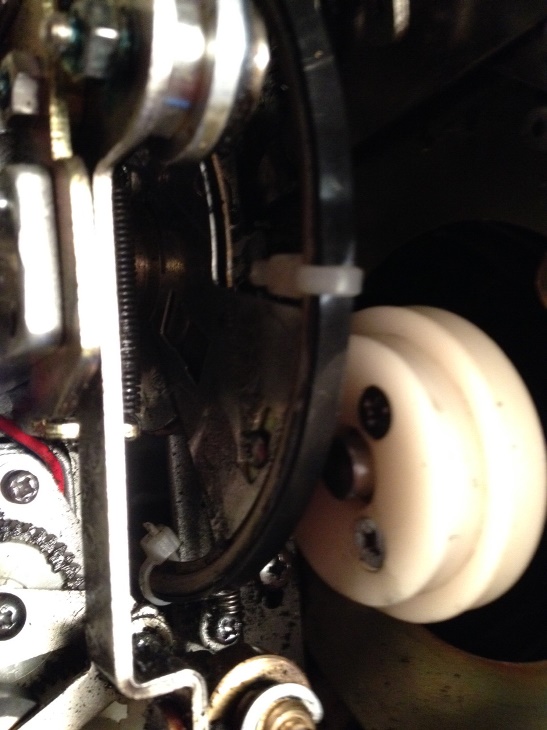

First thing is to remove the two screws holding the rocker/roller assembly to the chassis...

Could you post a picture of the two screws you are referring to?

Posted by Steve Klare (Member # 12) on July 02, 2015, 11:12 AM:

Thanks Barry!

Janice,

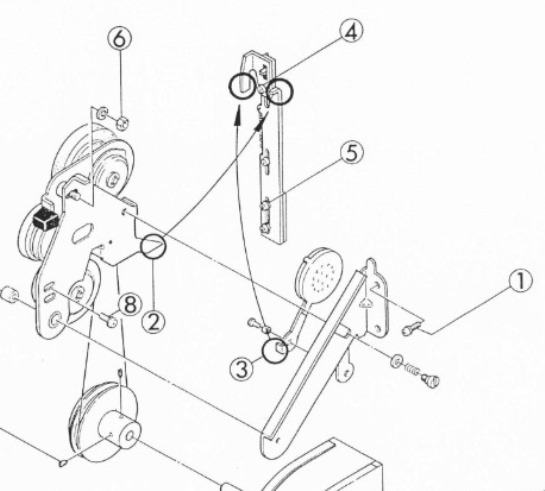

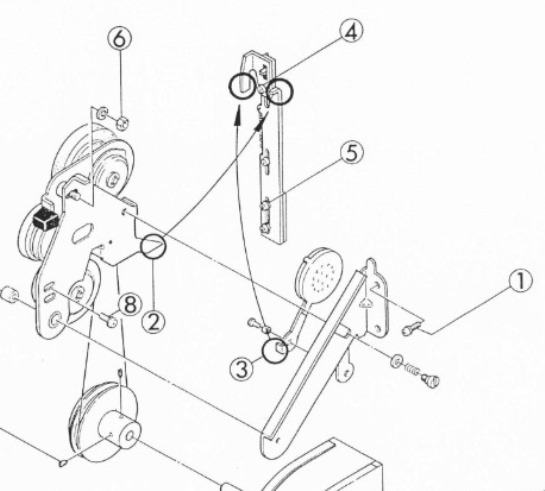

I refer you to a drawing we are probably all getting pretty tired of these days!

The two screws to remove the whole Rocker/Roller assembly are the one shown at "1" and its neighbor immediately to the south. Once they are removed the assembly comes off as a unit. You can carefully lay it aside, you just need to be mindful not to damage that yellow wire that runs up to the switch mounted on it.

Putting it back is another matter. That bottom screw is deep at the bottom of a valley of stuff so you can't hold the screw while you are turning it. It also unifies several layers of parts that have to line up exactly to open the way for the screw to find some mounting threads. It also is in a place that forces you to place the screwdriver at an odd angle. All of this makes life difficult!

-make an investment in sanity: the main transformer is mounted next door on four easily accessed screws. Un-mount it and gently move it aside for better access (-lay the machine lamp side down for this). Your blood pressure will thank you!

Also: That pointy thing shown at "2" has to wind up below that bendy thing at "4" (Don't you just love technical language?) for the adjuster to work (...assuming it ever really worked). It might pay to see how it fits together before you make the first incision.

It actually pays to leave the two screws slightly loose at first. There is enough slop in them that the assembly may not align optimally the first try. You should fish around for good pressure between the rollers before you finally commit yourself.

This is a process: it takes multiple steps and allowing the cement to sit for at least a day between them. It's the kind of thing you need to do for a half an hour, set side for a day and come back to the next night and do a half hour again for several days.

-then again, I lost this machine for more than 3 months. What's another week?

Posted by Janice Glesser (Member # 2758) on July 02, 2015, 12:15 PM:

Thanks Steve for the detailed process. I felt a little silly asking about removing two screws...but in looking at the part ... I just couldn't believe it was as simple as you intially stated. Your follow-up instructions proved that assumption ![[Smile]](smile.gif) I now know it's doable...just not a slam dunk

I now know it's doable...just not a slam dunk ![[Eek!]](eek.gif) You're the best!

You're the best!

Posted by Terry Sills (Member # 3309) on July 02, 2015, 12:23 PM:

Very well investigated, researched and executed Steve. However you've convinced me never to purchase a St1200. I was always of a mind to get a GS1200 - beautiful machines - but just too complex and too much to go wrong.

It seems to me that some of the later makes of projectors must have used poor quality rubber in the belts and rollers, which revert to black sticky goo, whereas others, and particularly older projectors, don't seem to suffer this fate.

I do hope your meticulous repair serves you well and the post was a great read. Well done Steve.

Posted by Steve Klare (Member # 12) on July 02, 2015, 12:42 PM:

What I would actually like is some kind of kit to replace the whole Rock 'n Roll assembly with a gear or belt transmission. (Might as well do a two bladed shutter in the same package.)

I realize this would fix the machine at one speed, but given my experiences with what can happen to that contact pressure after a speed change, I haven't shifted this one to 18 FPS since 2009!

Any DC-motored machine with an electronic speed regulator and an FPS select switch will do just fine here.

Posted by Janice Glesser (Member # 2758) on July 02, 2015, 12:47 PM:

Steve...are you using one belt or two?

Posted by Steve Klare (Member # 12) on July 02, 2015, 12:54 PM:

I went to one belt on the top pulleys. I'm not sure if it's a coincidence or not, but after I removed it the startup problem went away.

I'm certain installing the correct diameter pulley bumped my required starting torque up a little too.

My gut is telling me the purpose of the small belt is because the 18 FPS pulley has a narrower angle of belt contact: this way the 24 FPS pulley can provide some torque and prevent belt slippage at 18.

-but as I said: I don't do 18 FPS with this one.

Posted by Gary Crawford (Member # 67) on July 02, 2015, 01:10 PM:

Magnificent description of the process. I have one of those st's with no rubber on the shutter. I have used it like that for several years with no "apparent" problem...speedwise or noisewise. But I know I'd never be able to do what you describe. I have ten thumbs...and no time ...and attention deficit to boot. But I sure admire folks like you who CAN do that sort of thing.

See you in October.

Posted by Steve Klare (Member # 12) on July 02, 2015, 01:20 PM:

Hi Gary,

I wonder if there are any out there at all with their original rubber.

I've done a lot worse things than this. I changed a starter in one of my cars one night when it was about 20 degrees F and access to the top bolt was so bad I literally advanced like one click of the socket wrench each time. It was described as "two bolts and one electrical connection" and it was. It's in the details where it became awful!

I would gladly do 10 of these rather than ever do that again! At least this didn't involve possible hypothermia!

I think I would have approached this more like Janice if the machine was intact and running fine, but let's face it: mine started out a basket case and I might as well do it while it was apart anyway. In the best case I would have installed the belt around the wheel while the motor was lifted out to install the new pulley, but I didn't know it existed yet!

BTW: Astaire and Rogers liked my repair just fine! (inside joke...)

[ July 02, 2015, 03:20 PM: Message edited by: Steve Klare ]

Posted by Barry Fritz (Member # 1865) on July 02, 2015, 04:34 PM:

I just had to check mine out to see if it had the original rubber. I haven't used it since I originally bought it several years ago.

It is not there, but looking at that area live and in person, I can tell you it is going to stay that way! Talk about tight quarters! You are certainly to be commended, Steve, for putting that belt on and sharing your experience with us.

Posted by Steve Klare (Member # 12) on July 02, 2016, 05:26 PM:

Well, It's been a whole year...

One of the questions I had about this job was how well it would hold up. I gave up checking the firmness of the new rubber surface on the shutter wheel maybe 11 months ago. The machine has been running at least three times a week and well into the next lamp since I did the work. It's been running everything up to 1200 footers and has handled feature shows either alone or with another machine quite a few times.

This machine typically handles the longer reel when it is working with another one on the table, so most nights it runs at least one 400 footer, maybe a 600, or maybe several. It is also my only 1200 foot capable machine, so it probably is in the lead for screen hours this past year.

-so I decided to take a look.

The rubber belt looks the same as when I installed it: no splits or cracks. The cement was still firm almost all the way around. I found one loose spot, which I just re-cemented. I'll let the machine take the weekend off so the new cement can set and return it to service Monday night.

So I am glad I did this restoration work, and I plan to do it on any future ST-1200s I ever own.

Posted by Andrew Woodcock (Member # 3260) on July 02, 2016, 05:59 PM:

Well done with all of this Steve!

I agree, and have always felt that these machines run far better with the shutter tyre fitted than without.

Ironically, when I sold my HD with the tyre in perfect serviceable order, I found out later that it had been removed before it was sold on shortly afterwards?

I was really surprised to hear of this and couldn't help thinking to myself, that this would only ever compromise it's running performance, make it noisier and before you know it, lead to speed / drive related problems.

Many here in the UK believe for some reason, that these machines run better without the tyre fitted, but I personally do not subscribe to that theory one bit.

Posted by Steve Klare (Member # 12) on July 02, 2016, 06:18 PM:

You shouldn't have sold that machine, Andrew!

There can't be two ST-1200s on the whole planet with the original rubber intact!

Just for curiosity: how old was the machine when you sold it?

My feeling has always been if the machine didn't need the surface, they would never have designed it in there in the first place.

(YOU know Engineers!) ![[Wink]](wink.gif)

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Smile]](smile.gif) I now know it's doable...just not a slam dunk

I now know it's doable...just not a slam dunk ![[Eek!]](eek.gif) You're the best!

You're the best!

![[Wink]](wink.gif)