This is topic Wanted 8mm-super8mm projector in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=010838

Posted by Jim Terry (Member # 5492) on July 23, 2016, 07:24 PM:

My wife and I recently uncovered many old movies of our family. When we pulled our projector from storage we found it no longer was working. Its a Bell & Howell Lumina. After reading some reviews on it we decided to just look for a good used one in good working condition. Can someone help us buy one? Thanks.

Jim & Barbara Terry

Posted by Barry Fritz (Member # 1865) on July 23, 2016, 07:33 PM:

Welcome to the forum. You'll likely get some help here. You might want to check Craigslistings for your area. That way you will be able to examine and test any projector you might want to buy, and won't have to pay shipping costs. If you see a projector listed, search this forum for the model number. By reading posts regarding the model you will get some insight about it.

Your Lumina was a standard 8mm projector so if that is what your films are, make certian you don't get a Super 8 projector.

Posted by Janice Glesser (Member # 2758) on July 23, 2016, 08:06 PM:

Hi Jim...I've sent you an email.

[ July 23, 2016, 10:39 PM: Message edited by: Janice Glesser ]

Posted by Jim Terry (Member # 5492) on July 24, 2016, 08:42 AM:

Thank you both for your replies. I chose to post at this forum thinking these people know the product as well if not better than most others. I value your opinions and hope what we have purchased will last a long time.

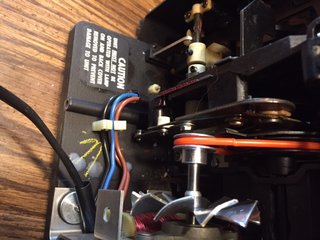

The projector we have has a bad drive belt. Looking at the interior there's no easy way to change it. The exact model is a Lumina MX60. It plays both 8mm and super 8 films. Its in super good condition and would love to get it going again. If anyone can help it would be greatly appreciated. Again thank you for your responses.

[ July 25, 2016, 06:19 PM: Message edited by: Jim Terry ]

Posted by Barry Fritz (Member # 1865) on July 24, 2016, 01:33 PM:

Hi Jim: I think Janice may know how to change the belt on that projector. She will chime in if she does. In the meantime, search Youtube for a video about changing the belt.

If you do decide to get another projector, go to http://www.donsbulbs.com and enter the make and model at the top of the screen in the box that says "Equipment" after it. From the results, find out the type of bulb the projector uses. Then google the bulb letter designation. You will find for example, your MX60 uses a bulb that will cost you between 60 and 90 dollars! Don't take a chance buying a projector that needs a bulb that cost that much. Newer projectors use halogen lamps that you can buy for around 10 dollars.

BTW, ebay seller isellprojectorbelts will likely have a replacement belt for your projector.

Posted by Janice Glesser (Member # 2758) on July 24, 2016, 02:26 PM:

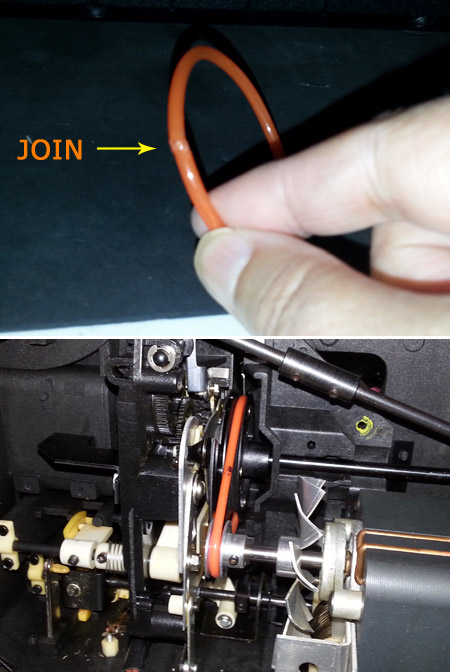

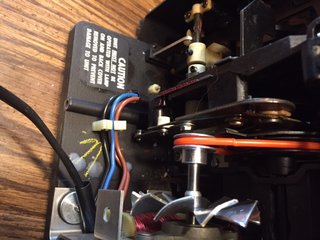

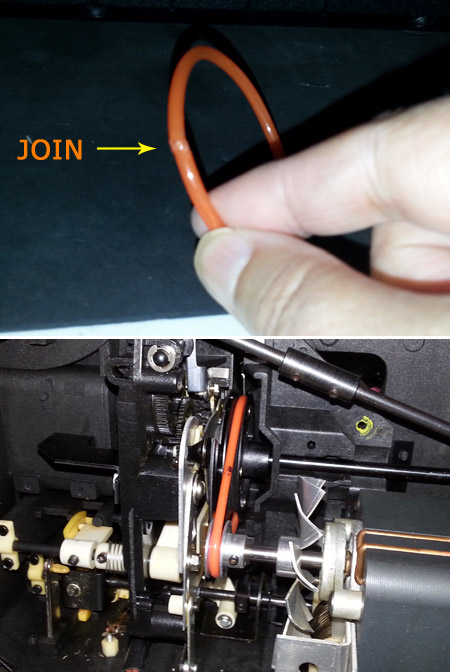

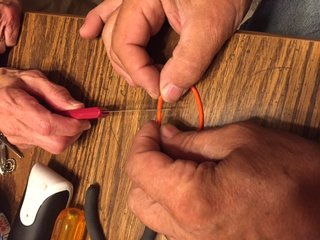

Hi Jim...Yes, you probably already have discovered you can find the motor belt for that projector on Ebay...however I challenge you to find anyone who can provide detailed instructions on how to remove and install a replacement belt ![[Roll Eyes]](rolleyes.gif) That said...I have come up with my own method to replace the belt on a few of these projectors. I wrap urethane belt material directly onto the pulleys and using a soldering iron join the ends of the urethane. It's pretty tedious (sometimes wish I had a couple more hands) and sometimes takes more than one try...but it does work.

That said...I have come up with my own method to replace the belt on a few of these projectors. I wrap urethane belt material directly onto the pulleys and using a soldering iron join the ends of the urethane. It's pretty tedious (sometimes wish I had a couple more hands) and sometimes takes more than one try...but it does work.

Here is what the replacement belt looks like. This was done on a MX33 model, but all the B&H Lumina Series projectors are basically made the same inside.

These B&H model projectors were not built with the highest quality parts and may not be worth the time or expense to repair. I think your decision to purchase another projector was a better choice.

Posted by Barry Fritz (Member # 1865) on July 24, 2016, 04:05 PM:

I've used that belt material in the past also. It is easier if you have someone to help hold or heat. Janice, did you get that material from Larry?

Posted by Janice Glesser (Member # 2758) on July 24, 2016, 04:19 PM:

No....Amazon.

Posted by Jim Terry (Member # 5492) on July 24, 2016, 06:32 PM:

Sounds like a good challenge! I've completed many soldering jobs in my time but never with that kind of material. I'll look for it on the Amazon site. Is there more than one size available? If so which one do I buy.

Posted by Janice Glesser (Member # 2758) on July 24, 2016, 07:42 PM:

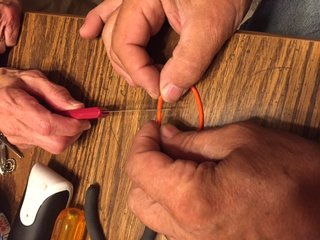

The soldering iron is only used to heat and melt the ends of the urathane. You then carefully put the two ends together. It cools extremely quickly so rapid positioning is important to keep the belt lined up at the join.

This is what I bought:

https://www.amazon.com/High-Performance-Urethane-Belting-Diameter-Length/dp/B006IZXJL8

Posted by Joe Taffis (Member # 4) on July 24, 2016, 07:50 PM:

I've also used that belt material from Larry Urbanski in the past. He still sells it...

Posted by Barry Fritz (Member # 1865) on July 25, 2016, 12:46 PM:

Thanks Janice. I held the two ends close togethr while the wife heated them with one of those long ended barbeque/fireplace butane lighters and then stuck the ends together.

Posted by Janice Glesser (Member # 2758) on July 25, 2016, 03:39 PM:

I've used the lighter also...but a flat-tipped soldering iron is much easier to control and you don't get the blackening from the flame. It's really only difficult when fitting the material directly onto pulleys. I tape the material to each pulley to stabilize the ends for the join.

Posted by Jim Terry (Member # 5492) on July 29, 2016, 10:25 AM:

A follow up to this thread. I received the belting material yesterday from Amazon per Janice. Reading the directions my wife and I tried repeatedly to create the new belt. We tried a soldering gun....butane lighter and a candle with bad results. We were either getting too hot or not hot enough. We paused for dinner with our in-laws. I mentioned the project to my brother in-law during dinner and he said he had done similar projects years past making and repairing models. So after dinner we resumed making a new belt. His method proved to be perfection. What he had me do was to heat an old knife on our stove. I have to prefix this by adding we experimented first getting the knife at a proper temp. Once we got it done I brought the heated knife to the projector where my brother in-law was holding the two ends of the new belt. He touched both ends to the hot knife and once we got the ends hot enough I withdrew the knife and he mated the two ends until cool. It worked perfectly! I've added some pictures showing the process. Afterwards we watched movies! Thanks Janice for guiding me.  [IMG]http://8mmforum.film-tech.com/cgi-bin/showpic.cgi?dir=uploads0503&file=rsz _img_3875.jpg[/IMG]

[IMG]http://8mmforum.film-tech.com/cgi-bin/showpic.cgi?dir=uploads0503&file=rsz _img_3875.jpg[/IMG]

Posted by Janice Glesser (Member # 2758) on July 29, 2016, 01:51 PM:

Awesome Jim. Yes a hot flat blade is the way to go. I have a flat tip on my soldering iron which acts pretty much like your knife. Sometimes it just takes a little ingenuity to make this stuff work and your hot knife did the trick. Congrats and happy viewing ![[Smile]](smile.gif)

Posted by Lynn Emerich (Member # 5502) on August 01, 2016, 06:36 PM:

Janice, That looks like a great idea. What is the original purpose of that material? I'm asking because I'd like to see if anyone local to my area would carry it. If not, it Amazon.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Roll Eyes]](rolleyes.gif) That said...I have come up with my own method to replace the belt on a few of these projectors. I wrap urethane belt material directly onto the pulleys and using a soldering iron join the ends of the urethane. It's pretty tedious (sometimes wish I had a couple more hands) and sometimes takes more than one try...but it does work.

That said...I have come up with my own method to replace the belt on a few of these projectors. I wrap urethane belt material directly onto the pulleys and using a soldering iron join the ends of the urethane. It's pretty tedious (sometimes wish I had a couple more hands) and sometimes takes more than one try...but it does work.

[IMG]http://8mmforum.film-tech.com/cgi-bin/showpic.cgi?dir=uploads0503&file=rsz _img_3875.jpg[/IMG]

[IMG]http://8mmforum.film-tech.com/cgi-bin/showpic.cgi?dir=uploads0503&file=rsz _img_3875.jpg[/IMG]

![[Smile]](smile.gif)