This is topic Beaulieu 708 losing film loop in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=012688

Posted by Alan Gouger (Member # 31) on December 30, 2018, 11:23 PM:

I am having trouble with my 708 not liking certain film formats as well as splices. Once it loses the film loop I cannot get it back. I am not sure if it is the alignment of the film or if the claw needs adjustment. When all is well the projector is purrs like a kitten, that is until it hits a splice.

I do not see any ware on the claw so Im guessing maybe the claw is in need of adjustment?

Thank you.

Posted by Phil Murat (Member # 5148) on December 31, 2018, 04:46 AM:

Hello Alan,

I am away from my computer so that I can't acceed to Beaulieu 708 service manual.

So I understand it is running smoothly until a splice is met , also a loop loss depends on film brand as well (triacetate or polyester ?)

I suggest you to check claw backward desengagement clearance and to check side press guide for wear and its spring efficiency included (lens holder has to be removed, you need a tiny hex wrench for the 1mm headless screw)

could you make a test at 18fps speed and manualy running main shaft by outside knob until you meet a splice.

let us know

best wishes

Phil

NB

In case your machine has accumulated hundreds of hours and cams were never replaced, it could be interesting to make a check up for cams wear . It can be done with a dial gauge on stand to make measures on both axis (X & Z) claw displacement.

It is recommended to lubricate regularly cams area (liquid grease with a spray pipe works fine). Cams are nylon material for this machine.

[ December 31, 2018, 06:40 AM: Message edited by: Phil Murat ]

Posted by Alan Gouger (Member # 31) on December 31, 2018, 10:28 AM:

quote:

So I understand it is running smoothly until a splice is met, also a loop loss depends on film brand as well (triacetate or polyester ?)

That is correct Phil. It is happening more with polyester yet a splice can set it off with ether film brand. The same print will play flawlessly on my other projectors.

I will try all your suggestions and report back. Thank you Phil.

Posted by Alan Gouger (Member # 31) on December 31, 2018, 02:05 PM:

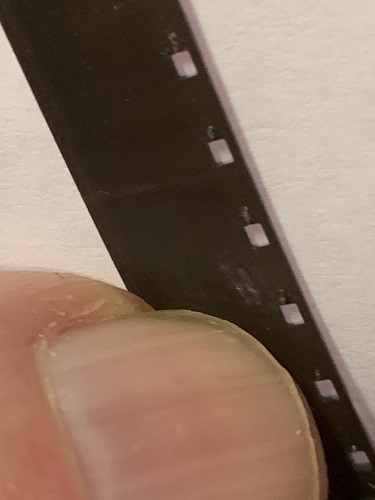

Phil, I will do the tests you suggested but first wanted to upload these pictures. The claw looks to be in good shape.

I put black material behind in one picture to help see better.

Posted by Larry Arpin (Member # 744) on December 31, 2018, 02:31 PM:

I had a similar problem but mainly in just reverse and I can see it was a worn cam.

Posted by Alan Gouger (Member # 31) on December 31, 2018, 05:24 PM:

Hi Larry, did you end up replacing the worn Cam. This may sound stupid, how do you tell the Cam was the issue.

Phil the backward disengagement clearance if fine. The forward engagement looks plenty also. The side press guide and its spring show no ware and the spring is fine also, like new.

Posted by Larry Arpin (Member # 744) on December 31, 2018, 06:49 PM:

I had another Beaulieu and replaced it and worked fine. It wasn't an easy task. Now it has a sound problem. It's been a long since I went over this and I think it was just a comparison thing.

Posted by Phil Murat (Member # 5148) on January 02, 2019, 04:21 AM:

Hi Alan,

Thanks for these informations. By the picture , I can see the claw looks fine , it doesn' t show particular wear.

I also understand claw displacement is full , both cams seems to be in a good health. (Anyway , take the opportunity to drop grease on cams and claw bearing too)

So, I suggest you to check position of claw (Z axis). Claw comes inside sprocket holes by the midle , so that , in case film is a bit lateraly stagged due to thickness of a splice on film outboard side, both do not hit outboard side of the notch.

To do that , it could be usefull to put a soft witness piece of sticker for the exact

widht of film. Then manually engage film with witness sticker until claw meet witness sticker.

Remove test film portion and inspect claw prints with a 10x magnifying device.

If claw evidences are not centered, it is possible to readjust pins lateral positionning for approx 0,1mm , Simply, just gently pushing pins from outboard to inboard direction, using a wooden stick.

As necessary , renew checking method with witness sticker to validate pins positionning.

If no witness tape available, insert a white leader , remove lens, and inspect with a powerfull light and magnifying lens for pins positionning.

When I'll be back on my computer I'll put big pictures for a removed claw drive assy to download. By these pictures you can easily figure out how Beaulieu claw works.

Hello Lary,

How many hours has your Beaulieu accumulated ?

Could you describe sound issue ?

Let us know.

Best wishes

[ January 02, 2019, 10:02 AM: Message edited by: Phil Murat ]

Posted by Larry Arpin (Member # 744) on January 03, 2019, 12:09 AM:

Here is a pic of the worn cam:

I had gotten a Beaulieu 708 off Ebay and it worked fine until I went in reverse and damage the film. BTW-I never run a good film through a newly bought projector. Since I had another 708 that had a broken board I decided to swap boards into that one. It went forward and reverse with no problem. For whatever reason, I don't remember since it's been a few years now, I decided to put the board back into the Ebay Beaulieu and change the cam assembly. I remember a wire got disconnected and maybe that is the reason there is no sound. If I get a chance I will pull out the projector and take a pic. I remember putting it aside for another day but I've been so busy with work and other things that I never got to it.

Posted by Alan Gouger (Member # 31) on January 03, 2019, 05:47 PM:

Thank you for the picture Larry it goes a long way to help understand how the claw works. You would think they would have made the cam out of a material that would not wear.

Phil here is a picture of what looks like the pull-down timing is off. Not sure I am using the correct description. You can see in the picture where the claw has left its mark.

Posted by Phil Murat (Member # 5148) on January 04, 2019, 05:50 AM:

Thanks for picture Larry, it shows how the spring makes all the pull down job for this fail safe system.

By your picture Alan, I can see claw pins seems to be properly centered on notchs axis.

I suggest you to check the pull down friction of film when it travels across frame guide assembly.

Remove lens to observe what happen when a splice is coming in frame guide guides and plates.

Clean thoroughly guides with a light thinner (call C or F thinner from our side, same used to clean cloths).

To perform friction test it could be usefull to remove claw cover plate (open lamp gate, loosen both scews, remove gate stop plate, remove plate ....). it gives you more room to pull down manualy the test film.

The idea is to estimate friction strenght (claw is disengaged), more particularly when a splice is travelling in frame guides.

Of course , friction has to be much lower than spring pull down strenght.

If friction is to high or a hard spot can be felt when splice is comming, it is necessary to eliminate hard spot and adjust friction.

As necessary, you can do a lubricant with 10cl of F thinner and 3 drops of Silicon oil, Lubricate Frame side guides first only (using a cotton swab) and check effect on friction .

Before to insert test film inspect splice . insure you rolled around edge splice is smooth and perfect.

Posted by Phil Murat (Member # 5148) on January 05, 2019, 08:19 AM:

Here are some records I have just made :

- Friction load (using Kodak white leader, not lubricated) is 80gr.

- Claw lift (pull down) is 250gr (measured next to pins).

I haven't compared to values in Service Manual yet....

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2