This is topic Eumig S938 slow and noisy in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=002528

Posted by Oskar Jalink (Member # 667) on February 20, 2007, 04:12 PM:

The Eumig S938 projector I bought some time ago is having a few problems. It is noisy and it is slowing down.

A lot of the slowing down has been delt with: I gave the main drive assembly a good cleaning: I treated the rubber drive wheels with sanding paper, and cleaned them afterwords with some cotton sticks and alcohol. Audio is a lot better now, but still not perfect.

The gatehouse and the main drive are noisy. That is to say, I'm under the impression that it should run quieter. It is defenately NOT running like a kitten, more tiger like. I found some parts that vibrated heavily and this was solved by squeezing in a view tiny peeces of foam latex in between the vibrating parts. But still, I think the S938 should be able to run more smoothly.

I think I may need to grease certain parts, but I don't no which parts, and I also don't know which parts are save to disassemble and which are not.

(I wish I had a digital camera so that I could show what parts I think I'm having trouble with)

Suggestions?

Posted by Lee Mannering (Member # 728) on February 20, 2007, 04:18 PM:

Hi.

Your problem is going to be the very small drive belt which can be seen at the front of the machine. This little belt has the huge job of driving the mech. If you replace the belt it will cure it as it did in my machine last year. You will find the banging is due to the swing rocker above it knocking on the machine as the belt is very slack. If you run it long enough it will cause damage to the cushion pads to the right rear of the rocker.

I tried all sorts when mine started and a simple belt change cured all ills.

Hope this helps.

Posted by Oskar Jalink (Member # 667) on February 20, 2007, 04:44 PM:

WOW! That's what I call a quick reply!

I wasn't prepared for this: the aparatus is back on the shelf again to be further worked on tomorrow (it's near midnight on this side of the Channel) I'll check the belt you mentioned. I will also try to get my hands on a digital camera. That will make posting a lot easier. ![[Big Grin]](biggrin.gif)

Posted by Maurizio Di Cintio (Member # 144) on February 21, 2007, 11:08 AM:

Curious: I didn't know that belt is prone to stretching.

Once I stumbled in an otherwise excellent S 932, having this problem of the rocker causing noise.

I fixed the problem by reducing the range in the movement of the rockers themselves, as the tensioning system seemed to me a little slack. Which made sense, since it the belt were stretched, its teeth woulnd't have engaged the shafts' teeth properly, ,I guess.

Comments?

Posted by Oskar Jalink (Member # 667) on February 21, 2007, 03:31 PM:

I have checked the gate-house area; I was asuming this was what you meant when you mentioned the front of the machine. I can't find a belt there ![[Confused]](confused.gif)

The only belt I know of is at the back (or what I think is called the back) of the machine: the one connecting the drive-wheels axis to the main-shaft, and that one seems to be working fine.

Unfortunately I don't have a manual of the S938, so I may be using the wrong discriptions for the wrong parts. Is it perhaps possible for you to post or mail a picture so that I know what I'm actually looking for?

I tried to get myself a digicam today just for this purpose but the d*mn things are still way beyond any budget I have. ![[Frown]](frown.gif)

----------------

PS: I just red a post by Paul Adsett, March 2006, about the gate claw being responsible for noisy film transportation. I just checked my S938 to hear when certain sounds are produced, and it appears that it runs a lot more silent without film.

But that, of course, is no solution... ![[Big Grin]](biggrin.gif)

Posted by Lee Mannering (Member # 728) on February 22, 2007, 03:40 AM:

If you take of the front cover (Lamphouse) and look to the bottom left you will see a very thin belt near the two drive wheels. This will be the problem.

Maurizio.

Better to fix the cause than the symptom.

My 940 started to do this in the middle of a show one time. I messed about fitting new cushion pads behind the cushion rocker but the mech still suffered. In the end I changed this very small belt and it cured it at once. Once a belt starts to stretch it has exceeded the tolerances it was designed for.

Oskar.

When you locate the front belt, run the machine and you should see the top wheel bashing against the cushion pad. This is whats making the noise as the belt has had its day.

Good luck my friend.

Posted by Oskar Jalink (Member # 667) on February 22, 2007, 06:26 AM:

I have checked the drive belt and indeed it's not as tight as I think it could be. I'll have to look for spare parts and try and replace it to see if that solves the issue. That is to say; is it possible for a mediocre non-technician like me to do this myself?

BTW:when looking at the what I call drive belt, I can clearly see that there's room for a SECOND belt right next to it on the left, which isn't there. I can see the drive wheels and the guidence wheels, but there's no belt. So, should there be TWO belts? ![[Confused]](confused.gif)

I'm still a bit cofused the term 'cusion pad'. Specially since I seem to be unable to locate this item ![[Confused]](confused.gif)

![[Confused]](confused.gif)

As for the noise coming from the gate: I think narrowed it down to the swinging thingie with the teeth that's holding the film in position when iluminated (is this English? Sounding more like Buffy-Speak I think)

It's a bit noisy when running empty, but really noisy when dealing with film.

BTW: a great many thanks for all the imput: I'm really getting to know this machine! ![[Smile]](smile.gif)

--------------------------------

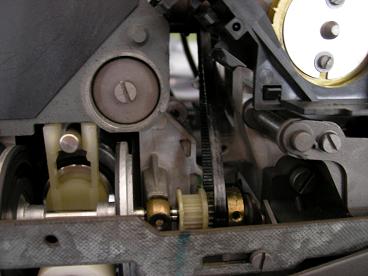

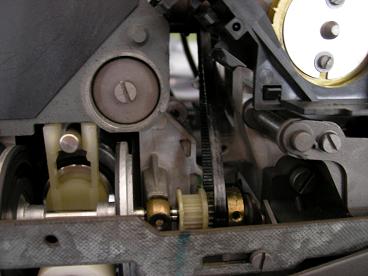

PS: I got my hands on a reasoneble prised digicam after all, so here's a picture of the drive belt assembly:

[ February 22, 2007, 09:04 AM: Message edited by: Oskar Jalink ]

Posted by Maurizio Di Cintio (Member # 144) on February 25, 2007, 10:18 AM:

Posted by Maurizio Di Cintio (Member # 144) on February 25, 2007, 10:19 AM:

Hi Oskar.

The room for another belt is in fact the room for the same belt as only one is needed; but machines sold in 60Hz mains countries, needed the belt to be mounted onto the other section.

For Lee: I agree it's better to fix the problem than the symptom, but I was assuming the problem was the rockers having a too wide swinging range; they are spring wound and at first sight they seem unable to exert enough strength to keep the belt covering a sufficient portion of the shaft's gear's circumference.

Anyway I read you wrote an article encompassing the last years of Eumig, in another thread; I'd like to read it? How can I find it?

Thank you

Posted by Lee Mannering (Member # 728) on February 25, 2007, 10:24 AM:

Hi folks.

Looking at that belt I would say it is overdue for a change. It does look very slack indeed. In stationary it should have tension and having measured mine the gap between each belt side is 5mm. You are not missing a belt by the way as the machine should only have one.

Hope this helps.

Posted by Oskar Jalink (Member # 667) on February 25, 2007, 01:57 PM:

Lee, by looking at the picture I can see what you mean, but it is not as bad as shown: Its the glimmer from the flashlight that makes it appear as if the belt is hanging loose. There you have it, a genuine 8mm optical illusion! ![[Big Grin]](biggrin.gif)

I will however keep an eye open for another belt since I've been told that the things were patent made. I reckon my chances of finding one are slim at least.

A large part of the speed-problems have been solved: The speed control knob has been fidled with by a previous owner, leaving the maximum speed setting, well, doing nothing. I could see this by looking at the marks on the two drivewheels. It seemed that the engine wheel wasn't able to reach those older marks. Only thing I had to do was to loosen the white plastic bold a bit.

With the speed problems solved, I can now concentrate on restoring the sound.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Big Grin]](biggrin.gif)

![[Confused]](confused.gif)

![[Frown]](frown.gif)

![[Big Grin]](biggrin.gif)

![[Confused]](confused.gif)

![[Confused]](confused.gif)

![[Confused]](confused.gif)

![[Smile]](smile.gif)

![[Big Grin]](biggrin.gif)