This is topic Making a Projector Belt in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=004001

Posted by Graham Ritchie (Member # 559) on September 14, 2008, 04:27 PM:

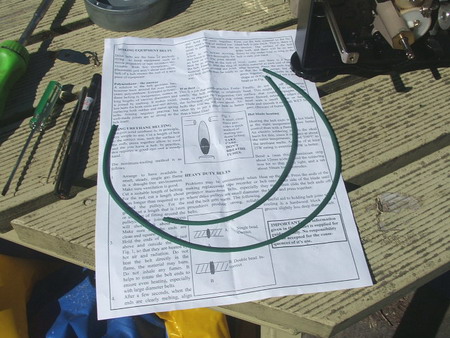

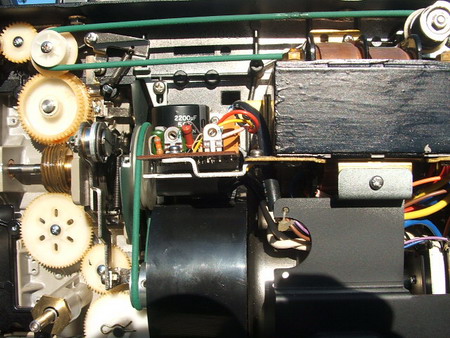

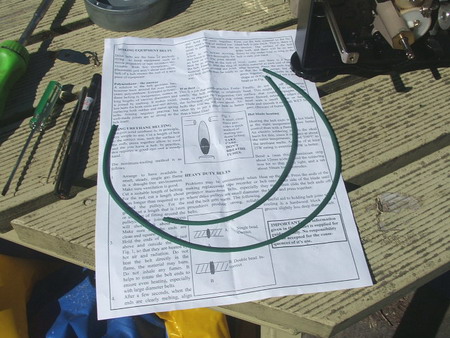

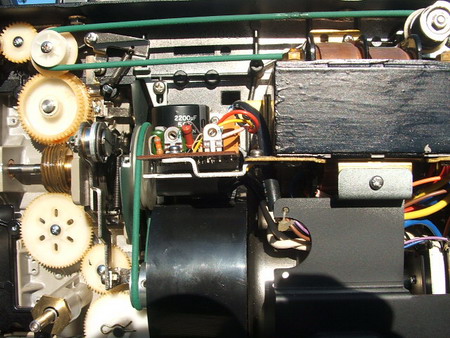

Yesterday I made up new belts for the ST180 although I have been using O rings up to now I think Polyurethane is better the 3mm "Green" has a rough suface ideal for grip and unlike 0 rings less stretch.

cut to length as per instructions

finished...the trick is... ![[Roll Eyes]](rolleyes.gif) to melt both ends to get a good join if you intend to make your own buy extra length so you can do a bit of practice first, its not easy in fact my first attempt the ends came away however my next try I attacked the ends with my soldering iron and that did the trick. The projector has been test running for a while with no problems. Derann can supply the material etc...have fun.

to melt both ends to get a good join if you intend to make your own buy extra length so you can do a bit of practice first, its not easy in fact my first attempt the ends came away however my next try I attacked the ends with my soldering iron and that did the trick. The projector has been test running for a while with no problems. Derann can supply the material etc...have fun.

this last photo is of the projector back together with my little helper my granddaughter who spent much of her time watching me. ![[Smile]](smile.gif)

Posted by Osi Osgood (Member # 424) on September 14, 2008, 05:46 PM:

Nice shots of your projector, (and the little one), just curious, what films are on the reel?

This is interesting, (as topic coming up), as I had the main belt on my "Copal" optical/mag projector break.

My question is, with, lets say a soldering gun, can I basically "melt" the belt back together again?

Posted by Graham Ritchie (Member # 559) on September 14, 2008, 08:37 PM:

Hi Osi

not sure what the films were on that reel I was using it to check that I had enough take up friction, time to soon sort out those films I have put onto reels but forgot what they were ![[Roll Eyes]](rolleyes.gif) .

.

I am not sure how you would get on with a drive belt other than the polyurethane type that Derann can supply which comes in 3mm 4mm and 5mm dia and buy in metre lenghts, thinking back I once tried using a soldering iron on a old belt some years ago but without success might have been the material, hopfully someone on the forum can add a bit more light to this subject.

Graham.

Posted by Josef Grassmann (Member # 378) on September 15, 2008, 04:43 AM:

Spend a eye on Shore hardness (A).

Most manufacturer have green colour for high Shore hardness.

Disadvantage of high Shore hardness is, that small tolerances in length result in very high change in stress.

High stress can result in shorter life of motor (current consumption too high, defective motor control circuit, high wear on carbon brushes) and much faster wear of bearings.

Apply as much stress as needed, only.

Start with longer belt and shorten it in steps of 2mm.

Posted by Graham Ritchie (Member # 559) on September 17, 2008, 01:11 AM:

Good point Josef with the "green belt" it is recomended to cut a length that is 1mm short of fitting around the pulleys you will lose that 1mm in the joining process.

I have been running the projector constant for over 8 hours now just to check how good my weld is ![[Roll Eyes]](rolleyes.gif) so far so good. I did however check the main motor belt between the two pulleys and measured about 4mm side play "which is fine" just like checking the adjustment on a car fan belt, as an example the GS1200 is adjusted to between 5-8mm. The motor on the ST180 is a good size and the armature is well supported by "ball bearings" at each end which should last forever and as such its impossible to have any extra than normal wear on brushes or anything else. Making a Polyurethane belt as instructed should last for many years and a good weld should be as strong as the material itself.

so far so good. I did however check the main motor belt between the two pulleys and measured about 4mm side play "which is fine" just like checking the adjustment on a car fan belt, as an example the GS1200 is adjusted to between 5-8mm. The motor on the ST180 is a good size and the armature is well supported by "ball bearings" at each end which should last forever and as such its impossible to have any extra than normal wear on brushes or anything else. Making a Polyurethane belt as instructed should last for many years and a good weld should be as strong as the material itself.

The good thing with this type of "green" belt in particular the long take-up is it wont slip on those small pulleys at either end and instead the cork slipping clutch should do its job instead of the belt. The trouble with using a long O ring that size is that it could come loose from the heat of the projector and not work properly, also it does come close to the rotating shutter ![[Eek!]](eek.gif) where as a belt made precisely is much safer and better.

where as a belt made precisely is much safer and better.

PS.Movie Maker Oct 1983 did an excellent test report on this projector

Graham.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Roll Eyes]](rolleyes.gif) to melt both ends to get a good join if you intend to make your own buy extra length so you can do a bit of practice first, its not easy in fact my first attempt the ends came away however my next try I attacked the ends with my soldering iron and that did the trick. The projector has been test running for a while with no problems. Derann can supply the material etc...have fun.

to melt both ends to get a good join if you intend to make your own buy extra length so you can do a bit of practice first, its not easy in fact my first attempt the ends came away however my next try I attacked the ends with my soldering iron and that did the trick. The projector has been test running for a while with no problems. Derann can supply the material etc...have fun.

![[Smile]](smile.gif)

![[Roll Eyes]](rolleyes.gif) .

.![[Roll Eyes]](rolleyes.gif) so far so good. I did however check the main motor belt between the two pulleys and measured about 4mm side play "which is fine" just like checking the adjustment on a car fan belt, as an example the GS1200 is adjusted to between 5-8mm. The motor on the ST180 is a good size and the armature is well supported by "ball bearings" at each end which should last forever and as such its impossible to have any extra than normal wear on brushes or anything else. Making a Polyurethane belt as instructed should last for many years and a good weld should be as strong as the material itself.

so far so good. I did however check the main motor belt between the two pulleys and measured about 4mm side play "which is fine" just like checking the adjustment on a car fan belt, as an example the GS1200 is adjusted to between 5-8mm. The motor on the ST180 is a good size and the armature is well supported by "ball bearings" at each end which should last forever and as such its impossible to have any extra than normal wear on brushes or anything else. Making a Polyurethane belt as instructed should last for many years and a good weld should be as strong as the material itself.![[Eek!]](eek.gif) where as a belt made precisely is much safer and better.

where as a belt made precisely is much safer and better.