This is topic GS-1200 takeup problem - HELP please!!! in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=006908

Posted by Bill Brandenstein (Member # 892) on February 18, 2012, 08:55 PM:

So here I am in possession of this machine that's not mine and it's developed a rather significant problem with the takeup. At most it will turn for about 3 revolutions and then gets stuck. Getting it unstuck feels like it's forcing a gear to jump or strip teeth. When opening the takeup arm I can see that those gears and belt all look fine, work properly and have plenty of lube. I've unscrewed the back cover and see that the rear arm motor covers up whatever gearing mechanism is there, but I'm sure that's where the problem lies. I don't feel qualified to disassemble this stuff, and if I find that there's a chewed-up gear in there, there's certainly no parts store to visit.

So I am appealing to you, my friends here, for advice. And to ask if any of you have a parts-only machine from which I might be able to buy some replacement pieces.

Thanks.

[ February 18, 2012, 11:19 PM: Message edited by: Bill Brandenstein ]

Posted by Hugh Thompson Scott (Member # 2922) on February 19, 2012, 05:04 AM:

It sound like the same problem I had some years ago with one of

these machines Bill, and that was the motor for take up had failed.

It was also the reason I gave up on GS1200s as the one I had cost

a fortune in carriage It was always going wrong, so I got a FUMEO

9112 which is kinder to film being manual thread and less

complicated.Iwas given one two years ago but still prefer my

Fumeo.I would advise getting in touch with a repairer and I

wouldn't be tempted to tackle it myself.I do believe it's still

possible to obtain new motors for this machine.

Posted by Paul Adsett (Member # 25) on February 19, 2012, 09:42 AM:

Bill,

I had this very problem a few years ago. The rear motor would kick in for a few seconds and then stop. In my case it was not the motor or gearing, but the control relay on the main mother board. There are two relays on the big board and they control the power to the reel arm motors through a logic circuit.

My opinion is that this may be your problem, and that it is less likely to be the motor or gearing. Leon Norris can supply and replace these relays if you want. I have purchased these relays from Leon and replaced them myself, but it is a tricky procedure.

Unfortunately, the GS1200 is a very complex machine, a classic example of over- design in my opinion. It seems that 90% of GS1200 problems are switch and contact related, be it relays, microswitches, or solenoids. All this complexity to avoid turning a control knob! ![[Roll Eyes]](rolleyes.gif)

Posted by Hugh Thompson Scott (Member # 2922) on February 19, 2012, 11:02 AM:

Paul,I couldn't agree more.The machine was designed to fit two

users,the showman and the cine sound man to re-record tracks

etc that could be done a whole lot easier on tape and then

transfered to stripe.The film path was none too clever either as

those nasty plastic parts will prove with use,scratching valuable film.I do think Bill would be better taking it to a repairer used to

handling this sort of problem.Bill Parsons here in the UK is a wizard

with projectors and specialises in Elmo's.That of course isn't much use to Bill but I still advise getting a professional to sort It

out, rather than try any remedies yourself Bill, as you could make matters worse.

Posted by Bill Brandenstein (Member # 892) on February 19, 2012, 02:58 PM:

Thank you, Hugh and Paul, for your input. What you're saying makes a lot of sense, knowing how many electronic parts there are in that to corrode or wear out. Still, when the reel sticks, it seems like it's doing so at the same mechanical spot in something tucked out of sight. And getting it loose again often requires an unsettling amount of force, nor does it sound nice, which is the only option other than shutting it off if the reel won't turn at all.

I don't think anything I've described here contradicts your suspicions, but I just want to make sure you still think that given my additional comments. I appreciate your advice, gentlemen.

Posted by Paul Browning (Member # 2715) on February 19, 2012, 04:52 PM:

Hi Bill, this is similar problem i had with my gs1200.This turned out to be the drive gear that's directly driven by the motor/ gearbox on these projector's.This is a plastic or nylon type gear mounted on a phosphor bronze body that splits and then leave's a gap that the mating gear cannot bridge.If you take the back off and get a torch you can just about see this working.Not an easy job to get to as the transformer has to be partly removed to get to the gear's and then you have to replace the damaged gear.I had some of these made in the uk but are completely bronze with a new clutch bearing in them,they will not break like the plastic one 100% reliable.I'd be interested to see what it is, if its a motor i'd like to know where a new one can be located.

Posted by Mark Mander (Member # 340) on February 19, 2012, 05:18 PM:

Paul,

that's exactly what happened to my GS,A call to FFR Filmtechnik in Germany took care of the part,Mark.

Posted by Jon Addams (Member # 816) on February 19, 2012, 05:49 PM:

I love my ST-1200HD - I sold my GS a long time ago, found another one and sold it to Leon for parts.

Jon

Posted by Hugh Thompson Scott (Member # 2922) on February 19, 2012, 06:06 PM:

Bill, while having a cruise around the forum some of the lads have

been experiencing the same problem as yourself.Go to the part

of the forum "What did I screen last night" page two and read on.

Posted by Bill Brandenstein (Member # 892) on February 19, 2012, 06:49 PM:

Nice catch, Hugh. I'll be having a careful look over this later. I wonder what Mal ended up doing to sort his problem out?

Posted by Paul Browning (Member # 2715) on February 19, 2012, 06:51 PM:

Hi Mark, yes i saw the price of them on the site and looking at them they are not as good as the one's i had made.I fitted mine myself no problem's since then.These machine's are now approaching there 30th birthday,so some part's are about to give up, unfortunately this problem seem's to have a similar symptom but many different cause's.

Posted by Bill Brandenstein (Member # 892) on February 19, 2012, 10:13 PM:

So Paul, you speak in a very past tense here; you had some, but no more? Did you sell them to anyone who could make that repair? What would it take to make more? Surely it can't be all that cheap.

I don't want anyone to give away trade secrets here (if there are any), so if that's a problem, please send a PM.

Again, I am grateful to all of you for this discussion.

Posted by Graham Ritchie (Member # 559) on February 19, 2012, 11:03 PM:

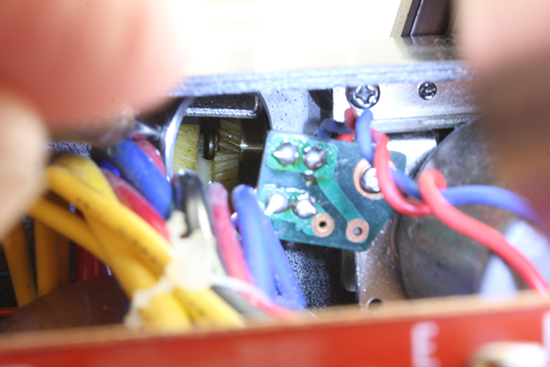

As well as what has been said I had a problem with the take up years ago. What I did was to clean the two small brushes and commutator on both motors in place by removing the two screws on the back of the motor and removing the back cover with its brushes, this can be done in place. What I did was to polish up the commutator with some fine 600 wet and dry, plus "very carefully" scrape away any build up thats shorting out between each of those segmants on the commutator. I finished with a wash down with CRC Electa-clean. The trick is also sliding the brushes back on. I used a couple of cut cotton buds for that,

Its been years since I did this and to date the projector "so far" has been running fine. I my view those take up and rewind motors with those tiny two brushes and commutators that they run on are way to small and over time gum up, cleaning this area of those motors for me did the trick.

Graham.

Posted by Paul Browning (Member # 2715) on February 20, 2012, 10:07 AM:

Hi Bill, you need to find out what it is that's causing your particular problem , if you can say for sure that it is the gear that is split, then i can supply you with a new gear as described in the previous reply.You are right in your assumption that these were not cheap to produce but i have two gs 1200 both xenon so more than two were needed in this case.Believe me when i say these are over engineered to do the job,but you need to be compitent enough to fit them , a tricky job on the rear one because of the power supply, but not impossible.Please get a picture if you can and upload.

Posted by Hugh Thompson Scott (Member # 2922) on February 21, 2012, 02:49 PM:

The problem with the motor in the GS I had Bill, was the brushes

disintegrating and causing the motor to jam, that might be your

problem too.Might be worth a peep.

Posted by Bill Brandenstein (Member # 892) on May 05, 2012, 05:42 PM:

Hello friends, 3 more months have already slipped by and I have no solution yet. However, I recently popped the back off and had a look and took some pictures. So the top rear of the back side of the GS-1200 looks like this:

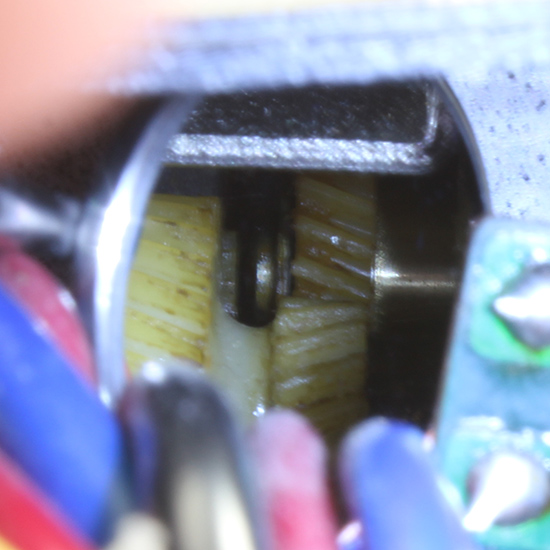

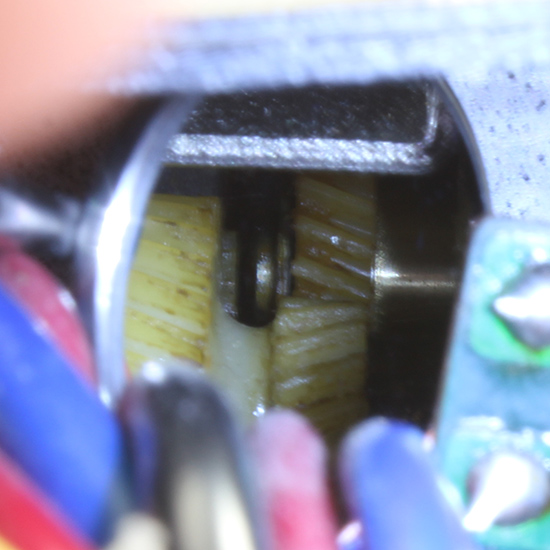

So what I'm going to do is stick a dental mirror in there and look at the gears from a side angle:

This is the same image but cropped to show what the mirror sees:

Now you can see that there are 3 gears on 2 shafts. The nearer shaft (frontward) has the largest-looking gear at the far left, and to its right on the same shaft is the smaller gear that fits into the rear gear.

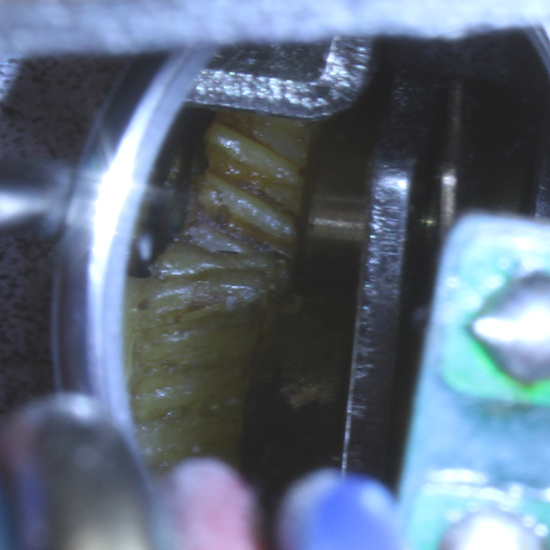

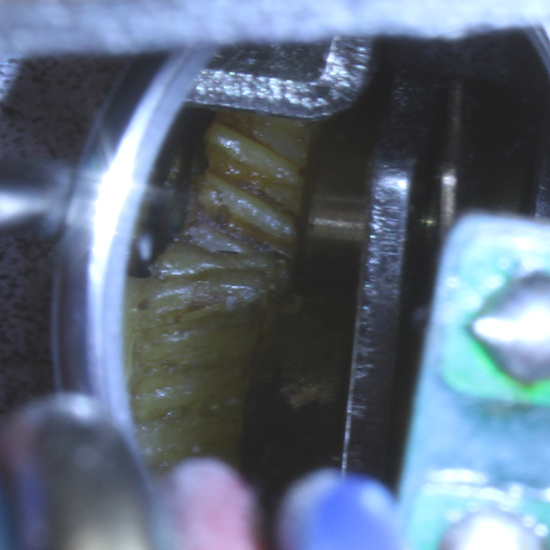

As you can see from the next photo, my several attempts at getting a look at all portions of the gear produced mainly nice pictures, even though as we started and stopped the machine there was evidence of unevenness. Here's a typical view:

There's grungy grease and uneven edges on the teeth, but nothing major that would prevent operation.

However, this next photo shows a rough spot that may be evidence of a super glue job on this gear:

There may be significant wear on the small frontward gear, but it appears that the rear one has problems, though I failed to get a photo that makes clear what it is.

I also took some video and might post it to YouTube. But it's easy to explain: pressing the reverse button results in all gears turning; pressing the forward button results in a jam where the front gear appears to want to turn (moves the distance of about 1/4 of a tooth), but it all ends up sitting there. I think one time the frontward double gear turned but the back one got stuck, but I didn't get that on the video.

Paul, if you're around, I would appreciate your kind assistance on which of the gears you can help me replace... and hopefully it won't cost me all 3! Of course, I'm grateful for anyone else's 2 cents, too, and for Brad making it all possible by hosting us!

Posted by Paul Browning (Member # 2715) on May 06, 2012, 04:08 PM:

Hi bill , i acually don't reconise that picture of the gs 1200, i'll have to have a look at mine to refresh my memory,although this could be the gear box that the motor meshes to? Any way what happened to mine was the small gear that is attached directly to the take up split, so the gear teeth are further away from each other,and as such will jam completely when trying to mesh with a good gear. This plastic gear is mounted on a phosphor or brass sleeve with a roller bearing inside and is well designed but prone to fail in time when the gear splits but stay's in place.I know that wittner do have these, but last time i checked both were out of stock.I do still have some these gear's,but you will have to remove the motor completely to see this and not i fear the the picture you have uploaded.The gear's i have can be fitted to the front or back its the roller bearing that distiguishes which goes where.I can send you a pm picture if thats any help bill, let me know.

Posted by Bill Brandenstein (Member # 892) on May 07, 2012, 12:22 PM:

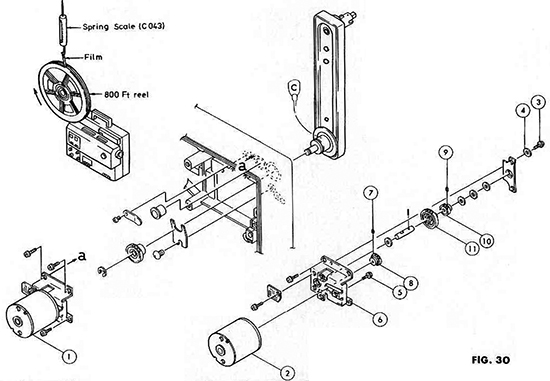

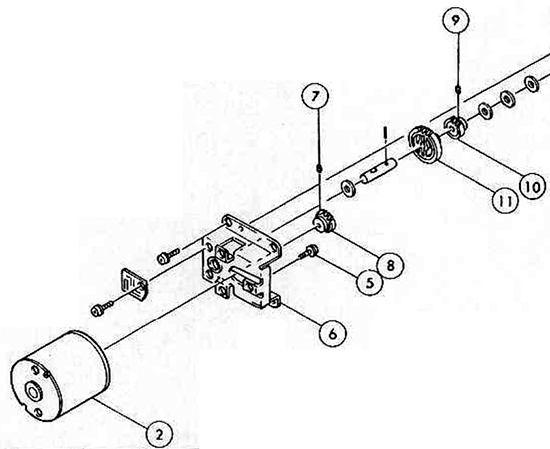

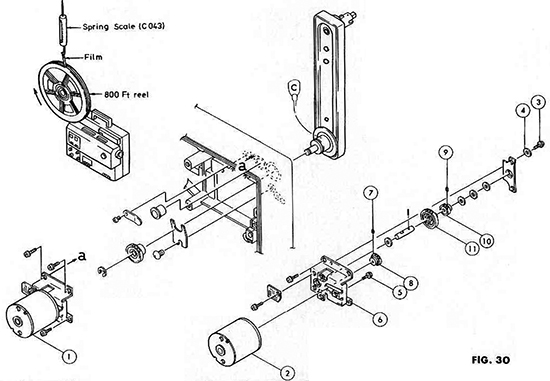

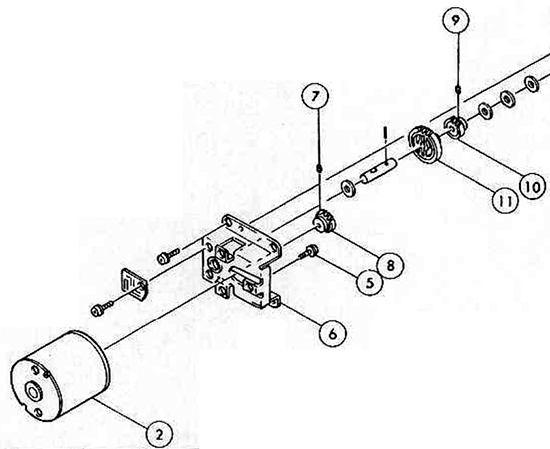

Well the good news is I have someone who can competently disassemble the rear motor area and get to the damaged gear. To further clarify what I've posted above, here are the exploded parts diagrams from page 59 of the GS-1200 service manual (available on the www.film-tech.com side of this site).

Here's all of Figure 30, showing the rear take-up motor area:

And here's a detail image of the specifics:

So the double gear to the frontward side is parts 10 & 11 as shown, and it's possible I have a problem with the smaller gear (10). But more likely what we're dealing with is a damaged number 8, which is the gear attached directly to the motor shaft.

Paul, so if I'm understanding you correctly, your parts will fit either 8 or 10, but not 11 -- which would actually be fine, maybe spectacularly helpful. (I'm still trying to figure out what 11 connects to.)

Posted by Mal Brake (Member # 14) on May 07, 2012, 01:29 PM:

My friend and I had the same problem a few years ago. That little cog had split, the take-up would revolve freely until the film was attached to the reel. It would then stop.

We obtained the cog from Germany for around £36 and fitted it ourselves which took about half an hour. We have had no problems since then.

Posted by Paul Browning (Member # 2715) on May 07, 2012, 05:08 PM:

Hi Bill, this picture is quite deceptive, in that it doe's not show the tranformer that has to be removed or just released onto it's long screw's in order to get at the suspect gear. This gear is not numbered on the exploded view here either but is fitted to the spindle on the base of the take up arm clearly shown in the diagram.The gear is directly driven by the motor none of the other gear's will need to be removed as they are in the gearbox.First thing you need to do is to see if that has gone, so to gain access to the rear arm all the above mentioned will have to be moved out the way.The motor will not come past the transformer if it's in place but this can be left on its screw's allowing enough space to remove the motor and then you will see the suspect gear.Get to this point and we will see if it's the gear , then i'll jump in help again if you need me to.Get a picture if you can.Good luck and keep the update's coming.

Posted by Bill Brandenstein (Member # 892) on May 17, 2012, 12:39 PM:

It's been a week or more already, so Paul, a belated thank you for your continued assistance, and I'm getting some help here with a correct diagnosis. Thanks again for the valuable information you've posted here and for willingness to see me through this mess. More to come!

Posted by Bill Brandenstein (Member # 892) on May 18, 2012, 07:46 PM:

OK, wish I had pictures but the diagnosis is clear: there are two broken gears: the main shaft gear ("gear 3 assembly with 1-way clutch drive"), part P413869, and the upper 3/8" gear that it locks to, part E413510. Paul, I will PM you and take it from there, but welcome any further input anyone might have, with my gratitude. As I stated earlier, this isn't my machine, so it's imperative that a solution is found.

Posted by Bill Brandenstein (Member # 892) on May 22, 2012, 01:00 PM:

I'd like to put this out there as my local tech guys are raising this issue: what is to keep even a well-machined, finely finished brass gear from tearing up (over time) the plastic/nylon gear to which it is fitted?

Posted by Graham Ritchie (Member # 559) on May 22, 2012, 03:47 PM:

I dont see a problem providing that there is a clearance between the meshing of the two gears "they must not run tight" a bit of play and the right grease. One thing I would not do is not to use the projector to rewind film. Although its the forward arm motor thats doing all the work, those gears on the rear arm could be turning very fast. Hand winders are the best bet. If those gears are turning slowly for take up only it should be fine.

Graham.

Posted by Vincent Zabbia (Member # 2453) on May 22, 2012, 04:38 PM:

The GS 1200 has a long history of this problem. I use to own a GS 1200 and it had this same problem. I ordered the part directly from Elmo on Long Island at the time. (Leon might still have these parts?) After I fixed the problem, I traded the projector in for two Elmo ST 1200HDs and one Elmo 1.0 lens. I've since sold the 1.0 and prefer to use my 1.1 Lens (easier to focus) My 1200HD never gives me a problem. All the gears are heavy and strong. I do have to change the lamp and belts once and awhile...The Elmo GS 1200 is fine if your a rich man and can afford to buy one everytime one breaks..Reminds me of the Abbott & Costello TV show, when Lou was trying to impress a woman and told her he bought a new car everytime the ashtray filled up..

Posted by Bill Brandenstein (Member # 892) on May 22, 2012, 04:39 PM:

Good point, Graham. Most of the time larger rewind job are done off the machine, but ALL of them need to be! Thanks for weighing in, I appreciate it.

Posted by Paul Browning (Member # 2715) on May 22, 2012, 04:39 PM:

Hi Bill, i just pm you. Just to add this gear has been tested to the max on a gs 1200, worked perfectly.These were not made by someone working out of his garage or on a hobby style machine, they were made by a company that make one off specialised gear's , syncro's for gearbox's and everything in between.With my 30 year's experience in a toolroom this guy was personally vetted by me,i will not accept nothing but right, you have my word on that my friend.Rgds paul.

Posted by Edwin van Eck (Member # 4690) on March 09, 2015, 05:52 AM:

Hello,

We fabricate these parts newly in a cost efficient manner using 3D print techniques. See:

http://shop.van-eck.net/PP-0036.html?_globalsearch=pp-0036

Posted by Bill Brandenstein (Member # 892) on March 25, 2015, 01:57 PM:

My broken-gear problem was solved with original Elmo parts purchased from Leon Norris and some careful local tech work (definitely over my pay grade!). I'm still in possession of that machine but use it rather infrequently, but the repairs are good are still "holding."

Edwin's ability to create compatible all-new parts, and an endless supply of them, is very exciting indeed, especially since Leon's supplies are finite.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Roll Eyes]](rolleyes.gif)