This is topic Help with very sick EUMIG in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=008399

Posted by Julian Baquero (Member # 2520) on July 23, 2013, 04:00 PM:

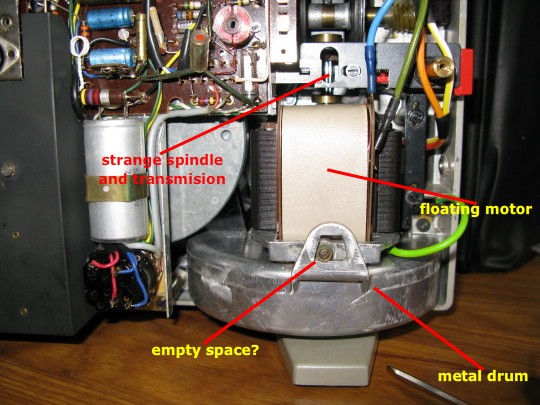

Hi, I just bought a EUMIG Mark S series 700 8mm projector, well the item was described as working, in the end the lamp turns on, but the film spindles don't move backward or forward. The projector construction is very nice, and the tube sound amp is a thing of beauty, but if the projector doesn't do its work, for my is just wasted money.

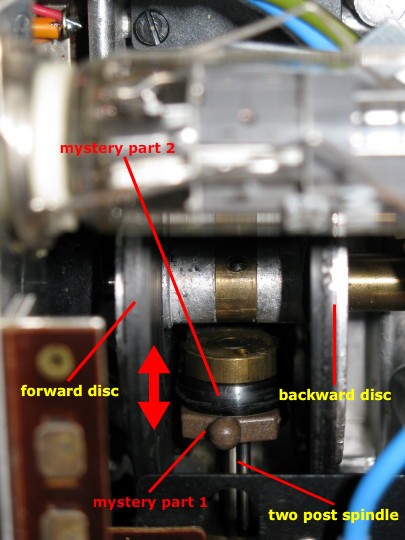

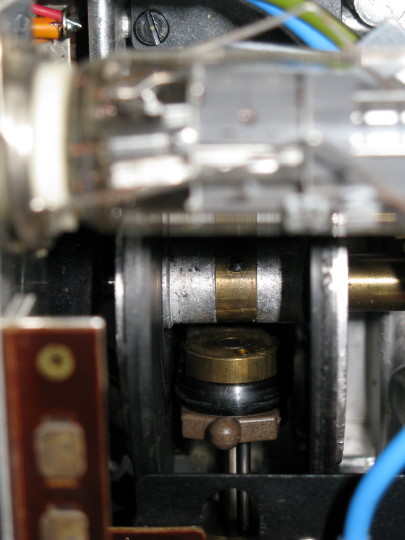

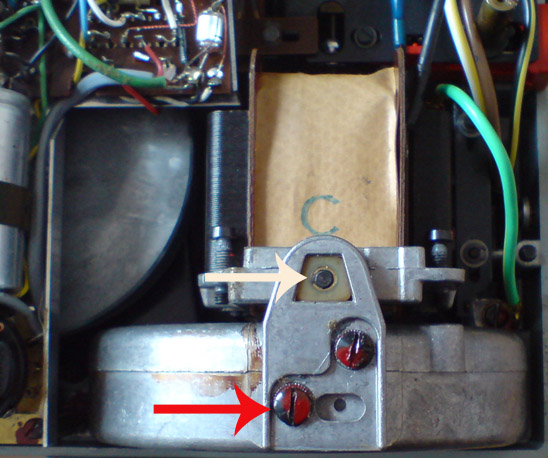

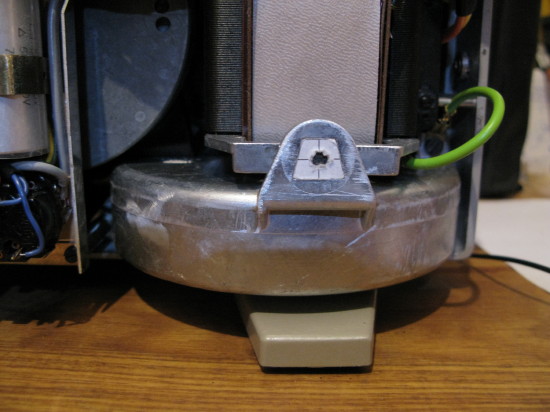

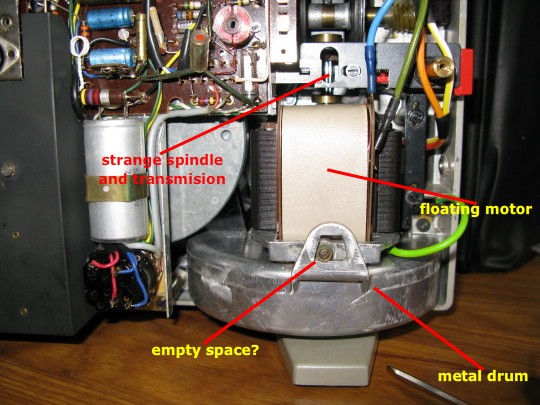

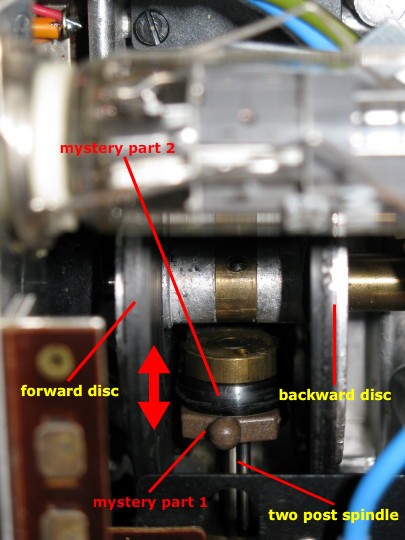

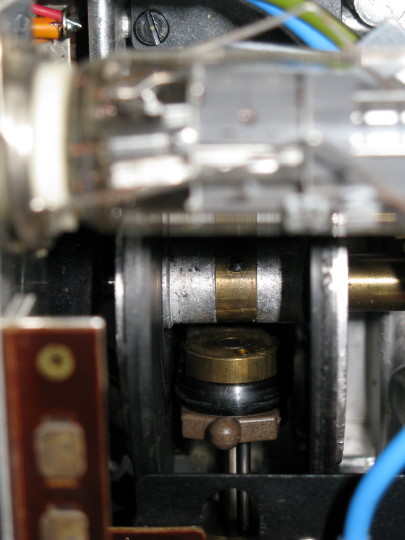

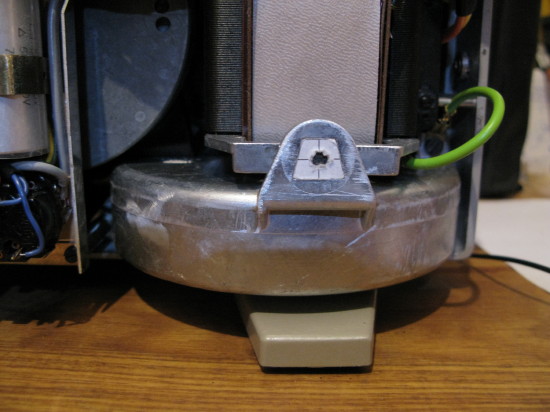

I opened the projector and found a very unusual construction. The motor turns, but to my surprise the motor is floating over a strange metal drum of unknown function (is it an electro magnet?) If I press with my hand the motor to the left it will transmit movement to the forward disc and if I do to the right it will reverse rotation, but it doesn't work when I turn the control knob. There are two parts I call mystery parts 1 and 2 which can be moved upward and downward over the two part spindle, but I really don't know which is the correct position of this parts.

This sort of floating construction is correct or is something missing in the equation? The motor rests in a sort of anchor which has a big empty space where the motor "floats", is this OK? I find very strange there is nothing creating tension (springs for example) to the right or the left of the motor when I turn the projector knob for forward or backward projection.

Can someone explain me this mysterious transmission system and clutch so I can get this beautiful projector to work. Mystery part 1 has a sort of pin, where must this pin go? Must mystery part 1 and 2 be together? I have moved the both downward (third picture) so the rubber mystery part 2 touches just the edge of the forward or backward discs when pushed to the left or right.

HELP PLEASE!

Please see attached pictures.

Posted by Janice Glesser (Member # 2758) on July 23, 2013, 04:18 PM:

I have a Eumig 810D. The motor turns an arm (mystery part 2) that is controlled with the selector switch. The two rubber disks on each side come in contact with the rotating arm depending on whether the selector switch is set to forward or reverse. On my machine I had to take a very fine piece of sandpaper and holding it lightly on the rubber discs rough up the layer of rubber so it made better contact with the rotating arm.

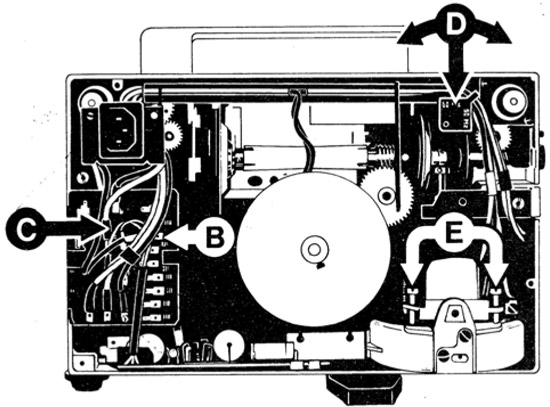

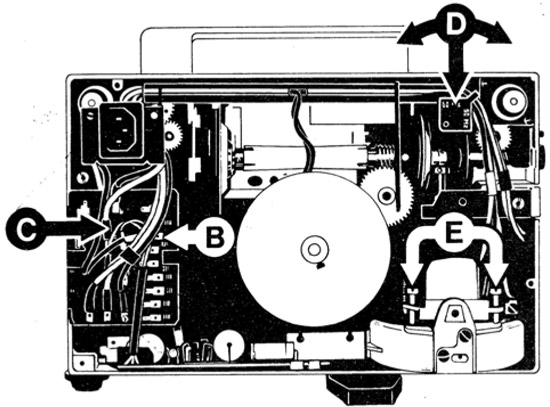

Here is a photo from the 810D manual. It looks very similar to your model. I still don't know what the lower drum is called...but when the projector was originally shipped new, the motor was held secure by two screws that fastened to the drum called "The Transport Lock." The screws were to be removed before running the projector.

[ July 23, 2013, 07:35 PM: Message edited by: Janice Glesser ]

Posted by Julian Baquero (Member # 2520) on July 23, 2013, 07:42 PM:

Hi Janice, thanks for the image from the manual, yes indeed the layout is almost the same as mine. Still the metal drum is a mystery. Does your projector have something in the "empty space" (1st picture)?

If it's not a problem, could you post a picture of how this components are set in your projector.

Posted by Janice Glesser (Member # 2758) on July 23, 2013, 07:55 PM:

I'm starting on a vacation for the next week... I know several members have similar Eumigs so perhaps someone else could provide you with a photo. If not ... I'll take one when I return.

Posted by Pasquale DAlessio (Member # 2052) on July 23, 2013, 08:25 PM:

Those 2 screws (E) in your photo actually adjust the angle of the motor which in turn adjusts the pressure on the wheels. Also , that motor should be pivoting on two bearings, one in front and one in the rear. Both inside plastic mounts The Eumig I had both plastic mounts were disintergrated. So I removed the motor, placed the motor mounts on a flat surface, set the bearings in the center, then filled around them with epoxy. I also put a small screw in each bearing to stop epoxy from getting inside the bearing. This fixed the problem with my Eumig. I didn't comment earlier because I forgot what I had done until I saw your B&W photo.

That mystery part 2 , if I remember correctly, rubs against either of the two wheels. Depending on the position, will determine the direction and speed of projector. If you play with the 2 (E) screws, you will see it makes a difference.

Mystery part 1 hasn't come back to me yet. But I think it pivots or something but not sure.

Have a great vacation!

PatD

Posted by Julian Baquero (Member # 2520) on July 23, 2013, 10:20 PM:

Pasquale and Janice, thank you very much for your help and explanations. I now know that the pivot support has disintegrated, this is what I called the empty space. I found the following website where the problem is described: http://www.cinerdistan.co.uk/eumig.htm

My projector opposed to Janice has no screws (E), but I should be able to make an epoxy or MDF support. Here is a picture of how the projector should look with the pivot support.

http://www.cinerdistan.co.uk/Pictures/Eumig%20Mark%20S%20002.jpg

Posted by Pasquale DAlessio (Member # 2052) on July 24, 2013, 06:20 AM:

I Think the 2 screws on the pivot support have slotted holes. This is a way of adjusting motor angle. I think I am right on this but not sure. ![[Confused]](confused.gif)

PatD

Posted by Lee Mannering (Member # 728) on July 24, 2013, 08:07 AM:

Hello Julian. The ‘empty space’ notation on your picture is where the nylon motor mount rocker should be and you will find another on the inside side of the machine. You used to buy these new and replace at one point so today it’s a case of come up with an idea to replace them with. Your machine will probably be made in the 1960’s so knocking on a little and all good things must come to an end…even a Eumig.

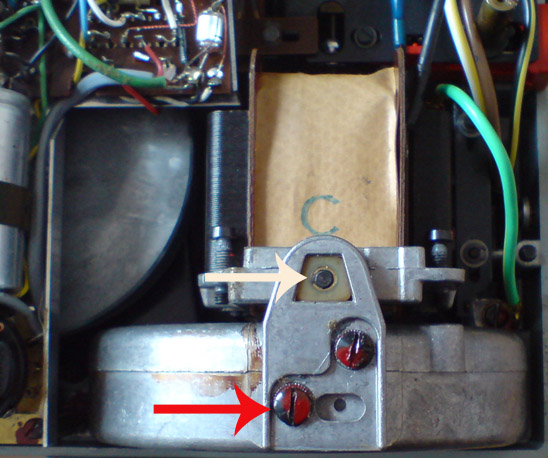

Some years ago I had a machine where only the front rocker mount had gone so I got a nut with a perfect fit centre to fit snug, I filed the nut outer to fit tight into the alloy opening securing it with some epoxy resin. The next day I popped a little grease on the pin you can see in the picture to lubricate the rocking motion of the motor. It is important to get the centre of the nut 100% or else you will not get any traction to the rotating drive discs. Not the ideal solution but a low cost fix which worked.

In my picture you can see the white arrow pointing at the correct centre point of the nylon rocker mount.

You will have to remove the two red screws to change the inner mount although you may not have to.

Hope this is of help.

Todays top tip!

If ever you take a projector apart to work on it always set a video camera up on a tripod filming the machine and your actions.

If you have a problem you can play the video backwards to see how to put it back together again.

Posted by Julian Baquero (Member # 2520) on July 24, 2013, 06:43 PM:

Hi Lee, thanks for you feedback. The mount rocker part has dissolved in my projector. For now I will try to do the part in HDF, MDF or/and EPOXY. My projector does not have the screws (red arrow) you note in the picture you post, suppose it's an older model, I have yet to figure out how can I access the front mount rocker. I can eventually create a 3d model that could be manufactured in ABS or Nylon in a 3D printer, so that anyone who needs the part could buy or download, as I did with the B&H adapter for the 16mm ELMO projectors.

https://www.shapeways.com/model/953318/bell-howell-lens-adapte r-to-elmo-16mm-projector.html?li=productBox-search

It's a pity to see that that a generally very well built machine as this one has other very lousy parts.

I will post the results here.

Posted by Lindsay Morris (Member # 3812) on July 25, 2013, 12:35 AM:

Julian,

Ages ago my Eumig MkS also had the same problem you have here & at the time I was living in a very hot area of Australia and both of those soft mountings for the motor pivot collapsed...nothing would work.

I pulled the motor out and carefully marked what I reckoned was the centre line for each pivot pin.

Then placed a piece of tape across the inside of the hole and filled them with a compound called poly sulphide rubber which was commonly available then.

Now a similar product is around called Sikkaflex 11FC.

I did each mounting pivot in turn and after the rubber compound dried I carefully drilled a hole of the same diameter of the pivot pin exactly on the centre lines I had marked.

Once each side was done, cured and drilled I re-assembled and it is still going well today almost 40 years after I did the repair.

Mystery part 1 is the speed control device that slides the driving wheel UP & Down the spindle to vary the speed from 18-24FPS...the speed control lever on the front face moves that up and down.

The drum bit below the motor is the cooling fan housing as there is a fan blower attached to the lower end of the motor shaft and not readily visible.

Eumigs are built like tanks or were and I bought mine in 1968 and it is still going well and so far have not yet replaced a valve.

A well engineered bit of Austrian gear...Rugged and will probably outlast me. ![[Smile]](smile.gif)

Posted by Julian Baquero (Member # 2520) on July 25, 2013, 10:24 AM:

Hi Lindsay, thanks for all the information, your really are an expert in this machines. Finally I know the use of mystery part1 and that the metal drum is nothing more than the fan housing. I managed to take the thing apart and access the front, the front rocker is also gone. I did a CAD drawing of the part and will have it cut in MDF or HDF in a laser cutter in the University where I am a professor, this has the advantage of very high precision. I also would like to try and fill the "empty space" with an epoxy filling, it would surely last forever, the disadvantage is that the drilling is difficult, specially in the front rocker.

I bought this machine because I am a audio valve/tube lover, and find the valve amp in this projector really beautiful and amazing, people don't seem to be aware that not all new technology is better than the old one, it might be cheaper and "more democratic", but not necessarily better, just take a look at the construction of the EUMIGs, ELMOS or BOLEX PILLARD, you surely won't get anything like that anywhere today.

[ July 25, 2013, 11:41 AM: Message edited by: Julian Baquero ]

Posted by Hugh Thompson Scott (Member # 2922) on July 25, 2013, 02:16 PM:

Hi Julian, I have used Eumigs, the Mark S, since I started the hobby. The rubber washer that has deteriorated, leaving the

motor hanging free, can be easily remedied by using a rubber

tap washer and shaping to suit the trapezoidal opening. I did this

with a little Mark S I purchased only six months ago.Works fine now.

Posted by Julian Baquero (Member # 2520) on July 25, 2013, 04:32 PM:

Hi Hugh, thanks for your help.

I need several items for this Standard 8mm EUMIG MARK S 700 Series:

Power cord (really strange),

550 feet EUMIG take up reel,

Projector logo silver plates that reads EUMIG and S,

Case RED label/plate that reads MARK,

Shoe for front leg,

Original manual.

Do anybody here happen to have any of this items available?

Posted by Lindsay Morris (Member # 3812) on July 25, 2013, 08:52 PM:

Julian,

If you would like a PDF of the User Manual I can copy off mine and send it to you.

Cannot help with any other bits but be careful with the power cord as the Earth connection is that bit of metal around the outside of the plug.

It MIGHT be just possible to fit an IEC socket and thus use a standard IEC plug OR fit an IEC CORD socket hanging outside the machine body and plug into that.

The amp is quite a bit of an art piece the way they built it around everything else but quite neat the way it simply comes out for any servicing...very practical design.

Posted by Lee Mannering (Member # 728) on July 26, 2013, 05:17 AM:

Julian. Yes the problem with the rocker mount is that they just disintegrate with age, a bit like us. I found using a reworked metal nut a solid option although others will probably have even better ideas. The old mounts had a small brass inner by the way. The picture I posted is from a 709 where these were replaced with genuine Eumig spares.

Posted by Hugh Thompson Scott (Member # 2922) on July 26, 2013, 08:48 PM:

It's a credit to members on here that solutions to these problems

can be found on machines that long ago would have been

scrapped, thanks to members like Lee Mannering, and others,

our little hobby should continue for a while yet.

Posted by Julian Baquero (Member # 2520) on July 28, 2013, 10:58 AM:

Success! I made a CAD drawing of the rocker mount, then printed the drawings to use them as templates for the parts. Then I prepared some two component epoxy resin and with it I made a 3mm thick rectangle from where I cut the parts using the templates. Let the parts dry and then sanded them until they perfectly fitted the holes in the metal mount. Finally I drilled the holes to a diameter of 4mm. Mounted the motor again and voila! The projector now works perfectly. While doing the tests the lamp burned. I will now have to replace the lamp, but it's cheap.

I have noted that all the parts that where glue why fall off very easily I suppose the glue or cement used at the time the projector was built (circa 1964) was not so good. Now I have to glue the plate that generates pressure between the film and the sound head, I also have to glue a plastic piece over which the film glides as it exits the sound section.

I want to thank everybody that answered this thread and in some way or another gave answers and solutions, without you I would have just a piece of junk, as Hugh said it his post we can still keep our hobby going on and our machines working.

Posted by Dominique De Bast (Member # 3798) on July 28, 2013, 12:10 PM:

A glue that lasts for almost 50 years is not so bad ![[Wink]](wink.gif)

Posted by Julian Baquero (Member # 2520) on August 01, 2013, 04:03 PM:

Dominique maybe you are right. I have now glue the fallen parts. I found out the bulb was not burned, but that there was a problem with a pin in the mine knob that did not permit the lamp to switch on. Now it has been fixed and I have 3 spare lamps ![[Smile]](smile.gif) . The projector is working very nicely and I love it!

. The projector is working very nicely and I love it!

Still need some spare parts to have it in original condition.

Posted by Erik Snel (Member # 4017) on November 14, 2013, 04:17 PM:

Hi There, i'm new here and as a first i'd like to reply on this post. the eumig Mark series projectors do indeed have two common problems, the first is the pivot motor mounts and the second is the rubber on the discs.

first of all i'm a eumig collector for about thirteen years now and i have seen my share of problems and horrible solutions.

your mystery part 1 tels me that your motor has been removed at a point and not put back in place in the right way, the little ball has to fit in a cavity on the other side and it is used to set your speed and mains frequency, the metal roller (mystery part 2) will shift up and down on it's axis.

then the drawing in the next post with the marking E, those are for transportation and not for adjusting the angle of the motor. when the machine is put in forward the motor is pushed against the rubberised discs and the tension of a little spring should apply enough force to keep the rollers together. the spring is behind the motor and not visible without some disassembly

the mysterious metal drum houses the cooling fan which blows air to the lamp.

often i come acros these machines with worn out pivot points and i replace them with brass parts which i fabricate myself, this fits best and will never again deteriorate. even so the little earth wire between the motor and the fan housing is then obsolete.

as for the discs. If the rubber has gone bad and it only slips constantly. I have started a experiment on a Eumig Mark DL to remove the old rubber and place new rubber on them by vulcanisation. this is possible for me because i am an instrumentmaker/ props builder and i have some contacts with companies that can do this for me.

since 2009 there is a eumig club in Austria founded by the people who actually worked there so they have a lot of useful information. their website is : www.eumig.at

a lot of text but i hope it will help you

here is a link to my eumig facebook page with pictures of the brass motor mounts and more...

https://www.facebook.com/media/set/?set=a.545521338842427.1073741830.168666729861225&type=1

Posted by Janice Glesser (Member # 2758) on November 14, 2013, 08:19 PM:

WELCOM ERIC! There are many Eumig owners here and your expertise is greatly appreciated.

Posted by Osi Osgood (Member # 424) on November 15, 2013, 12:57 PM:

Sadly, I wish I could help you, but I am not accustomed with that specific model, but I wish you the best of luck!

Posted by Dominique De Bast (Member # 3798) on November 15, 2013, 01:10 PM:

Welcome, Erik. I visited the Eumig site but it is in German.

Posted by Erik Snel (Member # 4017) on November 18, 2013, 02:50 PM:

yes it is only in german, but i belive they are working on an english version. but you can use the translate function from google chrome. it will be bad enlish but understandable

Posted by Terry Sills (Member # 3309) on November 30, 2013, 01:38 PM:

I've had exactly the same problem with the motor pivot mountings and I resolved it with a plastic washer that luckily had the exact size hole to accept the brass/bronze bearing. So all I had to do was carve the washer to the size of the pyramid shaped opening. If you have a workshop/shed you can usually find something to adapt. Necessity is the mother of invention.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Confused]](confused.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif) . The projector is working very nicely and I love it!

. The projector is working very nicely and I love it!