This is topic Convert Fixed Speed Projector to Variable Speed? in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=008956

Posted by Joseph Collura (Member # 4151) on February 12, 2014, 01:52 PM:

Hello all,

I piggy-backed a similar post to this one on another thread, so please excuse the double post. I'm converting some reels of super 8 film to digital and the B&H 357Z projector that I'm using has a fixed frame rate @ 18fps and doesn't match that of digital camcorders, which I believe is 29.97fps creating "flicker" in the digitized image. From what I've read in order to remove the "flicker" the frame rates have to be adjusted to match. I have also read that reducing the frame rate to 15fps will also stop the "flicker". In order to test whether or not that is valid I set up my homemade telecine box and while running the projector, pinched the ratchet sprocket between my thumb and forefinger, slowing the projector and the "flicker" disappeared.

So, I'm hoping there is someone here with knowledge of the motors used in Bell and Howell projectors and about whether the 466A motor, or any other rheostat controlled B&H motor, is of the same or similar design to the 357Z and can therefore also be controlled by a rheostat?

I thought of trying a Speed Control designed for a woodworking router. I realize it will also dim the light, the way its designed to plug into the controller but I'm thinking for transferring to digital via a camcorder that dimming the light some might not be a bad idea.

If it can't be done electronically, cheaply and reliably, I'll reduce the speed by changing the drive pulleys.

Thanks,

JC

Posted by Pasquale DAlessio (Member # 2052) on February 12, 2014, 02:21 PM:

Maybe a ceiling fan speed control? Cut one of the wires just before the motor connection so the voltage will be reduced for just the motor and the lamp will remain bright. Wire the speed control to the two ends of the wire you cut.

Posted by Joseph Collura (Member # 4151) on February 12, 2014, 02:44 PM:

Hi,

Thanks for the response. I'm hoping to find an answer w/o any maybe's. I don't want to guess at a solution and possibly damage the projector.

J

Posted by Steve Klare (Member # 12) on February 12, 2014, 03:32 PM:

The fan control could work. The thing is you'd have to match the voltage output of the controller to the voltage requirement of the motor. If the motor is supposed to operate from a transformer secondary at low voltage and the controller is meant to supply line voltage fans...welllll...(BOOM!)

Posted by Pasquale DAlessio (Member # 2052) on February 12, 2014, 06:03 PM:

Boom!

I used to install ceiling fans for Home Depot. They were all line voltage. 110-125v.

[ February 12, 2014, 07:35 PM: Message edited by: Pasquale DAlessio ]

Posted by Winbert Hutahaean (Member # 58) on February 12, 2014, 07:13 PM:

Some projectors are using AC motors, so i don't think the suggestion above will work.

Posted by Steve Klare (Member # 12) on February 12, 2014, 10:35 PM:

The fan controllers are for AC motors, and the projector in question has an AC motor.

Posted by Winbert Hutahaean (Member # 58) on February 13, 2014, 12:29 AM:

Steve, did you mean that we reduce/increase the AC voltage supply to the projector it will reduce/increase the motor speed?

But for how far?

My experience shows that a projector supplied with the line voltage around 220 - 240v will give the same speed, while we are talking about reducing/increasing the fps from 18 to 24 or 30 fps. How can we find the exact desired fps if we play around with the AC voltage?

[ February 13, 2014, 02:20 AM: Message edited by: Winbert Hutahaean ]

Posted by Joseph Collura (Member # 4151) on February 13, 2014, 01:35 AM:

I think it works in the same way as a sewing machine controlled by a foot switch or a variable speed drill, operating on 110/120 VAC.

I just need to verify that the projector motor is the type of motor that can be controlled by the router speed controller. I think it has to have brushes and cannot be a capacitor start/run type motor.

Those are the questions that need to be answered.

J

Posted by Maurice Leakey (Member # 916) on February 13, 2014, 02:55 AM:

The Super 8 Database says this model has a magnetic motor. I believe its speed is controlled by the mains frequency so it may not be possible to vary its speed.

Posted by Paul Mason (Member # 4015) on February 13, 2014, 03:07 AM:

Induction motors (ie brushless) ac motors are supposed to be fixed speed as the speed is controlled by the frequency of the supply. However the speed drops slightly with increasing load until 100% rated load is reached. Reducing the voltage will reduce the speed but will reduce the load the motor will handle so be careful not to stall the motor as it will burn out.

Posted by Steve Klare (Member # 12) on February 13, 2014, 07:29 AM:

These speed controllers work by using a solid state switch to chop notches out of the voltage waveworm being applied to the motor: less on time, less induced curent, less power available, lower speed.

Same peak voltage though.

My point is that if the motor is meant to operate at 24VAC and you operate it with a 115VAC controller it would be easy to apply too much voltage the the notor and have something regrettable happen.

Posted by Martin Jones (Member # 1163) on February 13, 2014, 09:36 AM:

Induction motors.They are all "brushless"

There are two basic types:

1 Asynchronous induction motor. Speed is FIXED and is a multiple of the supply frequency. Can ONLY be controlled by feeding it with a variable frequency supply.

2 "Shaded Pole" induction motor. Look very much like the above, but have (usually) two loops of heavy copper wire inserted in the stator. Most of the Eumigs use this type.

Their speed is a multiple of the supply frequency and can also be controlled by applying a variable frequency. BUT... the speed CAN be controlled over a SHORT range using a "lamp dimmer" type of control, which makes them IDEAL for real time transfer purposes. My Eumig 810 machine is very stable in speed when set with one of these to 16.667fps (20 fps in the US, of course).

Posted by Paul Mason (Member # 4015) on February 13, 2014, 10:04 AM:

quote:

Asynchronous induction motor. Speed is FIXED

Not quite. Speed can be reduced a small amount by reducing the voltage or increasing the load. The full load speed is typically 5 or 10% slower than no-load speed. However the ac synchronous motor (not normally found in projectors) is a true fixed speed motor, locked to the supply frequency in the same manner as an alternator.

Posted by Joseph Collura (Member # 4151) on February 13, 2014, 10:19 AM:

A lot of interesting facts and discussion. Besides changing pulleys to sync the speed, which I'm leaning toward heavily after what's been posted, is there a way to control the speed electronically?

Hey Paul. What kind of motor is generally found in projectors?

J

Posted by Martin Jones (Member # 1163) on February 13, 2014, 10:37 AM:

Quote: [Hey Paul. What kind of motor is generally found in projectors?]

The answer, Joseph, is ALL SORTS OF MOTORS!

The question that needs to be asked and answered before speed control of your motor can be postulated is....

What kind of motor is in YOUR projector, Joseph?

Give us a clue or two... perhaps a photograph....or a makers Part number from the motor.... or makers name. If no-one here has the same projector as you, then WE need clues from YOU to help US help YOU.

Posted by Joseph Collura (Member # 4151) on February 13, 2014, 02:48 PM:

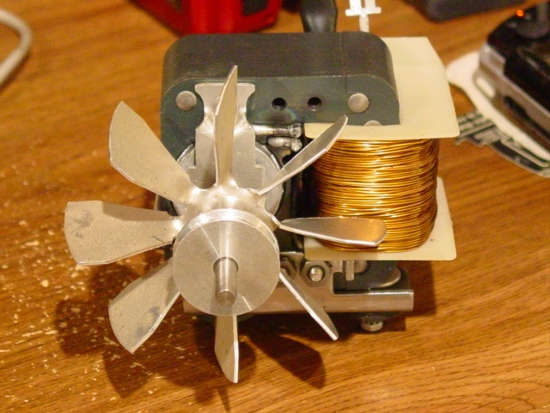

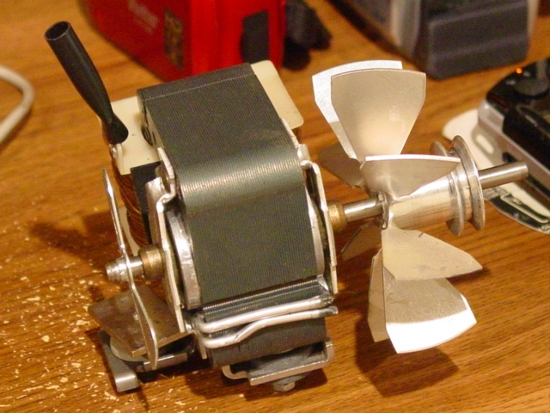

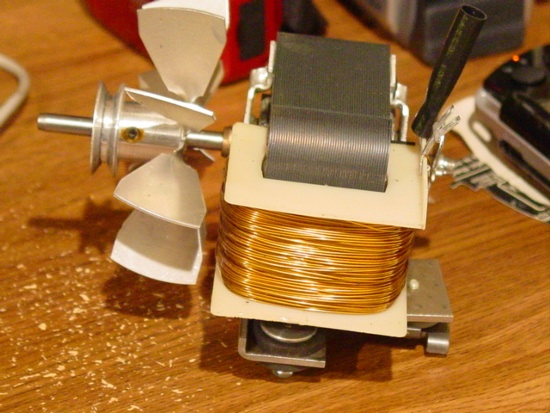

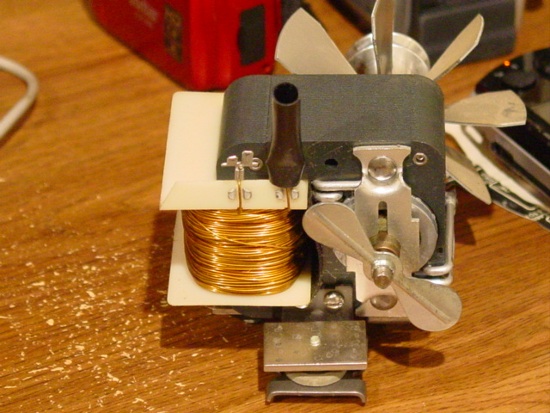

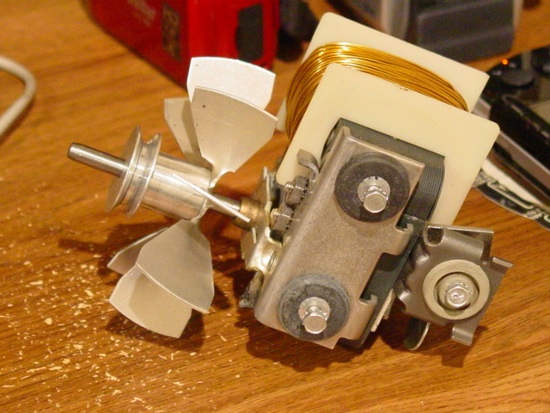

Here are some images of the motor. I find no information or identifying marks on the motor whatsoever.

J

Posted by Martin Jones (Member # 1163) on February 14, 2014, 03:18 AM:

That's more like it!

Your motor is a "Shaded Pole Induction Motor", similar, but not the same, to those fitted to many Eumig projectors.

It can only be varied over a wide range of speeds by supplying it with a variable frequency supply instead of the fixed mains frequency. Not really economical since such a supply would cost you more than a more amenable projector (in fact several!).

Speaking now from my experience with Eumig motors, it is possible to vary the speed DOWNWARDS from the set mains speed by using a Thyristor type controller such as the one I use...

http://www.quasarelectronics.co.uk/Item/cebek-r-8-230v-ac-motor-speed-controller-module-375-watt

With this one, I set my projector to about 17.5 fps, and I can control smoothly and stably down to about 15 fps, enough for transfer at 16.67 fps.How that particular device would perform on your motor depends on the motor: I reached my conclusions by experiment.

If you wanted to use "Rheostat" control of a projector you would need one with a "DC Magnetic Motor". With these, speed is varied over a wide range by varying input voltage or by using a PWM Controller

Posted by Maurice Leakey (Member # 916) on February 14, 2014, 03:46 AM:

Joseph

You ought to consider something like the projector which I have linked. It has variable speeds of 12fps - 24fps and should be ideal for Super 8 video transfer.

http://www.ebay.com/itm/Berkey-Keystone-1550-Super-8-Film-Projector-Mint-Variable-Speed-Paperwork-Etc-/350999919133?pt=US_Movie_Slide_Projectors&hash=item51b939ba1d

Posted by Martin Jones (Member # 1163) on February 14, 2014, 04:03 AM:

I would agree with Maurice. This is a clone of the Cinerex 818 etc and is ideal. The lower speed stop can be removed and it will then go down to 7 fps. A small modification of the film channel exit at the rear enables one to use 600 ft reels instead od 400 ft.

My other transfer machine is based on this machine and modified for Frame by Frame. But for "off-the wall" (or "direct from gate" with an LED lamp) it requires little work as the shutter can remain in place.

[ February 14, 2014, 05:39 AM: Message edited by: Martin Jones ]

Posted by Joseph Collura (Member # 4151) on February 14, 2014, 08:05 AM:

Thanks guys. I only have about 10 three inch reels to do, so buying another machine is out. There is a motor for sale on eBay for $27.00 from an MX60 which is a variable speed projector I'm looking at. But what I'll probably do is use a sewing machine motor that I already have and the $2.95 speed controller that's on the way from China.

I'll add a pulley to the original motor shaft and drive it with the sewing machine motor. It'll require leaving the back of the machine off, but once I'm through converting the 10 reels the machine'll end up back in it's box for another 30 years. I'll post some pics when it's together.

http://www.ebay.com/itm/151219068449?_trksid=p2055119.m1438.l2649&ssPageName=STRK%3AMEBIDX%3AIT

http://www.ebay.com/itm/400612284198?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1439.l2649

j

Posted by Joseph Collura (Member # 4151) on February 14, 2014, 06:43 PM:

Here's a pic of the sewing machine motor mounted in the chassis. The back is even still gonna fit.

Posted by Joseph Collura (Member # 4151) on February 17, 2014, 11:38 AM:

I noticed nobody has commented since my last couple of posts. The good news is, my modifications work and nothing that was done to the projector is not irreversible; meaning it can be reverted to its original form with the exception being, there's one 3/16" hole in the bottom that wasn't there before. And, the pulley/fan assembly was bored to 1/4" to fit the sewing machine motor shaft. A piece of heat shrink tubing on the original motor shaft as a shim will resolve that mod as well.

Thanks for all the help. While none of your suggestions were implemented, because of your combined knowledge it was realized a motor change was the easiest and most economical way to complete the project.

Thanks again,

Joseph

Posted by Bruce Wright (Member # 2793) on February 17, 2014, 12:16 PM:

Very nice setup Joseph. I'll make a copy of it to go

in my " how to " notebook. Thanks for the post.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2