This is topic What causes poor takeup tension? in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=009632

Posted by Pete Holzmann (Member # 889) on December 17, 2014, 04:09 PM:

I asked a while ago about poor takeup reel tension on my (Sniper HDL) 8mm conversion unit. At the time, the issue was a slipped belt.

Now it's more serious: everything looks fine to me, mechanically, but still the takeup is just too weak. As the reel fills, it gets weaker, to the point where with an almost-full (400') reel, I must manually help it along.

I believe this also may be a source of poor performance in terms of frequent slipped-frames where the frame does not advance as it should.

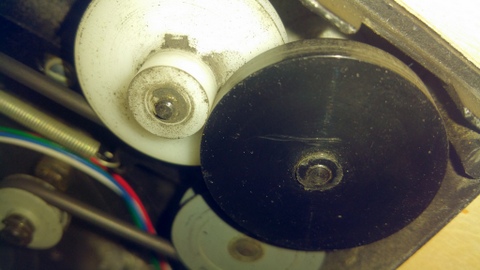

I opened up the unit and took a photo (below) of the key takeup reel drive wheels. It appears to be a friction-connect... that just slips too much. I have no idea what this ought to look like, so I am here for guidance!

My questions:

1) What can cause takeup reel weakness?

2) Do you see a problem in the photo below?

3) Is something missing from either wheel? Perhaps a (rubber?) friction cover? Perhaps they should be more smooth? Sticky? I dunno...

4) Does it make sense that this could cause frame slippage during capture?

THANK YOU SOOOO MUCH!

Posted by Andrew Woodcock (Member # 3260) on December 17, 2014, 04:13 PM:

Take up spool torque comes purely from the friction provided by the motor through a series of belts, pulleys, clutches and gears to finally provide a drive at the tale up spool hub.

Check the complete drive chain from the motor onwards right through to the take up hub and somewhere along that chain you will find the reasons why you are losing torque at the spool.

This may seem to be stating the obvious, but it really is as simple as that... following the drive path through from start to finish and finding where the fault or weak link occurs by testing at each step of the chain.

Posted by Pete Holzmann (Member # 889) on December 17, 2014, 04:15 PM:

The photo posted is where the torque is lost. The small white drive wheel has lots of power. The big black wheel simply slips too much.

So... what is the problem here?

Posted by Andrew Woodcock (Member # 3260) on December 17, 2014, 04:19 PM:

Do you have an original service manual for the machine to check if there are any missing parts for example rubber tyres etc etc?

Posted by Pete Holzmann (Member # 889) on December 17, 2014, 04:52 PM:

Service manual? I wish! I hear these are GAF projectors.

Posted by Andrew Woodcock (Member # 3260) on December 17, 2014, 05:50 PM:

Ok Pete, I hear you, have you tried a snug fitted elastic band to both those drive wheels to see what difference perhaps that may make to begin with?

Posted by frank arnstein (Member # 330) on December 17, 2014, 07:18 PM:

I have one of these GAF so decided to check it out.

Below the white plastic driving wheel is a spring loaded tension adjuster. This is to vary the friction between the 2 pulleys and will reduce slip if tightened.

Its located directly beneath the large white friction wheel. See if yours is the same. If it is, tighten the spring tension and tell us if its any better.

dogtor frankarnstein

![[Wink]](wink.gif)

![[Smile]](smile.gif)

[ December 17, 2014, 08:23 PM: Message edited by: frank arnstein ]

Posted by Pete Holzmann (Member # 889) on December 18, 2014, 04:20 PM:

Hmm... I see the spring loaded tensioner. I did not see any adjustment method. Can you think of a way to adjust it?

At this point, I have simply cleaned 100% of dust from the mechanisms, and wiped down with alcohol to remove any grease, etc.

Doing that seems to have helped so far, but I've only tested briefly. I've not really gotten serious with feeding more film yet.

Posted by frank arnstein (Member # 330) on December 19, 2014, 03:25 AM:

The adjustment is simple Pete.

One end of the spring goes to the swinging pulley bracket. The other end of the spring is hooked onto a small plastic piece thats held in place by a screw.

Loosen the screw then swing the small plastic locator to the left then retighten the screw. That will increase the spring tension and so increase the friction between the top pulleys. See how you go.

dogtor frankarnstein ![[Wink]](wink.gif)

![[Smile]](smile.gif)

Posted by Pete Holzmann (Member # 889) on December 19, 2014, 12:57 PM:

Bummer. Mine does not have the plastic locator; the spring is directly held in place by the screw.

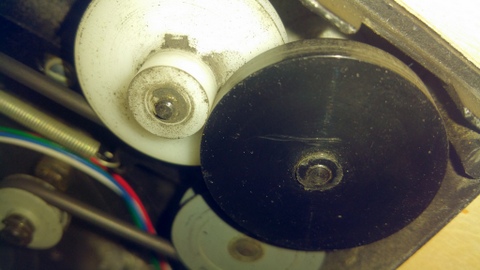

On the other hand, it appears that the swinging part at the other "business" end is mounted on a sliding bar... but I suspect that's only intended to adjust how the drive-wheel engages with the takeup-wheel. See below...

Is this at all similar to yours?

Posted by frank arnstein (Member # 330) on December 20, 2014, 10:44 PM:

Not really, mines different. There must be a number of versions.

mines like this one....

http://www.ebay.com/itm/Gaf-Projector-3-Belt-Set-388-1333-1388Z-1666Z-2388Z/140621248488?_trksid=p2047675.c100010.m2109&_trkparms=aid%3D555012%26algo%3DPW.MBE%26ao%3D1%26asc%3D2013

What happens when you pull the white pulley away from the black one with your fingers?

Does it spring back when you release it?

See if you can spot a spring anywhere that provides the pull.

[ December 21, 2014, 11:21 PM: Message edited by: frank arnstein ]

Posted by Pete Holzmann (Member # 889) on December 21, 2014, 08:02 AM:

The spring in the photo is what holds the white pulley in place. It just has no adjustment... unless that screw/bar is it. I may loosen that to see... (Mr No Fear Of Breaking Things here ![[Smile]](smile.gif) )

)

Posted by Paul Browning (Member # 2715) on December 21, 2014, 09:44 AM:

Hi Peter, on your first picture you show both white and black pulley wheels engaged. The spring in the picture is under no tension, for this to pull both wheels together to drive this mechanism, surely the tension must be on the black wheel in picture one, but you are saying its to adjust the white pulley wheel. In picture 2,its shows some tension on the spring, this would be pulling the white wheel away from the black pulley wheel, making it slip, in my opinion. This is just a simple friction drive, that's lost the friction between those two wheels.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif) )

)