This is topic Part required for Eumig S 912 ? in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=009803

Posted by Edwin van Eck (Member # 4690) on March 03, 2015, 01:21 AM:

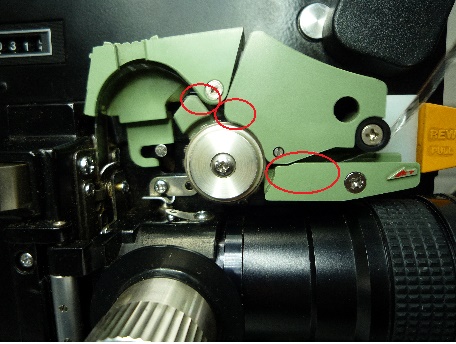

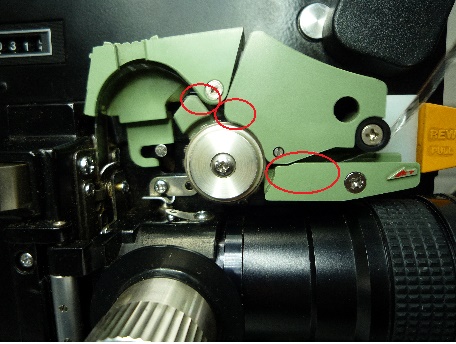

I got the request for developing this part for the Eumig S 912 projector:

Is this part required much?

Posted by frank arnstein (Member # 330) on March 03, 2015, 05:32 AM:

Hi Edwin,

I haven't had to replace that part ever.

It looks particularly complex to make.

I would pass on making this unless you have more support for it.

dogtor ![[Smile]](smile.gif)

Posted by Jose Artiles (Member # 471) on March 03, 2015, 01:02 PM:

Im really sure that if you can 3d printing this green loop former part for a version 1 of elmo gs 1200 will be a success because tends to broke often:

I think this is a very solicited part from the elmo gs 1200 version 1 owners.

Posted by Steve Klare (Member # 12) on March 03, 2015, 01:12 PM:

While we are jumping on the bandwagon a Scope lens holder for Elmos might go over well...

Posted by Edwin van Eck (Member # 4690) on March 03, 2015, 02:05 PM:

Ok. Good, add the scope holders to the list.

Scope holder for the Eumig 9-series for 41-44mm lenzes is ready.

I have made a prelinary list of diameters and weights of anamorph (scope) lenses. We design the lens holder in a modular fashion. So you can choose your projector and lens diameter.

Is this list sufficient for most needs?

Which diameters have the most need?

32 mm (76 gram)

37 mm (160 gram)

43mm (290 gram)

49 mm (225 grams)

52 mm (520 gram)

58 mm (653 gram)

67 mm (440 gram)

70 mm (800 gram)

78 mm (1000 gram)

Posted by Steve Klare (Member # 12) on March 03, 2015, 02:23 PM:

I have Sankor 16F, which is 42mm barrel diameter.

These are pretty common.

Posted by Andrew Woodcock (Member # 3260) on March 03, 2015, 03:03 PM:

The Elmo guide parts for GS1200 must surely be your best selling parts option Edwin.

Everybody would want one of these machines if they could be guaranteed non scratch for another 20 years!

Their mag heads seem to last forever so only really the motors to cause any real headache if the guides were readily available.

Posted by Chris de Gruiter (Member # 4744) on March 16, 2015, 04:23 AM:

Jose,

I'm working on behalf of Edwin van Eck on the realization of different replacement parts. So can you help me out?

Can you tell me where the loop former tends to break exactly or maybe provide a image of one that is broken.

And are there other parts from the ELMO GS1200 that tend to fail and need replacement that you know of?

Posted by Andrew Woodcock (Member # 3260) on March 16, 2015, 04:34 AM:

Chris, good to invite you to the forum and wishing you a warm and friendly sincere welcome.

Your work in partnership with Edwin is highly valued on here by us all I am certain.

With regard to the Elmo GS parts. Quite apart from the drive gear mounted in the drive side of the machine which always seems to fail, I predict there would be high demand for the green film guides that run throughout the film path on these machines as well as the ST1200's.

These have a tendency to wear as I am certain you are aware after many miles of film has been put through the machine.

The consequences of this wear is always the inevitable scratching of the film.

If these could be made from extremely durable polymers using your 3D technology to a very fine surface finish, then I am certain they would be in big demand and as such would become best sellers for your business.

Posted by Maurizio Di Cintio (Member # 144) on March 16, 2015, 01:02 PM:

Edwin, do you need a specimen of this Elmo part? I can help! In case you do, pleade PM me.

Posted by Paul Browning (Member # 2715) on March 16, 2015, 01:35 PM:

The 3D technology is great for the gears and probably function switches, but the green guides on the elmo's are some kind of acrylic based plastic, which is much harder and has a high gloss surface finish. These parts are injection moulded, and not generated with hot plastic wire. I dare say you could get the shape and design, but I doubt you would get the high gloss finish needed for film transport.

Posted by Edwin van Eck (Member # 4690) on March 16, 2015, 01:52 PM:

The 3D prints are not done using hot wires, but using a professional laser powder printer.

But we have to investigate whether this process is adequate for the film guides. If not, we have to mould it or so.

3D printing is one of the techniques we are using, but it is ofcourse not the holy grail or silver bullet !

Also we have now printed the CAM and nokken for the Bauer projectors and are testing, if the required properties for these parts are met in practice.

Andrew, please send the info PM to Chris. He is handling the technical design issues!

Posted by Paul Browning (Member # 2715) on March 16, 2015, 02:16 PM:

Edwin, I would very much hope, you can get these green guides manufactured with your 3D technology, and any other ware parts, I think the front guide and the upper guide ( that's pushed down to enable the auto lace to take place) cause damage when they ware on the elmo, not sure if the long green guide at the back of the machine causes any damage, not heard of this on the forum, but I stand corrected if someone knows otherwise. I guess with some R and D, these could be achieved with new technology. Looking at the those green guides, I don't think anyone appreciates how good these are, no distortion, no sinking of the mouldings in all the right places, the tooling cost just for these, must have been very high.

Posted by Steve Klare (Member # 12) on March 16, 2015, 02:49 PM:

The beauty of this technology isn't just making parts, but also making patterns for parts so they can be molded out of whatever material the manufacturer decides.

This is often the roadblock to making small quantities of parts: it's very skilled-labor intensive.

Posted by Paul Adsett (Member # 25) on March 16, 2015, 06:29 PM:

The finish on the Elmo green guides is superb. These appear to be very high quality plastic parts. I have never had any problems with any of the green guides other than the little top feed guide. But a common problem has been cracks forming on the green plastic piece that holds the rubber pinch roller, and this can weaken the pressure on the roller, resulting in film slippage and WOW, so Edwin might want to take a look at that piece as well.

Posted by Chris de Gruiter (Member # 4744) on March 17, 2015, 03:58 AM:

I've found that these 3 spots have the most wear. And I also found some cracks, so these 3 parts will be added to the project list.

We're locking into the wear and tear of the printed material as well as some alternative production methods to get the best result.

Posted by Edwin van Eck (Member # 4690) on June 03, 2015, 07:34 AM:

Hi, I am happy to announce a new part we created using our 3D printing services:

We got serveral request for this part, and we encountered in many projectors that this part was damaged and the friction could not be sell set.

=====

Eumig RS3000, R2000, S912 spoelarm friction shaft with gear - PP-0102 Van Eck (new)

New improved version in nylon.

In the original part, the wheel which sets the friction level, runs over 4 thin tabs. This is a weak point and can easily wear out. In this improved version these thin tabs are replaced by a strong thread.

For these projectors (and more):

- Bolex Sound 715

- Bolex Sound 815

- Eumig R2000

- Eumig RS3000

- Eumig S912

More info: http://shop.van-eck.net/PP-0102.html?_globalsearch=pp-0102

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Smile]](smile.gif)