This is topic Supply Reel Repair Film Looping - B&H 10MS + Similar Projectors in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=010189

Posted by Janice Glesser (Member # 2758) on September 09, 2015, 04:51 PM:

The B&H 10MS is a nice little variable speed dual format silent projector perfect for doing realtime telecine. It is a lower-end model projector...lots of plastic...but is actually a good performer.

A couple problems I've seen:

1) The plastic gear in the supply reel assy can get cracked and needs to be re-glued or replaced.

2) The supply reel intermittently turns inconsistently in forward mode releasing too much film before entering the threading slot.

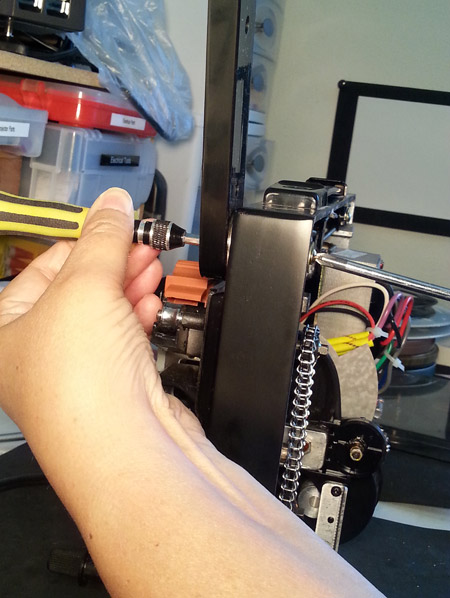

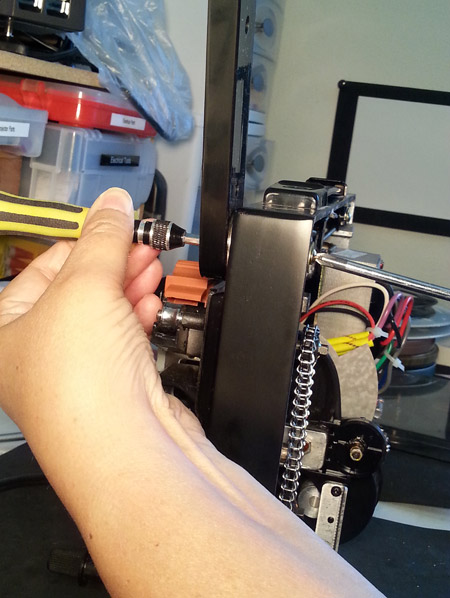

Problem 1. If the problem involved the plastic gear, then the supply reel assy needs to be REMOVED to replace or repair. This may seem simple enough until you try removing the Phillips head screw.

I have a machine right now where I have broken off the screw head trying to get it off. But, this week while repairing another 10MS, I stumbled upon a simple solution.

First remove the plastic facing on the supply reel by unscrewing the two back screws. Remove the upper spindle and the metal spring belt.

You will need a T9 Star Bit (or something else of approximate size an shape). I found this to fit pretty snugly into the hole of the lower pulley of the supply arm.

Now pressing the T9 Star Bit and pressing and turning on the opposite side with a Phillips head screw driver the screw should easily unscrew.

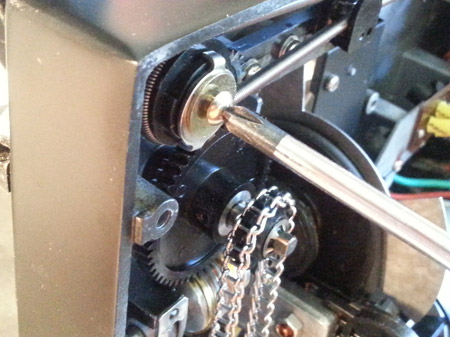

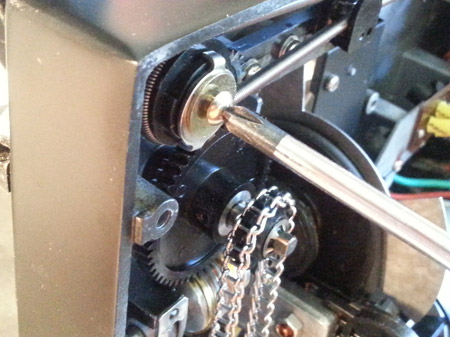

After the screw is removed you can start sliding the pieces off the rod that is connected to the lower pulley in the supply arm. The plastic gear is secured by a c-clip that will have to be removed. Behind the gear is a spring. If the gear is cracked you can try gluing it...otherwise it will have to be replaced.

[ September 15, 2015, 12:08 PM: Message edited by: Janice Glesser ]

Posted by Douglas Warren (Member # 1047) on September 13, 2015, 11:36 AM:

Janice,

I would definitely like to see a solution thread on this problem.I have a Bell and Howell 20 XS that has had similar issues with the supply spindle.Thanks for posting this.

Posted by Janice Glesser (Member # 2758) on September 13, 2015, 12:44 PM:

Problem 2) If you know the supply assy is working properly, but you are having a problem with the supply arm spindle turning too rapidly creating a loop in the film before feeding into the projector... Here's what worked for me.

The problem looks like this:

Remove the two screws on the back of the supply arm (pictured above) and remove the plastic casing. You should have a metal spring belt connected to the two pulleys. Over the years the grease on the belt gets hard and sticky which may cause the belt to slow down and then slip rather than ride the pulleys. You can try cleaning the spring by soaking it in some solvent or alcohol...this might help... OR here is what I did:

I cleaned the old grease off the pulleys and swapped out the spring belt for a DIY urethane belt, but you can use an O-ring. This belt was the exact size as the motor belt. The belt is much tighter now and the supply reel turns normally.

[ September 15, 2015, 11:15 PM: Message edited by: Janice Glesser ]

Posted by Janice Glesser (Member # 2758) on September 13, 2015, 09:35 PM:

Warren...I pulled out my 20XS and yes the supply reel had this problem too. Not as bad as my 10MS...but it probably would have gotten worse.

I had a similar size o-ring in my belt collection so replaced the wire spring belt as I did with the 10MS. It's a little trickier getting the belt on the 20XS. Here's how I did it:

1) Put the lower pulley in place.

2) Put the top pulley through the upper hole in the casing.

3) Put the belt around the lower pulley and then the upper pulley.

4) Carefully pull the casing up until the top pulley is secured on the top rod. It was difficult for me...but I'm not very strong. Then snap the casing into place and re-insert the two back screws.

Bottom line the problem was fixed on the 20XS too ![[Smile]](smile.gif)

Posted by Douglas Warren (Member # 1047) on September 14, 2015, 06:59 PM:

Hi Janice,

Thanks for posting the solution!The silicone belt (or O-Ring) replacements look like an easy fix for the problem.I'm rather fond of my 20 XS,as I bought it from Goodwill for $12.00 and it looked brand new.Other than the issue being discussed,it has ran really well.

Douglas

Posted by frank arnstein (Member # 330) on September 15, 2015, 09:38 AM:

Hi Janice,

Posting great pictures like you always do makes it much easier for us to follow what you are saying so keep it up. You do a great job for the forum.

Now this plan of yours may seem like a good easy fix, but have you considered the following 2 points.......

1. Why did the manufacturer chose to originally install these steel coil-spring belts throughout the machine instead of the cheaper rubber or silicon belts as you have done here?

2. What possible effect if any, could this change to the original steel belt design have on the projectors correct operation?

Lets see what you and others may think about this.

dogtor frankarnstein ![[Smile]](smile.gif)

![[Wink]](wink.gif)

Posted by Janice Glesser (Member # 2758) on September 15, 2015, 11:47 AM:

Hi Frank...always great to hear your expert feedback. Yes...I did ask myself why the manufactures of many makes of projectors used spring belts. However, I've seen rubber belts also used in some models. My Elmo 16CL uses rubber belts. Maybe the original thought was that the spring belt would just last longer...I don't know. But, over time the grease used gets hard and sticky. The belt gets caught briefly on one of the pulleys (probably the lower pulley) then the upper pulley just free-wheels. This causes the reel to spin and release the film before it goes into the projector. I have now found this to be a problem with several models that have the spring belt. I would guess it's difficult for even engineers to predict how certain parts will perform after 40 years ![[Smile]](smile.gif)

Last night I was working on a Chinon SP330MV. Everything ran great on this machine, but again the supply reel kept dumping the film faster than the threader could catch up. So I cleaned up all the old grease residue and made a new urethane belt. Problem solved.

Of course fixes like these are only offered as suggestions that should be used at an individuals discretion. I agree pros and cons should be considered. I also suggested cleaning the spring belt with solvent to remove the old grease and perhaps it will perform better. For me replacing the old spring belt was an instant fix and I liked the results.

I too encourage others to chime in here with comments or maybe their own experience with this problem.

[ September 15, 2015, 11:13 PM: Message edited by: Janice Glesser ]

Posted by frank arnstein (Member # 330) on September 20, 2015, 12:23 AM:

Hi Janice,

Sounds like no others are chiming in on this vexing issue...

There are many budget style projectors from Japan that all seem to have the same basic mechanical setup as your projector and these are usually fitted with spring belts.

I have one here called the Magnon Instdual and it too has these coiled steel springs in the arms and driving the take up spindle.

If you look at them closely you will notice that these machines don't have the conventional adjustable friction clutches at both spindles.

Instead they have a pair of one-way clutches to drive the take up and the rewind spindles, depending on direction of motor turn. These clutches are either on or off, so they don't provide the slip thats sometimes needed.

This is where the spring belts come into play. They stretch and absorb shock but are also designed to slip on their pulleys when the load is high.

This is why you will often find dry old grease on the pulleys and inside the arms. They will need cleaning and fresh lubing to be able to slip and do their job properly.

My concern about your projector was wether it could still handle a reverse project situation. You need it to take up film very gently or it may pull off the top sprocket and damage the film. So it must slip continuously during this function and the rubber belt may not be able to do this as its now tight and won't slip. Try yours in reverse and let us know if it copes without too much drag on the film.

When these projectors dump film faster than needed, it usually indicates some more lubrication is required somewhere between the front spring pulley and the small output shaft to the front arm.

dogtor frankarnstein

![[Smile]](smile.gif)

![[Wink]](wink.gif)

Posted by Janice Glesser (Member # 2758) on September 20, 2015, 04:46 PM:

I don't imagine too many members on this forum have these low-end projectors or if they do haven't had any problems with them yet. Since I almost never run my films in reverse other than rewinding I didn't think about testing that function. I will do that and report back.

In previous attempts to solve the film feed issue I have cleaned and re-lubed the pulleys, however that alone didn't seem to help. I think at this point doing a thorough cleaning of the spring belt might be in order. The cleaning and the re-lubrication should in theory return the supply reel back to it's intended functionality.However, if the results are positive from the reverse testing with the urethane belt...then there may not be any ill effects to the swapping.

I do want to correct the DIY belt material I used was not Silicon, but rather Urethane. The Urethane material is a lot smoother than rubber and may provide as much slippage as the spring belt... as long as it's not too tight.

Posted by frank arnstein (Member # 330) on September 21, 2015, 06:11 AM:

Hi Janice

Your 2nd picture from the top is a good shot of the front one-way clutch. This is the clutch that is either on or off.....

however, if the sliding clutch components are not well oiled and free to slide over each other, the clutch may actually try to drive the output shaft due to the friction between the sliding components.

The Philips screw in the center forms part of the front spindle drive and it may get unwanted intermittent drive by internal clutch friction.

So try spray lubing the front clutch with some fine oil and ensure that there is no unwanted friction there. Watch it working in both directions and see if you can eliminate any unwanted drive to the delivery spindle.

On these projectors, there should be absolutely no dumping of film by the delivery reel. The machine will pull in just as much as it needs by using its top sprocket and it doesn't need any help or it will soon get too much film. And so begins the forming of the big loop that is so symptomatic of this condition.

Good luck with it and keep us informed of any progress,

dogtor frankarnstein

![[Wink]](wink.gif)

![[Smile]](smile.gif)

Posted by Janice Glesser (Member # 2758) on September 21, 2015, 01:49 PM:

Frank...I did some testing based upon my last post.

1) Tested running film in reverse using the urethane belt. I added a little Superlube to the pulley's before testing. I ran a 200 foot reel in forward almost to the end...and then ran it back in reverse. It ran fine in both directions... no dumping of the film in forward and no pull of film in reverse.

2) I cleaned the spring belt by soaking it in decreaser for about an hour and rinsing it in hot water. I then did the same test as above. The supply reel with the spring belt did not turn evenly. It again was releasing too much film creating the looping action in the front. On this machine the problem wasn't ever that severe...but as you pointed out, there shouldn't be any looping at all.

The only thing I haven't done is to try your suggestion to lubricate the front of the clutch. I have to say I'm a little reluctant to do that since the machine is running so nicely now. I don't recall any lubrication on that part at all. In observing the clutch... it moves very freely. I don't see any binding. I guess I'm afraid that adding oil will some how make it too slippery and cause other problems. ![[Frown]](frown.gif) Have you done this yourself?

Have you done this yourself? ![[Smile]](smile.gif) Did it work with no ill affects?

Did it work with no ill affects?

Posted by frank arnstein (Member # 330) on September 21, 2015, 08:18 PM:

Hi Janice,

Yes, I have done it to my machine and it has no ill effects because there are no friction clutch surfaces there to contaminate. Just mechanical components that can get stiff if dry and tight. Have you also lubricated the small spindle shaft in the front arm that the front spindle spins on?

After cleaning the spring belt for your test, did you regrease the belt again to do the test or was it run dry for the test?

dogtor frankarnstein

![[Smile]](smile.gif)

![[Wink]](wink.gif)

[ September 21, 2015, 09:26 PM: Message edited by: frank arnstein ]

Posted by Janice Glesser (Member # 2758) on September 22, 2015, 12:41 PM:

Ok Frank...I faced my fears and oiled the clutch and lubed the spring belt (which I had not done previously). I ran some film and I think it did run better...but not perfect. There still was some looping of the film. I think if I have time today....I'll make a video. It's difficult to describe the action I'm seeing and I'm not sure if the way the spring belt is acting now is considered "acceptable."

I also have another projector that was looping much worse. Maybe that one would be a good candidate to see if your solution works on that machine. Stand By.... ![[Smile]](smile.gif)

[ September 22, 2015, 05:03 PM: Message edited by: Janice Glesser ]

Posted by Mathew James (Member # 4581) on September 22, 2015, 09:06 PM:

I love reading your progress reports Janice...and I love Franks knowledge each time, always here to help....

Learning lots! Thanx folks.

I just ordered some superlube today...I want to try lubing some of my machines soon.

Cheers,

Matt

Posted by Janice Glesser (Member # 2758) on September 24, 2015, 06:40 PM:

Glad this thread is entertaining and also helpful to you Matt. By now I probably could put together a short book of the trials and tribulations of troubleshooting and repairing projectors ![[Smile]](smile.gif) Frank has been a major contributor to my projector sagas and I miss our ol' friend Pat who use to chime in too. Despite the often frustrations ... collaborating on these repairs has been actually fun as well as educational

Frank has been a major contributor to my projector sagas and I miss our ol' friend Pat who use to chime in too. Despite the often frustrations ... collaborating on these repairs has been actually fun as well as educational ![[Smile]](smile.gif)

Here's a follow-up video that shows how the supply reel performs on two different projectors after cleaning and lubricating the metal spring belt and adding oil to the non-friction clutch (on the B&H 10MS only)... as Frank suggested. I then exchanged the spring belt with a urethane belt I made. All tests show running the projector in forward and reverse motion.

https://youtu.be/rZ92bsVXCyo

You can judge for yourself...but for me the urethane belt shows a significant improvement. Now the question is...Does using the urethane belt in any way harm the machine or cause any long term issues?

Posted by Andrew Woodcock (Member # 3260) on September 24, 2015, 06:56 PM:

Yes, Janice... Good point, what has happened to Pat?

Urethane belts appear to my eyes at least, to run far more like what I am used to seeing from a quality projector than those dreadful spring belts do.

A smooth, consistent, constant sized loop formation, non jerky movement in the delicate handling of film, is worth it's weight in gold I always find!

Hence my choices on the machines I use.

Your work is amazing Janice! You are a true stalwart of this forum and I love your relentless patience in trying to perfect all that is motion picture on our guages!

Hats off to you!!

Posted by Janice Glesser (Member # 2758) on September 25, 2015, 01:19 PM:

Andrew...Pat has moved on to a new hobby...miniature trains. I do miss his humor here on the forum and he actually had some very creative solutions to projector repairs. I've used several of his ideas.

As far as the urethane belts...are you saying you don't see any adverse effects to substituting one for the spring belt?

Posted by Andrew Woodcock (Member # 3260) on September 25, 2015, 02:55 PM:

I wouldn't have thought so Janice. If you were using rubber ones then they may not allow for slippage but these look ok to me, so long as they are not made too short and would therefore be too tight on the pulleys.

I'd have to feel one or two things to be certain but the drive looks far smoother to my eyes from watching your video using these rather than the steel spring belts.

Shame about Pat. I thought he was a keen collector and enthusiast from the time he was on here. ![[Confused]](confused.gif)

[ September 25, 2015, 05:40 PM: Message edited by: Andrew Woodcock ]

Posted by Janice Glesser (Member # 2758) on October 11, 2015, 02:05 PM:

I was hoping to hear back for Frank to get his take on substituting the spring belt after seeing the video. I have another B&H 10MS that runs fine with the spring belt...so if it ain't broken...don't fix it ![[Smile]](smile.gif) However, if cleaning and lubricating doesn't do the trick, then replacing the belt seems like a viable alternative. Of course making sure the belt isn't too tight is a must to insure proper slippage.

However, if cleaning and lubricating doesn't do the trick, then replacing the belt seems like a viable alternative. Of course making sure the belt isn't too tight is a must to insure proper slippage.

Posted by frank arnstein (Member # 330) on October 12, 2015, 02:18 AM:

Hi Janice,

Your videos show a smooth operation using the replacement belt and as long as it performs its functions OK for you then most should be quite happy to use it like that.

I am curious about wether it would work any better by using the old spring belt but shortening it a bit as it appears to be quite springy and loose. That could be the reason its a bit erratic and dumps film.

dogtor frankarnstein

![[Smile]](smile.gif)

![[Wink]](wink.gif)

Posted by Janice Glesser (Member # 2758) on October 12, 2015, 11:44 AM:

Thanks Frank for your thoughts. Yes...shortening the spring belt is something else to try. I don't have time to do this, but anyone having this same problem in the future might want to give it a try. If it works...then there's no need to make a urethane belt, which most projector owners probably wouldn't have the materials or have experience making DIY belts anyway ![[Smile]](smile.gif)

I believe this is a very useful thread in providing several alternatives to fixing this problem.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Frown]](frown.gif) Have you done this yourself?

Have you done this yourself? ![[Smile]](smile.gif) Did it work with no ill affects?

Did it work with no ill affects?

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif) Frank has been a major contributor to my projector sagas and I miss our ol' friend Pat who use to chime in too. Despite the often frustrations ... collaborating on these repairs has been actually fun as well as educational

Frank has been a major contributor to my projector sagas and I miss our ol' friend Pat who use to chime in too. Despite the often frustrations ... collaborating on these repairs has been actually fun as well as educational ![[Smile]](smile.gif)

![[Confused]](confused.gif)

![[Smile]](smile.gif) However, if cleaning and lubricating doesn't do the trick, then replacing the belt seems like a viable alternative. Of course making sure the belt isn't too tight is a must to insure proper slippage.

However, if cleaning and lubricating doesn't do the trick, then replacing the belt seems like a viable alternative. Of course making sure the belt isn't too tight is a must to insure proper slippage.

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)