This is topic Elmo ST1200HD Rewinding Issue in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=010888

Posted by Mathew James (Member # 4581) on August 13, 2016, 09:10 AM:

Hi All,

Well bad news for us!! We own 3 projectors, all elmos, and 2 are now not working. I couldn't fix my father-in-law's K110SM for a similar issue.

So what has happened is that after watching films, it(ST1200HD) no longer rewinds from the take-up end. The supply is working and turning, belts are intact and good(fairly new actually). This just started happening. Rewind has been somewhat slow compared to other machines, but now it has no strength to rewind. If i turn the supply end, it will pull from there, but stops because takeup end seems seized.

If this is a clutch problem again, I am pooched because i have not been successful in fixing as i cannot source a new cork gasket for the K110SM, and if that is similar here, I am pooched.I know that sounds defeatist. Just being truthful about my success here to date!

Well, we are down to our trusty ST180E, my first machine!! Maybe I should have just stopped there when i bought it- he hee...

Should anyone have any ideas, please let me know what i may be missing, but I am thinking i am pooched with another bad clutch!

I wish there was someone I could bring it to locally...

ps: i also took off rear arm and looked at all gears. They look fine.

pss: Steve, I saw your post to another member regarding a possible switch issue. Once i get my head around a multimeter better and where to touch the contact, i can maybe try to see if the switch is going...

Posted by Andrew Woodcock (Member # 3260) on August 13, 2016, 09:42 AM:

These "cork" washers or friction linings in this case, are very easily made with a standard engineers punch set.

No need to be defeated by something so simple as this pal. ![[Wink]](wink.gif)

Also, if the machine is only ever used to rewind films and never to clean them with, the friction lining to any clutch should ordinarily last for donkeys years. ![[Confused]](confused.gif)

Posted by Mathew James (Member # 4581) on August 13, 2016, 11:01 AM:

![[Smile]](smile.gif)

I made a cork for the K110SM and it didn't change things unfortunately. I am not saying it isn't the cork, but nothing has worked to date. That is the only reason i am frustrated. I love my St1200HD. Simple isn't simple if the part is hard to obtain. Proper cork, proper tool...Not everyone has an engineers punch and if it were that easy, it would have been fixed ![[Smile]](smile.gif) , but I am thankful Andrew you pointed me in that direction as i have never heard of one before.

, but I am thankful Andrew you pointed me in that direction as i have never heard of one before.

I wish this part was plastic so I could simply ask Edwin to make one...If someone has the rear cork for the takeup side as an extra or for sale, i am willing to try the cork anything again...

Posted by Paul Browning (Member # 2715) on August 13, 2016, 11:32 AM:

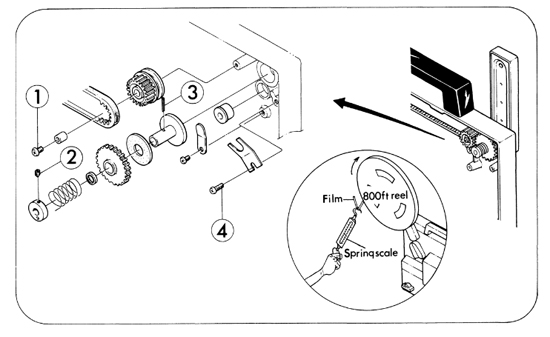

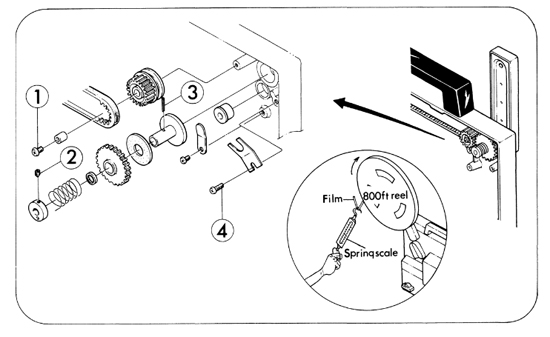

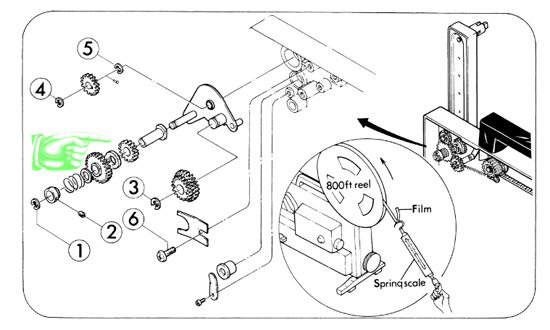

Hi Mathew, your diagram shows a spring and locking collar for tension on this drive, have you tried just unlocking the grub screw and turning it slightly to tension the spring against the

cork drive disc ?. The cork is just like a clutch on your motor car to take up the drive between the gearbox and engine, but it still needs adjustment for the wear that takes place, automatic now on new cars, but we use to have to this ourselves on cables to maintain the freeplay. Make a note of where it was before you move it, so you can put it back it case this does not change anything.

Posted by Mathew James (Member # 4581) on August 13, 2016, 02:22 PM:

Hi Paul,

No, I haven't tried that yet but will certainly do so now.

I wasn't sure exactly what the issue 'could' be yet, so this is helpful to give a try...

update:tried it now and it made no difference to this particular problem it appears , but led me to looking at how this runs, and I think i was wrong...I think this is driven from the other side, but then stops...Maybe the problem is on the front reel end.

When there is little load, like rewinding a reel loaded at the takeup end..it will start to rewind, but as soon as there is any weight added to the front reel end, maybe a inch worth off film, it will slow to a halt...If i push my hand on the reel, it will go a little, and then stop again...

[ August 13, 2016, 03:33 PM: Message edited by: Mathew James ]

Posted by Mathew James (Member # 4581) on August 19, 2016, 06:36 AM:

...well, it has been a few days since I reported this broken projector..and the time down has not been in vain. It has allowed me to give the projector a good goop cleaning.

I actually found a piece broken belt I had missed in cleaning before that had fallen on the transformer and is now a nasty pile of black licorice goop, he hee. I am also cleaning old lube off and putting on new super lube. Looking/running better!

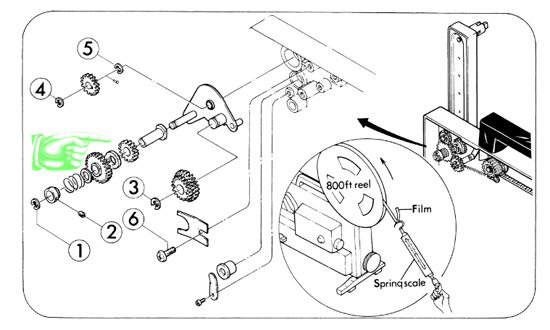

Now to the issue... in my cleaning i noticed that a gear(see green finger pointing in pic)would stop turning, and thus the whole rear reel would not turn anymore...

It seems there is another friction cork here as well, so the issue is either a bad cork in this spot, or the spring has lost its oomph...I have tried tightening this spring and it seems to be better, but not perfect.

I am still working and cleaning but wanted to let people know I am getting closer and also for anyone else who may have this issue...

Posted by Andrew Woodcock (Member # 3260) on August 19, 2016, 07:25 AM:

It seems you getting nearer to the truth of the issue here now Mathew thankfully.

An engineers punch set btw, can be picked up relatively cheaply if you find no ready made professionally manufactured alternative locally. So all is by no means lost here.

The spring compression setting is of course critical here, but so too are decent uncontaminated friction linings just as with any clutch mechanism.

I am sure you will be able to come to a satisfactory conclusion with this one soon Mathew. ![[Smile]](smile.gif)

Posted by Mathew James (Member # 4581) on August 19, 2016, 07:42 AM:

Thanx Andrew!

I am going to keep an eye out for the engineering punch. I go fleamarketing often as well so in my next round, I will look in the tools section and see what i can find. A nice tool to remove those nasty E-clips would be wonderful as well.

I think i've pinged them off one too many walls for my liking, and someone is going to lose an eye soon if i don't ![[Smile]](smile.gif)

One good thing about these problems is that they do force one to become much more familiar with something. I feel alot more confident fiddling inside the ST1200 than before this endevour. I just hope it will help others in future as well by documenting what we can.

Posted by Andrew Woodcock (Member # 3260) on August 19, 2016, 07:58 AM:

All very true Mathew! It's the only real way to learn about these things I find. ![[Wink]](wink.gif)

Documenting such events here, is extremely helpful to anyone experiencing similar problems in the future, so that too, can only be a good thing. ![[Wink]](wink.gif)

[ August 19, 2016, 10:29 AM: Message edited by: Andrew Woodcock ]

Posted by Mathew James (Member # 4581) on August 31, 2016, 11:03 AM:

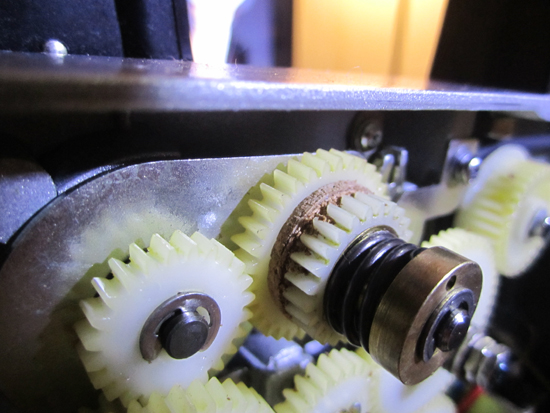

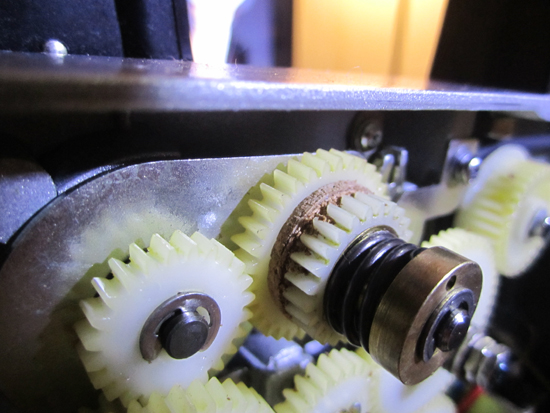

Well, continuing forward...I found the problem spot!!!

This is the culprit cork area right here!! This causes my ST1200HD to not rewind if this cork is at all loose.

Temporarily, I was able to find some cork and used a single-hole punch(.99cent walmart back to school specials) to make a perfect hole and it is working better than ever currently.

In this picture you can see some wear already from the cork i used, so i need a better cork or material that will not break down as such.

At least I am up and running again!!!

Posted by Andrew Woodcock (Member # 3260) on August 31, 2016, 11:43 AM:

G'job Mathew!

Now it's just a case of finding a harder and more durable version of this material.

Then you're cooking on 3 burners! ![[Wink]](wink.gif)

Posted by Paul Browning (Member # 2715) on August 31, 2016, 12:16 PM:

try some leather Mathew, I'm sure you can use your hole punch to put a hole in it, and it does come in all sizes, should be good enough to grip both sides and act like clutch material.

Posted by Andrew Woodcock (Member # 3260) on August 31, 2016, 02:22 PM:

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

Posted by Mathew James (Member # 4581) on September 02, 2016, 06:23 PM:

Top-notch idea Paul!

Never thought to use leather. I will keep my eye out for something that may work! Thx.

Posted by Paul Browning (Member # 2715) on September 03, 2016, 05:51 AM:

An old leather belt would do fine Mathew. This material has been around since the industrial revolution and used for driving machinery as flat looped belts and probably still is in some parts of the world. I'm surprised at the material choice by Elmo, I though it was leather ?.

Posted by Andrew Woodcock (Member # 3260) on September 03, 2016, 05:55 AM:

Leather would undoubtedly be better and harder wearing for this purpose than the original material used. It may have a slightly higher level of grip so no doubt the spring torque settings would no longer apply as i would expect much less pressure needed from the spring to still maintain a good serviceable clutch mechanism.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Wink]](wink.gif)

![[Confused]](confused.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif) , but I am thankful Andrew you pointed me in that direction as i have never heard of one before.

, but I am thankful Andrew you pointed me in that direction as i have never heard of one before.

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Wink]](wink.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)