This is topic Beaulieu: Fast & Easy Speed Setting Procedure in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=011550

Posted by Phil Murat (Member # 5148) on June 11, 2017, 07:24 AM:

Here is a very fast and simple procedure to pré-trim speeds for Beaulieu projector.

To do it no film is loaded.

However, as prerequisites, insure you that mechanic systems are perfectly free and smooth ! (Lub bearings as necessary with penetrant thin oil), belts are serviceable. Pinch Roller has to be free and perfectly clean,its Rubber has to be in perfect condition for surface and Roundness. If these conditions are not met you can experience speed(s) fluctuation (WOW / Flutter) which can make final adjustment hard to achieve.

Moreover, this small procedure allows to quickly check "Capstan Motor" health and Electronic drive quality.

It is very important to watch a perfect Capstan Motor speed stability as Capstan Speed is considered as the REFERENCE for the Electronic Dual Drive Stucture.

Tools :

- Multimeter with Frequencemeter capability included and allowing measures within +/- 1% (You can find it for 60 Euros approx)

- White Tape (5mm X 15mm)

- Black Fine Marker

- Flat screw driver , narrow tip, extra long

A) First Step

1) After removing Back cover, Once Multimeter is set on “Frequencemeter” position , put each probe tip on soldiers (White / Blue) Wires , Tacho Terminals:

2) 24fps is 2160Hz measured from Tacho

3) 18fps is 1625Hz

4) Observe these values have to be perfectly stable , doesn’t matter if values are different at this time

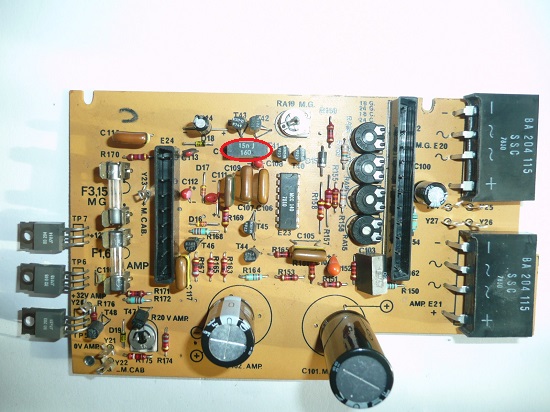

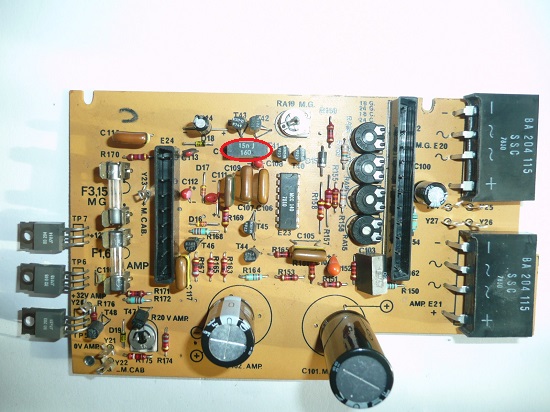

5) If values unstabilities are observed and if wire contacts are in good condition , replace the “Time Factor” capacitor (C4) by a new one 5% Class minimum.(15nf.J.100v)

6) 2160Hz is set by RA3 , 1625Hz is set by RA4.

7) To be note if Multimeter accuracy is +/- 1%, final result precision is much higher what you can expect (Final speed for capstan Shaft is divided with a good ratio)

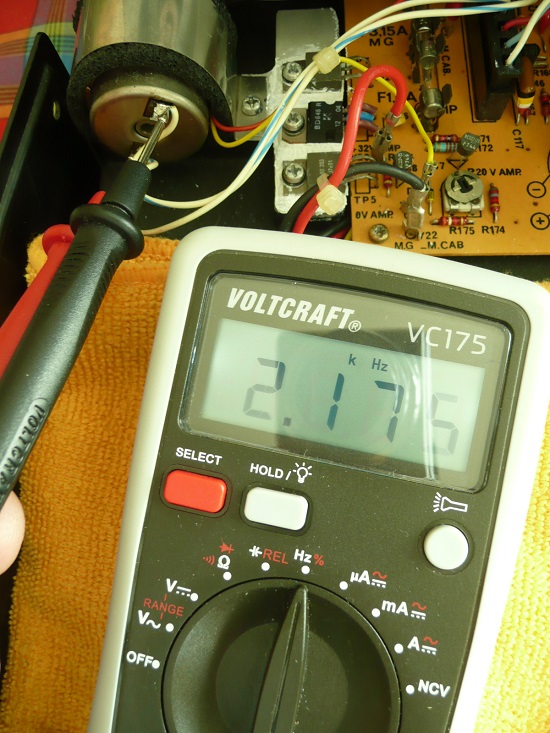

Exemple of Tacho Frequency measure (Here, a BEAULIEU 708EL MONO):

2,175Khz or 2175 Hz.

B) Second Step

Once “reference” well setted, the idea is to adjust “Claw Main Motor” to "mid range" when playing in Sound mode.

So, Turn off the machine.

1) Set main knob in sound position.

2) Stick on the white strip behind “Buckle Black Sensor” and to the case.

3) Facing the machine, Push Sensor to the left up to the 1St step but do not overpass it. With black fine marker report position on the tape.

4) Release sensor and report its new stop position on tape.

5) Then put a mark on white tape at mid range between Left and right stops reported before.

6) "Power On" the machine, Set main knob on "Sound" mode , and Block sensor with a soft material on "Mid Range" position reported on white tape.

7) With Multimeter, check Frequency from Main Motor Tacho terminals .

8) Observe value is around 500Hz. As necessary set RA6 to reach this value.

Additionnal Info :

RA1 (Also Labelised "E.G") is supposed to adjust Sensor efficiency (more or less Voltage to the tiny bulb located inside "Mask").

That means "Fast" or "Slow" sensor response.

Generally RA1 is set at Mid-Range position, which also increase tiny bulb life and allows a smooth operating.

This is what I did on my projectors. If properly done this “pré-set” procedure works much better than BEAULIEU procedure described in Shop Manual and an oscilloscop is not required.

This procedure takes around 15mn to set the machine

[ August 14, 2017, 10:26 AM: Message edited by: Phil Murat ]

Posted by Steven J Kirk (Member # 1135) on June 11, 2017, 10:18 AM:

Thanks Phil! I have made a copy of this should I ever need it. Great information.

Posted by Phil Murat (Member # 5148) on June 11, 2017, 10:24 AM:

Hello Steven,

I have just put it as a draft, I ll make some pictures to complete the informations.

Posted by Phil Murat (Member # 5148) on August 14, 2017, 10:23 AM:

TIP today updated :

Picture is showing a Capstan Motor Tacho Frequency measured with Multimeter. (2,175 Khz / 2175 Hz)

To be note this method can be applied as initial step to troubleshoot faulty synchro.

Fast & Easy ==> Just apply probes on tacho terminals (solders), any position (red/black), it doesn't matter because Tacho supply alternative current....

Posted by Andrew Woodcock (Member # 3260) on August 14, 2017, 10:31 AM:

Excellent post thank you Phil! ![[Wink]](wink.gif)

You mention RA1 (lamp voltage),RA3, RA4, RA6, but what adjustments do RA2, RA5 and RA7 control?

Some must be for main motor (claw) speed adjustment I presume?

But which is for 18fps and which is for 24fps adjustments?

Do you have frequency readings for these when set precisely at 24 and 18fps first during calibration?

Posted by Phil Murat (Member # 5148) on August 14, 2017, 10:45 AM:

Thanks Andrew. ![[Cool]](cool.gif)

Hope this help BEAULIEU's Owners to face Synchro problems. Some of them meets difficulties to find the "right" repair station. So, this kind of Tool is a modest investment.

In fact, its price is around 40 euros at this time.

RA3 = 24 fps CAPSTAN

RA4 = 18 fps CAPSTAN

RA6 = 24 fps CLAW

RA7 = 18 fps CLAW

RA1 = Sensor Response (Fast Response / Slow Response). Generally , it's set in middle range

RA5 = Variable Speed Range position (means you can get more than 28 Fps or less than 21 fps, but a schema should be better to explain the idea)

Posted by Andrew Woodcock (Member # 3260) on August 14, 2017, 10:52 AM:

Please see questions above Phil. This is invaluable advice you're handing out and could save a lot of time using a frequency meter on a multimeter.

Please list the functions and values from tachometers(Hz) for RA2to RA7 if you will please Phil.

500hz (RA6) = Main motor- 18fps or 24fps??

My Multimeter doesn't have a frequency setting currently, but it soon will! ![[Smile]](smile.gif)

![[Wink]](wink.gif)

Cheers Phil you're a Gent!! ![[Wink]](wink.gif)

RA2 ??

RA7 = 375Hz?

Posted by Phil Murat (Member # 5148) on August 14, 2017, 11:09 AM:

Yes Andrew, when I get more time I'll make a diagram (curve) to cross actual frames speed with Tacho frequency.

As well, it should be interesting to make a complementary diagram dedicated to Claw Motor speed.

RA1 to RA7 are speed trimmers for the (Stereo) Projector Board.

For Mono Projector, references are different.

RA2 is not concerned by this TIP. RA2 is used to adjust incomming Voltage to Preamp .

Posted by Andrew Woodcock (Member # 3260) on August 14, 2017, 11:26 AM:

Thanks again Phil, invaluable advice and I look forward to your update when it arrives! ![[Smile]](smile.gif)

![[Wink]](wink.gif)

I've just found a true RMS multimeter on Amazon with a frequency meter built in. Also measures capacitance!

£42 ...Happy Days ![[Smile]](smile.gif)

Not a Fluke though of course at these prices! 😊😊

[ August 14, 2017, 04:38 PM: Message edited by: Andrew Woodcock ]

Posted by Phil Murat (Member # 5148) on August 15, 2017, 01:02 AM:

Hi Andrew,

I suggest you before to choose a Multimeter, check within "Tehcnical Data" for accuracy of measures (for exemple, this one is +/- 0,7%) and try to get the one which offers the tighter accuracy....... for an equivalent price ![[Wink]](wink.gif)

Let me know

Posted by Andrew Woodcock (Member # 3260) on August 15, 2017, 04:34 AM:

Thanks Phil and I will let you know which model I finally choose based on your recommendations.

I'd like another Fluke, but these days just for home use, I simply cannot justify the expense.

Obviously at work, those are all we use.

The ones I looked at with a frequency meter built in, was £149 cheapest

Posted by Andrew Woodcock (Member # 3260) on August 15, 2017, 08:59 AM:

It would also be most useful Phil, if you have any proven data points surrounding the settings on the mono/ twin track boards for the Capstan Drive?

Posted by Phil Murat (Member # 5148) on August 15, 2017, 09:30 AM:

Hi Andrew,

Not sure to understand exactly, but at this time , I have not checked all the points, means all the speed range.

But , logically , Capstan Motor Speed has to be proportionate to frequency and can be drawn as a straight line.

Of course, to confirm, I need at least more than 3 points.

Posted by Andrew Woodcock (Member # 3260) on August 15, 2017, 09:53 AM:

So the layout is the same just the labelling of RA1 to RA7 is different Phil?

Sorry I haven't looked inside my twin track much to date.

I certainly haven't had a need to study the motor board on it anyhow, so you would know the answer to this far better than I currently do.

Posted by Phil Murat (Member # 5148) on August 15, 2017, 10:10 AM:

Absolutely Andrew, RA1 to RA7 referencing only concerns Stereo Family.

Labelling is different for Mono Machine, but idea stays the same.

However , so far I can remember, 2 "secondary" trimmers do not exist on Mono Board (Voltage adjustment and "Range" speed positionning)....

Posted by Andrew Woodcock (Member # 3260) on August 15, 2017, 10:13 AM:

Many thanks once again Phil. ![[Wink]](wink.gif)

Posted by Phil Murat (Member # 5148) on August 15, 2017, 11:49 AM:

Andrew, I am realizing these "lalelling" differences can lead to some confusions to understand how work both cards......

So I think about a kind of "Summary Chart",Simple, all in a single page, showing cross reference Functions => Labellings for Mono & Stereo families.... ![[Roll Eyes]](rolleyes.gif)

Posted by Andrew Woodcock (Member # 3260) on August 15, 2017, 12:00 PM:

Great idea Phil.

I look forward to the resulting calibration table.

Posted by Phil Murat (Member # 5148) on August 16, 2017, 04:06 AM:

Hi Beaulieu's Fans,

Here is a Speed Regulation "Summary Chart" MONO/STEREO Machines to download (pdf) within 15 days :

Can be updated REGULATION SUMMARY CHART

[ August 16, 2017, 05:13 AM: Message edited by: Phil Murat ]

Posted by Andrew Woodcock (Member # 3260) on August 16, 2017, 04:17 AM:

Thank you so much Phil for all of your efforts with this and for sharing them with us all!

It is truly most appreciated thanks. ![[Smile]](smile.gif)

Phil, I have just downloaded your chart and on it it appears RA15 and RA17 are doing the exact same job.

Is this a typing error and should it perhaps say"claw" against one of them instead of three trimmers for Capstan?

Posted by Phil Murat (Member # 5148) on August 16, 2017, 04:49 AM:

Oups !!!!

....... Big Mistake ![[Wink]](wink.gif)

I am correcting that

Posted by Andrew Woodcock (Member # 3260) on August 16, 2017, 04:52 AM:

![[Big Grin]](biggrin.gif)

![[Big Grin]](biggrin.gif)

![[Wink]](wink.gif)

Am i right in assuming RA17 should be changed to say "Claw" Phil?

If so, I will just alter my downloaded chart now thanks.

Posted by Phil Murat (Member # 5148) on August 16, 2017, 05:09 AM:

This is correct Andrew ![[Wink]](wink.gif)

I am on it at this time

Posted by Andrew Woodcock (Member # 3260) on August 16, 2017, 05:11 AM:

Thanks Phil. ![[Smile]](smile.gif)

One last piece of advice if you will please Phil,...

In your original post of this ingenious and "user friendly"technique here for setting the mid position of the floating roller and balancing the mechanism,.. in point 8 above you say a reading of 500HZ should be obtained by adjusting trim pot RA6 @ 24fps for "balancing" the speed of the claw motor, but do you have a known and proven value at this stage for repeating this exercise at 18fps for the claw motor using trim pot RA7?

Posted by Phil Murat (Member # 5148) on August 16, 2017, 05:15 AM:

And now, this is done Andrew....

Take a look. If you see anything more thing(s) to add/update, don't hesitate to tell me ![[Razz]](tongue.gif)

Posted by Andrew Woodcock (Member # 3260) on August 16, 2017, 05:43 AM:

Got it thanks Phil. ![[Wink]](wink.gif)

Please see my one last question above Phil.

I'm guessing 375HZ but this is purely a guess at this stage,based on your quoted figure of 500hz at 24fps and the fact that I'd expect this to be linear by association.

Posted by Phil Murat (Member # 5148) on August 16, 2017, 09:02 AM:

Yes Andrew , your estimation is certainly correct.

I have only experimented this method with 24 Fps setting only.

I assume result for 18 Fps is around 375 Hz value as an extrapolation. But this is something to confirm practicaly

So, I test more points around 18 Fps & 24 Fps for better accuracy

[ August 16, 2017, 10:11 AM: Message edited by: Phil Murat ]

Posted by Andrew Woodcock (Member # 3260) on August 16, 2017, 09:10 AM:

Thanks Phil and once I have a suitable meter, I will let you know what my own readings are from the Stereo model.

It's running perfectly fine so it will be nice to get some of my own reference points to collaborate with your own on these.

Bill informed me that often when there is issue on the Capstan circuit, it simply does not run in stop mode but with main power switched on of course.

From experience, Bill also advises that a special long thin purpose built instrumentation screwdriver should be fashioned for adjusting the trim pots as many of these are concealed dangerously close to the revolving shutter, which from having a look recently, I can certainly confirm is very much the case!

I certainly wouldn't want my hand anywhere those trim pots when the shutter is running!😂

There is also a very useful piece recorded in a late FFTC edition that advises changing one of the transistors to a higher rated type (1.5a instead of 0.5a).

This was discovered by a chap called Luigi and he advised that one in particular from the CS 140 IC, simply wasn't the correct rating for the demand placed on it and it caused two machines that he was servicing to fail.

Once changed to the uprated version, both came back to life and worked perfectly.

I have the original piece if you'd like me to mail you a copy for you to read?

Posted by Phil Murat (Member # 5148) on August 16, 2017, 10:17 AM:

Yes Andrew , You are right :

Last Beaulieu's Machines are showing an ugraded Transistor from production to drive Capstan Motor.

I have already install it on my boards as this is a very common failure.

Reference is BD136 (T4 Transistor Position on SEREO Family) :

Pay particular attention for terminals position which is different from former one.

Also, you will need to drill out former Board terminals holes (up to 0,9mm) to install new one.

Normally, if input voltage is properly rated (around 13V), there is no reason for CS140 to fail out.

Moreover "CS140" IC features a built in "Short Circuit" Protections available on Pins 9 & 16 both.

Posted by Andrew Woodcock (Member # 3260) on August 16, 2017, 10:45 AM:

Thanks Phil, let's hope I never need go there!

Drilling circuit boards given their delicate nature is not something I want to experience.

I'd need to have a look to see which type is fitted to my own, I've not studied the transistors on my motor board so far.

Yes I've seen the SC protection feature on the CS 140 from the Cherry Tree data sheet for this component.

Posted by Phil Murat (Member # 5148) on August 16, 2017, 10:57 AM:

Upgrading T4 transistor is pretty easy to do. I have used a magnifying glass of course because I have not same sight as young.

Reaching RA6, RA7 or RA17, RA18 is a game of skill.

To do it, I have preformed a kind of extra long screwdriver from a "more or less" flexible plactic rod... ![[Eek!]](eek.gif)

To be note the "Cloned" Board pots (ALL pots) can be setted SAFELY in any conditions , OUTSIDE from the Machine due to an EXTENSION HARNESS using.

Then, when properly adjusted , board is installed in the machine.

Posted by Andrew Woodcock (Member # 3260) on August 16, 2017, 05:51 PM:

I will take a preset cloned Motor board from you Phil once you make them available. It would make a great addition to my spares for these machines.

Also please advise on electronics suppliers for the mask light bulb and LDR's if you know of any.

I have one of each from Beaulieu Cinetec, but another of each would not go a miss for the future.

Posted by Phil Murat (Member # 5148) on August 17, 2017, 02:03 AM:

Hi Andrew,

Concerning Mask tiny bulb (in french called "luciole", "Lightening Bug" or "Firefly" ??) , tell me if this could be usefull ?

12 V "LIGHTENING BUG" BULB

You 'll find detailed technical data sheet in the last tab.

Let me know

Posted by Andrew Woodcock (Member # 3260) on August 17, 2017, 05:29 PM:

It certainly appears similar thanks Phil.

I'd have to get my original spare out of storage to compare the physical dimensions.

Have you any input for the Light Dependent Resistors used in these Phil?

They are very very small for one of these components and nothing like others I have been used to seeing.

Posted by Phil Murat (Member # 5148) on August 18, 2017, 02:31 AM:

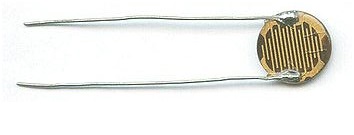

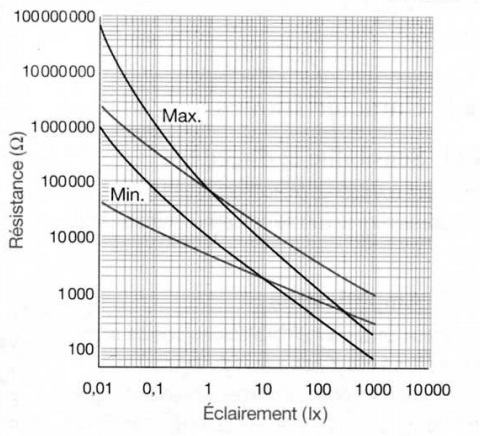

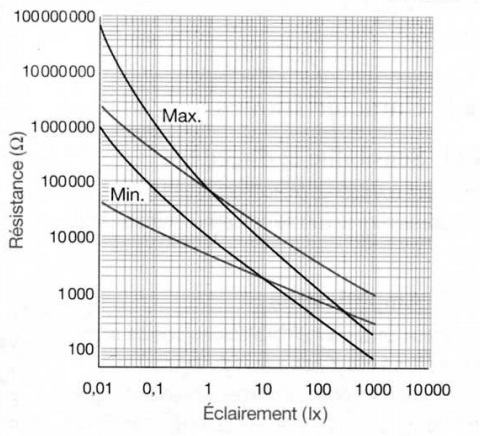

Concerning Photoresistors inside Sensor Mask , Andrew ,The only things I know :

- There are like this

- Works like this (The diagram below is just for information but do not match for the ones used in BEAULIEU's)

- 2 Photoresistors are installed inside the Mask housing

- Their overall reliability is "normaly" excellent.

In this particular case, BEAULIEU' design choice is simply "Excellent" as the Mask assembly looks "unbreakable" offering a high steady operating and reliability (no parts subject to wear).

For this reason, my machines keep RA1 (RA19) setted at mid-range to increase bulb life, also regulation response stays fully satisfactory in this condition.

From my own experience, the only things to watch out is :

- Avoid dusts to come inside Mask assembly

- Insure Copper Slider is free

- Main faults (Sensor Out Off response) come from bulb terminals which can cut easily

Posted by Andrew Woodcock (Member # 3260) on August 18, 2017, 04:08 AM:

Thanks Phil. I haven't had any issues either so far with this assembly but as said, I ordered one of each of the lamp and LDR (Photo Cell) just as precautionary measure.

The LDR they supplied looks even smaller than the one above and was from their official stock pile.

As you imply though Phil, I'm sure they potentially will last a lifetime or more in their dust sealed chamber.

Posted by Phil Murat (Member # 5148) on August 18, 2017, 04:21 AM:

Yes Andrew, I am pretty confident in that.

However these photoresistors come under reference RPY 58 (according to Beaulieu's Service Manual) and are obsolete now.

I have not find out yet data sheet to get an equivalent as necessary..... ![[Roll Eyes]](rolleyes.gif)

If you find something, let us know

Posted by Andrew Woodcock (Member # 3260) on August 18, 2017, 04:25 AM:

All I can tell you at present Phil, is Wittner Cinetec still have one or two originals from their existing Beaulieu stock pile but of course they are not 0.9€ and you may feel a perfectly acceptable equivalent can be sourced elsewhere for far less.

Finding a data sheet now for the originals may prove very tricky indeed.

Posted by Phil Murat (Member # 5148) on August 18, 2017, 04:27 AM:

I should be ok for 1,234 Euros ![[Big Grin]](biggrin.gif)

Posted by Andrew Woodcock (Member # 3260) on August 18, 2017, 04:29 AM:

Ha ha ha.

Not quite that expensive either Phil I have to say! ![[Big Grin]](biggrin.gif)

![[Wink]](wink.gif)

Posted by Stuart Reid (Member # 1460) on September 17, 2017, 11:27 AM:

Phil, using your method of testing the tacho terminals I am getting an unstable reading of around 2.040 to 2.070, does this point to the capacitor C4 failing do you think? Also, I am using the exact same meter as you but I find that unless I am extremely precise with the probes I am also picking up a reading of 50Hz?

Posted by Phil Murat (Member # 5148) on September 17, 2017, 11:55 AM:

Hi Stu,

So far I can remember, this is good .

Considering 2040 / 2070 is for 24fps applicable, Difference between 2040 and 2070 is equivallent to 0,3fps.

You can replace C4 (15nF / 100V class "J") and check again.

Class "J" is important for precision of work.

Also a slight fluctuation could come from contact quality for motor brushes.

The motor is sealed and it is difficult to gain access to them.

How is running your machine at this time (In "Sound" Mode) ?

Is your machine "Stereo" or "Mono" one ?

Posted by Stuart Reid (Member # 1460) on September 17, 2017, 12:17 PM:

It's a mono machine Phil. As you might have seen on here I'm having problems with a severe audio flutter, can't work it out at the moment, so thought I'd get as many of the settings to factory standards as possible. Can you tell me where on the board I can locate the capacitor?

Posted by Phil Murat (Member # 5148) on September 17, 2017, 12:36 PM:

For Mono Machine :

In that case , not called C4

Also, let me know if Buckle sensor stay stable when machine is playing (Sound) or is swinging a bit proportionnaly to flutter.

Posted by Stuart Reid (Member # 1460) on September 17, 2017, 12:38 PM:

Thanks Phil, I'll order and replace it. No idea if that will help the flutter problem but it certainly won't hurt matters.

Posted by Phil Murat (Member # 5148) on September 17, 2017, 12:50 PM:

You can check :

- Quality of contact between Pinch Roller and Capstan Shaft (taking a piece of film, may be 20cm, and pulling it outside when installed between pinch roller and shaft, same direction as machine do it itself). It have not to slide easily.....

- Loosen (and dry) belt

- Capacitor

- Motor (brushes)

- Loosen contacts : Resized spade contactors on terminals board.

Posted by Andrew Woodcock (Member # 3260) on September 17, 2017, 01:10 PM:

Are you referring to the main motor here Phil?

Also Stuart, isn't your machine a duo play model?

I know this still makes it primarily a mono machine but Beaulieu also made early track one only models also I think which are different again according to Phil regarding the motor controlling circuit boards.

Posted by Stuart Reid (Member # 1460) on September 17, 2017, 01:29 PM:

markings on the front amp panel (near the line/micro faders) state it's a double track capstan drive 708el. Lamp housing states it's a 708el capstan drive. Here's the board:

Posted by Andrew Woodcock (Member # 3260) on September 17, 2017, 01:41 PM:

Yes, I think it's the same as my "black" model except just to add further confusion into the melting pot it is labelled as a double piste machine.

Two Track mono capstan driven machine basically.

Your board appears very very clean there Stuart and as we have discussed previously appears to be fully working with respect to the functions of the floating roller , the mask, lamp and LDR's so hopefully it won't need much to get it calibrated well.

If you run out of ideas Stuart and still are getting no joy with the wow issue, a main motor for these can be purchased fairly inexpensively to eliminate any possible brush problems.

The reading appears ok though as Phil says.

Posted by Stuart Reid (Member # 1460) on September 17, 2017, 01:45 PM:

Yes Andrew, I'm convinced it's something trivial/stupid!

Posted by Andrew Woodcock (Member # 3260) on September 17, 2017, 01:48 PM:

I guess you've checked your capstan drive belt also Stuart and everything looks ok?

Posted by Stuart Reid (Member # 1460) on September 17, 2017, 02:28 PM:

Wow. OK. So, I tried running a film without the capstan drive belt attached, and it sounded just fine. I have now reattached the belt and it sounds... Just fine. No trace of the flutter I was experiencing. Er, seems to be fixed?

Posted by Andrew Woodcock (Member # 3260) on September 17, 2017, 02:35 PM:

Weird Stuart but maybe the belt was just mistracking slightly if it partially had slipped out of the machined groove in the flywheel etc.

Surprised to hear it was ok without the capstan drive motor in circuit though????

Either way, a result with no expenditure! ![[Smile]](smile.gif)

![[Wink]](wink.gif)

Posted by Stuart Reid (Member # 1460) on September 17, 2017, 02:42 PM:

Who knows? Maybe running it and running it trying to find what the problem was just loosened up something? Whatever it was, I've run 800ft so far with no problems.

Posted by Andrew Woodcock (Member # 3260) on September 17, 2017, 02:51 PM:

That's all the matters Stuart, the fact that you now have no problems.

I haven't found this aspect of my main machine to be anything other than 100% reliable to date Stuart, so other than dabbling in the research aspect of all this Capstan drive theory, I have absolutely no experience yet regarding any practical repair work on this part of the machine.

My other one (like yours),I haven't had too long and don't use it too much either to be honest, but again, no hassles at all to date.

So I've had the Stereo one nigh on 5 years at least now, so if used regularly and handled and stored correctly, with respect, I'd say you'd be pretty unlucky if you continue to see regular problems with your machine.

I've found them totally reliable so far. ![[Smile]](smile.gif)

All of my problems, mainly amplifier related, were present when I first got the machine but since getting it all sorted, it's worked like a dream, used almost daily since.

I changed the main motor out also in the early days but I since was able to fix the problem on the tacho coil original motor and that was only due to the cables being originally permanently soldered on the tacho terminals, which now they are not, so that won't ever happen again thankfully.

Dry joints can be an issue on these now, but that applies to any machine of this age and especially those heavily laden in electronics.

I think the main thing with all our projectors now is to use them regularly and store them well.

I now have too many to use them all regularly and so I try and concentrate on using my most valued in order of priority to me, to keep these at least healthy and fully working at all times.

Posted by Phil Murat (Member # 5148) on September 18, 2017, 12:51 AM:

Hi Stu, Andrew,

Happy to ear « flutter » is probably due to a poor transmission phenomenon between Motor and Flywheel for this particular case.

This is cohesive with a belt slipping issue. (means film speed , in heads area, is maxi 24 fps and below , 20 fps and for a 1 or 2 sec period , …… for exemple).

So, I suggest :

A) Check Motor/Flywheel pulleys alignment (they have to work in a same plane)

B) Check Belt condition (more particularly looseness , dry rubber material , loss of material elasticity)

C) Remove belt and gently dry both pulleys grooves using a light thinner (removing grease evidences or any dust deposit)

Anyway, If any doubt, do not hesitate to renew Capstan belt.

Also , as above mentioned suggestion , check driving regularity/smoothness between Pinch-roller and Capstan shaft with a piece of film leader (machine powered OFF).

As necessary, lubricate ball bearings (with a spray, thin oil, Flywheel removal and pinch Roller could be necessary) initialy.

Important : If Pinch-roller has to be removed, don’t forget to turn CLOCKWISE for retaining screw removal.

Do not overtorque during screw re installation (Lubricate threads, 2 "tip fingers" torque only).

Back to your speeds recording, I forget to tell you that the equivalent fluctuation is not 0,3fps but………………0,1fps actually !!!!

(Because I forget take account of speed ratio between pulleys which is around 1/3.... ![[Wink]](wink.gif) ).

).

So, records are very, very acceptable and your Electronic Card / Capstan Motor system seem to be healthy enough at this time.

Let us know

NB:

If now, Stu machine is running smoothly for a long , I like the idea of a fixing issue without "almost expenditure" (exepted FREQUENCEMETER-MULTIMETER investment) and a fast DIY process closed loop

Posted by Stuart Reid (Member # 1460) on September 18, 2017, 01:25 AM:

Thanks Phil, I think it would be sensible to lubricate and change belts now as I don't know the history of the machine.

Posted by Phil Murat (Member # 5148) on September 18, 2017, 01:51 AM:

Yes Stu, Simple, Easy, Fast, and efficient at the end.....

May be Andrew will agree :

BEAULIEU's 708 family are certainly the easiest machines to Maintain and Troubleshoot among S8 projectors !! ![[Wink]](wink.gif)

You love it for a long !!!!

Posted by Andrew Woodcock (Member # 3260) on September 18, 2017, 04:02 PM:

In some respects from my limited experience so far with these I agree Phil.

For example here are some examples of tasks which are some of the easiest I've ever come across on any Super 8mm Projector,..

1/ changing a drive belt- can be done in seconds by opening just the lamp house cover.

2/ changing the main motor- very straightforward layout with plenty of access room to remove the fan cowl, the fan and then the motor.

3/servicing the cam lobe, adjusting the claw- quite probably the easiest and most self explanatory layout I've ever come across to successfully carry out any of these duties.

However there are aspects of these machines which are certainly no easier to diagnose regarding these machines than many others and in some cases, just through complexity alone, many others are easier to understand and therefore diagnose.

Not least, the amplifier section for the Stereo machines and their quirky individual and unique features, that don't always make too much common sense regarding certain configurations.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Wink]](wink.gif)

![[Cool]](cool.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Wink]](wink.gif)

![[Roll Eyes]](rolleyes.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Big Grin]](biggrin.gif)

![[Big Grin]](biggrin.gif)

![[Wink]](wink.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Razz]](tongue.gif)

![[Wink]](wink.gif)

![[Eek!]](eek.gif)

![[Roll Eyes]](rolleyes.gif)

![[Big Grin]](biggrin.gif)

![[Big Grin]](biggrin.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif) ).

).![[Wink]](wink.gif)