This is topic GS-1200 No Balance Strip Playback in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=011614

Posted by Mike Blasko (Member # 5867) on July 21, 2017, 12:51 PM:

This is unusual. I have a backup GS1200 that only plays from the main stripe. It doesn't appear to be an amp issue as when in mono mode on either optical or magnetic, both outputs are loud and clean. I hear light white noise on the balance channel, but don't see any broken wires, bad caps in the pre-amp, anything obvious. Do the heads just go bust sometimes?

Any ideas?

Posted by Phil Murat (Member # 5148) on July 22, 2017, 12:09 AM:

Hi Mike,

I assume this is an unusual fault you introduce here.

Starting trouble shooting as a simple way:

A) Check film path within reading head area (for foreign material, cleanness, path uneveness, etc...)

B) Check films Head "skates" for condition and if worn out of limit, renew them as a set (4 skates on holder)

C) Gain acces to Sliding (or rotary, as well) switches (for Channels 1/2 Change) and spray (back side) electrical contacts with Electrical Contact Cleaner (with a pipe !!)

Posted by Alan Rik (Member # 73) on July 22, 2017, 01:17 AM:

I has this happen to me once with a GS1200 Xenon. I took it to Du-All Camera here in NYC and they found a broken solder trace on the main board. They charged me an arm and a leg but they found it and it took a few days. Prior to that I had someone else replace everything they could think of short of replacing the whole audio board!

Wasn't fun but at least the machine was put back to Stereo.

Posted by Phil Murat (Member # 5148) on July 22, 2017, 04:01 AM:

Hi Rik,

Very good information !!

Did the Repair Station gave you back the former board when you get the machine ?

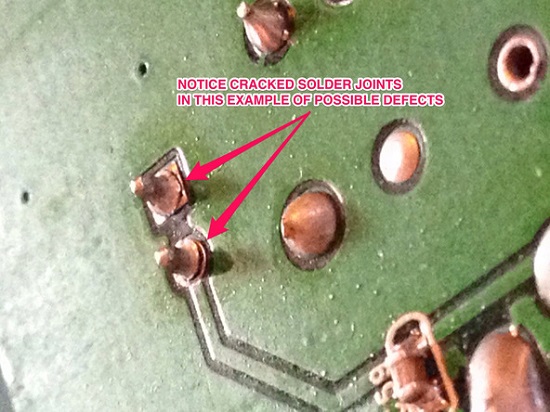

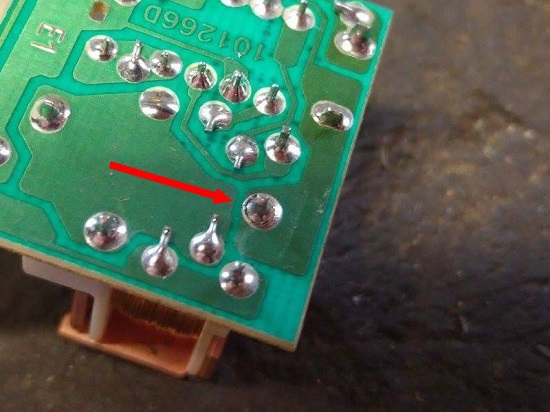

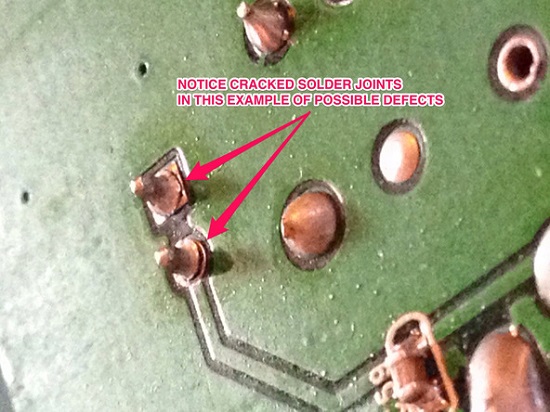

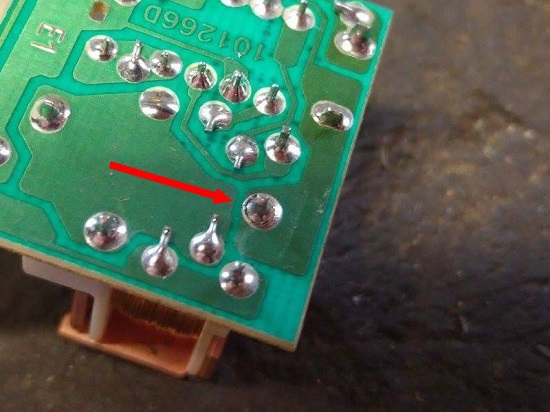

Track(s) failure(s) and/or cracked solder(s) occurs from time to time on old machines.

In case of track broken, It's often possible to save the card by bridging up with a wire or tin material as well, etc....

If this is our case, once board removed, it is very helfull to visually check track side and solders using a powerfull magnifying glass (x 10 should be nice)

Some exemples(not from a projector....).........

In summary, not abvious to find out without a good magnifying glass.

Also, you can help you with a Ohmmeter . If R (between terminal and track nuded) is not zéro or is fluctuating, refresh solder joint with a good Electronic quality Tin

[ July 22, 2017, 10:22 AM: Message edited by: Phil Murat ]

Posted by Alan Rik (Member # 73) on July 22, 2017, 03:56 PM:

With my GS they didn't replace the board but worked on the one that was currently in the machine.

Posted by Mike Blasko (Member # 5867) on July 22, 2017, 09:20 PM:

Thanks for the tips. The notion of a cracked solder joint took me down the right path. I still don't see an actual bad contact, but I used a meter near the news itself to the breakout, as well as applied some contact cleaner to all in that region.

Magically, in the process of cleaning and probing, it all came back suddenly. It does appear to be something near the heads forsure, so worst case I can start back there. Unless of course I just caused some downstream capacitor to come to life.

These machines are intense for what they are...

Posted by Paul Browning (Member # 2715) on July 23, 2017, 08:51 AM:

Mike, not sure what board could be the cause, but if you position the machine so you can see the underside of the board or boards, a dry or fractured joint can detected by its arcing, so in in darkened room, with torch handy, covers removed, and plugged in, with no lamp on, run up the projector, carefully tap the top or side with a piece of wood or insulated screwdriver you may witness the joint sparking as you tap it. It was a method I used to repair a bose eq once, I just could not find this fault, it would just fizzle out, cracked soldered joint, I went straight to it, still working to this day.

Posted by Alan Rik (Member # 73) on July 23, 2017, 09:08 AM:

Thats a pretty cool tip Paul. I'm working on a Sankyo Projector with a motor problem. I'll try your suggestion!

I guess part of being in this hobby is being resourceful which we all seem to be!

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2