This is topic Attn Leon Norris or anybody else TRV Problem in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=013086

Posted by Jim Schrader (Member # 9) on July 30, 2019, 11:13 AM:

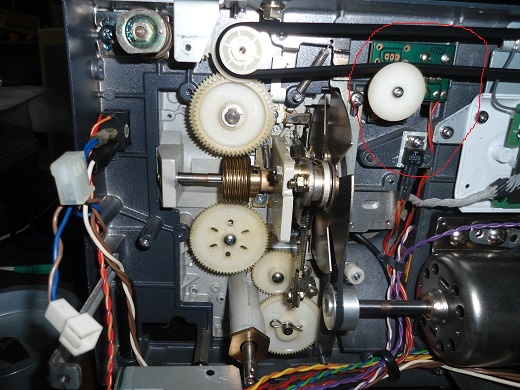

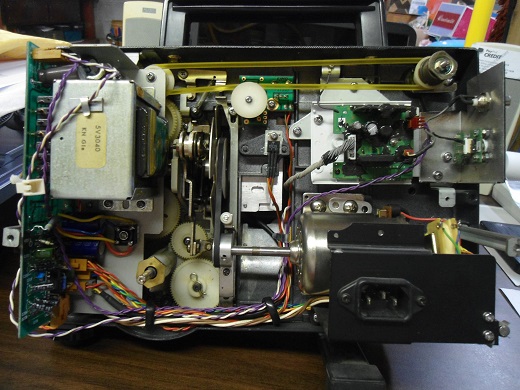

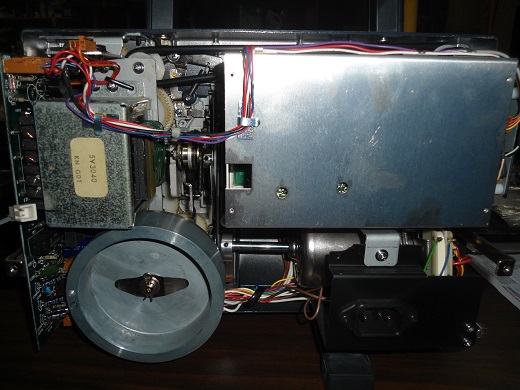

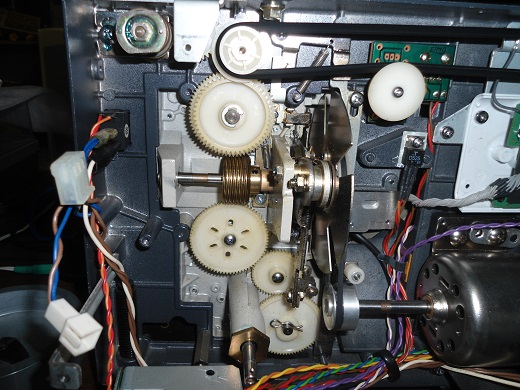

Here are the pics you requested the first 3 are of the rebuilt unit the next 3 are of a stock trv

Posted by Leon Norris (Member # 3151) on July 30, 2019, 12:05 PM:

I see the nice pictures you posted! Know which machine is the bad one ? Also when you disconnect the connector does the motor stop running? Let me know! Leon.

Posted by Jim Schrader (Member # 9) on July 30, 2019, 07:00 PM:

Both machines run slow the top 3 are of the rebuilt machine what do I disconnect?

Posted by Leon Norris (Member # 3151) on July 31, 2019, 10:11 AM:

Jim, turn on machine let it run then unhook the connector to see which one makes the motor stop running! Then send me a picture of the one connector that made it stop running! Thanks, Leon.

Posted by Jim Schrader (Member # 9) on August 01, 2019, 12:19 PM:

Leon is this safe Iím not going to wreck something or getted zapped am I ?

[ August 01, 2019, 03:20 PM: Message edited by: Jim Schrader ]

Posted by Leon Norris (Member # 3151) on August 01, 2019, 01:40 PM:

I need to know which connector runs the motor? Let me know! Thanks!

Posted by Jim Schrader (Member # 9) on August 01, 2019, 03:30 PM:

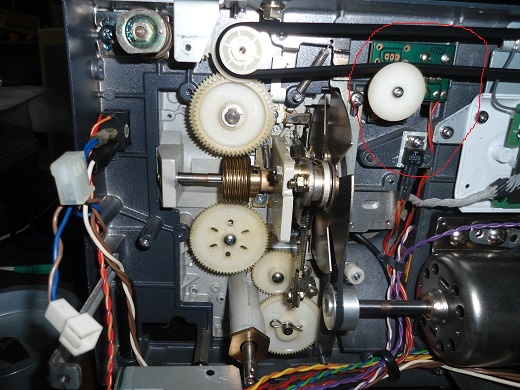

Leon the connector circled in red is the one that stopped the motor and following the wires it goes right to it.

Posted by Leon Norris (Member # 3151) on August 09, 2019, 11:39 AM:

Jim, your going to have to trace what components run to the connector! Does any thing look burnt out? Check the wires also! Let me know!

Posted by Jim Schrader (Member # 9) on August 14, 2019, 04:25 PM:

Ok not seeing anything that looks like itís burnt

Anybody else the unit is not running steady one can hear it while itís playing and the sound is warped.

https://youtu.be/g-NFztvLPFY

https://youtu.be/_txnaFuBWu4

https://youtu.be/QzRAwVv1UEQ

I have added some you tube clips for others to chime in on getting lots of answers as to what it can be why not add a few more

[ August 14, 2019, 06:33 PM: Message edited by: Jim Schrader ]

Posted by Brian Fretwell (Member # 4302) on August 15, 2019, 02:36 AM:

Could it be trouble with the flywheel bearings? That would give wow on the sound and variable load on the transport.

Posted by Jim Schrader (Member # 9) on August 15, 2019, 10:05 AM:

Brian, your the second person to mention the flywheel how would one know the bearings are bad?

Posted by Brian Fretwell (Member # 4302) on August 15, 2019, 10:15 AM:

Noise from them or it stopping quickly after a film has gone through (it should keep turning for a minute or two) are a couple of signs.

Posted by Phil Murat (Member # 5148) on August 15, 2019, 12:12 PM:

Hi Jim,

I suggest you as an initial evaluation to check Rubber pinch roller efficiency (Quality of rubber, roundness, cleaness, Roller Bracket Return Spring , etc..) :

I see film swinging a lot next to rocker arm (3rd Video), I don't think this is normal.

A Capstan roller bearing(s) failure is very rare, however there are easy to check :

- Remove flyweel

- Launch with fingers Capstan shaft, it has to run (a few second) smoothly WITHOUT any play (AXIAL/RADIAL), no "crunchy" noise, no "hard" point (Lubricate as necessary with thin oil spray (with little pipe)

let us know

Posted by Jim Schrader (Member # 9) on August 15, 2019, 06:58 PM:

Brian, your the second person to mention the flywheel how would one know the bearings are bad?

Posted by Jim Schrader (Member # 9) on August 16, 2019, 08:43 AM:

Phil checked all the above the pinch rollers are in good health the fly wheel came off next and that rolls smoothly as a matter of fact the film I ran before I took it off the flywheel was still turning when I took the back off.

I have 2 of these units I took the other fly wheel off and noticed that that shaft has the slightest warble on it whereas the unit were talking about has none and that machine does not have this issue I'm swapping out fly wheels to see if that makes a difference.

[ August 16, 2019, 09:15 PM: Message edited by: Jim Schrader ]

Posted by Phil Murat (Member # 5148) on August 17, 2019, 05:02 AM:

Thanks for these informations Jim.

Providing there is room enough around Capstan on this machine, it could be interesting to make a sliding test with a S8 stock lenght inserted between capstan and pinch roller only , when machine is in playing mode.

The S8 lenght will not be drove by claw and sprockets for this test.

When you pull S8 portion with fingers at an equivalent operating speed, driving only capstan shaft (and pinch roller), they have to spin steadily and film come without sliding on capstan.

Do not use a S8 portion which has been treated with silicon !!

Before test, insure perfect cleanliness of Capstan tip, rubber roller, free of any deposit and silicon evidences....

I use "F" Thinner to clean these parts (Same thinner used to clean clothes).

FLYWHEEL Installation : Insure that Capstan shaft can not slide easily on flywheel journal when installed. If this is the case, check spacers and Spring Lug for proper fitting.

Let us know

Posted by Dominique De Bast (Member # 3798) on August 17, 2019, 05:28 AM:

Phil, if you're refering to "essence F", it may be sold only in France under that denomination. I was advised by some French enthusiasts to use "essence C" to clean films (before stripping since it removes the grease) but couldn't find that product in Belgium. So I bought a bottle in Paris (I would have prefered champagne, though).

Posted by Phil Murat (Member # 5148) on August 17, 2019, 08:10 AM:

Hello Dominique,

You're right.

At this time , I have not find "C" fuel but I remember it was common in the past. It can also be mixed with some drops of silicon oil to lubricate films.

It is necessary to vent room and use vinyl glothes too.

A good "Champ" , of course, is better for health ! ![[Wink]](wink.gif)

Posted by Dominique De Bast (Member # 3798) on August 17, 2019, 08:34 AM:

Essence C is still sold but not dispayed on the shelves. They have to stock it separately so you must ask a seller (I sent in a small shop).

Champagne is never hidden 😀

Posted by Paul Browning (Member # 2715) on August 17, 2019, 02:18 PM:

If it was a tape machine I would look toward the rubber roller and capstan drive, because it sounds like something is slipping on the approach to the sound heads. Do you clean your films with any kind of cleaner, as this maybe the cause, this could be coating the rubber bits making them slippy.... check all the rollers in the film path, should look black with a slight sheen....

Posted by Jim Schrader (Member # 9) on August 18, 2019, 08:48 AM:

Thanks Paul unless the film has been treated by the previous owner I usually do not clean them I usually run the film on a pair of rewinds with my forefinger and thumb as its passing through to see it it leaves any residue behind.

[ August 18, 2019, 03:08 PM: Message edited by: Jim Schrader ]

Posted by Leon Norris (Member # 3151) on August 18, 2019, 09:46 AM:

Jim you say it runs slow? Well its either the motor or the governor board! Now how does it run with no film in it! Do you hear a change in motor speed? If you don't then its the board! Please check!

Posted by Jim Schrader (Member # 9) on August 19, 2019, 10:28 AM:

Phil the unit ran with a 50 ft sound practice reel just through the sound head then through the rollers no variation though upon rewinding this I could hear the variation slightly.

Then ran another longer film the same way an saw the rocker arm bouncing a bit not as bad as the video.

Leon, I ran the unit both in pre-load position and lamp mode for 5 minutes each and heard a slight variation while in lamp mode several different times.

Posted by Leon Norris (Member # 3151) on August 19, 2019, 01:10 PM:

Jim, Does it do the same thing when you take the motor belt off? Do you hear a change in the motor? Let me know!

Posted by Phil Murat (Member # 5148) on August 20, 2019, 06:08 AM:

Thanks Jim for these informations.

At this time , based on your informations, we can consider that the Capstan section is satisfactory for the essential.

Reviewing Your video Nr3, we can see a slight speed fluctuation which can be initiated by a faulty electronical regulation (if it exists....)

This machine is pretty "advanced" and looks to offer many Electronic circuits.

There is a high probability that Main motor speed is regulated throughout a control card :

I suggest you to check if an Infra-red (and an Half "Moon" blade) sensor is installed next to Claw shaft (probably hidden behind big transformer on left)

If yes, check sensor cleanliness and also , as necessary, its connector condition.

Let us know.

Posted by Jim Schrader (Member # 9) on August 20, 2019, 10:50 AM:

Leon, the motor hums very quietly no difference in sound variation, keep in mind this was rebuilt earlier this year.

Phil, not seeing what you described as a half moon blade here is behind the transformer if you see it please open it up in paint circle it and repost it or email me. Someone else told me to check the gears bbehind there too all look good.

Posted by Phil Murat (Member # 5148) on August 20, 2019, 11:52 PM:

You are right Jim , there's no (abvious) sensor observed in this area.

-Could you report how many wires are coming to Main Motor (and wires colors too) ?

-Concerning the small rocker arm (Which is swingging in Video Nr3), is this rocker arm linked to an electrical device ?

Posted by Jim Schrader (Member # 9) on August 21, 2019, 07:27 AM:

Phil the "swinging arm" is not linked to anything electrical its just attached to a small spring that gives it flexibility.

Posted by Phil Murat (Member # 5148) on August 23, 2019, 02:00 AM:

Jim, according to Van Eck description, this machine is showing an "electronically governed DC magnetic motor".

We know now that there is no sensor on the claw shaft.

Logically, you could find something fitted at the end of the motor :

- an Infra red sensor (with a coding wheel)

or

- a Tacho generator

(In any cases , logically you could also find 4 wires coming to the motor.)

Did you replace motor belt ?

If yes, did you install a genuine belt ?

If yes, is it a reinforced micro "V" belt (like elmo GS1200) ?

Here is Van Eck explanations concerning "GS1200" typical Belt grade :

"New belt, replacing your broken or stretched belt:

The motor belt is a quality belt for Elmo GS-1200 (all versions). Brand product of current production. Given specifically for Elmo GS-1200 projectors from us in order, highest durability. Belt of rugged polyurethane with embedded special fiberglass-tension cords. We recommend the use of this particular form of V-belts, because here only the geometry to 100% corresponds to what Elmo has provided for these devices."

In summary, this means that installing this belt grade will improve speed steadiness too.

Posted by Jim Schrader (Member # 9) on August 23, 2019, 06:42 AM:

Phil this is what was on there when I changed it to the square belt still have to get back on the color of wires and how many.

[ August 23, 2019, 10:55 AM: Message edited by: Jim Schrader ]

Posted by Phil Murat (Member # 5148) on August 23, 2019, 08:49 AM:

Ah, Ok Jim, I understand a tipical "V" belt was installed on this machine.If you kept it, l suggest you to re install it if it is serviceable yet (normaly this kind of belt is extra long life) and make new tests.

Let us know

Posted by Leon Norris (Member # 3151) on August 23, 2019, 10:11 AM:

Try replacing the v belt! Like the GS1200 belt! That belt does not stretch! Do that and test it!

Posted by Phil Murat (Member # 5148) on August 23, 2019, 10:31 AM:

hello Leon,

Do you know what are Elmo machines fitted with plyurthane "V" belt at the origin ?

These belts insure a very good transmission for a long !

May be the Gs 1200 ref can fit with other ones ....

Posted by Jim Schrader (Member # 9) on August 23, 2019, 10:56 AM:

I did keep it will put it back on not sure how old it is.

Posted by Mathew James (Member # 4581) on August 23, 2019, 12:08 PM:

i recently watch a video, and forget where i saw it now.... and the fella restored his belts by boiling them in water in the microwave. It was a belt for a cassette deck that was stretched, it gave me the idea that one might be able to do the same for super 8 belts that are not gone to black goop but are simply stretched.

...don't try this yet jim until we learn more, but i thought i'd throw the idea out there in case anyone knows what i mean...

btw- i think this is a belt problem as well. i have seen this if i don't use the square belt on one of my elmos...

Posted by Jim Schrader (Member # 9) on August 23, 2019, 08:17 PM:

All the trouble began with the v belt on thatS why I changed it out so changing it back wouldnt help I think.

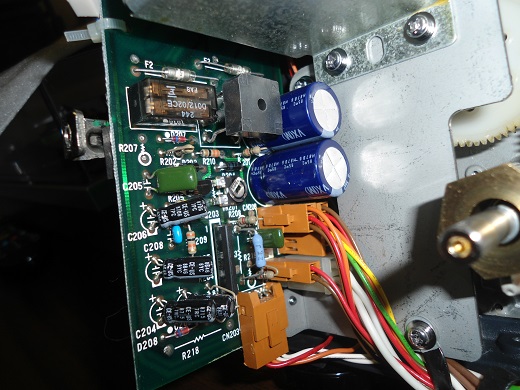

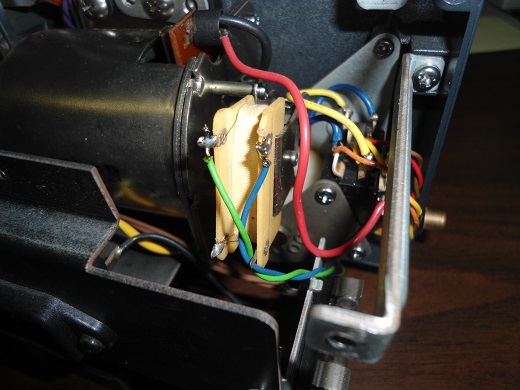

Phil here is some pictures of the wires going to the motor

Posted by Phil Murat (Member # 5148) on August 24, 2019, 05:41 AM:

Thanks Jim for your pictures.

At a first sight , I only see 2 wires (RED/Black) comming from motor.

May be there are others hidden, I don't know.

I suggest you to perform cleaning of speed potentiometer and toggle switch (16 / 25), connectors as necessary, installed on a small circuit behind upper belt.

Try to use a very powerfull contact cleaner (Cleaner & Lube fluid, spray gun).

You can soak and actuate them in a same time.

As the small circuit is removed, take the opportunity to make a closed inspection of its solderings and tracks (magnifier x10).

It should be interesting to get a schematic & WD for this machine.

Let us know

Posted by Leon Norris (Member # 3151) on August 24, 2019, 09:30 AM:

Jim, take off the motor generator and clean it! It will act up if dirty or going bad! The motor generator is on the motor! It has two wires soldered to it! Clean with contact cleaner!

Posted by Jim Schrader (Member # 9) on August 25, 2019, 08:44 AM:

Leon, where about is the motor generator what color wires go to it from the pictures?

Phil, is the speed potentiometer and toggle switch (16 / 25), connectors in the area i circled?

Posted by Phil Murat (Member # 5148) on August 25, 2019, 08:53 AM:

Yes Jim, normaly this is the "speed adjustment" knob board.

Posted by Leon Norris (Member # 3151) on August 25, 2019, 09:10 AM:

Jim its on the rear end of the motor! The front end has the pulley on it! Has two wires soldered to it!

Posted by Jim Schrader (Member # 9) on September 05, 2019, 12:10 PM:

Phil took parts off to clean but donít have a magnifying to check connections just eyed them.

Posted by Leon Norris (Member # 3151) on September 05, 2019, 12:46 PM:

Jim, did you check the motor generator? Let me know!

Posted by Jim Schrader (Member # 9) on September 05, 2019, 01:42 PM:

Leon Not yet, will check it soon and no film yet.

Posted by Leon Norris (Member # 3151) on September 05, 2019, 02:02 PM:

Keep me updated Jim!

Posted by Janice Glesser (Member # 2758) on September 05, 2019, 06:17 PM:

Just an observation guys....Why is this thread in the General Yak Forum? It is definitely related to 8mm projector repair so I suggest it should belong in the 8mm Forum.

[ September 05, 2019, 08:12 PM: Message edited by: Janice Glesser ]

Posted by Douglas Meltzer (Member # 28) on September 09, 2019, 03:03 PM:

Janice,

I agree. The thread has been moved.

Doug

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Wink]](wink.gif)