This is topic Dehydrated Film in forum 16mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=5;t=000970

Posted by Bryon Fields Harrington Jr. (Member # 3210) on August 30, 2013, 11:38 AM:

Hello,

I transfer 16mm film with the Elmo TRV-16 and someone has brought me some "Dehydrated" film that is really brittle and curled. I have also seen the term "sprider webbing" which refers to the shape of the film and the white powder that comes off the film due to bad temperature/humidity conditions that the film was stored in.

Is there any method I can take to repair this film? I have seen some film to dvd companies online using a "film-o-sizing" method that restores the film to it's normal condition.

thank you

fields

Posted by Mark Todd (Member # 96) on August 30, 2013, 12:07 PM:

The only thing on the market nowadays, I`ve found to help on dried film and bring it back a bit etc is Filmgaurd.

Worth a try. Maybe someone your way could mail a smallish amount to try. Or its fairly affordable stateside.

Good luck.

Mark.

Posted by Michael O'Regan (Member # 938) on August 30, 2013, 12:43 PM:

My experience has been that Filmrenew is better for this situation - available from Larry Urbanski over there in the US.

Isn't Filmguard more for cleaning and lubrication?

Posted by Douglas Meltzer (Member # 28) on August 30, 2013, 01:15 PM:

I would think that a brittle print would need to be lubricated.

Bryon,

Is there a vinegar smell to the film?

Doug

Posted by Michael O'Regan (Member # 938) on August 30, 2013, 01:26 PM:

It certainly would need to be lubricated, Doug.

However lubricating the print will not cure any warping or curling in my experience.

However, I'll stand corrected if anyone has more experience in this matter.

Posted by Douglas Meltzer (Member # 28) on August 30, 2013, 01:49 PM:

Michael,

A tight reverse wind after applying might help. I've used FilmRenew for VS prints which is why I asked Bryon about the smell.

This print might need to sit in FilmRenew for a few days and then get an application of FilmGuard.

Doug

Posted by Vidar Olavesen (Member # 3354) on August 30, 2013, 01:53 PM:

Are you saying vinegar smell can be cured with a bath? Thought they were gone when it first gets the syndrome

If that's the case, I will reconsider throwing a short 16mm Western Feud

Posted by Michael O'Regan (Member # 938) on August 30, 2013, 01:59 PM:

quote:

A tight reverse wind after applying might help.

Quite right.

I've also had success which amazed me a few years back with a product called Liquid Film Plasticiser, manufactured by Peter Goed.

I had a couple prints which didn't have any vinegar smell but were warped to the point that they would not take up at all without severe sagging. Following the procedure described by Pete, the prints wound, and continue to wind, tightly.

Pete also reported "fixing" of prints with actual VS with this product, though I have no direct experience with that.

Posted by Douglas Meltzer (Member # 28) on August 30, 2013, 02:01 PM:

Vidar,

I've never seen anything cure VS, but if you're trying to screen a warped print or slow done the process these products (along with molecular sieves) can help.

Doug

Posted by Vidar Olavesen (Member # 3354) on August 30, 2013, 02:08 PM:

Ah, okay ... Then I guess it's lost cause ... only a short 7-8 minute (was my first ever 16mm, so for that reason I would want to keep it, but scared of what it will do to my other prints)

Thanks

Posted by Michael O'Regan (Member # 938) on August 30, 2013, 02:19 PM:

If it was a cherished print, Vidar, I would just keep it apart from my other prints. If the print is of no real interest, then I would probably chuck it.

As Doug says, there isn't a cure for VS.

Posted by Robert Crewdson (Member # 3790) on August 30, 2013, 02:22 PM:

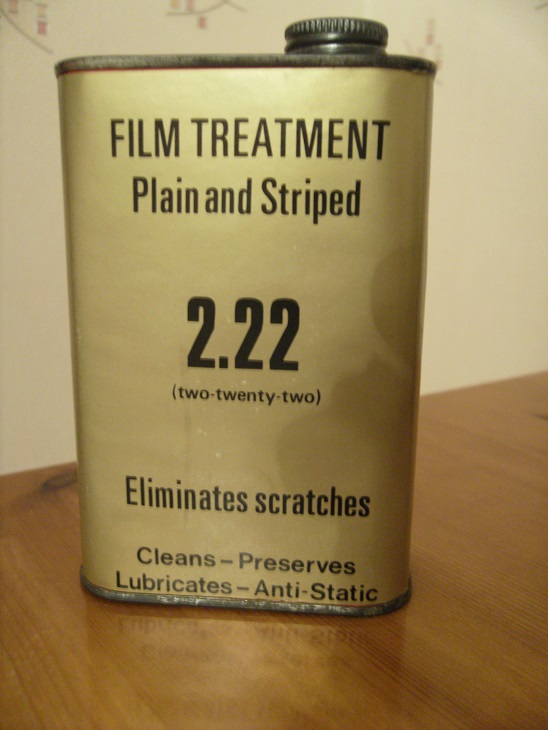

Michael, I am still using a 30 odd year old tin of 2.22, which sadly won't last much longer. I had a film from 1929 that was warped, especially where there was a cement splice, I was worried that it wouldn't go through the projector so gave it several coatings of this lubricant and left it several months. The film has still some shape to it, but at least it was flexible and projected ok. I was using a manual threader, I haven't tried it in an auto threader.

The other case concerns an amateur film I bought; a splice broke and I panicked in the dark. I don't know what happened, but the film bunched up like a concertina. I rejoined the film using tape, and gave it a liberal coating of 2.22, then I tightly rewound the film and left it for 3 weeks. When I checked the film, I was only able to find the spot by looking for the tape; the film was completely flat, and no one would know there had ever been an incident.

Posted by Michael O'Regan (Member # 938) on August 30, 2013, 02:25 PM:

I'm not at all familiar with 2.22, Robert.

Who manufactured this?

Posted by Robert Crewdson (Member # 3790) on August 30, 2013, 03:01 PM:

It was made by a company called Kanus Chemicals in Crawley, Sussex. It was a one off treatment, and the company used to sell a solvent if you wanted to remove it for any reason. I was wondering whether I should get a sample analysed before it runs out, although I suppose it would be costly to get it made up. From what I could find out Kanus Chemicals was a one man operation and he took the secret of it to the grave when he died.

I often forget that a lot of members will be much younger than me, and I probably have bulbs that I bought new for my Eumig that are older than some members.

Posted by Allan Broadfield (Member # 2298) on August 31, 2013, 05:31 AM:

I well remember the 2.22 fluid.It acted in a similar way to wet gate priting, filling in surface scratches and also acted as a lubricant.

As regards the buckling of film stock, the labs often had to 're-dimension' buckled and shrunken stock ready for making prints. These would go into an airtight steam cleaner for several hours, then a print would be taken from it before it returned to it's previous state.

[ September 02, 2013, 12:23 PM: Message edited by: Allan Broadfield ]

Posted by Jon Byler (Member # 3933) on September 19, 2013, 02:48 PM:

yes, you should have the 2.22 analyzed! I was just thinking I should ask someone for a sample of it, to see if we could figure out what is in it. Maybe you have a local uni with a chem department who needs a problem for one of their grad students to solve? or maybe someone on this forum knows a film buff who is also a chemist or materials engineer?

We may not be able to get the exact composition, but one might come close. do it for the children and those of us who don't have any of this miracle stuff.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2