|

Author

|

Topic: Review Wolverine Reels2Digital MovieMaker 8mm film digitizer

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Stan Jelavic

Master Film Handler

Posts: 314

From: Fort Lauderdale, FL, USA

Registered: Jan 2019

|

posted November 29, 2019 08:50 AM

posted November 29, 2019 08:50 AM

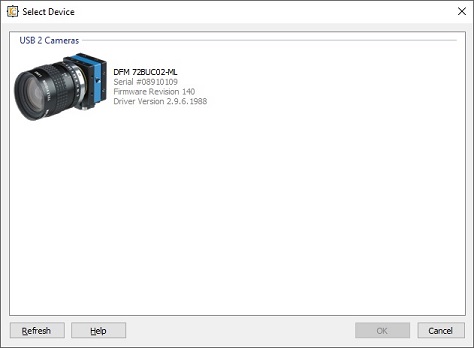

I will forward your input to the imagingsource engineer, Bob. May be a faulty camera.

HERE IS LATEST UPDATE ON JITTER:

Did a test with no takeup tension, pulsed tension, and continuous tension. Found out that the jitter is significant in all three cases. Studying the claw operation found out that the gate cover is inserting quite a bit of force on the film. On some film the claw is not perfectly aligned and it hits the film and then engages the hole. Extra tension does not help that and could cause jitter.

So, I applied teh Wolverine fix for wide film:

https://www.wolverinedata.com/assets/downloads/Wider_Film_test.pdf

https://photos.app.goo.gl/1u9hygTttNQCSsZH9

That almost eliminated all jitter even with the standard Wolverine it is almost gone.

Here is the test:

https://photos.app.goo.gl/ywUfD9mK4XAgroUe9

Try using different number paper pieces. It also may be possible that the cover is too loose in which case you have to adjust the cover screws.

So, looks like this should fix the jitter issue and capstan should work as is - no changes except for capstan connector.

HAWKEYE RUNNING 1 FPS

Running 1 FPS. Tested JPEG for now. Will check BMP and TIFF later.

https://photos.app.goo.gl/LLSnMuAigquTyhaU9

And the resulting video:

https://photos.app.goo.gl/zc3Wpkoxf9oka7ba9

TIFFs also work ![[Smile]](smile.gif)

https://photos.app.goo.gl/YUqeojzQKLw7HENF6

Set slow frame rate in Virtual Dub...

One issue - capstan code is disabled because MSP cannot keep up.. will have to test.

Also possible 2 FPS I think... will need some more work.

[ November 29, 2019, 02:29 PM: Message edited by: Stan Jelavic ]

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

David Brown

Film Handler

Posts: 42

From: Centerville, UT, USA

Registered: Oct 2019

|

posted December 01, 2019 01:32 PM

posted December 01, 2019 01:32 PM

5 things that cause film capture to jitter.

1. There is inherently some jitter with film.

Here is a recent super8, shot in October this year. If you buy Kodak super8 today it is processed and scanned by Kodak.

"iceland on SUPER 8

2. Slow SD card. This a streaming problem, single frame captures would show up differntly. Not sure what would happen if the capture rate exceeds the save rate?

3. Torn sprocket holes, when not completly torn through.

capture the film backwards, the top of the sprocket hole will be intact. This also can help reduce the severity of deep scratches that are reflecting light. This is more of a problem with the light source. The Wolverine's light should be very difuse, the light source is at the end of the panel, not directly under it.

4.The width of the film. I never heard of this issue before the Wolverine! The paper in the door clearly works as Stan's test shows. Wolverinedata says to fold the paper 4 times. That is too much, I can't even close the gate. I don't know why this method works, the gate seems to be made of one piece. I'm not going to verify that!

5. Gate pressure is too tight. I'm still looking for more information on that. I expect extra thickness with Super8 sound. Splices should not matter inside the gate.

Changing gate pressure might be too hard for many. I have just completely dismantled the Wolverne and while there, I will be playing with gate pressure.

Has anyone adjusted the 3 pressure screws?

Mike, did you do this?

From October: There are two screws that can be unscrewed half a turn, to increase the downward pressure on the film in the gate.

Since I'm suggesting capturing backwards, Here is The best editors of 2019. Free versions in the first 7 minutes.

Primal Video-Best editors

| IP: Logged

|

|

|

|

|

|

|

UBBFriend: Email this page to someone!

UBBFriend: Email this page to someone!

Printer-friendly view of this topic

Printer-friendly view of this topic

![[Wink]](wink.gif)

![[Smile]](smile.gif)