|

Author

|

Topic: Elmo GS1200 Scratch parts

|

|

|

Phil Murat

Jedi Master Film Handler

Posts: 671

From: Villeneuve St Georges, France

Registered: Dec 2015

|

posted January 17, 2019 10:26 AM

posted January 17, 2019 10:26 AM

Hello Paul,

Immediately, I have not any very good drawing to show concerning the Upper Guides modification/conversion.

At this time, I am looking for a drawing software simple and easy to use and which can offer 3D features as well.

When I learned Engineering at school (40 years ago), drawings were hand-made using "Rotrings" with black (or red) ink.

Concerning DLC Anti-friction coating claw itself is not included in the project as claw wearing only depends on the way it works. If general film pull down load can be decreased upon treatment , all the chain claw plus cams will get an increased life :

- Claw plus Cams ==> Increased life*

- Main motor ==> A bit more power available for extras

- Film ==> less wears evidences, less stress for notches

- Main Film frame guides ==> increased life

- Increased smoothness operation

* According to Beaulieu 708 Service guide, the Pull-down spring is rated to 500 gr (This is a lot).

I assume the pull-down spring can be derated up to 250Gr.

Important : Beaulieu Cams are Nylon material and need to be properly lubricated (claw bearing too !!)

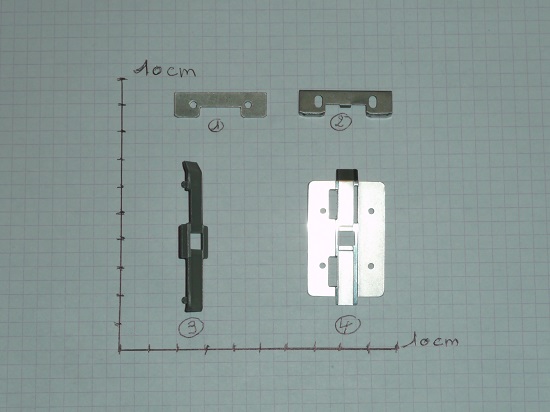

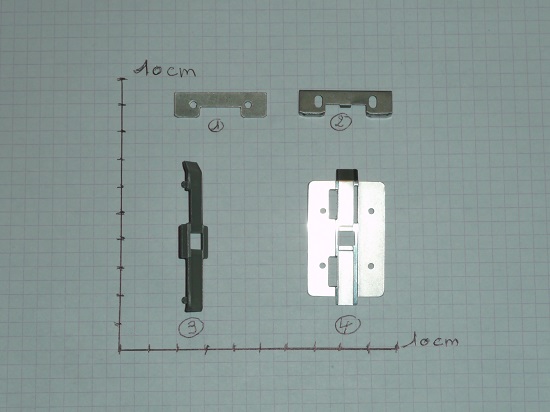

Guides to be coated :

NB

Paul, do you have any link(s) about Cubic Zirconia coating ?

| IP: Logged

|

|

Paul Browning

Phenomenal Film Handler

Posts: 1006

From: West Midlands United Kingdom

Registered: Aug 2011

|

posted January 17, 2019 11:23 AM

posted January 17, 2019 11:23 AM

Hi Phil, this not a coating, its a material fired like a ceramic pot at very high temperatures. It can be machined but you need a machining centre or cnc machine to do this because of the high spindle speed needed for the tungsten carbide cutting burrs. It would be ideal for a fit and forget part, certainly no film medium would wear it out, and you can get a diamond sparkle finish, so les resistance to wear, and its resistant to all liquids that you would use on film. Its main use is sushi kichen knives, I think the Japanese chefs discovered its ideal for this as it does not loose its edge, and I can vouch for that sharpness on a few occasions. Its incredibly stable in high temp situations, so again ideal for a film gate /aperture, where intense heat would affect normal ferrous materials.

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

UBBFriend: Email this page to someone!

UBBFriend: Email this page to someone!

Printer-friendly view of this topic

Printer-friendly view of this topic

![[Roll Eyes]](rolleyes.gif)