This is topic GS1200 Has Passed The Test in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=003492

Posted by Graham Ritchie (Member # 559) on February 25, 2008, 02:15 PM:

Well it has been just over 5 months since the projector was converted to a two bladed shutter and the ELC Osram Xenophot 250 watt with an external power supply, the coversions have really worked out very well, a huge improvement to how things were a year ago, also with fine tuning of the apature plate, lens holder alinement "minimum pressure on the film" changing the recording capacitor top guide replacements fixing the rewind/take up motors and the auto thread, the projector is now running like a swiss watch, ![[Big Grin]](biggrin.gif) the GS1200 is a very capable machine upgrading with excellent results, as long as those motor brushes and commutator's don't wear out to quickly the projector should have quite a few more years left in it.

the GS1200 is a very capable machine upgrading with excellent results, as long as those motor brushes and commutator's don't wear out to quickly the projector should have quite a few more years left in it.

Graham. ![[Smile]](smile.gif)

Posted by Paul Adsett (Member # 25) on February 25, 2008, 05:30 PM:

Hi Graham,

Glad your GS is performing so well. Could you please explain in more detail exacty what your " minimum pressure' and aperture adjustments were, and how you carried them out.

Posted by Graham Ritchie (Member # 559) on February 25, 2008, 09:56 PM:

Paul

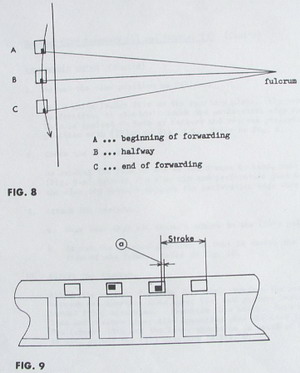

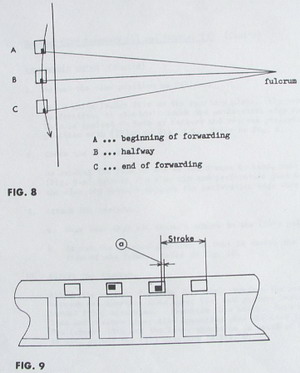

Regarding the fixed apeture plate which is held in place with the four screws I found that with very slight re-positioning in relation to the claw and using some white leader in the gate as a test "lens holder open" and a strong magnifying glass I checked and adjusted for the exact edge clearance of the claw to the films perforations ie. how the claw engages the film at the top until it retracts at the bottom this is shown in the Service Manual, machine frame section Fig 8 and 9 because the claw works in a arc, any contact between the claw and the edge of the perforation will not only damage the sprocket hole but will cause side movement, my thinking was, that the claw must only ever make contact with the bottom of the perforation during its travel although there are other adjustments one can make as well eg the vertical post "2 screws" but that adjustment also effects the position of the film "on screen "in the apeture and the edge spring pressure on the film.

I also found in relation with lens holder and the spring pressure Fig 14 that by adjusting the lens holder assy "2 screws" away from apeture plate and then re-adjusting the stop screw this in turn reduced the spring pressure on the pressure plate, as long as there is enough pressure to keep the film flat but also giving it the least resistance as it moves through the gate, what I found after all this ![[Roll Eyes]](rolleyes.gif) is that the film now runs through the gate without any strain and as smoothly as possible with both the focus and picture looking good.

is that the film now runs through the gate without any strain and as smoothly as possible with both the focus and picture looking good.

The problem with the GS1200 is that many of the screw holes are larger than the diameter of the screws themselves which means things might not be as aligned as they should be. I think once the projector is properly set up thats it for life {hopefully}

Graham. ![[Smile]](smile.gif)

Posted by Kevin Faulkner (Member # 6) on February 26, 2008, 08:54 AM:

Adjustments in this area should only really be done with std SMPTE test film where the exact dimensions are guaranteed.

Yes you can use leader but make sure it is dead on 8mm and the perfs are in the correct position otherwise if you now play a film which is under or over width you may have problems.

The procedure you used is not really the correct one for claw position etc. This should be carried out by adjusting the claw mechanism in the rear of the machine.

I wouldn't recommend this as a general procedure for others to take on.

Kev.

Posted by Mark Todd (Member # 96) on February 26, 2008, 09:35 AM:

Hi Kev, can you check your ditch box as I think I`m in there.I`ll try again.

Best Mark.

Posted by Graham Ritchie (Member # 559) on February 26, 2008, 01:53 PM:

Hi Kev

Thanks I did not realize there was an adjustment that could move the claw left or right, had a close look at the manual and there it is {15}2 in Fig 7-C. ![[Roll Eyes]](rolleyes.gif) I thought at the time that there was no adjustment due to the claw itself being held in the cam, thanks again Kev so folks dont do what I did.

I thought at the time that there was no adjustment due to the claw itself being held in the cam, thanks again Kev so folks dont do what I did.

Graham. ![[Smile]](smile.gif)

Posted by Kevin Faulkner (Member # 6) on February 26, 2008, 04:45 PM:

As long as all is running ok I think you can say you got away with it. ![[Smile]](smile.gif) If however you get steadiness probs on some films it could be for the reasons stated earlier with over or under size film.

If however you get steadiness probs on some films it could be for the reasons stated earlier with over or under size film.

Kev.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Big Grin]](biggrin.gif) the GS1200 is a very capable machine upgrading with excellent results, as long as those motor brushes and commutator's don't wear out to quickly the projector should have quite a few more years left in it.

the GS1200 is a very capable machine upgrading with excellent results, as long as those motor brushes and commutator's don't wear out to quickly the projector should have quite a few more years left in it.![[Smile]](smile.gif)

![[Roll Eyes]](rolleyes.gif) is that the film now runs through the gate without any strain and as smoothly as possible with both the focus and picture looking good.

is that the film now runs through the gate without any strain and as smoothly as possible with both the focus and picture looking good.![[Smile]](smile.gif)

![[Roll Eyes]](rolleyes.gif) I thought at the time that there was no adjustment due to the claw itself being held in the cam, thanks again Kev so folks dont do what I did.

I thought at the time that there was no adjustment due to the claw itself being held in the cam, thanks again Kev so folks dont do what I did.![[Smile]](smile.gif)

![[Smile]](smile.gif) If however you get steadiness probs on some films it could be for the reasons stated earlier with over or under size film.

If however you get steadiness probs on some films it could be for the reasons stated earlier with over or under size film.