This is topic Plastic spindle for a Beaulieu 708EL take-up reel anyone? in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=005672

Posted by Rob Young. (Member # 131) on September 02, 2010, 09:33 AM:

Does anyone by an chance have or know where I can find a replacement for the plastic spindle which holds the take-up reel onto the Beaulieu 708EL?

I see Wittners still list a new set of 2 for sale but at over 110 Euros the cost is a bit steep! That's assuming they still actually have them.

These spindles are such a pain as the three plastic clips which hold the reel gradually break one by one! Grrr! The one that holds the take-up reel on my otherwise perfect Beaulieu has finally broken the last useful clip. ![[Frown]](frown.gif)

Posted by Rob Young. (Member # 131) on September 05, 2010, 12:47 PM:

Anyone? ![[Frown]](frown.gif)

Posted by Roy Neil (Member # 913) on September 06, 2010, 03:01 PM:

Wittner-Cinetec bought the entire inventory of Beaulieu parts, unless someone is manufacturing these parts or has an old parts machine to dissect then you better call Wittner.

Posted by Joerg Polzfusz (Member # 602) on September 07, 2010, 10:56 AM:

Hi,

have you tried Björn Andersson (Sweden) ( Bjorn dot andersson at brevet dot nu ), Klose (Germany) or Ritter (Germany)? I don't know if they're willing to sell their spare parts without getting your projector serviced by them, but I would give it a try... . There are also several German/Austrian 2nd-hand shop that sometimes sell spare parts without having them listed on their webpages, e.g. http://www.super8film.at/ or http://www.kinotechnikrinser.de/ .

Jörg

Posted by Ricky Daniels (Member # 95) on September 08, 2010, 05:58 AM:

Rob,

Here's a link to Witttners Beaulieu website and the page with the item you are looking for, just scroll down the page.

http://www.beaulieu.de/pages/s8_wzub1.php?rubr=s8_wzub1

Don't worry about the language barrier (if there is one) as you can order in English on the specific page and they are also very helpful if you telephone.

I recall they also used to have a metal version with a retaining clip for the spool but may have sold them, best to enquire.

From a once proud 708EL Stereo owner who turned Japanese ![[Wink]](wink.gif)

Best,

Rick

Posted by Martin Jones (Member # 1163) on September 08, 2010, 06:01 AM:

You don't sound Japanese, Rick!

Posted by Rob Young. (Member # 131) on September 09, 2010, 06:03 PM:

Thanks to all for your replies; I will follow them up and let you know how I get on...

bit reluctant to pay up £100 for two bits of ancient plastic parts...still if it is the only way to keep my Beaulieu going...

Posted by Alan Rik (Member # 73) on September 09, 2010, 09:38 PM:

If I had the metal locking spool clips for my Beaulieu 708EL I would have kept the machine. Every time I would play a 1200ft reel the reel would work themselves slowly off. I actually never had one come completely off but I was always pushing them back on. Not the best design.

Posted by Rob Young. (Member # 131) on June 21, 2011, 04:45 AM:

Thought I'd bring back this old thread with some happy news ![[Smile]](smile.gif)

I've finally fitted a new spindle! It was a gift for my 40th last month; my better half ordered it from Wittners and although it was VERY expensive, she tells me they were really helpful and great to deal with.

To be fair, it is a more elaborate part than I remembered, with it's micro ball-bearings and all! Although parts are pricey, I've realised just how glad I am that we can still at least get them (sadly no metal ones left, but never mind).

Anyway, while it was on the "work bench" I had a tinker with other bits and bobs that needed sorting and it is now up and running...and running like a dream.

I fitted a replacement Xenovaron lens about a year ago (courtesy of forum member Mark Todd - the original one literally fell apart) and although I'd tested it and knew it was a good one, the spindle broke shortly afterwards so sadly I didn't get a chance to use it for very long.

Well, now it's had a few films through it I can confirm that the lens is a beauty; super-sharp image with really rich colour. Cheers Mark!

The Beaulieu is just purring and everything I've shown in the last few weeks has just been perfection! I've been using my trusty ST1200HD for the last year and I'd forgotten just what a bright image the Beaulieu has; LOTS brighter than the Elmo despite using the same bulb.

I've plugged the sound through the big surround amp and the results are amazing; totally free of any wow and crystal clear, even tracks that can sound a bit muddy on the Elmo are sounding great.

So I'm one happy bunny! I've been going through loads of films that I haven't run in a while and the Beaulieu is giving them a new lease of life, I've owned it for about 10 years or so but I'd truly forgotten how great it can be when up and running properly.

What a fab projector ![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

Posted by Ricky Daniels (Member # 95) on October 05, 2011, 05:55 AM:

Anyone else need Beaulieu spindles?

http://www.ebay.co.uk/itm/Beaulieu-708-EL-Super-8-Projector-Reel-Spool-Holder-New-/350473486994?pt=UK_Photography_VintagePhotography_VintagePhotoAccessories&hash=item5199d90292#ht_ 784wt_1398

Posted by Lee Mannering (Member # 728) on October 05, 2011, 06:54 AM:

Sold

[ July 01, 2014, 02:51 PM: Message edited by: Lee Mannering ]

Posted by Maurice Leakey (Member # 916) on June 27, 2014, 11:11 AM:

Rob

The Wittner picture seems to show two separate spool spindles, but the wording says "1 stck" which translates as one piece. The eBay link refers to Wittner only supplying one for the price.

For €119 do we get one or two? And, are the front and rear spindles identical?

Posted by Rob Young. (Member # 131) on June 27, 2014, 01:27 PM:

Only one I'm afraid, Maurice.

I agree the picture is a little misleading.

Both feed and take-up spindles are the same.

At least we can still get them.

The new rear spindle is still going strong three years on...

Posted by Andrew Woodcock (Member # 3260) on June 27, 2014, 03:50 PM:

Mine is 4 months old and still going strong! ha ha

Seriously though, extortionate price but the machine itself is well worth spending the money on in my opinion to get back to A1.

At the end of the day, I was looking in a FFTC edition from 1997 and in it, on the front inside cover, was a brand new Beaulieu Stereo that you could buy back then for the princely sum of £2397

and by that time they didn't even come with a Schneider Lens.

The point I am making is that anything Beaulieu was never cheap, so I don't suppose we could ever expect parts to be, just as in the same way parts for a Silver Shadow now wouldn't be cheap either!

BTW:- as posted earlier, stick to their own spools or other high quality spools such as Elmo and they will last forever.

[ June 28, 2014, 09:24 AM: Message edited by: Andrew Woodcock ]

Posted by Maurice Leakey (Member # 916) on June 28, 2014, 02:18 AM:

I've translated the Wittner ad "New improved version with two ball-bearings."

How does this differ from the old spindle?

My take-up spindle only has two "springy" claws, the third is broken.

Should I invest? Is replacing the spindle easy?

Posted by Andrew Woodcock (Member # 3260) on June 28, 2014, 07:24 AM:

Very simple to fit,remove the outer coverplate for whichever arm you are dealing with, just two screws, then just one centre screw to remove and re-fit on the hub itself Maurice.(Obviously you will have to remove the toothed drive belt momentarily). It will give much improvement over the standard ones fitted to all machines except the Stereo models, especially when using 2300ft spools.

All original mono and duoplay models were originally just fitted with the basic hub which contained no bearings causing problems when using with large spools especially on rewinding.

Wittners now only sell the improved version with the bearings fitted (2 per hub)and as said, these were already fitted as standard to the Stereo models as a lot of the improvements were, ie 2/3 blade shutter, adjustable lamp holder etc etc.

Keep to using Beaulieu or Elmo spools for longer shows and you will never need replace again Maurice.

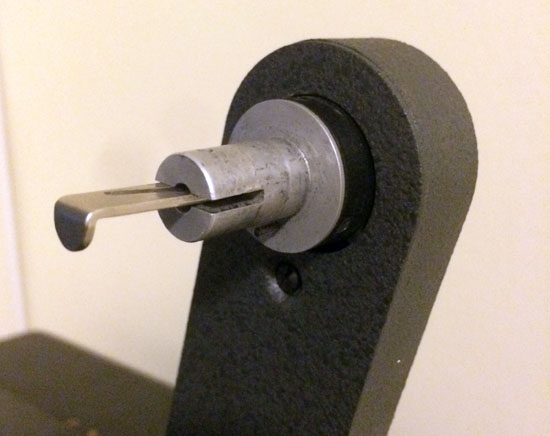

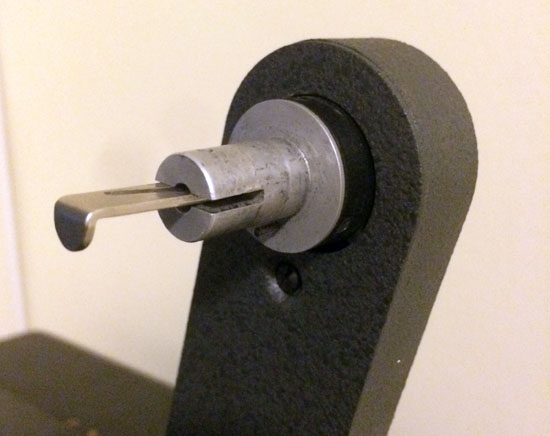

Lovely photograph earlier BTW Rob of this beautiful machine!

[ June 28, 2014, 10:03 AM: Message edited by: Andrew Woodcock ]

Posted by Maurice Leakey (Member # 916) on June 28, 2014, 10:26 AM:

That's just the point, neither 1200' Elmo nor 2200' Beaulieu spools will fit.

My 708EL came with an 800' Bonum spool which fits OK although a trifle tight. It was only when I bought two Beaulieu large spools that I discovered that they would not fit either front or rear. A close examination revealed the broken-off "springy" pin on the take-up.

I then checked the Elmo 1200' which didn't fit either!

I don't want to spend over £200 for two more spindles which will not accommodate my problem spools.

Does removal of the arm side cover reveal the fixing screw? I am used to Elf 16mm spindles which have a screw on the rear side which locates into the end of their spindles. My Beaulieu appears to have round blanking pieces on the reverse side.

Will the new replacement spindles accept all spools without trouble?

Are the ball-bearings used to retain the spools and do they replace the "springy" pieces?

Posted by Andrew Woodcock (Member # 3260) on June 28, 2014, 10:37 AM:

All your Elmo and Beaulieu reels will fit perfectly Maurice once you change out both hubs. I have no idea why they don't already apart from the fact some of your plastic leaf springs have snapped off. The reels should still fit on ok albeit they would be loose and prone to working there way off the hubs.

The screw that attaches the hub to the shaft is in the centre of the plastic hub as said previously. It is a very small screw, probably only M2 or M2.5. This is the only screw that retains the actual plastic hub with of course a plain washer fitted.

You only need to take the coverplate off to remove the toothed belt and then refit over the new hub which the rear part of the hub contains a built in plastic drive gear for the belt to slip over. Hope this helps, if not PM me your e mail address and I will send you some photo's to show the coverplate removed and the hub before fitting.

As ever I always photograph and document any work carried out on my machines so photo's are already there from a few months back when I did the changeout.

BTW the ball bearings fit into a bore on the inside of the plastic hub and then onto the stationary shaft which becomes exposed once the hub and screw are removed. They do not hold the reels on, nor can they be seen once fitted. Only the plastic leaf springs retain the reels but will not wear or break off again if you only ever fit larger quality reels.

Also, as I have said many times, these hubs will not accept ANY spools. In particular Taylor spools should be avoided. The ones that fit fine are Beaulieu, Elmo, Grasso (800ft or below), Bonum, Gepe, Sankyo etc etc. All of the type that have a solid core to their hubs are generally fine. I also dislike Fumeo reels as these have no solid core on their hubs either.

Posted by Maurice Leakey (Member # 916) on June 28, 2014, 11:02 AM:

Andrew/Rob

Did you have problems getting spools to fit on the shafts before fitting the replacement parts?

As I read it, some owners have had trouble with spools trying to fall off, my trouble is I can't get them on in the first place!

Posted by Andrew Woodcock (Member # 3260) on June 28, 2014, 02:14 PM:

No Maurice, never.

Posted by Maurice Leakey (Member # 916) on June 29, 2014, 02:49 AM:

Thank you, Andrew

It does seem strange that my spindles appear to be too big, also I wonder why Beaulieu inserted ball-bearings?

When I first read Wittner's ad I assumed the ball-bearings were in some way for retaining the spools.

We all know that heat makes plastic expand, viz, the Bell & Howell worm gear problem. Perhaps constant use over the years produced friction inside my spindles, friction means heat. Could it be that my spindles have expanded in some way?

I suppose the only answer is to invest in a couple of new spindles.

I paid £912.89 for my projector from Stephan Binder of Super 8 Film in Vienna, Austria. Now it seems I am going to have to spend more money.

Posted by Dominique De Bast (Member # 3798) on June 29, 2014, 03:02 AM:

Some British Super 8 metallic spools don't fit my projectors as the central hole is too small. It is a question of mm but I had to use a round file to fix it some years ago. I bought a film in UK that was also on a metallic spool that has the same problem (and of course, I cannot find my round file anymore, so I have to wait to see it reappear to watch the film). It is surprising for what is supposed to be standard sizes.

Posted by Rob Young. (Member # 131) on June 29, 2014, 03:16 AM:

No, I haven't had any trouble getting spools to fit with the old or new spindles either, Maurice.

I think it is generally acknowledged that these aren't the best design though, as they rely upon the plastic parts bending each time you put on or take off a spool, so there is always a chance that they will fail eventually.

Add to the fact that these machines are designed to take big, heavy spools as well and the logic behind Beaulieu's design becomes even more questionable.

There are a few examples of "quirky" design on these machines. They are such well designed projectors in so many ways and beautiful when up and running properly, but some parts you just have to look at and think, "why???"

Posted by Paul Browning (Member # 2715) on June 29, 2014, 06:10 AM:

I too have one of these projectors and despair at some parts fitted to it especially the back cover!!!!. I just wish it had the retaining clips the GS has, which are simple and work 100%.The clip on the beaulieu looks similar to that on any super 8 viewer editor, perhaps you could buy one cheaper than the clips and adapt them to do the same job, just a thought.

Posted by Alan Rik (Member # 73) on June 29, 2014, 07:54 AM:

I hated the plastic ones too...so because of this I sold the Beaulieu. But lo and behold I finally received my dream machine many, many years later, a Beaulieu HTI and this came with the upgraded metal clips. Now all reels fit AND they don't fall off. Too bad Wittner sold out of the clips. The Beaulieu is one of my favorite machines ever.

The cool thing about these clips which are better than the Elmo design is that once they are clipped down to prevent the reel from coming off they are then pushed to the rear of the machine which locks them into place. They are Locking reel clips. Cool!

Posted by Paul Browning (Member # 2715) on June 29, 2014, 10:57 AM:

Good design, but I've seen this on another machine and not the beaulieu you mention, but where and what was it?. I still think the GS is as good.

Posted by Andrew Woodcock (Member # 3260) on June 29, 2014, 02:09 PM:

whats the issue with the rear cover? Seems perfectly acceptable to me for what its purpose is?

Posted by Paul Browning (Member # 2715) on June 29, 2014, 03:49 PM:

It just don't look to be of the same quality as the rest of the machine, by comparison the GS 1200 got the balance just right for me. Its a personal thing, I guess, if I owned a Rolls Royce, I wouldn't expect the rocker covers to be plastic !!!. A great projector just let down by the quality details.

Posted by Andrew Woodcock (Member # 3260) on June 29, 2014, 03:56 PM:

steel covers resonate and cause added running noise to the machine. This type of plastic deadens the vibrations from the two bladed shutter etc and to that end, I feel it was the perfect design choice especially as both loudspeakers are mounted to it. The rear cover on my ST 1200 acts like another amplifier picking out every last sound from within the inside of the machine. I hate it. I have tried fitting various gaskets etc but still it resonates throughout. Give me soft durable plastic anyday.

[ June 30, 2014, 03:53 AM: Message edited by: Andrew Woodcock ]

Posted by Paul Browning (Member # 2715) on June 29, 2014, 04:23 PM:

I don't own an st1200 so I cannot comment on that machine, but I would say that my GS1200 is as quiet as the beaulieu, I have not noticed any added noise from the cover, given they both house a set of speakers, it just looks like the cover was made from recycled carrier bags. The rest of the machine is top notch and beautifully made where it matters.

Posted by Maurice Leakey (Member # 916) on June 30, 2014, 02:34 AM:

It seems that only Dominique and I have problems where some spools will not fit on their Beaulieu.

In my case only certain spools will fit and for some films I have to re-spool before they can be shown. I paid a lot for the special large Beaulieu spools which I can't use.

Therefore I have made a decision to buy some replacement spindles even at their excessive price. Members have said that they have no problems with their replacements.

I have found out why ball-bearings have now been added, the following is in the manual:

Drawing SAV/100/50/8 dated January 10, 1979 explains the modification.

SUBJECT: Adding of ball-bearing on take-up and feed reel shafts.

PURPOSE; a) to avoid seizing (binding) b) to eliminate friction

No comment on why the shafts won't accept all spools!

Posted by Andrew Woodcock (Member # 3260) on June 30, 2014, 03:00 AM:

I don't know what type of hubs are on your PJ Maurice, but rest assured the new ones will be fine so long as you only fit the spools I mentioned plus of course, Posso spools, which is what they came with originally.The fit is excellent when new on the Beaulieu or Elmo large reels.

The statement you have given explaining the mod to now include two ball bearings per hub, taken from the service manual, just confirms what I already told you, which is, to assist with the added load of the large heavy reels, especially during rewinding.

All will become very apparent once they arrive Maurice and they really are childsplay to fit. Half hour tops!

The reason not all spools fit these projectors is because not all spools were manufactured to the standard spindle diameter size for super 8mm projectors. Elmo spindles have a much smaller spindle diameter size than any other machine I have ever owned by around 0.5mm on average in diameter. This is the reason why almost any spool fits the Elmo machines, albeit quite sloppily for some reels. Ironically 1200ft Taylor reels fit the Elmo machines quite well as the bore fits snugly on the spindle.

All quality Reels with a solid bore appear to have a standard bore diameter that appears to be universal. Ones which are not solid eg Taylor reels tend to have varying bore sizes from one batch of reels to another. Maybe by only fractions of a mm, but this nevertheless, effects the fit of the reel on the hub.

Finally, just to add another factor into the equation, the Beaulieu hubs clamping mechanism (the bits that broke off yours) will only work as intended if the THICKNESS of the spool is standard, if they are only very slightly thicker in depth, the spools spring off. This is another reason why some reels simply do not work on these machines. All the ones that I have seen coming off my new hubs are cheap non branded reels, which have a very slightly thicker depth to them when measured.

Due to the amount of discussion and general dissatisfaction witnessed on here of the original plastic hubs offered by Wittners, not to mention the very high cost of obtaining a pair, I am seriously considering having a batch of improved ones made at a small local engineering shop similar to the metal improved ones fitted to the HTI model. I am certain they would cost little more than the originals and, whilst I am happy with my plastic ones, they would no doubt be popular to other owners out there judging by the amount of comment.

[ June 30, 2014, 04:08 AM: Message edited by: Andrew Woodcock ]

Posted by Maurice Leakey (Member # 916) on June 30, 2014, 10:13 AM:

Andrew

Many thanks for the detailed answer. My hubs look quite standard as I compare them with photos. I have now ordered two hubs, my order was accepted on-line although Wittner seem to be on holiday until next Monday.

Your idea of local manufacture of metal hubs interests me very much, please include me if you do proceed.

Posted by Andrew Woodcock (Member # 3260) on June 30, 2014, 10:37 AM:

I think I may very well do just that Maurice. A nice little project for me in the Autumn, I think!

Up until recently I had every opportunity to gain access to a lathe and could have done the work myself, however it is a sign of the times these days when a huge manufacturing org subs all of their engineering work out to small industrial units rather than doing it themselves in-house. Lathe now therefore deemed out of commission,very annoying for us old school!

Once they arrive just let me know if there are any issues Maurice as I can easily send you a job aid in the photographs I mentioned if you should happen to incur any problems or issues.

I hope you are happy with them Maurice when they arrive.

[ July 01, 2014, 05:10 PM: Message edited by: Andrew Woodcock ]

Posted by Paul Browning (Member # 2715) on July 01, 2014, 12:47 PM:

Maurice, that picture uploaded by Alan Rik with the later spool clips, as I mentioned I had seen these on another machine, that was a heurtier stereo model. I don't think any spares are available or that they fit your beaulieu, but wondered if they copied this idea from them.

Posted by Josef Grassmann (Member # 378) on July 01, 2014, 01:53 PM:

Plastic spindle is like a tube. Put an aluminium or brass stud with 1/4" thread into plastic spindle and glue it.

Use a knurled 1/4" screw with rubber washer. Now reel is hold in place and can´t fall off.

PS: For those friends wich prefer metric system might feel free to employ M5 or M6 Thread

Posted by Lee Mannering (Member # 728) on July 01, 2014, 02:54 PM:

Never stopped spending on my 708 and it was silly little things that were so expensive to replace such as those reel mounts needless to say it went. Amazing for what was in its day such an expensive machine.

Posted by Andrew Woodcock (Member # 3260) on July 01, 2014, 03:37 PM:

My design would be based on the retrofit like the HTI, perhaps with locking tabs like the Elmo type. The original plastic hub would be needed for the 12 toothed plastic pulley to the rear but then the front of the new hubs would appear the same as the HTI upgraded ones, made of stainless steel preferably and containing a slot for the locking tab. All i would do different, is make a sprung locking tab like the Elmo design and would prefer three location dowels instead of just the one as in the existing HTI design.

So a message to Maurice and anyone else for that matter who may be interested in the new improved ones of the future, keep any old ones you may have as these can be used to fit the new front stainless hub to if the design works well. I have my old one and that is what I shall use as the prototype to trial before making a batch of new hub adaptors.

Lee, I have no idea what you had to keep throwing money at on these machines. Most of the components are top quality as you would expect at nearly two and half grand in the early 90's.

Maybe yours had been well used perhaps before you got it?

What model type was it?

[ July 02, 2014, 10:21 AM: Message edited by: Andrew Woodcock ]

Posted by Maurice Leakey (Member # 916) on July 06, 2014, 06:20 AM:

Just sent payment to Wittner for two spindles, came to total GBP £219.00 including postage and German VAT of 19%.

Posted by Andrew Woodcock (Member # 3260) on July 06, 2014, 01:43 PM:

Not cheap Maurice, as said. You will be gobsmacked when you see what you get for all that money! Still, if you need them, then you need them no matter what the cost I suppose.As said, at least it is a machine well worthy of spending the money on ![[Smile]](smile.gif)

Don't forget to keep your old knackered ones Maurice, they may be needed for the future upgraded ones all being well!

[ July 06, 2014, 03:01 PM: Message edited by: Andrew Woodcock ]

Posted by Maurice Leakey (Member # 916) on July 10, 2014, 11:26 AM:

UPS just delivered my Wittner parcel. Opened with baited breath, removed all the super packing material to reveal two white boxes. Gingerly removed the spindles.

Opened storage cupboard to remove 2200' Beaulieu spool and a 1200' Elmo (both thin alloy spoked).

Joy upon Joy.

Spools slipped onto the spindles, well, slightly tight, but they did slip on with a satisfying click as the retaining clips returned. Other spools passed the test!

As I have had the 700 EL CD for four years I will be taking it to my service engineer for a check-over and lubrication. As I don't seem to have such a small screwdriver that is necessary he will also remove the old spindles and fit the new ones.

The old ones will be retained in the hope that Andrew will be able to supply replacements which he has mentioned.

Posted by Andrew Woodcock (Member # 3260) on July 10, 2014, 03:27 PM:

I am really pleased you are satisfied with them Maurice. I reported when I fitted mine that they are a really nice snug fit when they are brand new and clearly you have found yours to be the same Maurice. Keep using the reels I mentioned and they will stay that way Maurice.

You will love the machine with the large reels once your repair man has serviced it. There is no better experience in Super 8mm screening than seeing an entire feature from start to finish with no reel changes. Just like being at the cinema!

It's really good that you are keeping the old ones Maurice and I will keep you posted in the Autumn after the holiday season as to how I am getting along regarding the upgrades ![[Smile]](smile.gif)

Ps:- As well as everything else, get your repair man to lubricate the nylon shutter cam with Molycote Dow Corning grease using a syringe(see FFR Filmtecknik or Van Eck for grading).

This will keep the picture rock steady on these machines and stop any premature wear to the cam if it hasn't been serviced for some time. Very easily accessed once main motor has been removed, which again is really simple to do so on these machines.

[ July 11, 2014, 05:40 AM: Message edited by: Andrew Woodcock ]

Posted by Maurice Leakey (Member # 916) on July 11, 2014, 06:16 AM:

Thank you, Andrew, for all the information. It's very useful as the Beaulieu manual, although extensive, makes no mention of lubrication.

I think the Beaulieu service manual suffers from loss in translation. I must admit that I thought their reference to two ball-bearings was rather odd. I see that each spindle has a ball race which contains nine ball bearings, perhaps they meant one unit for each spindle. We'll never know.

[ July 11, 2014, 08:56 AM: Message edited by: Maurice Leakey ]

Posted by Rob Young. (Member # 131) on July 11, 2014, 03:01 PM:

Also, Maurice, when the spindles are removed, check the washers inside the arms for wear.

The originals are felt and can degrade and clog the mechanism.

It's fairly easy to find nylon replacements from DIY stores if they have worn; you just need to remove the old ones, clean it all up and super glue the new ones in place.

It becomes obvious once you have the arm covers off!

Posted by Maurice Leakey (Member # 916) on July 12, 2014, 03:45 AM:

Rob

Thanks for your comment.

When I had an L516 the take-up arm had a felt washer which needed to be kept saturated with oil, this was to allow the spindle to slip when a large spool was becoming full. If left to dry out the spool would sometimes snatch the film.

Does the felt washer and any part of the Beaulieu spindle assembly, or shaft, need any lubrication?

Whilst the service manual is quite good it does not cover lubrication. Can I get such details anywhere?

Posted by Andrew Woodcock (Member # 3260) on July 19, 2014, 02:17 AM:

Maurice, I don't think the felt washers were ever intended to be lubricated however it would do no harm whatsoever if you lightly greased the two ball bearings using alvania grease between inner and outer races of the bearings.

Don't over pack the bearings with grease as this will shorten the life of the bearings but a small amount will lengthen the life of your new investments.

Posted by Andrew Woodcock (Member # 3260) on July 22, 2014, 06:06 PM:

Has your service engineer done the work on your Beaulieu 708EL yet Maurice?

Posted by Maurice Leakey (Member # 916) on July 23, 2014, 07:02 AM:

I take projectors for servicing about every six months. There is a batch away at the moment, so only when I go to collect will the Beaulieu go with me.

Posted by Andrew Woodcock (Member # 3260) on July 23, 2014, 08:15 AM:

Oh ok Maurice, keep us posted then please upon it's return ![[Smile]](smile.gif)

Posted by Maurice Leakey (Member # 916) on September 10, 2014, 04:39 AM:

Andrew

My Beaulieu 708EL (with many other projectors) is now with my engineer who will be giving it a general service and fitting the new spindles.

It may be some time before my projectors are slotted into his schedules but I will further report later.

I have asked for the return of the old spindles in the hope that your possible manufacturing venture comes to fruision.

Posted by Andrew Woodcock (Member # 3260) on September 10, 2014, 05:08 AM:

It will do Maurice, I am already working on several different design concepts. I think there will end up being two different designs. One will entail sending me the old ones to fit the adapter front steel improved ones to. (this is because the plastic old spindles will need to be modified prior to fitting the new steel fronts). From discussion with engineering works these will work out expensive but very professional.

The other design is far simpler and will just entail removing the current centre screw which holds the plastic spindles onto their steel shafts, then fitting a new steel adaptor from where the screw fitted. Then you will have a knurled locking collar to secure the reels onto the existing plastic hubs.

This will mean I can simply send the parts out to anyone who wants them and it becomes a really easy job to fit these yourselves with a photographed set of fitting instructions including a fitting/ removal tool enclosed for the centre adaptor.

Also the plastic spindles will still be able to accept any 1200ft reel including the Taylor / Grasso ones that currently do not fit properly by removing all of the plastic retaining clips and then just use the steel knurled collar that I will supply to do all of the reel securing to the existing plastic hubs if you so wish.

These will work out far simpler to manufacture than the first ones described but will still be simple to use and relatively inexpensive to manufacture compared to the first design concept I have spoken about.

[ September 11, 2014, 05:49 PM: Message edited by: Andrew Woodcock ]

Posted by Maurice Leakey (Member # 916) on September 10, 2014, 10:16 AM:

Some very interesting ideas, Andrew. I look forward to reading more when your plans have advanced.

Posted by Andrew Woodcock (Member # 3260) on September 10, 2014, 06:23 PM:

The simple solution type should be ready in a month, latest hopefully, fingers crossed. I am hoping my old engineering training centre (which I was surprised is still going), will manufacture these by their current crop of second year company sponsored apprentices.

These are a very easy project for someone who has been turning for over a year so the standard of workmanship I expect will be excellent hopefully. The workshop has now been in existence for 48 years and I served there for my first year off site basic training in 1982/83. Back then you studied all aspects of Turning, Milling, Welding,Brazing,Soldering, Fitting, Sheet Metal Work & Electrical Engineering for one year. You then went on to specialize in whatever your company wanted from you before then returning to "The Big House" ready for action! Ha ha.

CNC Machines were just about present back then albeit that they were in their infancy including the old punch tape type just like the Eumig factory used in that same era!

[ September 12, 2014, 05:21 AM: Message edited by: Andrew Woodcock ]

Posted by Maurice Leakey (Member # 916) on October 21, 2014, 05:17 AM:

My Beaulieu 708 EL is now back with its new spindles and also has been lubricated. My comments are:

1) The new spindles are quite tight, it needs very careful alignment before gently pushing on the Beaulieu 2200' spools. I consider that Beaulieu could have allowed less on the o/d.

2) Not much room to enter film into the auto-thread slot with a large feed spool in position.

The old spindles are now awaiting Andrew's manufacturing endeavours!

Posted by Andrew Woodcock (Member # 3260) on October 21, 2014, 05:26 AM:

coming soon Maurice, I promise! ![[Wink]](wink.gif) You are quite correct about there not being a great deal of room to thread when mounting the very largest of spools onto these machines, however what I have found is if you have the threading mechanism already running, with practice and the right shaped cut on the edge of the film, even just "offering" the film to the slot grabs the film leader into position and this soon becomes an easy way round threading when using the larger spools I have found Maurice.

You are quite correct about there not being a great deal of room to thread when mounting the very largest of spools onto these machines, however what I have found is if you have the threading mechanism already running, with practice and the right shaped cut on the edge of the film, even just "offering" the film to the slot grabs the film leader into position and this soon becomes an easy way round threading when using the larger spools I have found Maurice.

For the Disney features, I prefer to mount them to the 1800ft Beaulieu reel size giving you plenty of room to thread.

Also to gain an even better chance of a 100% perfect top and bottom loop whilst threading I have found that switching to 18fps on these machines really helps, although having said all of that, they generally do thread well and reliably no matter what technique you use so long as you cut your leaders with a chamfered 45 degree cutter rather than the bevelled edge style cut prefered by Elmo machines etc.

[ October 21, 2014, 04:29 PM: Message edited by: Andrew Woodcock ]

Posted by Maurice Leakey (Member # 916) on October 21, 2014, 09:30 AM:

Andrew

The second concept only seems feasible for spindles that already will accept most/all spools. It could also replace any broken securing clips. In my case, the idea would not work as my problem (apart from one broken clip) is that they would hardly accept any type of spool.

Therefore, for me, the only solution for a stand-by pair would be your first idea, a metal version, complete with turn-over key to secure the spool.

As regards film trimming, the built-in cutter always seems to work for me.

Posted by Andrew Woodcock (Member # 3260) on October 21, 2014, 01:23 PM:

Your new spindles will accept the "simpler" locking collar type Maurice without modification to them in any way.

The best "all metal" type like the Beaulieu HTI has, needs modification to the old plastic worn spindles to allow them to be fitted.

These are the best but will also be expensive to manufacture based on my submitted drawings. Let me know if you would like a set of the simple locking collar type to be made especially for you. Whatever spools already fit on your new plastic spindles from Wittners will continue to fit except they will be secured by a 28mm diameter steel knurled collar to give peace of mind and better tracking when using the larger spools as all of the "play" between reel and hub is removed by the retaining collars.

The collars would only ever be need to be fitted when using 1200ft spools or bigger. For all other spool sizes you would simply leave the collars off stored in your accessory case etc.

[ October 21, 2014, 04:25 PM: Message edited by: Andrew Woodcock ]

Posted by Maurice Leakey (Member # 916) on October 22, 2014, 02:25 AM:

1) The new spindles are fine as they are, I would very seldom use the very large spools. As such, no modification is necessary.

2) The old spindles would accept only a few spools, therefore they would need to be modified to have the metal turn key idea.

I hope that the new spindles will last a long time and I would like to have modified spindles as a very future back-up.

Posted by Andrew Woodcock (Member # 3260) on October 22, 2014, 04:01 AM:

In that case Maurice, you would have to send me your old two plastic worn ones once I have had the prototype made for the HTI copied type. Upon return you would then fit these as a two stage procedure, plastic rear first to fit the belt to the pulley, then steel fronts including locking tab like Elmo etc.

May sound complex but it isn't really. One screw is the centre screw that is used already to hold the plastic type onto the steel shaft and the other three screws fasten around the periphery of the plastic hub to retain the new steel portion.

I will send you a photograph Maurice once I have my prototype of this kind made if you like. Would have to be by mail as I never had any success posting photographs on here with the low res ruling etc.

In the meantime, if anybody has any old worn plastic spindles for sale please just let me know. Then I can get a batch made in advance, then sell as the new modified steel type.

Posted by Maurice Leakey (Member # 916) on October 22, 2014, 08:34 AM:

That sounds an excellent idea Andrew, let us know how you get on.

Posted by Rob Young. (Member # 131) on October 22, 2014, 08:55 AM:

Andrew, I have my original spindle with two broken prongs you can have if that helps.

Posted by Andrew Woodcock (Member # 3260) on October 22, 2014, 09:21 AM:

Rob that would be fantastic thank you. The front section of the hub all gets removed so as long as the toothed pulley section and shroud is ok, that is all that matters Rob.

If both of the bearings are present, better still, but it doesn't matter too much as these can be transferred from the existing plastic ones that are currently in use on any of the machines.

Posted by Rob Young. (Member # 131) on October 22, 2014, 10:54 AM:

Yep, apart from the broken prongs it is all intact and in good shape.

Just message me where you'd like it sent. ![[Smile]](smile.gif)

Posted by Andrew Woodcock (Member # 3260) on October 22, 2014, 02:51 PM:

Brilliant Rob, thank you very much sir! Will PM you with my address thanks.

I will now have a broken Pair of these so I can make the first duo of uprated spindles. If people approve they can of course be rolled out to others if they supply their own old plastic set.

[ October 22, 2014, 11:41 PM: Message edited by: Andrew Woodcock ]

Posted by Maurice Leakey (Member # 916) on February 26, 2017, 05:38 PM:

Andrew

What happened to your proposed project for modified spool retainers with a turn-over key?

Posted by Andrew Woodcock (Member # 3260) on February 26, 2017, 11:37 PM:

There will come a time Maurice, one day perhaps, when I'm forced to put my long existing drawings to the test.

Like yourself Maurice, I purchased a new one from Wittners for just my front hub, the rear one felt like it had always only ever seen either Posso or Elmo spools.

As often happens, it's previous owner had clearly tried fitting many different types of spools onto the front spindle hub.

The nylon ones will not last 5 minutes if you try to force certain spools onto them, for example Taylor spools. The springy plastic retaining splines either snap or wear down in an instance and subsequent fitted quality spools can no longer be retained correctly.

Since first knowing this before even buying one of these machines, then since buying the new spindle hub, like yourself, I haven't had any issues or a need to concern myself with the first planned upgrade.

However, should the day arrive when the new one shows any signs of wear, despite fitting only quality spools, then I would try to improve the situation on these. By then, I'm guessing I'd be left with no other option than to manufacture my own as I doubt Wittners would still stock the nylon ones then.

If I had a few made and they proved a success, I'd then get around 5 other sets made to hopefully help other users.

I had two designs planned. One utilizes the M3 tapped hole in the centre of the nylon to add an additional steel centre adaptor that then allows a knurled retaining steel cap to be fitted to existing nylon hubs.

My other design was an all steel arrangement that uses a,sprung ball bearing latching mechanism somewhat similar to your Fuji machine but utilizing 3 location and driving splines for accuracy of fit, not one.

My issue with the Beaulieu designed tab type, is that I feel they are slightly fiddly in removal of the spool though they work well apparently for securing any reel of Film.

Any that are made have to respect the rear datum point on these hubs to ensure 100% alignment onto the floating roller at the input guide. At 2200ft sizes, wheel wobble has to kept to absolute minimum by accuracy of hub bore sizing and also the same for the 3 driving splines.

The better the fit, the greater the success with these I feel.

Posted by Steven J Kirk (Member # 1135) on February 27, 2017, 12:00 AM:

Anyone ever tried grafting the Elmo spindles to the Beaulieu back part to improve the 708? An idea I have...

Posted by Paul Browning (Member # 2715) on February 27, 2017, 01:37 AM:

Not tried that Steve, but suggested a look at the elmo one's earlier in this thread, probably would fit with a bit of fettling, and they rarely brake and are trouble free. The beaulieu price's for those clips ,that look rubbish any way are just madness, and they disguised copy of the Elmo one, and not as good either.

Posted by Phil Murat (Member # 5148) on February 27, 2017, 01:41 AM:

Hello,

From my side , I am still happy whith that :

100% Efficient........

Posted by Andrew Woodcock (Member # 3260) on February 27, 2017, 02:55 AM:

Even if the Elmo type could be grafted as Steven says, which is not a possibility, they would not suffice at very large spool sizes for reasons stated above surrounding accuracy at input guide.

Phils design here shows that a true datum point to the rear seating of the spool is absolutely critical on these to avoid scratching of film at input guide.

Phils design will work well for sure as it solely relies on a clamp fit to a machined face.perfect!

Posted by Paul Browning (Member # 2715) on February 27, 2017, 04:06 AM:

What a load of rubbish you talk. To dismiss the use of the Elmo part without it being proven not to work, is tantermount to stick you head up your arse, and saying I won't try it but I will dismiss it.

Posted by Phil Murat (Member # 5148) on February 27, 2017, 04:28 AM:

Hello,

I am not sure to pretty understand what is wrote above......

So, just have a look for the link below and you get a more precise idea how my spindle works :

BEAULIEU MODIFICATIONS IN PROGRESS

The "Jumbo" reels (means 750 Meters) are very heavy , so it is very important to get them firmly installed.

Moreover the design described is "much, much" better than the last Beaulieu device you can find on last products and also than any super 8 machine on the market , even for Top machines...

At the end, this design is also very simple, very basic....

A "StandBy" Solution:

Anyway, replacing the original spindle for an other one, brand new, but showing same design is not a satisfactory solution.

So to avoid you to waste money in a part for that you know the same ploblem occurs a day or an other , I suggest to make a stand by modification of the spindle "in situ" :

1) Cut 3 flexible lugs (unused anymore)

2) Insert a sleeve (Aluminium, Brass or Steel soft, any) Outside Diam Approx 9mm , inside Diam 4mm Approx (Both dimensions to be determined)

3) Manage a "cross Hole" Approx 2mm/3mm Diam(90° from main Axis) so that a Securing Pin could pass through to block any Film Reel installed

4) The idea is to secure the bushing with 3 small screws installed 120° from each one, Head screws had to be flush once installed

Obviously,with this "Stand By" device, the reel is not "Firmly" secured , but it can not slide over and fall down....

[ February 27, 2017, 07:18 AM: Message edited by: Phil Murat ]

Posted by Andrew Woodcock (Member # 3260) on February 27, 2017, 05:19 AM:

Paul there is a physical reason why the Elmo part cannot be used, not an emotive one.

As you own both of these machines, i will allow you first to explain what that reason is.

Posted by Paul Browning (Member # 2715) on February 27, 2017, 11:32 AM:

I will have look at both mech's and see why this can't be used, for this, nothing I believe cannot be modified or reused from one machine's to another, in this case the more over engineered beaulieu will need all the help we can give it in the future.

Posted by Dominique De Bast (Member # 3798) on February 27, 2017, 12:16 PM:

Thanks for the link, Phil. You do wonderful things !

Posted by Alexander Vandeputte (Member # 1803) on February 27, 2017, 01:41 PM:

Merci Phil ! C'est IMPRESSIONANT.

Posted by Phil Murat (Member # 5148) on February 27, 2017, 02:21 PM:

Hello Dominique , Alexander

You can "keep an eye" on this link as I complete the informations in case there is something new.

I am also working on a Regulation Card fully rebuilt including modifications and modern material......

The drawing is ready so that I am in position to send it for PCB printing.

I modify first a STEREO Model . Upon test result, I modify a MONO model to introduce the new card as a full kit (Regulation Card plus Control Panel) and to allow the MONO to get the same Variable Speed range as the STEREO one.

Sometime you can discover a new issue somewhere you have not expected . For exemple, I realize that "Toggle switch" (Slide Switch) are difficult to find for the same dimensions. the common ones are smaller. Same thing for Connectors. The Beaulieu's one are now obsolete and no more available. I had to change the design for new configuration connectors.

Posted by Andrew Woodcock (Member # 3260) on February 27, 2017, 03:01 PM:

Great work Phil,as always. ![[Wink]](wink.gif)

Posted by Paul Browning (Member # 2715) on February 28, 2017, 07:09 AM:

Half way there to solving this problem. If my calculations are right you would need some surgery of the spindle that holds the hub in place, but other than that its farely straight forward to use the elmo hub on the beaulieu, and it would be as strong as the variants we have already seen. Lets not forget this hub is used on the extended arms that Wittner made, 800m capacity, its no more or less what your doing here, but with much less cost. If you don't believe this works, someone asked if they could take the strain on a GS, the answer was yes and for sometime with no noticeable problem from the hub or the GS.

Posted by Andrew Woodcock (Member # 3260) on February 28, 2017, 07:26 AM:

If i get time tonight. I will post 2 photos one of each of the spindle hubs. Then it will be obvious what the restraints are of trying to fit an elmo style spindle onto the remainder of the beaulieu one would be.

I looked into it quite deep at the time and there wasnt one other existing style that i could find to integrate with any degree of ease.

Not even the Bauer ones which came closest.

Hence the drawings and hence the conclusion id more or less be starting from a blank slate.

Also bear in mind, any reel will fit onto a elmo hub. This is acceptable at 1200ft but produces far too much play at 2400ft for the larger reel diameters.

Exactly the same with the fuji ones.

You need a precise clamp fit to hit the floating roller dead on centre at all times to avoid mistrack and subsequent risk of scratching.

Either that or a greater distance apart like a LPU provides.

Posted by Phil Murat (Member # 5148) on February 28, 2017, 09:31 AM:

Hello,

Andrew, Paul, reviewing the content of the main subject , I have just miss to tell you or emphasize something (in fact this is something which is just crossing my mind again).

When I worked out the Reel carrier part (many years ago....), I remember to have observed a BIG DIFFERENCE between Reels products Quality and more particularly concerning fitting diameter (Reel Inner Diameter)

So I had to take in account this problem to allow installation from different kind of reels from the best to the worse product.

In summary, as I cut the spindle to the minimum diameter observed, the fitting clearance is important before tightening the finger knob, depending on reel source ........

Of course, once the knob tightened, any quality of reel is perfectly secured and do not float at all.....

So far as I can remember, HEURTIER projectors allow to firmly fit reels as their Spindle keys show a slopped (Bias) cut.

So , as much you push keys from outside to inside , better is secured the reel.

This is a clever design, quite simple, which works pretty good too....

However, ELMO keys are locking in a same plane and are not in contact with the reel flange......

[ February 28, 2017, 10:38 AM: Message edited by: Phil Murat ]

Posted by Andrew Woodcock (Member # 3260) on February 28, 2017, 10:40 AM:

Based on your initial statement above phil, i would want the bore diameter of the hub to be machined to upper end tolerances. Ie snug fit for elmo and posso reels. I wouldnt want taylor reels etc to be able to be fitted due to poor axial concentricty of these type of reels with smaller hollow bores.

Only solid precise bores like those of an elmo spool at 1200ft would be able to be fitted.

This then, would gurantee the safe tracking of any spool that will fit, just in the same manner as the nylon ones currently do the same.

Posted by Paul Browning (Member # 2715) on February 28, 2017, 11:14 AM:

I did say half way through. I recognise the Elmo clip is not ideal, but it could be help to locate the reel better with some sort of flange /washer that would lock between the reel and the latch. I have never had a 1200 ft elmo reel come off while running or rewinding on the GS, not that it couldn't but hasn't as yet. I'm surprised with your design that locks to the reel did not incorporate a saucer shaped washer to spread the locking pressure over a greater area.

Posted by Phil Murat (Member # 5148) on February 28, 2017, 01:24 PM:

Yes Paul, at the origin I made a very simple design to get parts easier to be cut on the lathe, so the button is a simple cylindrical part, single diameter.

May be it could be interesting to increase outside diameter, but interest to stay on a small Diam is to naturally limit finger torque and tightness.

Anyway, any kind of Finger-knob can be tested, up to user requirements.....

I make tip outside diameter measure for Andrew.

An other thing which could be important is to keep an "elegant" design (as possible) or good looking to stay in the general Beaulieu typical concept ......

Posted by Paul Browning (Member # 2715) on February 28, 2017, 05:00 PM:

Phil, I'm talking maybe 25mm dia with an angle of 15 degree's 12-15mm height, sorry I have not done the math's to see if this is correct, just by eye. This would not detract too much from your original design, but would give you more clamping to the reel.

Posted by Phil Murat (Member # 5148) on March 01, 2017, 04:42 AM:

Hello Paul, Andrew,

Here are measures I record for mating diameters :

1) Elmo Spindle ===> 12,56mm

2) Beaulieu Modified Spindle ===> 12,68mm

12,68mm is the max Diam limit. Above this dimension, Beaulieu, Elmo, Posso reels will seize a bit.

Paul, did you mean mating sides with conical surfaces in your description ?

I was thinking to this kind of solution to get a perfect centering for the reel but this a bit more difficult to perform (That could involve a spring loaded conical sleeve fitted inside securing knob or on the opposite part)

Posted by Andrew Woodcock (Member # 3260) on March 01, 2017, 04:46 AM:

I had it as 12.65 on my drawings Phil, but I won't be disagreeing with you sir for three hundredths of a mm! ![[Big Grin]](biggrin.gif)

![[Wink]](wink.gif)

Thanks again Phil! ![[Smile]](smile.gif)

I now have a tolerance +0.03 - -0.00mm ![[Wink]](wink.gif)

Posted by Phil Murat (Member # 5148) on March 01, 2017, 05:01 AM:

Yes Andrew, you are perfectly right.

12,65 mm is much better. Normally that could fit with any Beaulieu reels and get a more "confortable" reel installation.

Anyway it is easier to diminish a diameter than the reverse procedure..... ![[Wink]](wink.gif)

Also , let me know what did you observe for Derann Reels as necessary....

Posted by Andrew Woodcock (Member # 3260) on March 01, 2017, 05:06 AM:

I haven't measured the Grasso 600ft type yet Phil. Except to say they have a similar fit to the others you mention above and they have the all important solid bore!

Bonum, Grasso, Sankyo,Posso, Elmo, Gepe,Schneider, Fuji and any other quality spool I can think of, will all fit onto a spindle measuring 12.65mm very well with no slop in their fit.

Ones with hollow metal inserts into their plastic reels will not, thankfully, nor will the heavy American steel reels that only have a keyway on one side of the reel.

[ March 01, 2017, 06:24 AM: Message edited by: Andrew Woodcock ]

Posted by Andrew Woodcock (Member # 3260) on March 01, 2017, 05:24 PM:

Incidentally, contrary to popular belief it would seem, all parts that were available before the announcement at the back end of last year, are still available to buy.

I've got a set of most of the necessary parts on the list, but not all of their entire inventory, just to quash the myth.

[url= http://www.wittnercinetec.com/epages/WittnerCinetec-Super8-16mm-Film.sf/en_GB/?ObjectPath=/Shops/WittnerCinetec-Super8-16mm-Film/Categories/"Beaulieu%20708%20EL%20Zubehör"]htt p://www.wittnercinetec.com/epages/WittnerCinetec-Super8-16mm-Film.sf/en_GB/?ObjectPath=/Shops/WittnerCinetec-Super8-16mm-Film/Categories/"Beaulieu%20708%20EL%20Zubehör"[/url]

Nothing's any different now, than it was this time last year.

Posted by Kevin Clark (Member # 211) on March 01, 2017, 05:46 PM:

I can't believe you feel Grasso's are quality spools Andrew yet you don't rate Goldberg and Fumeo metal spools simply because they don't have a solid centre?

Kevin

Posted by Andrew Woodcock (Member # 3260) on March 01, 2017, 11:51 PM:

No Kevin I don't particularly like Grasso 600ft spools, but their centre hubs are perfectly fine.

Ordinarily, they wouldn't be on the list, but Phil was talking only of how they fit on Beaulieu spindles and from this perspective, Grasso 600 footers, made the list Kevin.

I'm sorry Kevin but no, I personally don't rate Golgberg spools as I find them way too heavy but admittedly they are well made with a bore size and design that isn't compatible in use with Beaulieu.

They've always been ok for my optical prints though Kevin.

I personally have always found, that a solid centre hub is absolutely imperative for larger spools in particular,in order to avoid "spool wobble" issues and subsequent mistrack.

[ March 02, 2017, 02:38 AM: Message edited by: Andrew Woodcock ]

Posted by Paul Browning (Member # 2715) on March 02, 2017, 01:14 PM:

Quality control at its best,

Posted by Phil Murat (Member # 5148) on March 02, 2017, 02:15 PM:

Hello,

Reviewing one more time what it is talked about above, I understand much better why Paul emphasize the idea to increase knob mating surface.......

I am mainly using spools showing "solid" hub.

In case of using spools showing a recess between both rims , you can experience rims permanent distorsion if knob is overtighten .

So , as Paul said above, increasing knob diameter and matting surface will prevent you from this issue !!!!

So, what I can do , is to manage an optionnal pressure plate (Like a big washer) to install upon request between the knob and spool , as necessary.....

![[Eek!]](eek.gif)

Posted by Steven J Kirk (Member # 1135) on March 12, 2017, 08:45 PM:

Don't know if anyone has tried out the Van Eck parts for the 708:

http://www.ebay.de/itm/Beaulieu-708-EL-Reelholder-PP-0012-new-/261902450997?hash=item3cfa9a4135

Posted by Andrew Woodcock (Member # 3260) on March 13, 2017, 12:55 AM:

Yes I have a set Steven (not fitted), and I reported the differences from those original ones sold by Wittners at the time I very first obtained a set. ![[Wink]](wink.gif)

Posted by Maurice Leakey (Member # 916) on March 13, 2017, 04:52 AM:

Andrew

Would you please be kind enough to repeat (or a link to) your comments about Edwin's part number PP-0012 "Beaulieu 708 EL Reel Holder".

It is described as "New version of strong high-grade industrial artificial fibre with sintered bronze bearing."

As we all know, the plastic "springy" spool retaining clips have a habit of breaking off.

Would the same problem apply to Edwin's new part?

Posted by Andrew Woodcock (Member # 3260) on March 13, 2017, 06:14 PM:

Of course Maurice! 😊

I'm off during the daytime tomorrow, I will post a full resume then.

Please bear in mind though,these are only ever my own findings based purely on my own experiences with these things.

Opinions may well differ and I don't ever profess to be any kind of mentor on these things, simply a heavy user with a resulting heavy time honoured experience. Sometimes for the better, but much in the early days,.. often for the worse!

Wouldn't want to ever upset anyone now, would we? ![[Wink]](wink.gif)

[ March 14, 2017, 06:36 AM: Message edited by: Andrew Woodcock ]

Posted by Maurice Leakey (Member # 916) on March 14, 2017, 03:38 AM:

Andrew

I look forward to your reply.

I always appreciate your comments on various matters as a user of similar projectors to those which I own.

Sharing information is an important part of this Forum.

Posted by Andrew Woodcock (Member # 3260) on March 14, 2017, 06:09 AM:

I couldn't find my original post sorry from when I very first obtained the newly then manufactured Beaulieu copied spindle hubs from Edwin and for all I now know, these may now be being made to a slightly different specification than the early prototype ones I received but here was my findings regardless, Maurice..

They are made to a very good standard of precision was my first observations, the reels fitted onto the standalone spindle hubs with that familiar new "clunk" we associate with these type of plastic hubs when brand new.

The vulnerable plastic splines appeared to my eyes at least,to be somewhat thicker than the originals and the all important retaining lugs, 70% along the way down of these retaining splines, also appeared a slightly different shape and size than the originals.

In both cases this was for the better in my opinion. If you look very very closely at the Beaulieu originals, the lugs on the ends of the three splines, are all curved throughout their length.

What this means in usage is, you have a peak to climb while the reel enters onto the splines and while the splines themselves become deflected downwards, but then as the reel enters over and beyond the crest of the curvature on these lugs, the reel then slides down the opposing side of this curvature on the spline lug and then sits firmly up to the rear abutment face on the spindle hubs.

At this same point in time, the splines themselves, become relaxed again and should, when new and healthy, return to their original relaxed position and retain the reel only by this rear curvature on the lug.

When you compare this spline profile to one of Edwins, his differ in so much as the lug on the end of the three splines is differently shaped.

His are are a far more "chiseled" arrangement, where the profile is simply a tangential slope front and back, and then a straighter taller section for the peak of the lugs.

This means that while these splines do deflect a whole lot more as a result of the larger lugs, the reel sits more firmly against the abutment face due to the chamfered design of the actual lug, as opposed to the original curved design lugs.

Also, as the splines are thicker, you'd expect them to be stronger and more durable so long as the polymers used contain enough elasticity within them to allow theses splines to flex many thousands of times as required.

That is something only time would tell and so far at least, I have never needed to fit mine.

On the appearance front, these spindles do not particularly look similar to the originals.

They are of a more dull grey appearance than the original smooth shiny black originals.

Also as with any 3D printed part that so far I have personally seen, they are a much rougher surface texture also.

This of course, should be of insignificance for a part doing what these do, however.

Finally. The main reason why I personally, felt slightly disappointed with these newly designed spindle hubs, was because Edwin chose to go with original "brass or bronze" bushed type of bearing arrangement for these.

As you know, Beaulieu superseded this design by fitting a dual ball bearing type arrangement to each of these hubs to allow them to spin very very freely with heavy loads of film mounted upon them.

The original Bush bearing type were known in some instances of heavy use, to cause premature wear to the motors due to massive load felt by the motor when rewinding 2400ft reels of film.

If the bronze bearings were regularly lubricated with a fine machine oil, no problem, but otherwise over lengthy periods of heavy use, problems involving the motor windings could develop.

Because of this information above, this is why I'd much preferred if these had been identically designed to those sold by Wittners that follow the later Beaulieu design with these, the ones with the two ball bearings fitted to them in other words and the ones which cause no such motor problems on the later Beaulieu Stereo models etc etc.

Posted by Maurice Leakey (Member # 916) on March 14, 2017, 07:09 AM:

Andrew

Thank you for the most interesting and useful information which makes my purchase a possibility.

How does the O/D compare with the Beaulieu originals? Are the spools still a tight fit which needs a very careful line-up before gently pushing on?

Posted by Andrew Woodcock (Member # 3260) on March 14, 2017, 07:21 AM:

Yes Maurice in every case spoken about there.

If anything, even tighter.

If you plunge for these type, get your engineer to lubricate your spindle shafts well before fitting them and then if over time, your motor breathes its last ever breath as a result of these type of bearings fitted, just request a new one from me as I now have many of these motors, brand new and at a very reasonable price point.

If you go ahead and buy these spindle hubs from Edwin, I recommend on each major service interval your projector receives by your engineer, get him to also remove these hubs and re lubricate the shaft beneath.

This should help prolong the healthy lifespan of your main motor on these , especially if you use your machine to rewind full features of films on it, like I always do with mine.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Frown]](frown.gif)

![[Frown]](frown.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif) You are quite correct about there not being a great deal of room to thread when mounting the very largest of spools onto these machines, however what I have found is if you have the threading mechanism already running, with practice and the right shaped cut on the edge of the film, even just "offering" the film to the slot grabs the film leader into position and this soon becomes an easy way round threading when using the larger spools I have found Maurice.

You are quite correct about there not being a great deal of room to thread when mounting the very largest of spools onto these machines, however what I have found is if you have the threading mechanism already running, with practice and the right shaped cut on the edge of the film, even just "offering" the film to the slot grabs the film leader into position and this soon becomes an easy way round threading when using the larger spools I have found Maurice. ![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Big Grin]](biggrin.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Wink]](wink.gif)

![[Eek!]](eek.gif)

![[Wink]](wink.gif)

![[Wink]](wink.gif)