This is topic Elmo running a bit slow in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=007066

Posted by Phil Slater (Member # 2388) on May 01, 2012, 05:51 AM:

Hi, does anyone know if there is an easy way of adjusting the running speed on an Elmo ST 1200 super 8 projector? Mine runs a bit slow on both speeds.

Not sure if it's a DIY job or whether it would need to go in for repair. Any advice would be appreciated.

Thanks

Posted by Steve Klare (Member # 12) on May 01, 2012, 10:17 AM:

Hi Phil,

I find with my ST-1200 the speed is slow at first and improves as it warms up. What I typically do is let it run with the lamp lit for maybe two minutes and after that the speed is fine. I usually do this while I'm gathering films. If instead I just dive right in and show a film from cold, the audio sounds awful until it warms up.

The SD-1200 has an AC motor, which means the motor speed follows power line frequency. The adjustment in projection speed for 50/60 Hz. is the position the belt occupies on the motor pulley. If you happened to be operating at 50 Hz with the belts in 60 Hz position you would be stuck with only 5/6th of the correct speed! Has someone changed your belts lately?

Posted by Phil Slater (Member # 2388) on May 01, 2012, 02:52 PM:

Hi Steve, thanks for the reply. Just done a test counting the frames on 10 seconds of film found that it's just under 23 fps, so it's not too far out. As you say, it needs to warm up first so maybe that was the problem when I thought it was running slow. The belts haven't been changed for a year or two.

I'll monitor it some more but it's probably OK.

Another problem I have with this projector is a crackling from the speaker on certain films. It usually improves if I lubricate the films and demagnatise the heads, but it doesn't happen on my other projectors - Elmos GS800 and Yelco DS810MT. Must be a build up of static.

I used to get a build up of static on my Elmo GS800 when I first got it, but Ian of Perrys Movies showed me how to solve this with a bit of fuse wire. Apparently it's a design fault.

Anyone else had this, or know how to cure it on an Elmo ST1200?

Posted by Steve Klare (Member # 12) on May 01, 2012, 03:42 PM:

I recall a hair under 23FPS for mine from dead cold too. It's bad enough that actresses actually sound a touch masculine until it warms up.

I used to warm it up with the lamp off, but I find it's more effective with it lit.

I also have the static discharge on my ST-1200 (and only on my ST-1200). I've only really had it become noticeable during the middle of winter when the air is driest.

Posted by Vincent Zabbia (Member # 2453) on May 01, 2012, 04:19 PM:

Is this a new development or recent development...Might need a new belt..

Posted by Steve Klare (Member # 12) on May 01, 2012, 05:53 PM:

From what I've heard with these machines this is so common it's almost a genetic weakness!

-although I suppose if somebody had one that snapped to 24.0 FPS immediately they wouldn't be on the Internet griping about it.

Posted by Akshay Nanjangud (Member # 2828) on May 04, 2012, 01:00 AM:

Actually, I have the same speed issue on my ST-1200 as well.

Posted by Colin Robert Hunt (Member # 433) on May 04, 2012, 01:57 PM:

Same here. Was alright from new up to about ten years ago. Now needs that warm up with lanp on.

Posted by Steve Klare (Member # 12) on May 04, 2012, 02:46 PM:

Interesting....

So it should be possible to fix it.

To me this problem is like dating a really beautiful woman with an obnoxious laugh. The rest of the package is so good you learn to live with it.

...but if you could fix it?

Colin, does your machine still have the rubber around the shutter wheel?

Posted by Phil Slater (Member # 2388) on May 05, 2012, 08:40 AM:

Just to throw in yet another problem with my Elmo ST 1200, the sound quality will suddeny deteriorate part way through a film, as if it's just picked up some dirt on the heads. Cleaning the heads doesn't improve it.

I'm wondering whether it's because the film stripe is not making proper contact with the sound head, perhaps the rubber rollers are worn? It's annoying because I can never rely on it to behave, so I can't use it for shows.

Posted by Colin Robert Hunt (Member # 433) on May 05, 2012, 03:07 PM:

Steve the rubber was removed and the shutter wheel ground down about 10 years ago when it had it's service, along with some ajustments to the main control knob levers. This is a 1200Hd bought from new. Still needs that few minite warm up with lamp on, just seems it needs it now. When new was up to speed straight away. The other projector is the first one Elmo released in 75. That works better and does not neeed the warm up. At the moment that one has no sound and is in need of some new repair. Phil that sound problem is not something I have experiened with Elmo. Films that have sound problems due to bad stripe that run other makes does not hapen on my Elmo's. May be head contact but just might need a good service. We have in Uk John White in North London who can fix most problems. This was the guy who serviced my 1200Hd and sorted out the rubber on the shutter and other problems that was on the projector. I will be sending the old 1200 of 75 to him to fix the sound problem and get it serviced as well. Considering the ammount of film these projectors have run I think they have had no major problems. Good luck in fixing but, maybe get the projector repaired ad serviced once and for all Phil.

Posted by Steve Klare (Member # 12) on May 06, 2012, 07:06 PM:

I had problems with mine a few weeks back where the sound went out almost entirely, and I couldn't get it to any better than "awful" by the traditional repeated operation of the sound key.

I went in and found the snap-switch connected to this key and soldered a short circuit across the normally open contact (Which are closed with the record key undepressed. Then I snipped the wire connected to the normally closed contact and insulated the end with tape.

This kludge brought the sound back to normal, but if I ever want to use the machine to record films I'll need to replace the switch entirely.

Phil, maybe if you try working the record key (volume set low!) your sound will come back just by cleaning the contacts. My switch was simply shot and this didn't work any more.

It doesn't hurt to work all the other switches associated with sound while you are at it.

Unfortunately a lot of these switches were meant to be used at line level voltages and the low voltage and power they experience in these sound circuits don't reliably break the oxides that build up, so these kinds of problems are basically part of normal operation.

(Should have used switches with gold plated contacts, not silver, but....)

Posted by Paul Adsett (Member # 25) on May 06, 2012, 07:40 PM:

I believe that the switch and relay contacts account for at least 90% of all the problems on the GS1200. The auto thread front and rear micro- switches are notorious for failure. Fortunately these micro-switches are commonly stocked at Radio Shack and seem to be much better quality than the OEM Elmo switches. So if you are having auto-threading or take-up issues, chances are its the switches. Since replacing mine I have had no further problems.

Posted by Steve Klare (Member # 12) on May 07, 2012, 12:18 PM:

I'm close to a theory on this slow speed warm-up issue.

I think the fact that these machines have all had that rubber edge removed from the shutter wheel means there is less traction for the roller riding on the edge: a little slippage.

Then we flip on that projection lamp and the inside of the machine starts getting warmer. The rubber roller heats up and softens a little, a little more contact area, a little more friction at the surfaces, a lttle less slippage.

-more speed.

I can't prove a thing. It's just what my gut tells me.

Posted by frank arnstein (Member # 330) on May 08, 2012, 03:35 AM:

To Phil, Steve, Colin, Paul, Ashkay and any others in here....

I too have faced this annoying "slow till warmed up" issue with Elmo ST 1200's that I have serviced in the past. It seems to confront most Elmo ST 1200 owners sooner or later. Yet it is quite easy to fix when you understand why the projectors are all exhibiting the same symptoms.

After many years, some pinpoint servicing is required to maintain the projectors ability to get up to normal speed quickly.

The first critical thing to check is the contact point of the rubber driving wheel against the shutter edge. Any slippage here translates into loss of shutter shaft running speed. There is a long extension spring that pulls the overcentering drive wheels assembly hard against the shutter shaft edge. That spring becomes weak over time and needs to be replaced or shortened to restore the correct pressure between the shutter edge and the drive wheel. You can test it with your finger pushing the drive wheel harder against the shutter edge. If it speeds up quicker then you know you have found a weak point. Replace the spring.

The second critical area is where the claw drive peg sits against the grooved cam track which provides us with the intermittant movement of the claw. The enormous pressure required to pull-down the film very quickly generates a lot of friction on the cam and peg and it will slow down the projector speed unless it has fresh grease in there to slide things along smoothly. Use a wooden chicken skewer to spread the grease deep into the cam track. Now friction is minimised at the cam and running speed restored.

So I suggest you all check those two things on your slow Elmo ST 1200's and then let us all know whether you cure the problem or not. I think it will fix most cases.

dogtor frankarnstein

![[Wink]](wink.gif)

![[Smile]](smile.gif)

Posted by Joseph Randall (Member # 4906) on January 13, 2016, 08:46 PM:

Does anyone have any details on exactly how to get to the cam to lubricate it?

thanks

Posted by Steve Klare (Member # 12) on January 13, 2016, 09:09 PM:

I've actually been in there myself.

I wrote the story of my adventure lubing this machine for the information (and maybe amusement!) of the Forum here:

My Great Worm-Glop Weekend!

The cam tank is located behind the gate. It's what makes the claw jump up and down. It is pretty sheltered in there. You'll probably need a flashlight to look in while you move the transport to see the follower riding up and down on the cam. It's no joy to access for cleaning purposes either.

Characteristically all the parts involved in the cam tank are the same color: "old, dirty grease", so they are a little hard to see in the darkness of Elmo Innards!

Ultimately my ST-1200 got to a real 24 FPS because I replaced a badly worn motor pulley (and also restored the rubber around the shutter wheel), but good lube certainly helps.

Posted by Joseph Randall (Member # 4906) on January 13, 2016, 09:51 PM:

Thanks Steve!

Posted by Andrew Woodcock (Member # 3260) on January 14, 2016, 01:46 AM:

Frank has it spot on above, but it also worth remembering that A.C. induction motors can and do lose an element of starting torque as they age through useage.

Once at full speed they usually perform as normal but the rotors laminations, in extreme cases of full load or higher than full load torque being experienced by the motor regularly, will turn blue in colour through extreme heat.

When this occurs, the rotor can become defunct altogether.

Try to avoid using these machines, or any other projector for that matter,to clean film with using a cloth and thumb and forefinger.

This places extreme loads on any projector motor and can cause motor failure as well as prematurely wearing clutches at the reel arms etc etc.

Just use low geared long play units With no clutch mechanism or rewind arms preferably, to do this task.

Posted by Tom Photiou (Member # 130) on January 15, 2016, 06:42 AM:

Like all things mechanical, these will at some point require the correct lubrication in more than one part of the projector, i myself covered this many times over in the Film for the collector magazines, including replacement of rubber wheels and the exterior rubber around the shutter. IF this has been done i used a modified lower pulley to sort out the speed difference when this rubber was removed.

Starting slow for a few minutes, or more, almost sounds like things may by drying up.

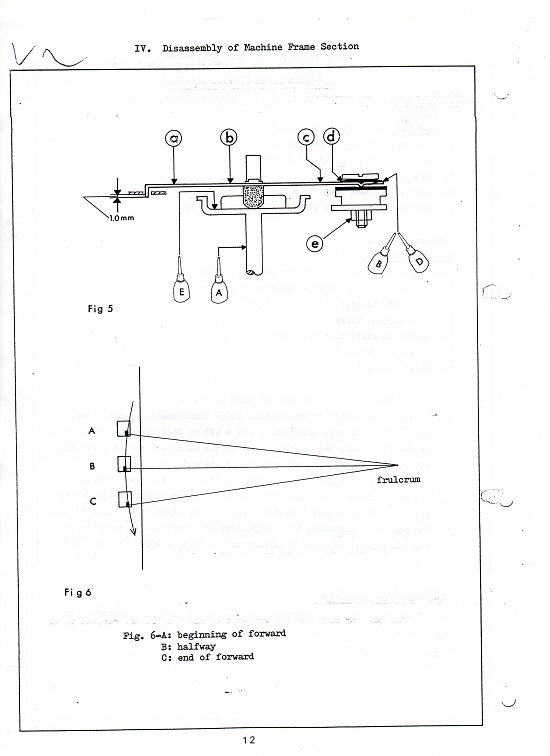

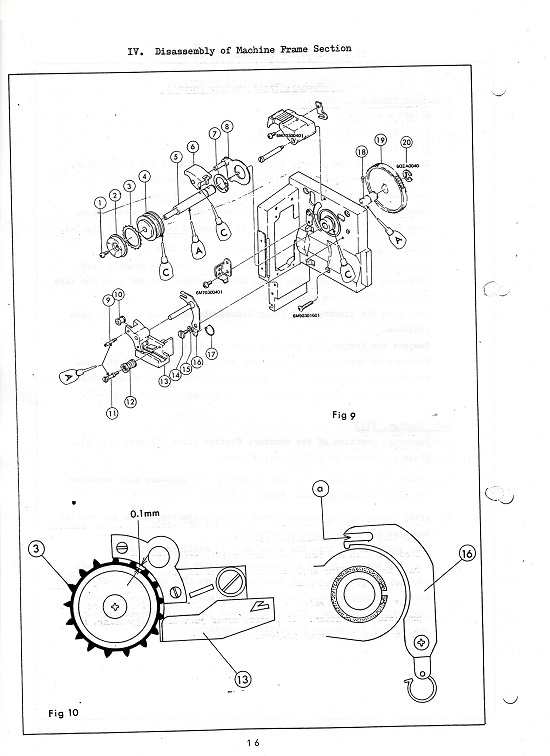

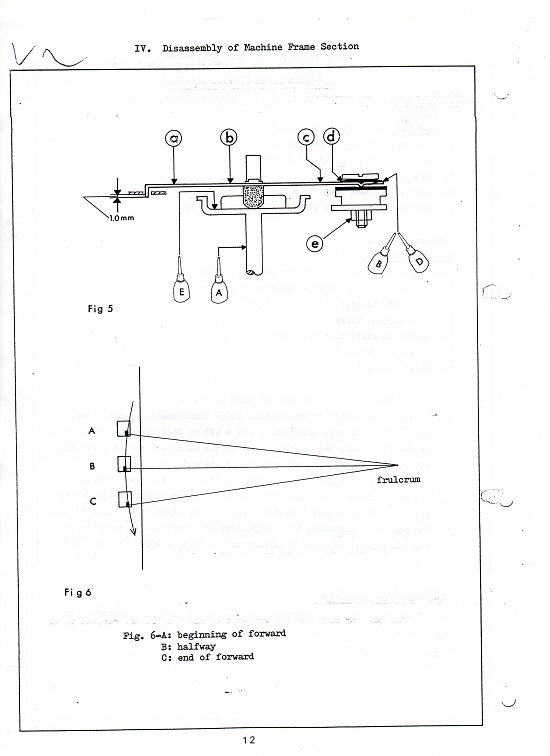

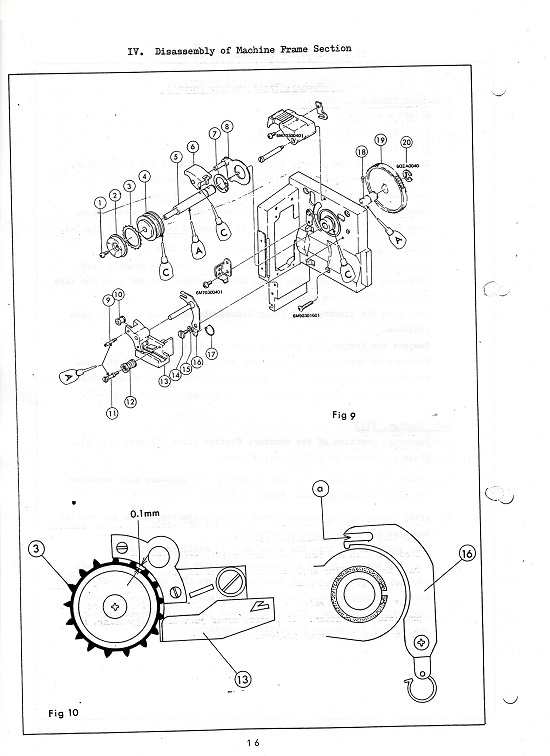

These two pages from the service book are just a starting point, if you would like to see any more let me know

Posted by Osi Osgood (Member # 424) on January 15, 2016, 11:58 AM:

I'm finding what Steve said at the beginning, to be true of some of my projectors. They run slower at the start but once warmed up, run smoothly.

Posted by Tom Photiou (Member # 130) on January 15, 2016, 12:57 PM:

there is an operating temperature ,(like cars) where they do work better but the running speed should be correct from the off. ![[Wink]](wink.gif)

Posted by Andrew Woodcock (Member # 3260) on January 15, 2016, 01:16 PM:

This characteristic among projectors, is only a trait of ac motor driven machines.

No electronically controlled D.C. driven machine fluctuates in speed by any noticeable margins right from the first revolution.

It's the nature of the motor and the result of the forced methods of driving the shutter main shaft because of the motor used.

All speed regulation on ac motors without using an inverter, has to be done mechanically. This involves the use of friction discs, intermediate rubber wheels, spring mechanisms and clutches etc etc.

All dc driven machines are more or less directly driven straight from the motor itself via one solitary drive belt.

D.C. motors also have completely different starting torque characteristics than their A.C. counterparts.

This is what makes All the difference, just like a Technics SL-1200 turntable could be at full speed in less than a third of one revolution when cueing up a record.

Posted by Steve Klare (Member # 12) on January 15, 2016, 01:59 PM:

I battled breaking the 24 FPS barrier with my ST-1200HD for years, and I am finally there.

For years I thought the gradual speed-up was because of slippage on the shutter wheel, but if you think about it, how consistent would that slippage need to be for the sound to be at all good? (How smooth is your car in a skid?) I expect it would grab and let go and the sound would be full of wow and flutter. I actually replaced the rubber on the shutter wheel, but still think the contact was good enough even on bare metal.

The root of all evil here is definitely lubrication. It's the whole reason the thing gradually moseys up to speed: the old stuff is thick with dust and emulsion and it takes a couple of minutes of agitation for it to warm up enough to soften and let things turn easily.

This is especially true of the lube on the worm gear: I literally unwound hair several inches long from the spirals of at least two of my machines. Who's been sticking their heads in there I have no idea!

So when I did a thorough lube, did I get up to 24?

(ummmm)....No!

-and here's the reason:

(I just happened to have this in my desk drawer...no, I don't know why either...)

This is my old motor pulley. It is worn right through the bottom of the sheave. (!)

How it got that way is this: In olden days when I started the machine there was this thin squealing sound for about 20 seconds. I assumed it was the roller slipping on the shutter wheel. I now know it was my motor belt slipping on the pulley and gradually wearing through the bottom of the sheave. (See where sticking to a theory too long can land you?)

-and why did this happen?

Lubrication!

(-or the need for it...)

That slippage was because the old lube made the machinery stiff enough to force the belt to slip.

Once I lubed the machine, this stopped, but it was too late. The wear on the pulley means the effective diameter is smaller and what would pass for a "gear ratio" (if this was a gear) now allows the machine to operate slower at the correct motor speed.

I could have the best lube humanly possible, but with the pulley worn down in diameter like that the math just couldn't work out to 24 FPS.

With the new pulley I am at a consistent 24 FPS: the pitches of my sound tracks are consistent with all my other machines, both AC and DC motored. The "warm up" is faster than the time it takes me to stuff the leader into the feed end of the path.

-so if you have this problem, definitely do a lube. While you are in there give the motor pulley a good look and make sure it's a nice "V" profile and not worn round and deep like this one.

If you hear that squeal, stop!

-it's a cry for help!

[ January 15, 2016, 03:02 PM: Message edited by: Steve Klare ]

Posted by Andrew Woodcock (Member # 3260) on January 15, 2016, 02:21 PM:

If you are convinced, they are both as capable of maintaining a true 24fps throughout a films entire running time Steve, just try recording in lip sync with both!

No matter how well you sort your traction issues out, on these type of machines they cannot maintain a true accurate 24fps or even close.

Posted by Steve Klare (Member # 12) on January 15, 2016, 02:26 PM:

Engineering is the art of "Close Enough".

This machine is just for showing films anyway. I suspect most ST-1200s are and always were.

I have friend at the power plant, If I really wanted it tweaked within +/-.1 FPS I'd just ask him to nudge the frequency!

Posted by Andrew Woodcock (Member # 3260) on January 15, 2016, 02:28 PM:

That'll do it Steve! ![[Big Grin]](biggrin.gif)

![[Big Grin]](biggrin.gif)

![[Wink]](wink.gif)

Posted by Steve Klare (Member # 12) on January 15, 2016, 02:30 PM:

Yeah, so what if the neighborhood's clocks don't keep time anymore!

Posted by Andrew Woodcock (Member # 3260) on January 15, 2016, 02:41 PM:

I'd love my local electric supplier to supply our clocks at 49hz when I'm OFF work then give us all 51hz when I'm in! Ha ha ha.

Posted by Brian Fretwell (Member # 4302) on January 16, 2016, 06:00 AM:

London supply frequency always varies with load on generating plant I suspect Manchester does the same, but it is evened out over 24 hrs so that would work.

I know this because working in a BT computer switching centre we had a frequency meter on the main fault desk. I think this was due to the no break emergency power generators were frequency triggered to keep the supply good at all times. The machines worked with the mains passing through the generator set and keeping it spinning when it dipped the diesels started with the energy in the rotating alternator giving power until speeds matched and the clutch between them engaged. Thus the need for a frequency meter as you could see during the change over if it dropped too low.

Posted by Joseph Randall (Member # 4906) on February 11, 2016, 02:09 PM:

I gave my ST1200HD a good lube, and it helped a little, but it still took a few minutes for it to get up to speed with a film running.

So I took the back off, plugged it in, and noticed that the belt connected to the motor pulley was flopping a bit. It's a wonder that this machine ever got up to the correct speed.

I replaced the belt, and now it runs at speed from the get-go.

I agree that a good lube is always a good idea, though, to keep the machine running at its best.

Posted by Steve Klare (Member # 12) on February 11, 2016, 02:48 PM:

Excellent!

It seemed for a long time like we just accepted that these machines were always slow, but one by one we seem to be finding the real problems and straightening them out.

-Elmo didn't intend they would act like this! There must be a reason (or several...).

My ST-1200 didn't get to a real 24 FPS for years. Early on I measured the speed with an optical sensor and a meter with frequency measurement and I came up with something under 23 FPS even warmed up.

This has real consequences. I run my audio through a mixer that has an equalizer for each channel. Before I fixed my ST-1200 I ran it with the bass turned way down because the sound was kind of muddy. Since I lubed it, replaced the shutter wheel rubber and replaced the motor pulley the equalizer settings are much closer to what I use for my other machines.

Posted by Andrew Woodcock (Member # 3260) on February 11, 2016, 03:31 PM:

the HD models on these can produce excellent CLARITY of sound, I agree. Lovely low end powerful bass and very good top end also!

I ran a digitally re recorded print of a favourite Elvis film of mine through my HD just before parting with the machine.

I ran it through a Numark CM200 mixer then onto a vintage stereo amp and through to some decent Mission bookshelf speakers.

The tonal sound quality was remarkable that day I have to say.

"One of those days" was sensational!

Posted by Joseph Randall (Member # 4906) on February 11, 2016, 08:08 PM:

BTW, the belt I replaced was about 20 years old. Not bad -- it didn't even break -- it was just stretched out a little too much.

The "new" belt is about 20 years old, too, just never used. Bought it directly from Elmo as a spare when they still had them available. Should have bought more than one.

Posted by Andrew Woodcock (Member # 3260) on February 11, 2016, 08:11 PM:

Just watch those guides and rollers buddy!!!

Your next BIG focus point!

Posted by Joseph Randall (Member # 4906) on February 12, 2016, 04:07 PM:

Guides and rollers seem to be in good shape.

Posted by John Capazzo (Member # 157) on February 14, 2016, 11:28 AM:

The motor belt means everything on the original ST 1200. If it's 1/8 off (or a few mm), it makes a difference. Does it rewind entirely or stop during a 400' film? Usually that's also the sign of an incorrect belt. The motors almost never die or run slowly on those machines. The main concern in the future is the amp. Some start to get high piercing noise.

Posted by Steve Klare (Member # 12) on February 14, 2016, 12:06 PM:

I had the high frequency shriek a couple of times and I "fixed" it by working the recording key. One day even this didn't work anymore. I soldered a jumper across the normally closed terminals and clipped the wire off the normally open one.

It's been a couple of years and now I haven't heard the shriek again.

(The last time it happened I was working through an Amp...I'm lucky I didn't kill half the dogs on the block!)

I suppose I should replace the switch, but it's not exactly at the top of my list.

The Amp IC is still out there as New Old Stock. If you are good with a soldering iron replacing it yourself is doable.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Big Grin]](biggrin.gif)

![[Big Grin]](biggrin.gif)

![[Wink]](wink.gif)