This is topic Why dont Eumig's scratch? in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=007315

Posted by Graham Sinden (Member # 431) on July 22, 2012, 07:10 PM:

There have been many comments over the years from Eumig owners that their machines do not scratch film and I would like to delve into it deeper. Well IMO every projector can scratch film and Eumigs and Sankyos are no different. As I see it, the problem with Eumigs is that they have a smaller gate picture than say Elmos so your Eumig could be scratching on the extreme left and right edges but you may not see it until you run that same film through another machine.

We all know why Elmo's scratch (the green guides, black tensioner etc.) But I like to hear from Eumig (and Sankyo) users as to why the Eumig (and Sankyo) film path is so much better. All these machines have rollers, pressure pads, plastic guides. Are the rollers a better design than the Elmo and are they made from a better material? What about the film path guide used on the Eumig? What did Eumig do right that Elmo should have done?

As for myself I mainly use Elmo's. I have a few dual guage Eumigs but dont use them much and a 926GL stereo but I dont like the dual core reel design so dont use it that often.

Your thoughts please.

Graham S

Posted by Paul Adsett (Member # 25) on July 22, 2012, 08:06 PM:

Hi Graham,

I have heard that statement before about not being able to see Eumig scratches because the Eumig aperture is just smaller than the Elmo aperture, but I do not believe it. I run my films on both Eumigs and Elmos and the only scratches that I have on my prints are quite definately Elmo induced. Eumigs do not induce deep green scratches 1/4 of the way into the right of the picture -that is a distinct Elmo characteristic.

Its hard to understand exactly why Elmos scratch and Eumigs don't, and I want pretend to have the answer but here are a few thoughts of mine for what its worth:

The Elmo's have that little black flapping film tensioner below the sound head, which their designers must have found out was necessary to smooth out the inconsistent and varying tension from the take up spool which causes WOW. This tensioner eventually develops grooves in its surface that can scratch film. Eumigs have no such feature, as it is not necessary on their machines which have much bigger sound capstans and pressure rollers which really clamp the film very firmly compared to the very small diameter Elmo capsan.

The film path on Elmos goes through two tight reversal loops before entering the sound head, whereas Eumigs just have a single gentle turn. The loop reversals on the Elmo necessitate an additional pressure roller at the input of the sound head, which pushes the film down onto a metal guide which can wear and scratch film.

Also the top feed sprocket on the Eumigs has a much more relaxed bend for the film, and does not force the film tightly against the plastic film channel in the way that the Elmo does. This is known to be a definate scratch hazard on the Elmo, and some people ,like Dave Locke, have fitted rollers to eliminate the feed channel scratches.

Whatever the reasons, in my opinion Eumigs are just much kinder to film, and the Eumig designers must have paid much closer attention to their film path design than the Elmo designers.

Having said all that I should state that my Elmo's currently do not appear to be scratching film - if I meticulously clean the film path before EVERY reel. Eumigs are much more relaxed in that regard, not requiring nearly as much film path TLC.

By the way, are you planning on going to the October BFCC?

Posted by Alan Rik (Member # 73) on July 23, 2012, 12:22 AM:

I had a Sankyo S800 which scratched my print of "The Snowman".

Grrr!!

Posted by Joe Balitzki (Member # 438) on July 23, 2012, 01:51 AM:

What is ironic is that the film path on the Elmo & Sankyo is more easily accessible for cleaning. And unthreading in the middle of a reel is impossible on some (all?) Eumig's.

Posted by Hugh Thompson Scott (Member # 2922) on July 23, 2012, 04:49 AM:

The answer is simple,the Germans have a reputation for precision,

and therefore everything is made to order and it must be right,

the Japanese are not known for this type of engineering,and so

take short cuts like the tracking common in all Elmo's,they never

innovate but tend to copy or try to improve on accepted ideas.

Their machines are the cause of a lot of damaged prints out there

and I can't think of any German projectors that have a reputation

for film damage.

Posted by Joerg Polzfusz (Member # 602) on July 23, 2012, 05:04 AM:

Hi Hugh,

due to Napoleon and the winners of WWI, all Eumig-devices are "Made in Austria" (except for a few cameras that are "Made in Japan") and hence haven't got anything to do with German reputation. ![[Big Grin]](biggrin.gif)

Jörg

Posted by Martin Jones (Member # 1163) on July 23, 2012, 05:05 AM:

Or even the AUSTRIANS,Hugh!

Martin

Posted by Alexander Lechner (Member # 1548) on July 23, 2012, 05:43 AM:

Being an Austrian I have to say: the ones with a reputation for precision are the Swiss (just to add another nationality).

Back to the subject: also Eumigs scratch film. I have a few 800 Series and made the observation that there is wear on area around the gate; the chrome polished surface wears off with time and the base metal (some brass coloured alloy) gets exposed. The surface gets rougher and fine scratches can develop there. They are ofcourse not visible on the screen when projection is done with this projector, but still. I have also seen gate plates that had a rougher surface and were not polished from the start - saving money in production?

Posted by Lee Mannering (Member # 728) on July 23, 2012, 06:00 AM:

The only time I have known the Eumig 800 range projectors scratch is when as Alexander says the gates are worn out. Thankfully the Eumig design team came up with instantly removable gate plates so it is a quick change of gates to cure the normal wear problem. If the 2 gate plates are nice and shiny then you will not have a problem.

Posted by Pasquale DAlessio (Member # 2052) on July 23, 2012, 08:27 AM:

I have the best of both worlds. An Elmo ST1200 and a Eumig Mark S 807D . Neither of them have scratched any of my films. I keep the film gates clean as well as the complete film transport mechanism and therefore have had no problems. At least none that are visible with the naked eye ![[Eek!]](eek.gif)

Posted by Hugh Thompson Scott (Member # 2922) on July 23, 2012, 09:35 AM:

I was just about to apologise for my faux pax ,and beaten to the

post before I could rectify,of course Eumig is Austrian,but the fact remains,these machines are legendary especially the older models,before plastic moldings took over, and well do I remember being told by a well known UK supplier when

I asked about the Elmo's scratching,"Well they do if you use them a lot!",which beggars the question as I use my old Mark S

machines a lot and not a frame marked.When they were called

"The Wizards of Vienna" by a well known journalist some years

back,he knew what he was talking about.

Pat,don't be complacent with your Elmo's,no matter how clean you keep them,that isn't the problem,it's down to the plastic wearing.The late Paul van Someren itemised all the points of

wear in his mag,and identified the position of the scratches on

screen,he didn't have to do that with any other make.

Someday,you'll watch a favourite film and discover some nice

green scratches that were'nt there before,and then another

print and another,they are not to be trusted without modification.I found that out through bitter experience.

Posted by Gary Crawford (Member # 67) on July 23, 2012, 10:20 AM:

I had a Eumig 709D....which scratched the devil out of my prints....especially when used for Super 8. I have not had any scratching with the elmos....and I've been using them since the mid 70's.

Posted by John Clancy (Member # 49) on July 23, 2012, 11:00 AM:

I too have experienced the famous Eumig emulsion scratches that render your prints unwatchable and worthless. They did some good machines but they also produced some complete crap.

Posted by Hugh Thompson Scott (Member # 2922) on July 23, 2012, 11:27 AM:

The have/nt done half the damage that Elmo have done John,

even you no doubt have alterations to your projectors for anti

scratch.

Posted by Winbert Hutahaean (Member # 58) on July 23, 2012, 11:29 AM:

quote:

all Eumig-devices are "Made in Austria" (except for a few cameras that are "Made in Japan")

Look how the economy is working.

1. 1950-60s Europe made good machinery, then to cut the cost they sent to Japan

2. 1970s-1980s Japan made good machinery, then to cut the cost they sent to Korea

3. 1980s-1990s Korea made good machinery, then to cut the cost they sent to China

4, 1990s -2000s ....?

Posted by Hugh Thompson Scott (Member # 2922) on July 23, 2012, 11:44 AM:

In this little corner of the world Winbert,anything that had

Made in England or Made in Gt Britain stamped on it,people

knew they had an item of good quality that would give years of service (the iron bridges in Venice were all manufactured in

England),unfortunately that is not the case now,as we follow the

idea of "calculated obsolescence" where certain items are given

a certain life then discarded.Then we have to listen to the

political arseholes talking about recycling.You do realise that the

people out there think we are all a bit odd forever getting

projectors repaired when all you need is a dvd player.

Posted by Osi Osgood (Member # 424) on July 23, 2012, 12:55 PM:

I'm sure that continual good maintenace of your projectors also help, but I will also say that the top of the line Eumig's are pretty much scratch free, while the cheaper models can sometimes be unreliable.

Posted by Graham Sinden (Member # 431) on July 23, 2012, 08:03 PM:

thanks for all those replies.

Paul, Very interesting observations and mabye you have a point about the loops in the Elmo. I think that Elmo based their film path on their 16mm machines but dont have an Elmo 16cl to compare with. BTW I will be going to the october BFCC ![[Smile]](smile.gif) .

.

quote:

What is ironic is that the film path on the Elmo & Sankyo is more easily accessible for cleaning

Joe, that is one feature that I really like on the Elmo's, the fact that you can quickly pull down the film path cover to check if the film is ok. And you can easily gain access to the gate by swinging out the lens. On Eumigs, even the later ones, you have to unscrew the cover and pull it out. Not as neat as the Elmo where you can inspect the film path quickly and quietly in seconds.

Certaintly Elmo's can scratch if not carefully checked from time to time but can be modded for scratch free but this was not something Elmo thought of from the start. Eumig's might possibly have a better film path but not sure if we can call them 'scratch free'.

What is interesting is that Elmo placed 2 nylon rollers at the entry and exit of the top sprocket on the ST-1200HD and the GS800 but only 1 on entry of the GS1200 (their top machine?) which leads to wear on the exit of these on the GS1200. Many people add an extra roller here but its something we shouldnt have to do. Also the ST1200HD has a rubber roller for the tensioner instead of the black plastic type used for the GS series. This rubber roller can be used in the GS series (I believe) but its a shame that Elmo didnt continue to use this type when they desingned the GS series.

Graham S

Posted by Hugh Thompson Scott (Member # 2922) on July 23, 2012, 09:04 PM:

On the whole Graham, the Elmo is a nice projector, the ST1200

gives the impression of a scaled down 16mm machine,bar for the

snubber roller being before the bottom sprocket.Cleaning is relatively easy,but you can clean the thing till the cows come

home,it is STILL gonna scratch,and that is a serious defect,especially

on prints costing many hundreds of pounds.Making excuses for their designers oversight cuts no ice with me,the projectors are a menace to film until they are modified,Which is why I said earlier,the Japanese are not innovators.

The problem with the majority of these machines lies with

auto thread,and that was fetched in by a designer because he

thought joe public could'nt lace up a projector.If the Elmo's

had been designed like a true pro machine,they would not have

been auto threading, because that is where the trouble lies.

Posted by Akshay Nanjangud (Member # 2828) on July 23, 2012, 09:45 PM:

Isn't it possible manually thread Elmo projectors? If automatic threading is the major source of scratching, we can always just manually thread projectors.

Posted by Hugh Thompson Scott (Member # 2922) on July 24, 2012, 05:32 AM:

I'm afraid it isn't that simple Akshay,as a lot of the projectors

are fixed track,by that I mean the film path is an integral part of the projector.As John mentioned in the other thread regarding

Elmo,it could be feasible to remove the guides etc and he is

right.

Posted by Akshay Nanjangud (Member # 2828) on July 24, 2012, 09:53 AM:

Now I sometimes manually thread my ST-1200 and ST-1200HD sometimes. I shouldn't do that?

Posted by Hugh Thompson Scott (Member # 2922) on July 24, 2012, 11:54 AM:

If you want to do that Akshay,that's fine,but I don't know what

advantage it would be,it's just that John did say,and he's right,

that the Elmo's would still function without the auto film guides.

Posted by Andrew Woodcock (Member # 3260) on October 19, 2012, 06:00 PM:

Hello again Hugh, you appear to be extremely knowledgable on this film scratching issue associated with Elmo's.I have been fairly lucky so far having owned 4 different machines some being different varients of the ST1200. I was wondering if you could point out exactly in a detailed explanation what modifications are needed before any of my prints get damaged please. Thanks Andrew

Posted by John Clancy (Member # 49) on October 20, 2012, 03:46 AM:

Worst damage ever done to any of my films was on a Eumig RS3000. One heck of a deep emulsion scratch. Never did find the reason for it and it never did it again.

But to be fair Eumig had become mass market by then and corners were being cut. I have an earlier Eumig that whilst it feels cheap compared to a similar Elmo of the day, it is a great little machine.

Posted by Osi Osgood (Member # 424) on October 20, 2012, 01:14 PM:

As a general rule, they do not scratch, but they will if not properly maintained, but still magnificent projectors!

Posted by Paul Adsett (Member # 25) on October 20, 2012, 02:02 PM:

I have several Eumigs of the 800 and 900 series, and I can honestly say that I have never had the scratching experience that John describes. But, I also have never used the particular (rear projection) model that he used.

Posted by Hugh Thompson Scott (Member # 2922) on October 20, 2012, 02:04 PM:

Hello Andrew,I have had my share of damaged prints through

Elmo's.I would go so far as to say I have a pathological hatred

of those shoddy plastic guides.John is right about the Eumigs

as they produced each later model, I have one of the 932s and

the difference between the 700 series and this is like night and day,plastic mouldings and casing, not good.Back to Elmo's, the

ST1200 is a great projector, good design,great playback and

a dream to use if recording it's just that they "spoilt the ship for

a ha'porth of tar" and I can never forgive them.Points to watch

are the upper sprocket guide, that should have relieved rollers

the feed shoe that does wear and requires a roller, the head presser that also supports the loop below the gate will wear

and need either polished or replaced ( i actually fitted a roller on

this after cutting away the plastic) the guide for the soundheads eventually wears and the film actuall cuts into it,

the lower sprocket guide is also a point for additional rollers

I have also removed the less than useless spring guide that

pushes back for large spools.but can cause havoc if it springs while your back is turned Elmo's I have had ST 1200s; one brand new,one

obtained from a chap who got one and hardly used it and one

from the actor Brian Murphy via Perry's and they all scratched

eventually.I was sick of buying replacement guides from

Hanimex, so I modernised them myself and fitted extra rollers

which eliminated any fear of marks,also with the GS1200.

Don't get me wrong Andrew,Elmo's are a great machine,just be

on your guard with those guides.As for Eumigs not scratching,

they are to be checked around the picture gate area,as the

copper plate on some models will wear and scratch.The film

path on the 700's was well thought out and is easily kept clean

with a thin piece of wood with lens tissue wrapped around dipped in Meths.The early Eumigs and Elmo ST1200's have a

very important common denominator, and that is it is simple

to remove a film partway, and if need be, replace it.

Posted by Paul Adsett (Member # 25) on October 20, 2012, 02:37 PM:

Hugh is right about the build quality of the early Eumigs. The 700 and 800 series were built like tanks, with the main chassis and cover structures made from aluminum pressure die castings. On the 900 series, the main chassis is still an aluminum casting, but Eumig went to injection molded plastic front and back covers to a) reduce weight and b) absorb noise and dampen vibration. Anyone who has lifted a GS1200 will be grateful for Eumigs weight reduction efforts. The front and back covers on the GS weigh a ton, and 5lbs could easily be shaved off by using plastics, but I doubt that many GS owner would have preferred Elmo to use plastics. But, probably what Hugh is alluding to is the greatly increased use of plastic moldings for film path and other parts on the later Eumig series. On the 926, some of the features associated with the film guide parts , rewind roller arm, and main control knob, are ridiculously fragile and could never have been put through any stress analysis- were Eumig trying to save a few bucks on injection molding material, or what? ![[Confused]](confused.gif)

Posted by Laksmi Breathwaite (Member # 2320) on October 20, 2012, 04:19 PM:

Well I guess I have heard everything. Hugh you must have studied the ELMO projectors. I happen to love the elmo SC-18 and have had no trouble sines now. My Forbidden Planet film from Red Fox has a a green line on the left far side of the film. only until it gets 3/4 way into the first reel then it just is gone? I first thought was the projector has been used to much and I did not clean it enough? Sometimes if you show films that leave a residue on rollers,gates,plastic self loading plastic bits. I thought that the print is simply in a state of decomposition in which the dyes are breaking down. because of age or climate conditions . Any way I have checked out all my films and found the same type of scratch on my first reel of my Magic Sword film also from Red Fox that is turning a bit red. The line scratch went on half way through the film but just stopped . It was nowhere else on the film. . So I'm back to my dear friend Elmo? I cleaned the film track with alcohol and sent my Goldfinger film from Pat with a prayer when I re showed it and nothing was there. I did show other films a few times before the Bond. And nothing was there. My older films had no scratch like the ones on the Red Fox films. So now I am afraid to show my high priced films on my trusted Elmo? Anyway I saw Forbidden Last night and the other reels look good with that gorgeous color. even the 007 film look great . So should I take all the plastic bits off and replace with rollers/ If I even really new how to do that. If I did it wrong I would be in worse trouble. Hugh you got to make a drawing or show pictures or something ,illustrations and detail descriptions. I once had a Eumig projector and as I remember it scratched the hell out of my Disney Cartoons I had to replace everything. I got into Elmo and kind of really liked the self loading bit because of time and everything. I seemed to scratch and tangled up the film or it got scraped on the ground . Especially out doors on those out door showings. I thought that if you keep a print clean and lubed it would be much harder to get scratched. Or keep the projector clean till the cows come home as Hugh has said ,would help. But cleaning the film like Pat has said may show things you don't want to see like those hidden emulsion demons. So what do you do just look at the film boxes like a CGC comicbook plastic case? And just only watch the film on DVD or Bluray? Or just be worried that you will play your Eumig or Elmo and those green monsters from the IT will appear.

Posted by Hugh Thompson Scott (Member # 2922) on October 20, 2012, 04:30 PM:

Laksmi don't worry, I did mention on another thread about this

with your film scratch.Send me your address and I'll forward

some information as I can't upload or scan with this server.

Posted by Laksmi Breathwaite (Member # 2320) on October 20, 2012, 09:04 PM:

Okay remember Hugh I have a Elmo SC-18

Posted by John Clancy (Member # 49) on October 22, 2012, 02:49 AM:

Whilst I now think the deep emulsion scratch caused by the Eumig was probably a piece of acetate film debris it is fair to say the late 70s Eumig's were cheap and fairly nasty in the main. Paul has a later machine (I believe) when they'd moved away from the tandem spools and back to conventional feed and take-up.

But I do like the RS3000 projector despite being a bit of a clunker. One day I'll try out one of the late Eumig stereo machines but right now I have enough GS1200s to keep me going and in my experience they are far superior to everything else except perhaps for the robust machinery produced by Fumeo. The problems come with the GS1200 when you purchase one second hand and don't realize how knackered it is in the first place. These machines have usually done a lot of work in their lives and you wouldn't tend to put the same amount of usage through a Eumig or most other makes.

Posted by David Ollerearnshaw (Member # 3296) on October 27, 2012, 05:31 PM:

My first projector was a 'Electricity Light Machine Organization' Elmo Sound ST-1200 Magnetic & Optical. I remember this sometimes did scratch film, if memory serves me it was a green scratch down the right hand side. But for some reason not all films were scratched.

Some films seemed to have very rough slitting, if you held your fingers on the edges it felt rough. One company in the UK made a machine called something like 'equaliser' (made by the same company that made 'Cut-A-Rut'). it was made for standard 8, I think because sometimes the slitting was not smooth. Of course this could be used for super 8 too.

Another problem I found was 'green prints' these were new prints never projected before. One was scratched on its first run though. Green prints could also cause a slight up and down stutter on the image.

Cured this by using 2:22 a cleaner/lubricator, this was fantastic stuff though not made for a long time, but the prints it was used on are still lubricated. Plus it altered the light refraction and could reduce the impact of scratches. That's what it said on the tin!

I sold my ST1200 for the GS1200 mainly for stereo sound. This had a couple of 'design' faults on the film path.

I suppose the main fault was the use of plastic for some of the film guides.

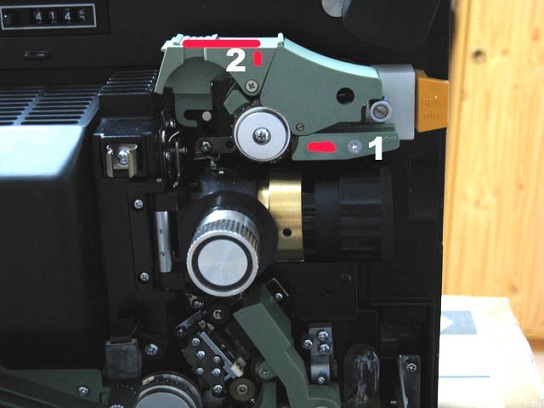

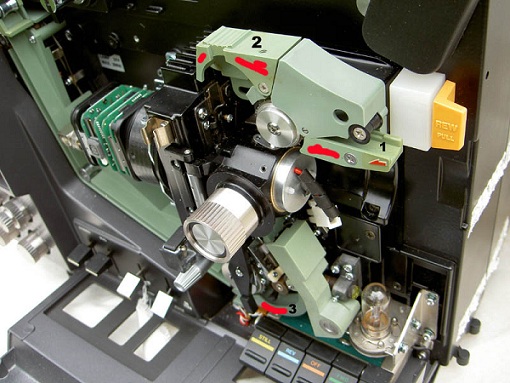

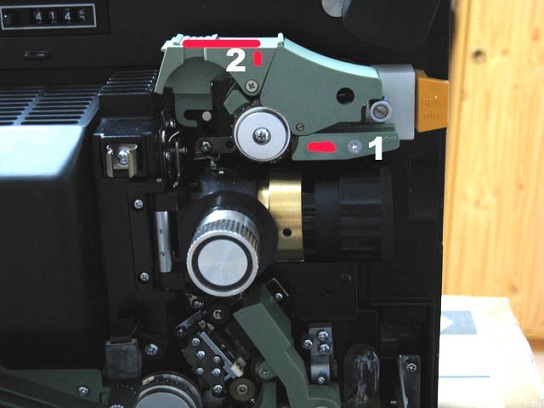

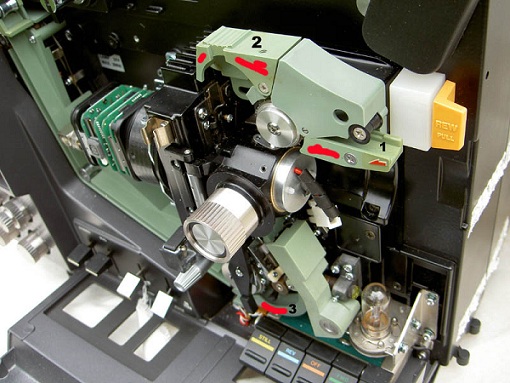

I was told by CZ Scientific that the bits highlighted in red are the main problems.

Number 1 is part of the auto thread system, this can be removed, but you lose auto thread. I wonder if 2 & 3 could removed? This also is part of the auto thread. 3 is also a part that suffers wear. I would say on the GS1200 the parts that cause the most trouble are 1 & 3. On 2 the film should not make contact anyway. All the green bits seem to be for auto thread anyway.

I always clean before, during and after each use. A blast of canned air for the film path in general, & a brush for the gate area. The compressed air could cause damage to the gate area due to its very cold air.

Think the reason I went for the ELMO's was the spool size & they looked well built. Almost forgot reviews for Eumig's was problem with hum, that put me off them.

Remember Bill Davison who reviewed 'Bootlace' in Movie Maker' used Eumig projector.

Like your view Winbert, just think how many films would be ruined if they still made projectors. Most things now seem to be made to break ASAP.

Your right Hugh. In days gone by the words Made in England/Great Britain/UK/America/Austria/Germany/France/Italy and Japan were a sign of quality. They lasted. My wife is of the "Oh its broke buy new"

Laksmi what's in the card box on the second photo? They don't look like film. ![[Big Grin]](biggrin.gif)

Posted by Patrick McGrath (Member # 1210) on November 01, 2012, 04:34 PM:

This is a very interesting topic. I am fairly new to this hobby(4 or 5 years now) and have had a couple prints scratched from a couple different projectors. Early on I had a GAF 3000(?) that was really a Chinon in disguise. That machine was responsible for a few scratches. A Sanko 600 put intermittent faint scratches to the far left side.

The Sankyo 800 I still own was scratching when I first got it, but I was able to resurface the offending areas and added a roller at the feed-in. That one had wear at the point where the lower loop feeds into the sound head area. Basically the film bounces off the bottom of the head entrance and creates grooves. I smoothed those out but tend to keep my eye on it for further wear.

Last year I acquired a nice used ST-180 from Japan. I have used it several times, after a thorough cleaning and polish of everything plastic. I've learned a thing or two about possible scratch hazards!

I've had no issues with this machine however I decided to see if I could reduce the potential hazards by eliminating everything in the film path that could scratch.

In essence I have modified the machine into a manual thread by removing the feed tray thing, the top and bottom loop formers, and also modifying the 1st and 2nd sprocket pieces which hold the film onto them.

I'll post a few pictures when I can.

I don't find the manual thread to be inconvenient in any way, but I also collect 16mm and have an old Bell and Howell 179 which is manual thread, so I am used to it. As a matter of fact I used the 179 as a bit of a model,if you will, for my ST-180s manual thread mod experiment.

I can't agree with the sweeping statement aimed at the Japanese early on in this thread and in defense I would say that both Elmo and Eiki 16mm machines are superbly crafted, with much more thought put into film path and higher grade materials. I would guess that because the super 8 market was a lower price point certain materials were used to keep costs down for the end user. And as stated about many aspects of this hobby, it is unlikely that there was ever any thought that these projectors would still be in use 30 years later.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Big Grin]](biggrin.gif)

![[Eek!]](eek.gif)

![[Smile]](smile.gif) .

.![[Confused]](confused.gif)

![[Big Grin]](biggrin.gif)