This is topic Elmo ST600: Threading mechanism break: To epoxy or not? in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=009052

Posted by John Wilton (Member # 395) on March 21, 2014, 12:21 PM:

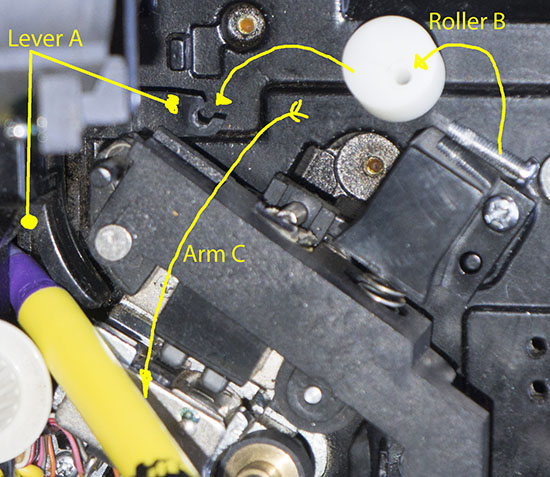

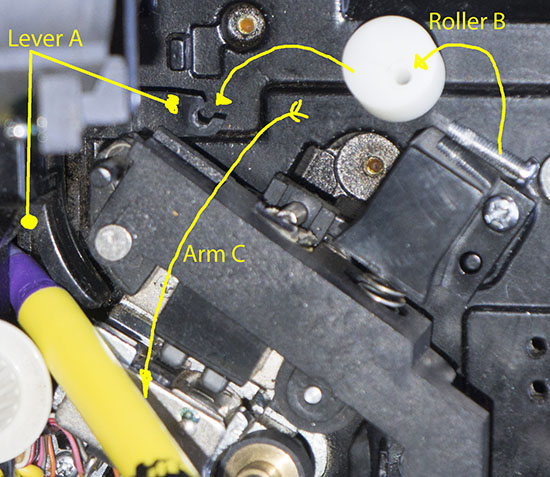

My Elmo ST600 is jamming. The guide that feeds the film into the sound reading section, the bottom part of Lever A in attached photo, was retracted. (In the photo, the spring-loaded Lever A is held in loading position by the pen). I found Roller B floating loose. Eventually found the top part of lever A hiding under Arm C, solving the mystery of where it came from.

Evidently, when Arm C is in the off/threading position, Roller B holds Lever A in threading position. When Arm C lowers into playing position, Roller B follows it down, and the film guide part of the lever retracts.

Roller B is eccentrically drilled. Unfortunately Lever A is made of plastic and the tip has broken off, rendering the screw hole non-functional.

Questions:

1. Why is the screw-hole in Roller B drilled eccentrically? Is the roller intended to pivot; or is it supposed to be screwed down tightly, and intended to be a way to adjust the loading position of the lower film guide portion of lever A?

2. What is the advisability of simply epoxy-ing Roller B to Lever A?

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2