This is topic Question Re. Eumig 824 Sonomatic in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=009297

Posted by Terry Lagler (Member # 1110) on July 15, 2014, 08:52 AM:

Friends of our just gave me a couple of “broken” projectors that were stored for years. A Bell and Howell dual 8 with a DJL lamp and the one I want to get working, a Eumig 824 Sonomatic.

Being a dual 8 sound machine I’d love to get this going again. Good news both super 8 and standard 8 gates were in the carrying case. The control knob “sleeve” was cracked so turning it did not engage the mechanism – it just slides. A mini hose clamp solved the problem and it seems all functions work

Unfortunately I only have a German PDF of the manual so my rusty German will have to suffice until I find an English version. At least I was able to that the inching knob white dot needs to be in the up position before changing gates. The standard 8 gate is in but here is where my questions arise. From reading elsewhere the super 8 sprockets need to be removed leaving the standard 8 (although this seems odd to me) The problem occurs when trying to load film. The from sprockets turn but once the film touches them they stop so the film will not feed.

I’m assuming it has something to do with the removable sprockets. Anybody have this machine and could enlighten me?

Cheers

Terry

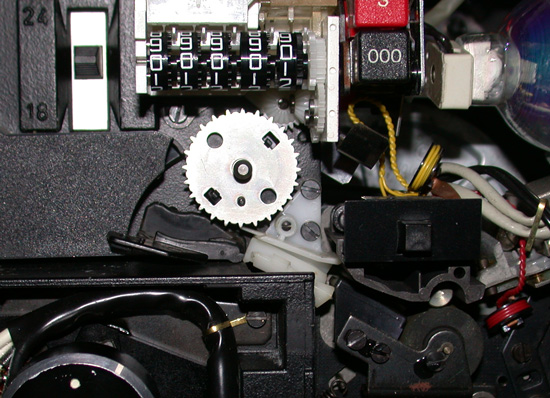

Front Sprocket turns until I attempt to load film.

Super 8 sprockets removed (not sure if they need to always be on)

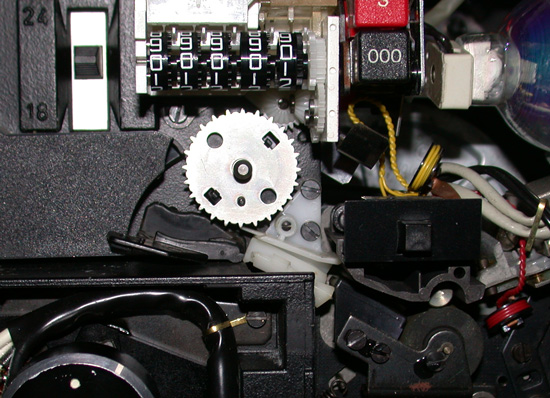

Rear sprockets

Posted by Dominique De Bast (Member # 3798) on July 15, 2014, 09:13 AM:

I am not sure I understood well. Do you remove the Super 8 sprockets and load the film or do you replace them by standard 8 sprockets ? You mention only the gate replacement. I would be more than surprised that there would be sprockets for one gauge and not for another. If I misunderstood, don't take my message in account.

Posted by Terry Lagler (Member # 1110) on July 15, 2014, 09:29 AM:

Hi Dominique.

The super 8 sprockets shown (in second picture) have been removed. The standard 8 sprockets (which I don't think can be removed)are shown in the first and third picture.

You can see that the two removed super 8 sprockets clip on top of the standard 8 sprockets with the two locating pins/knobs.

So the standard 8 sprockets are on the machine and the super 8 are removed.

Cheers

Terry

Posted by Maurice Leakey (Member # 916) on July 15, 2014, 09:31 AM:

I understand that the standard 8 sprockets stay in position and cannot be removed. To use Super 8 the sprocket teeth assemblies shown in your separate picture just clip on via the two pins.

Make sure the film leader is trimmed correctly.

Posted by Terry Lagler (Member # 1110) on July 15, 2014, 09:35 AM:

Thanks Maurice, I do believe you are correct. I assume the first set of sprockets should drive the film through to the gate but they stop spinning as soon as the film touches them.

I've learned that the 810 uses a similar system and I have that manual in English. I'm going to check it out.

Cheers

Terry

Posted by Maurizio Di Cintio (Member # 144) on July 15, 2014, 09:43 AM:

Terry, that's right: the Reg 8 sprockets are not meant to be removed: they are just left visible when you need the Reg 8 format. When you need S/8, you clip the proper sprocket on them and there you go.

Posted by Maurice Leakey (Member # 916) on July 15, 2014, 11:14 AM:

Terry

You said that the projector had been stored away for years. Maybe the lubrication has dried out and making the drive stop when it feels tension.

The Eumig instruction books recommend running the motor on standby for some five minutes or so before turning the control knob to run. Even then, some Eumigs start quite slowly and only reach correct running speed after quite a few minutes.

It maybe that this is your problem. Turn it on without any film and give it a good run for some considerable time to let everything get accustomed to being used after all these years.

With the earlier 700 series which had a valve amp it always helped to turn it on to help warm up the "innards".

Posted by Jon Addams (Member # 816) on July 15, 2014, 11:18 AM:

Hello Terry,

I just sent you a PDF of the manual in English, let me know if you rather have it in French.

Enjoy the projector

Best regards

Jon

Posted by Terry Lagler (Member # 1110) on July 15, 2014, 11:50 AM:

Thanks You Maurizio, Maurice and Jon for the extra input, it has been very helpful.

Jon, EXTRA thanks for the manual! I'll be printing it out for reference.

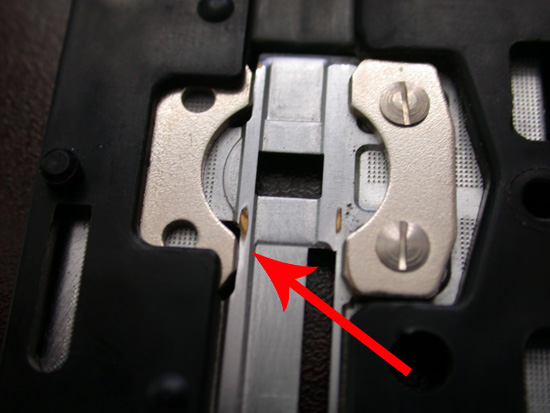

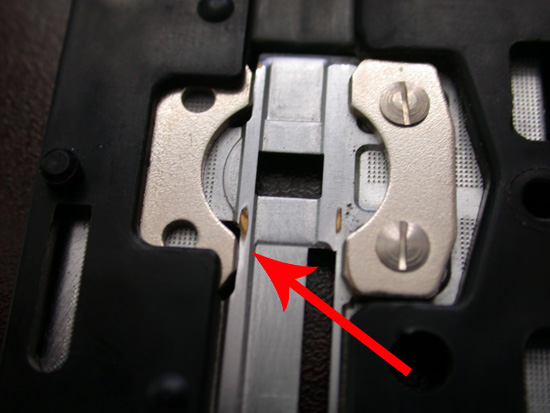

So the setup is correct. I pulled out the standard 8 gate again to look at it and noticed a piece out of alignment blocking the gate. (see photo for reference)

This is the super 8 gate as reference but the left guide had popped out and was sitting skewed blocking the gate. After popping it back in place on the reg 8 gate the projector loads.

I will take Maurice's advise and let the projector run for a while. I haven't given it a thorough clean yet but have noticed some dry lubrication.

At this point the projector loads but the front sprocket does not engage the sprocket holes correctly causing the film to skip over the teeth.

I'd say that would be the problem to work on.

Hope I can get it going - Would be nice to have a standard 8 sound machine!

Cheers

Terry

EDIT - PROBLEM DISCOVERED -

The front sprocket "wheel" is the problem.

Since it wasn't engaging properly I took a closer look at the part using the inching knob. On rotating the "wheel" I found a set screw that can be tightened with an allen key. Good Sign. But rotating it further I found the plastic wheel the sprockets sit on was broken - NOT Good. I've removed it so for the time being I'll try to superglue it back and replace it and see what happens.

Darn

[ July 15, 2014, 01:37 PM: Message edited by: Terry Lagler ]

Posted by Terry Lagler (Member # 1110) on July 16, 2014, 01:51 PM:

Gave the superglue a good long time to dry, put everything back together and ran a 400ft silent film.

very happy to report projector performed great with a rock steady picture.

Fingers crossed it holds.

Cheers

Terry

Posted by frank arnstein (Member # 330) on July 17, 2014, 09:27 AM:

Hi Terry,

You have done a good job glueing the plastic sprocket driver and restoring operation of the projector.

However you have only repaired a symptom of something else thats wrong with your Eumig and it has caused the breakage to occur.

These plastic sprocket drive wheels shouldn't break. There is very little load on them as they help tractor the film into the projector by driving a single sprocket.

So as the actual cause of the breakage is still not rectified, it can only be a matter of time till this wheel breaks again, in much the same way as it did now.

Lets see if any members here can figure out the real cause of this annoying breakage and tell us how to prevent it from ever recurring.

If no one comes up with the right answer within the next few days, I will reveal the answer here to all thats interested.

Dogtor Frankarnstein

![[Smile]](smile.gif)

![[Wink]](wink.gif)

Posted by Dominique De Bast (Member # 3798) on July 17, 2014, 11:42 AM:

Waw, you're good in creating suspens...

Posted by Terry Lagler (Member # 1110) on July 17, 2014, 01:07 PM:

Hi Frank

Ok, the suspense is killing me!

I did find it odd that this part was broken because as you say I can see no real reason for it ( I don't know if anyone ever got mad at this projector as there was lots of bunched up broken film in its innards! )

Will patiently wait for enlightenment.

Cheers

Terry

Posted by Maurizio Di Cintio (Member # 144) on July 17, 2014, 03:36 PM:

Mmmm: perhaps the reason has something to do with the very action of removing/replacing the S/8 sprocket wheel? ![[Confused]](confused.gif)

Posted by frank arnstein (Member # 330) on July 19, 2014, 06:32 AM:

Hi to the Members,

It's time to see if anyone has the correct answer to the Eumig problem and I must say, it is very pleasing to see the many responses from members. All were very good answers although not quite correct.

And now......The correct answer is "a faulty reversing clutch".

The drive wheel breakage usually happens because the reversing friction-clutch tension has been over tightened by someone.

The result of this over-tightening is, a very sharp yank on the film is applied when it's turned from forwards to reverse project. Every time you turn to reverse project, any slack in the film between the top sprocket and the delivery reel is taken up with a hard yank. Eventually the weakest part breaks and that is the plastic sprocket driving wheel.

When put into reverse project, the reversing friction clutch should slip initially and then continuously, and in doing so it will prevent the violent tug by the film to the top sprocket thus protecting the attatched plastic sprocket drive wheel.

In most cases, the reason some one has tightened up the clutch is because it had started to slip during fast-rewind. Tightening the friction clutch will improve the fast-rewind as it doesn't slip now, and so "the repairer” considers the problem is fixed.

The unknown side effect of over-tightening that friction clutch is that it won't slip when it should slip, and that’s when it is turned to reverse project. A clunk is sometimes heard as the slack in the film above the top sprocket is taken up and then the top sprocket is jerked hard around by the film. Often, it will pull the film off the top sprocket teeth and so can’t really project film in reverse any more. So don’t over tighten the reverse friction clutch to improve rewind function.

Rather, dismantle the clutch itself and check the cork friction disc is still glued to its backing metal washer. They have a habit of becoming unglued, and then they just spin with the other washers and don’t function as a friction brake. Reglue the cork washer to its metal backing washer and after lubricating the cork face, refit. Adjust the spring tension to provide just enough pull in reverse-project to rewind the film without coming on with a sudden clunk to the top sprocket.

That is the conclusion of this instructional rambling.

Thank you all for your attendance.

Dogtor Frankarnstein

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Big Grin]](biggrin.gif)

[ July 19, 2014, 07:51 AM: Message edited by: frank arnstein ]

Posted by Maurizio Di Cintio (Member # 144) on July 19, 2014, 06:40 AM:

Amazing!!! Although I think there might be another cause: when I refit the Super 8 sprocket, I have the habit to move it a little in both directions to check if the pin has properly engaged. Perhaps I have put too much strenght in doing so and maybe over time this has led to the break of this plastic element...

In any case it's time for a good overhaul on my old Mark 804 D ![[Big Grin]](biggrin.gif)

Posted by Terry Lagler (Member # 1110) on July 19, 2014, 08:48 AM:

That's detail! Thanks Frank

So, I'm assuming this is only an issue when you put it into reverse when projecting?

Cheers

Terry

Posted by Janice Glesser (Member # 2758) on July 19, 2014, 11:09 AM:

The Incredible Dogtor Frankenstein!.. Your knowledge of projectors never ceases to amaze me. This forum is truly fortunate to share in your expertise. Your contributions have been invaluable and have breathed life back into many of these great old machines. I know I'm personally in this hobby because of the attention and assistance you gave me when I first got started. You are my hero ![[Smile]](smile.gif)

I have an Eumig 810D ... but would love to have a 824 Sonomatic one day ![[Smile]](smile.gif)

Posted by Maurizio Di Cintio (Member # 144) on July 19, 2014, 11:22 AM:

Terry, this problem may impact on forward projection too: if the plastic bearer is loose enough, then if you stop FWD proj, reverse for a few sec and then resume FWD projection, chances are the upper loop will be too small even to such an extent as to cause frame instability. If the plastic bearer is very loose and there is much drag from the feed spool (like when you are using a 50' one towards the end), then the upper loop will be reduced even without passing through REV proj. So it's an issue one may want to fix...

Posted by Dominique De Bast (Member # 3798) on July 19, 2014, 12:31 PM:

I remember reading that (in general, not specifically for this specific model of projector) reverse projections are not good for the projector. Fortunatelly, it is not something you do often.

Posted by Paul Adsett (Member # 25) on July 19, 2014, 08:14 PM:

In most cases Dominique, reverse projection is not good for the film either.

Posted by Terry Lagler (Member # 1110) on July 22, 2014, 07:52 AM:

Just want to thank everyone for your input. Very Helpful.

Frank, I will look into your solutions further.

Cheers

Terry

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Confused]](confused.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Big Grin]](biggrin.gif)

![[Big Grin]](biggrin.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)