This is topic Bell and Howell 10MS Projector issue - please help in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=009301

Posted by Greg Peterson (Member # 4363) on July 17, 2014, 10:46 PM:

I just purchased a Bell & Howell 10MS projector off eBay. It's not fully working, but I want to see if I can fix it before simply returning it. Everything seems to be working except the long spring belt at the top that turns the two spool knobs for the take-up and source reels. The problem seems to be with possibly a broken pulley on the source spool, but I'm not entirely positive that both "discs" are two sides of a pulley that should be connected. One "disc" turns fine, and the other doesn't. I can't take the mechanism apart, as there is a Phillips screw holding everything together (all the way to the arm for the source reel) that I can't get off - it might not be meant to be removed.

I've posted a video of what I've found here: http://youtu.be/LXrxFdsttjM

Any help would be appreciated!!!

P.S. All I'm trying to do is transfer old home movies from Super8 to DVD, and I need a variable speed projector. I have another B&H 456a projector (fixed speed at 18fps), but my camera records at 20fps. If anyone knows of a way to get around this issue, please let me know....other than replacing the motor to speed it up to 20fps. 10MS Projector issue

Posted by Jon Addams (Member # 816) on July 20, 2014, 06:17 PM:

Hello Greg,

You are correct in assuming the problem lies with a broken pulley. that is a 2-part piece than usually comes apart, it is repairable but you need to take it off the projector.

When you take it off by unscrewing it and removing the E clip, you'll probably end up with 2 pieces in your hand, You can glue them back AFTER making sure the pieces are totally dry and free of oil.

If you can't repair it, for whatever reason, I have the part you need but you still have to take to old piece off.

Good luck

Jon

Posted by Greg Peterson (Member # 4363) on July 20, 2014, 07:02 PM:

Thanks, Jon. Any advice on how to get that screw off? I've tried, but it's on there tight, and the pulley turns with the screw, along with the pulley that drives the source reel. I'm worried about cracking more pulleys if I try to lock down anything to keep the screw still.

Posted by Jon Addams (Member # 816) on July 21, 2014, 08:41 AM:

Hello Greg,

I Understand the frustration in trying to remove that screw but it has to come off to either, repair of replace to the broken part.

I wish I could be of more help.

Jon

Posted by Greg Peterson (Member # 4363) on July 21, 2014, 09:56 AM:

I understand, thanks. If anyone has had any experience getting this screw off (top left, goes all the way through the unit to the front and holds the source arm up), please let me know. I've taken the cover off the arm to try to get at it from the other side, and there's just a small circular opening - no nut, groove that I can see, etc. Tried everything.

Posted by Maurice Leakey (Member # 916) on July 21, 2014, 10:37 AM:

I am not at all familiar with this projector. According to the Super 8 data base it was actually made by Haking in Hong Kong and only badged as a Bell & Howell.

It certainly sounds as if the slipping clutch arrangement has packed up. If the parts are plastic some bits may have sheared off. Not a happy prognosis I'm afraid.

You might be better off to buy another projector, one which has a guarantee that it is in working condition. There are too many projectors on eBay which have been hauled out of the loft after many years of non use.

Posted by Janice Glesser (Member # 2758) on July 21, 2014, 11:51 AM:

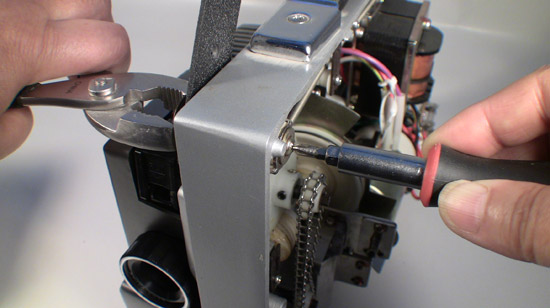

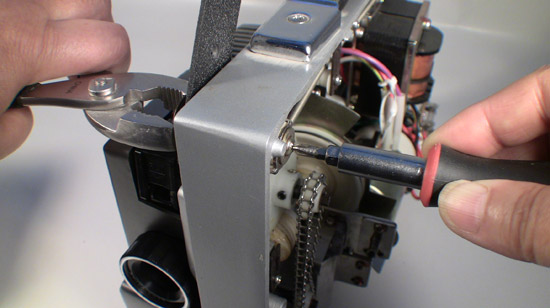

Hi Greg...I still suggest you return the projector, since it was described as working and it's not. However, if you are still wanting to repair it yourself. Here is a suggestion to get the screw removed. The projector I'm showing you is not a B&H 10MS...but I've had a couple of those in the past and the supply reel assembly on this machine is very similar.

It's important to have the correct phillips driver head that will snuggly fit into the screw. Then after removing the front cover of the supply reel arm...take pliers and hold the bottom pully stationary to keep it from turning. Then try to remove the screw. Hope this helps.

Posted by Greg Peterson (Member # 4363) on July 21, 2014, 03:03 PM:

Thanks, Janice, I actually had started that exact procedure, but the more pressure I put, I worried about cracking the gear. The eBay seller has agreed to refund my $$$ without having me return the item, so I'll not worry about breaking it now....just keep putting more torque on it.

I have a Chinon 2500GL coming, so if I break the 10ms, I'll try with the new one (they swear everything has been fully tested).

Thanks, everyone!

Posted by Janice Glesser (Member # 2758) on July 21, 2014, 03:11 PM:

Sounds good Greg. Glad you worked it out with the seller. Good luck with your transfers ![[Smile]](smile.gif)

Posted by Jim Schrader (Member # 9) on July 21, 2014, 04:08 PM:

Greg, if it wont loosen try tightening it then loosening it? how about any spray lube would that be recommend in this situation?

Posted by Greg Peterson (Member # 4363) on July 21, 2014, 05:21 PM:

Thanks, everyone. I finally did get the screw off. I had already tried all the suggestions here and finally just applied some brute force by really grabbing that plastic pulley on the supply arm. The torque finally broke and I got the screw out. It looked like a little bit of rust and what looks like old dried superglue in the screw threads....did someone superglue this screw in there??? That would explain why it was so tough to get out. I did booger the pulley on the supply arm something fierce, but there's enough "pulley wall" left to keep the spring belt on to turn the roller. I did superglue the pulley back together, left it for a couple of hours, and VOILA! Everything works like a charm. This is definitely one of the cheaper B&H models, but things work great. The pulley did break again after a few test runs, but I'll leave it overnight to cure this time. Jon Addams, if it still keeps breaking, I'll contact you to purchase a replacement.

Thanks again everyone! This one was a lot tougher than all the different fixes I applied to the B&H 456a, probably all due to a little rust and a little 40-year old superglue in screw threads.

Posted by Andrew Woodcock (Member # 3260) on July 21, 2014, 05:37 PM:

More than likely one type or another of loctite Greg as often applied during manufacture on all critical set ups.

This was mainly so they (the manufacturers) knew, during the guarantee period, whether or not the machine had been tampered with, in which case the warranty would be thrown through the window if that was proven to be the case.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Smile]](smile.gif)