This is topic Elmo ST 1200 HD M Belts in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=009587

Posted by Tom Dee (Member # 4468) on November 29, 2014, 09:38 PM:

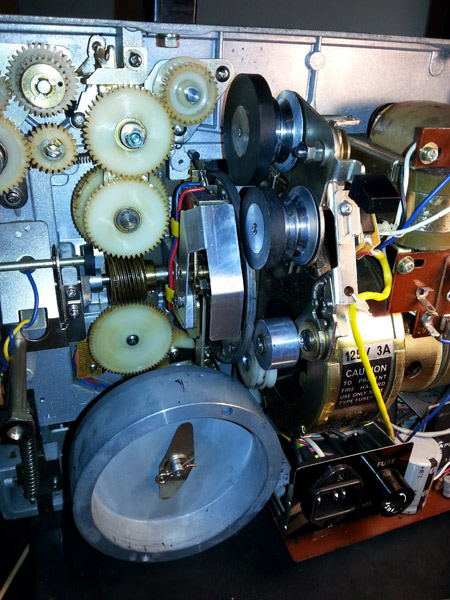

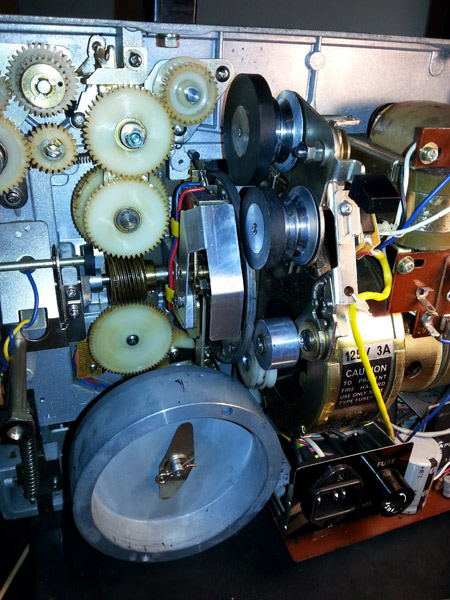

I have just recently aquired a Elmo ST 1200 , when I opened the back up I noticed that there was like a black licorice looking thing in there which I assumed were the belts. I see the belts on E-Bay for different prices. My question is... are there any brands better than others to use, how many belts should be replaced, I see packs of 2, 3 and 4 belts. And I have never done this before...is it an easy job? what do I need to watch out for etc. Any help on the matter would be greatly appreciated.

Thanks

Posted by Steve Klare (Member # 12) on November 30, 2014, 06:37 AM:

Hi Tom,

You probably don't have a good belt in the machine anymore, so they'll all need to be replaced with one being optional.

My ST-1200HD showed up with a brand new set of belts, so I haven't had to change them (yet). From what I've heard the hardest one to change is the small one that drives the footage counter. Fortunately as long as you don't need it, you can skip this one.

I've always had good results with this E-bay seller:

isellprojectorbelts

He's not the cheapest, but there are a lot of cases where the belt needs to have a square cross section and the cheaper ones will come as round belts (large O-rings) and often these don't work as well or as long.

He also has other listings where he sells the belts individually or in smaller sets. He's pretty good at answering questions as well.

Sometimes a belt will go in as simply as putting it in place and snapping it over the pullies. In others you have to take some parts out and put them back afterwards. They are meant to be replaced, so it's not impossible. If there are sticky remains of the old belts they'll need to be cleaned out.

This is a service manual for an ST-1200. It may be useful here:

ST-1200 Service Manual

Posted by Joe Taffis (Member # 4) on November 30, 2014, 09:52 AM:

What Steve said...also, the four belt set from Mark has the little counter belt. I found it pretty easy to change on the ST1200D models when you remove the lamp, but I gave up trying to change it on the ST1200HD....

I have made several purchases from Mark (isellprojectorbelts) off eBay with no problems and fast service. I sent you a PM with his e-mail address if you want to contact him directly ![[Wink]](wink.gif)

Posted by Andrew Woodcock (Member # 3260) on November 30, 2014, 05:25 PM:

It really isn't so bad replacing the tiny counter belt once the counter assy has been removed.

Posted by Janice Glesser (Member # 2758) on June 02, 2015, 12:11 AM:

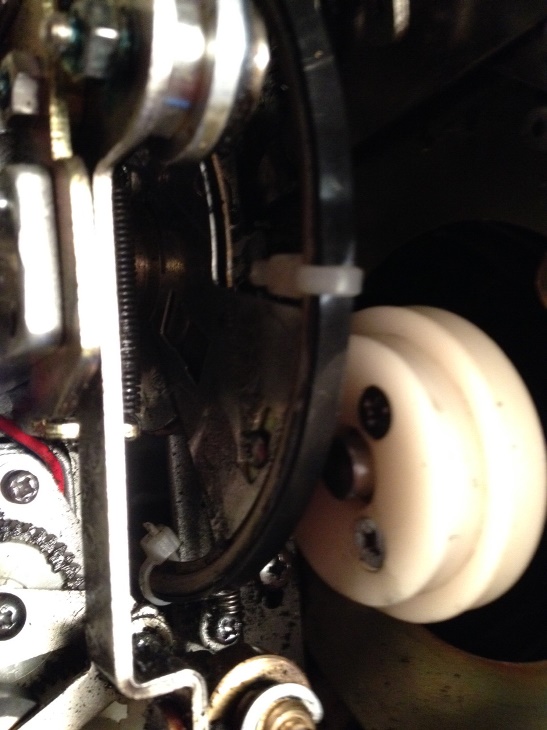

I just bought a Elmo ST1200HD also. Thanks for the link to the Service Manual Steve. I counted the 4 belts mentioned and yes they all need replacing ...however it looks like on the shutter wheel there is a badly deteriorated belt attached to it also. I'm not at all familiar with the ST1200HD...but from pictures I don't recall a belt on the shutter wheel....why?....seems odd. Replacing the shutter belt doesn't look like an easy task. Any comments about the shutter belt?

Posted by Maurice Leakey (Member # 916) on June 02, 2015, 02:41 AM:

The shutter is surrounded by a rubber ring, and Janice is right. It's not an easy job to remove the old deteriorated rubber.

Posted by Edwin van Eck (Member # 4690) on June 02, 2015, 06:43 AM:

For the belts and spare parts of the Elmo ST 1200 HD, you can have a look at the film projector spare part finder.

http://van-eck.net/itable.php?lang=nl&size=0&cat=film&merk=elmo&type=ST1200%20HD

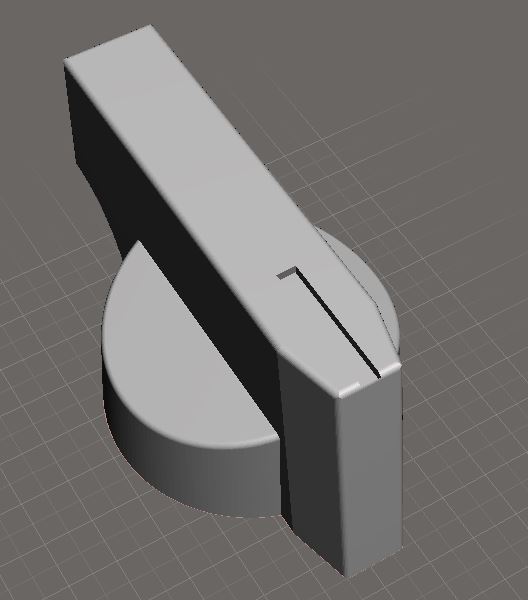

Note that in a couple of day's we will start selling the main button (new using 3D printing techniques).

About the belt around the shutter. In some cases the rubber was bad here and we removed it. The projector seems te be working fine. But if needed we can have a look to also fabricate the shutter belt.

Posted by Janice Glesser (Member # 2758) on June 02, 2015, 10:46 AM:

Finding the belts really isn't the problem. they are available on eBay...including the shutter belt. It's the process of removing the old belt and installing the new belt that I am asking about. From previous post on this forum some say you can just remove the shutter belt and the projector will run fine only a bit noisier. Has anyone tried removing the belt from the shutter wheel and installing a new belt? Instructions on eBay indicate you have to use contact cement to apply the new belt. This sounds like something a professional or experienced repair person would need to do. If not applied correctly I could see the shutter wheel being out of balance. What do you think?

Posted by Steve Klare (Member # 12) on June 02, 2015, 11:04 AM:

Your timing is good Janice,

I have the five belt set on the way right now.

Mark (isellprojectorbelts) says you can do contact cement if you want, but it isn't mandatory.

-Besides, somebody who does the repairs you do should laugh at the puny threat of mere contact cement!

We'll find out soon. I think once the belt is in place, lifting it up and applying the cement a small section at a time wouldn't be too bad.

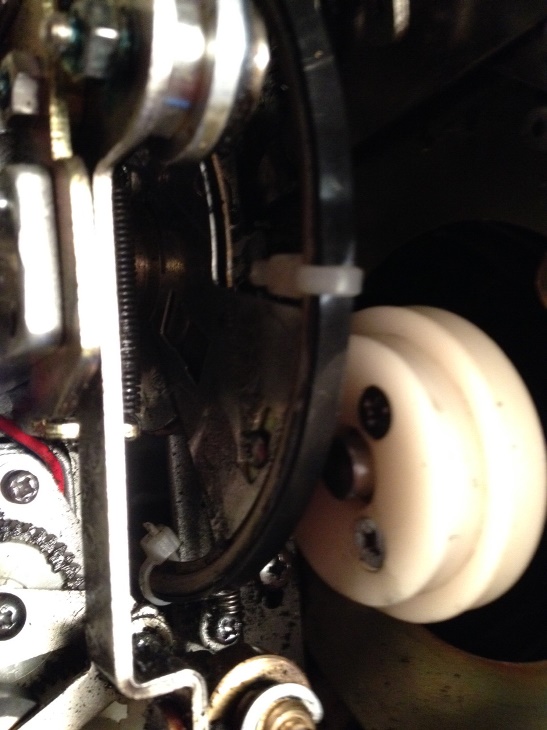

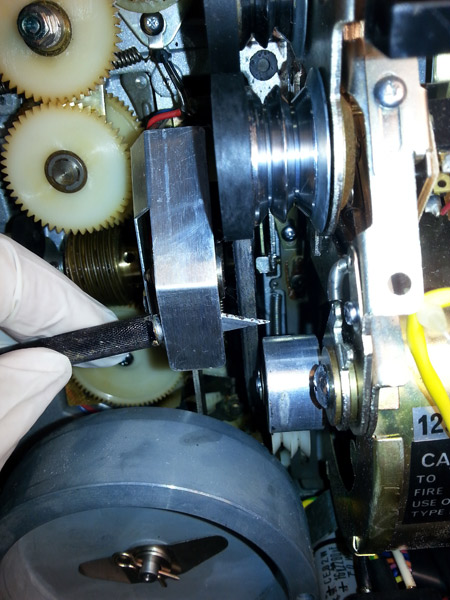

What concerns me is stretching this thin, narrow belt over the thin, narrow shutter wheel edge with the narrow passage through the projector chassis behind the wheel and also the rollers in the way. If it's easy to remove the roller assembly I am going to consider this.

It may come to needing a third or fourth hand on the job. My wife and son don't know it yet, but they may be...volunteered soon.

Posted by Janice Glesser (Member # 2758) on June 02, 2015, 11:17 AM:

I'm going to go ahead and buy the full 5 belt set also. Is it possible for you to take some video or pictures of your installation?

Just a thought Steve... Did your shutter wheel have the belt on it originally? If not, it may not need A shutter belt since the shutter wheel may have been sized to run without the belt.

Posted by Steve Klare (Member # 12) on June 02, 2015, 11:40 AM:

I'm not completely sure. I bought the machine used about 5 years ago and it didn't have the belt at that time.

There is some discoloration on the wheel edge that could be an indication that there was something cemented there at one time...

I think the thickness of the belt is not a big deal in the scheme of things, besides it is on the driven wheel so if anything it being gone would speed the machine up, when it is actually a little too slow.

Pictures? -certainly, video? -absolutely not!

-the freedom to swear is critical to success in this kind of work! ![[Wink]](wink.gif)

I used to work with a technician that cursed at our projects in Italian. The stuff he built worked perfectly!

(Maybe we'll get whoever isn't the second set of hands to be the photographer...and cover my son's ears where needed!)

Posted by Janice Glesser (Member # 2758) on June 02, 2015, 12:30 PM:

The swearing part I totally understand Steve :-) It comes with the territory of working on these projectors. When I make a video I generally have to over-dub. If I used my original sound track I'd have to add "bleeps." ![[Eek!]](eek.gif)

![[Wink]](wink.gif)

![[Eek!]](eek.gif)

Posted by Andrew Woodcock (Member # 3260) on June 02, 2015, 02:30 PM:

When I had a HD, I prefered to leave the shutter belt in place as it really did dampen the noise from the clutch drive chain.

The projector always ran smoother than the others I had without the shutter belt fitted but it did also cause a slight amount of vibration through the imbalance of the bonded belt.

Never needed to remove or replace mine but I believe once I sold this machine on, the eventual owner chose to remove it.

With it on, the drive becomes rubber on rubber so there is less chance of slippage from the clutch drive wheel if it is slightly in need of adjustment as often can be the case on the ST range.

Posted by Steve Klare (Member # 12) on June 03, 2015, 08:04 PM:

Welll.....

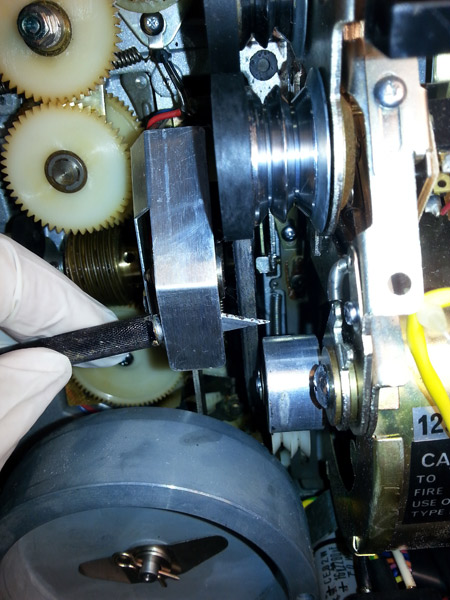

The belts showed up and the process of putting the shutter wheel belt on was at least as bad as I had imagined.

Imagine putting a bicycle tire on the rim...but the rim is passing through a narrow slot in a wall and you have access to maybe a third of the circumference! It pops off the top, then the bottom, then right and left. It's also a black belt in a dark space: it's tough to keep track of it!

The bonus is in this case the "rim" isn't a nice valley between two flanges to hold the "tire" in place, but flat edge.

You really need many hands to hold it in place while you stretch it into place all the way around: the catch is they would have to be tiny, tiny hands! (It's a job for elves!)

The best I could do was find the smallest Ty-Raps we had, line up the belt on the wheel, ty-rap it through the shutter aperture, turn the wheel part of a turn, and repeat until at last it snapped in place.

The clearances were so tight I had to put the Ty-Rap's sliders on the inside of the shutter or the wheel wouldn't turn.

I don't trust this to not slip sideways and fall off the wheel. My next stop is a hardware store for some contact cement. The Ty-Raps will come off as I'm applying the cement.

-and no, I didn't curse!

Now excuse me, I believe I've earned a beer!

Posted by Janice Glesser (Member # 2758) on June 03, 2015, 08:38 PM:

Thanks Steve!!! Cable Ties!!!!...Now that tip is worth the price of admission. ![[Smile]](smile.gif)

As far as the contact cement...My experience has been to put contact cement on both sides of the surfaces you are cementing and then press them together. Obviously this can't be done with the shutter wheel belt. Steve...how do you plan on applying the cement? There doesn't seem to be much give in the belt to lift it to apply cement.

Posted by Steve Klare (Member # 12) on June 03, 2015, 09:28 PM:

My plan (for the moment at least) is to use the parts of the Ty-Wraps I cut off as an applicator. I may insert some kind of spacers on either side of where I am working to lift the belt off the wheel and give me some working clearance.

-there is a little bit of "give" in the belt. There is enough it doesn't take much pressure to get it to slide sideways on the wheel, and that's what concerns me here.

-I am only motivated enough to do this once!

If it slips off, it stays off!

BTW: I had to disassemble the rollers and push them out of the way as much as I could to gain better access.

Posted by Janice Glesser (Member # 2758) on June 03, 2015, 09:32 PM:

I'm wondering if something like this industrial adhesive with a small tip might be easier to apply http://eclecticproducts.com/e6000-precision-tip-adhesive.html

Posted by Mathew James (Member # 4581) on June 03, 2015, 09:42 PM:

If anyone gets to wanting to try to change their counter belt if/when needed....we documented one way on how to do it here recently. It is still working great!

http://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=009616# 000000

Have fun!

Matt

ps: @Janice- Welcome to the st1200 club ![[Smile]](smile.gif) I really like the thing myself. Lots of fun and just the right amount of Super8mm nerdiness to play around with all the buttons and knobs

I really like the thing myself. Lots of fun and just the right amount of Super8mm nerdiness to play around with all the buttons and knobs ![[Smile]](smile.gif)

Posted by Steve Klare (Member # 12) on June 03, 2015, 09:57 PM:

I thought I lost the counter belt, then I saw it and was amazed how thin it is!

(This is a battle for another day!)

Janice, I will consider your adhesive!

Posted by Janice Glesser (Member # 2758) on June 03, 2015, 11:29 PM:

Thanks Matthew for the counter belt instructions. I love anything with pictures ![[Smile]](smile.gif) I think next to the shutter belt the counter is the most difficult to install ... most people don't bother.

I think next to the shutter belt the counter is the most difficult to install ... most people don't bother.

I've always wanted a 1200HD. The one I got looks like it hasn't been used in 30+ years. The motor wouldn't even turning over at first...but with a little prodding it's running ok now. Hopefully...cleaning...some new belts...and lubrication will restore it to working order so I can test it with film and for sound.

Posted by Tom Photiou (Member # 130) on June 04, 2015, 04:46 PM:

ive had a couple of the HDs with the rubber outer on the shutter.

When these and the belts turn to goo my only solution was to take it all out and do a proper clean up.

The best way for us on the shutter was to send the shutter itself to John White here in the UK who will then keep yours but send you one which has been turned on a lathe and had all the rubber removed and the edge of the shutter very slightly skimmed, what this does is it gives you a flat surface instead of a slightly rounded one,allowing the 18 and 24fps rollers much better,smoother and quieter running with a good match of surface between the rubber rollers and the edge of the shutter.

You may recall in the past i also had a number of the 24fps clutch drives manufactured.

As for the belts themselves i only ever use the square section belts as theses are designed to sit properly in the grooves.

The seal type or round belts do the job but wont last as long and wont sit proper;y in the grooves of the drive wheels.

i usually use an electrical cleaner to clean up the belts every couple of years and very importantly the grooves that the belts sit in. Its a slow and tedious job but keeps it all clean and the belts grip better with no slip. ![[Wink]](wink.gif)

Posted by Janice Glesser (Member # 2758) on June 05, 2015, 12:20 AM:

Tom are you saying you only replace the shutter...but not the rubber belt?

Posted by Tom Photiou (Member # 130) on June 05, 2015, 01:30 PM:

Hi Janice,

Sorry, no I meant I change all the belts but also,(if the shutter is the type with the rubber outer ring), replace the shutter if you can get one which has been fixed up the way John White does them here.

If necessary it may be that the outer rubber has to be removed but to do this it is a job requiring patience and time so as not to damage the shutters metal edge, it is quite a soft metal and if damage will lead to all sorts of problems.

Posted by Janice Glesser (Member # 2758) on June 05, 2015, 02:14 PM:

Tom, I have removed the old rubber off the shutter wheel. Yes it was a tedious job. Especially since I didn't remove any parts and had very little access to the wheel. I used a small Exacto blade and carefully shaved off the old gooey rubber. I cleaned the residue off with alcohol and GooGone.

Do you or anyone else have a procedure for removing the shutter or the entire shutter assembly? I have checked the repair manual, but oddly there doesn't seem to be any diagrams relating to the shutter.

If anyone has any pictures and/or instructions relating to replacing the shutter wheel belt...this would be very helpful.

[ June 05, 2015, 05:16 PM: Message edited by: Janice Glesser ]

Posted by Andrew Woodcock (Member # 3260) on June 05, 2015, 05:31 PM:

I would be able to do this for you Janice if no one else posts them first. I would need a day or so to take photographs of the procedure while doing the work if nobody else posts them for you in the meantime. ![[Smile]](smile.gif)

It is whole lot easier on a GS from what I have seen but not too bad a job I don't think on an ST1200 and nowhere near as challenging as some projectors like Bauer etc etc.

Posted by Janice Glesser (Member # 2758) on June 05, 2015, 07:22 PM:

That would be terrific Andrew. Some guidance would not only help me but lots of other too I'm sure. Other than Steve I don't see anybody but yourself jumping to the chance to offer their expertise with this machine. So when ever you get a chance to document the procedure...I'm patient...I'll wait ![[Smile]](smile.gif)

Posted by Andrew Woodcock (Member # 3260) on June 05, 2015, 07:49 PM:

Janice, I will always do my bit to help anyone out with this wonderful hobby of ours with any aspect I can be of assistance of, sometimes to the extent of the absolute hatred demonstrated by others, but thankfully to the extreme gratitude expressed by other people.

I am in a bit of a tip at the moment with doing a little bit of much needed decorating to our lounge, but somewhere in my five days off now I will come to your assistance. This sort of stuff I do for my fun and wind down, much to the extreme annoyance of my lovely, totally uninterested in film, yet unbelievably understanding wife, God bless her!! ha ha ![[Smile]](smile.gif)

Posted by Roy Neil (Member # 913) on June 08, 2015, 09:55 PM:

Typically the shutter band is removed and not replaced, it is not entirely necessary however it does provide additional surface friction to help turn the shutter and reduces a little noise but not much. Provided the machine is in good working order and lubricated nicely the shutter band is not necessary. Only if the motor is old/weak have I found the shutter band to make a difference.

Friendly advice, remove the shutter before trying to remove / replace the band !

Also, be very careful not to gouge or nick the shutter with that x-acto blade as that will eventually chew up the rubber drive wheel(s) and likely make some hideous cyclic noises ... akin to a nail in a tire.

Removing the shutter means some pretty serious disassembling & reassembling, ( worst of which is reassembling the solenoid for the auto-thread )

I would not suggest a novice try to remove the shutter/camtank without some help, since it is not trivial and also involves re-timing the shutter, but it sounds like you are very mechanically inclined.

Posted by Janice Glesser (Member # 2758) on June 09, 2015, 12:14 AM:

Thanks for your feedback Roy. As I wrote in a previous post...I have already removed the old belt so no going back now. I'm just waiting for delivery of the new belts. Steve has made some nice progress without really removing much...but it wasn't a cakewalk. Maybe you are right and this is not a DIY project, but I'm willing to listen to others experiences if they have any suggestions.

QUESTION: Since I'm not familiar with the projector this maybe a dumb question...but I don't see the large rubber wheels touching the shutter at all. Even when I turn the main switch to Forward... nothing is touching the wheel. Is this because there are no belts on it right now?

I'll put on all the new belts and see how it runs before addressing the shutter belt. Learning more about the projector will help me understand what are my options. ![[Smile]](smile.gif)

[ June 11, 2015, 11:26 AM: Message edited by: Janice Glesser ]

Posted by Andrew Woodcock (Member # 3260) on June 09, 2015, 03:08 AM:

Janice this is where clutch adjustment would be made if you were leaving the shutter belt off. If you are putting another shutter belt on it then wait and see how the clutch performs with the new belt.

Too little adjustment and the clutch wont have enough friction beteewn the drive wheel and shutter wheel to drive it correctly.

Too much adjustment and on switch posiion 1 the machine will turn over instead of just the fan turning. In other words you lose the still frame facility.

Let me know Janice if you still intend to fully remove the shutter shaft after Roy's advice earlier. You may decide not to bother if you feel it may do more harm than good.

I don't mind doing the timing work but not everyone is comfortable with this aspect of the job. Also on the Elmo's a lot of the factory fitted screws tend to be really tightened to excess and many can easily be rounded. You do have to take extreme care when first trying to undo some assemblies as you really do only get one chance with them before a Dremmel is the only answer!

Therefore take care at every step if you do decide to remove it Janice.

[ June 09, 2015, 03:50 PM: Message edited by: Andrew Woodcock ]

Posted by frank arnstein (Member # 330) on June 10, 2015, 09:26 AM:

Andrew, How do you carry out this clutch adjustment?

I had an ST-1200 recently which was showing that symptom of too much adjustment.

I.E. In the 1st clik position, it drove the whole machine and not just the fan. In reverse it was OK with the fan only working at 1st clik. I couldn't see where the adjustment was so I had to leave it as it was but I knew it wasn't right.So would like to know how its adjusted.

frankarnstein ![[Confused]](confused.gif)

Posted by Andrew Woodcock (Member # 3260) on June 10, 2015, 09:55 AM:

Hello again Frank, when you completely remove the clutch arrangement there is straight cam track at right angles to the tilting clutch mechanism.

The most forward protruding point on the clutch is a pointed tip with a flat surface beneath it.

The amount of forward movement or tilt on the clutch arrangement and therefore friction is determined by where the stationary cam track is set along its adjustable elongated slots and where this strikes the protruding tip.

To understand fully Frank What I am saying to you,you need to refer to page 10 of the ST1200 service manual. This is available as a free download from both forum and other places on the web.

Posted by frank arnstein (Member # 330) on June 11, 2015, 06:08 AM:

Thanks for that concise explanation Andrew, it helped me a lot.

I will check out the manual as you suggest and then practice adjusting on a wrecked machine from the boneyard here.

For Elmo ST-1200 owners this is an important adjustment to know about and so you were right in bringing it to the attention of Janice.

My personal feeling is that its best to remove these flat belts whenever they are encountered as they usually soon melt then go soft and lumpy. The drive wheels will then rumble, slip and vibrate as the surface is no longer flat and smooth. Its a terrible sound to hear.

With the flywheel removed and using a blade with patience and care, it's possible to take off the remnants of the old belt without doing damage to the edge of the shutterwheel. Then run it driving direct on the metal edge.

If you have any slip occuring, tighten the extension spring that pulls the wheels against the shuttershaft and that should fix it.

Janice, I wouldn't be going to the trouble and risk of removing the shutterwheel just to install a belt around it when you don't really need it.

dogtor frankarnstein ![[Razz]](tongue.gif)

![[Smile]](smile.gif)

Posted by Tom Photiou (Member # 130) on June 11, 2015, 06:40 AM:

You will be surprised at how the belts do stretch when removing and fitting. Don't forget with the exterior rubber removed there may,(most people don't notice it)a slight difference in FPS speed, this in my case was remedied when I had a modified sized lower pulley made.

Posted by Janice Glesser (Member # 2758) on June 18, 2015, 01:51 AM:

I've decided to go with Dogtor Frank's suggestion. Except for the shutter wheel belt, I have installed all the other belts, including the counter belt. The shutter wheel without the belt doesn't sound noisy to me. It seems to run fine. When cold the motor on this projector has a delay in starting, but once started it comes up to speed in a minute or so. Sound films sound normal... I think it must be running pretty close to 24fps. I'm not experiencing any slippage so I haven't made any adjustments to the clutch.

This projector was in poor shape when I got it, but with a good cleaning, lubing, and new belts... it's running nicely now. I've learned so much from all the feedback here. I still may add the shutter belt down the road, but for now it's good. ![[Smile]](smile.gif)

Posted by Andrew Woodcock (Member # 3260) on June 18, 2015, 03:50 AM:

Probably not too much to be gained Janice for all the work involved,especially if you were removing the shutter wheel just solely for this purpose. Hence the reason I sent you the question.

It's one of them to me where if it already has the belt on and its fine...then leave it on.

If it's already been removed by somebody and its running fine ...then leave it that way I'd say.

It doesn't make a huge difference either way, just dampens the noise slightly and gives it slightly better traction when all is like new, but many prefer this belt removed altogether.

Posted by frank arnstein (Member # 330) on June 18, 2015, 05:57 AM:

Hi Janice,...

Well done on getting your Elmo ST1200 going well again.

You mentioned.............

" When cold the motor on this projector has a delay in starting, but once started it comes up to speed in a minute or so. "

Curiously enough Janice, my Elmo ST 1200D is doing exactly the same thing and I don't like it very much.

When cold, there is an unexplained delay of a few seconds before the motor actually spins. Once its made the first start for the day all seems fine till its cold again and it then reverts.

Have just replaced the a/c motor capacitor but I can't tell yet if its fixed. Will now recheck all the belt tensions and also try oiling the end bush on the motor.

Has any member with an Elmo ST 1200 experienced this baffling delay on cold start and why is it so?

This is the question which more and more members are asking themselves. Time will tell if anyone discovers the cure.

dogtor frankarnstein ![[Smile]](smile.gif)

![[Confused]](confused.gif)

Posted by Andrew Woodcock (Member # 3260) on June 18, 2015, 08:10 AM:

How long is the delay Frank?

Posted by Janice Glesser (Member # 2758) on June 18, 2015, 10:24 AM:

Frank and Andrew ... I'm going to start a new topic on the delayed motor starting problem.

http://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=010038

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Wink]](wink.gif)

![[Wink]](wink.gif)

![[Eek!]](eek.gif)

![[Wink]](wink.gif)

![[Eek!]](eek.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif) I really like the thing myself. Lots of fun and just the right amount of Super8mm nerdiness to play around with all the buttons and knobs

I really like the thing myself. Lots of fun and just the right amount of Super8mm nerdiness to play around with all the buttons and knobs ![[Smile]](smile.gif)

![[Smile]](smile.gif) I think next to the shutter belt the counter is the most difficult to install ... most people don't bother.

I think next to the shutter belt the counter is the most difficult to install ... most people don't bother.![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Confused]](confused.gif)

![[Razz]](tongue.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Confused]](confused.gif)