This is topic Sankyo 2000H. Calling Dogtor Frank Arnstein in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=009767

Posted by Barry Fritz (Member # 1865) on February 12, 2015, 11:32 PM:

Dogtor: The roller on my 2000H does not disengage when put in reverse. This causes the upper loop to get pulled flat, resulting in jittery picture in reverse. In a previous thread, you addressed the issue of the roller not disengaging in reverse. You said:

The drive to the roller is by means of a one way dog-clutch. This dog-clutch is spring loaded using a very fine spring that pushes the 2 halves of the clutch together. They lock up and provide drive to the rubber roller in forward project mode. When reverse is selected the dog-clutch will disengage itself automatically. The fine compression spring collapses to allow the 2 clutch halves to slide apart and so interrupts drive to the roller. This symptom is the direct result of hardening of the grease which normally helps the 2 clutch halves to slide apart. Solidified grease will prevent the automatic coupling and decoupling of the drive to the roller. The cure is to clean and lubricate the sliding, spring loaded inner clutch-half so it slides on its guide again.

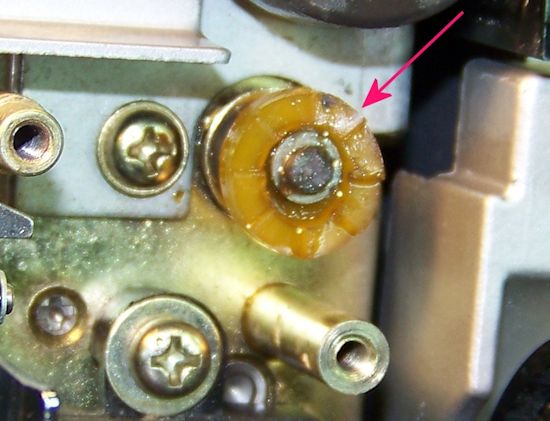

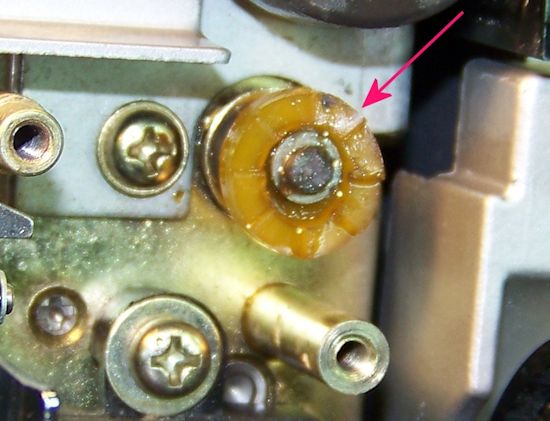

I have removed the roller assembly and need clarification as to which part slides. Is it the one shown by the arrow in the pic? That part is really frozen if that is the one you refer to.

Posted by frank arnstein (Member # 330) on February 13, 2015, 05:30 AM:

Yes Barry, thats the one. Try to free it up so it slides in and out easily again. There is a fine spring involved that normally pushes it outwards so it locks with the outer half.

Dogtor Frankarnstein ![[Smile]](smile.gif)

Posted by Barry Fritz (Member # 1865) on February 13, 2015, 09:20 AM:

Thanks Frank. Yes, the spring is behind it. To clarify, it is supposed to slide on the shaft itself, correct? The shaft is not supposed to slide.

Posted by Barry Fritz (Member # 1865) on February 13, 2015, 03:12 PM:

Well, that nylon cog is not going anywhere. I was able to tap it down just a little tiny bit but that was it. Now it's really not close enough to even engage the forward cog on the roller. The shaft itself does move in and Out just slightly. I'm not sure if I'm doing something wrong or not.

Posted by frank arnstein (Member # 330) on February 13, 2015, 06:08 PM:

Hi Barry,

The nylon gear is supposed to slide inwards along the shaft, but only about 1mm because that is its full range.

See if there is a tiny screw and washer in the centre of the shaft. That screw will release the plastic gear from the end of the shaft. You should then be able to slide it right off the shaft to allow you to clean the end of the shaft. Refit when its clean and lubricated.

If you can't remove the tiny screw then just get the nylon gear to slide 1mm in and out. Then reassemble it all and it should work OK.

Try that and report back when the gear is free to slide in and out, about 1mm on the end shaft. Don't damage the plastic teeth on the gear.

Good Luck.

Dogtor Frankarnstein ![[Wink]](wink.gif)

Posted by Barry Fritz (Member # 1865) on February 13, 2015, 06:54 PM:

Hi Frank. I removed the screw and washer and found out why the cog was so hard on the shaft. The shaft has a flat spot on it, as does the nylon cog. That is how it keeps from turning on the shaft. Somehow,that nylon cog turned anyway and the flat spot were not aligned anymore. That made the cog extremely tight on the shaft. I had noticed that the cog look slightly out of round and appeared off-center compared to the washer on the end. If you look closely at the pic, you'll notice it. Anyway, got it off and aligned,and lubed but it still doesn't want to move forward on its own. I can get a little probe on it and move it forward so it meshes with the roller cog, and then it is fine going forward. If I put it in reverse, it comes out like it should but then won't go back in on its own. I may need to stretch the spring a bit or carefully enlarge the nylon cog hole slightly. The motor is also acting a little strange in reverse. It seems to slow a bit and then surge back up to speed at times. I appreciate your help Frank. Thanks.

Posted by Janice Glesser (Member # 2758) on February 13, 2015, 07:06 PM:

This is a very interesting thread Barry. I hope you get things worked out. Keep us posted ![[Smile]](smile.gif)

Posted by Barry Fritz (Member # 1865) on February 13, 2015, 07:19 PM:

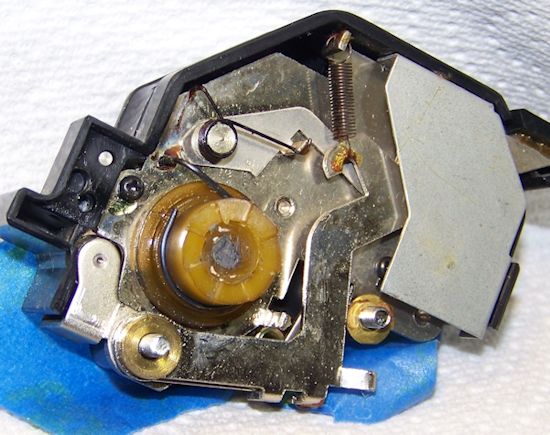

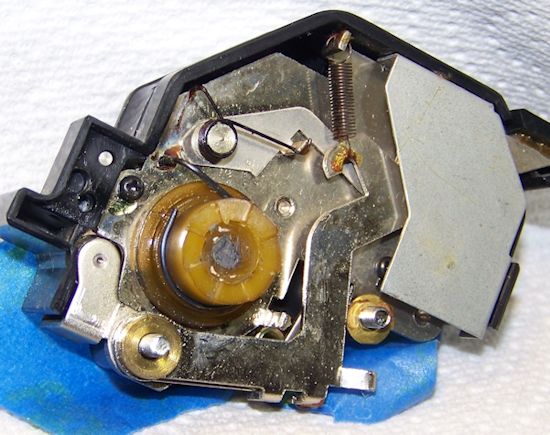

I will Janice. For those that may have a similar problem in the future, here is the backside of the assembly showing the nylon cog that the other one meshes with. The entire assembly comes off as one, with the removal of just two screws. There is a little, very thin washer on the left screw so be careful with that.

Posted by frank arnstein (Member # 330) on February 14, 2015, 02:45 AM:

This demonstrates to us how a routine auto-threading can turn into a minor disaster.

I believe this damage was caused by something which happened in the past, before Barry got the projector.

When it was auto-threaded then, the film wrapped itself round and around the rubber drive wheel till it actually jammed the wheel. The drive shaft to the nylon gear kept driving, until it is forced over the special cutout keyway in the nylon gear and then they both jam together as yours did Barry.

Hope you can repair the distortion to the nylon gear so it will slide freely again or you may need to get another from a wreck.

Good Luck with it Barry...

dogtor frankarnstein

![[Smile]](smile.gif)

![[Wink]](wink.gif)

Posted by Barry Fritz (Member # 1865) on February 14, 2015, 11:48 AM:

This is getting a bit frustrating. The nylon gear slides freely on the shaft, but is not getting pushed forward enough to engage the roller gear. There is a washer on the shaft behind the spring, so I added another washer to put more pressure in the spring. Still not enough. The gear just barely touches the roller gear and occasionally catches and turns the roller a bit, but then pops out. It is acting like there is simply not enough tension in the spring. I stretched the spring a bit but that did nothing. The only thing else to try, I guess, is to put another washer behind the spring. The only issue with that would be if it was to much tension, it may not disengage the gear when put in reverse. That may not occur however because the gears cannot mesh in reverse. Frank, the gear returned nicely to round once it was off the shaft.

Posted by Janice Glesser (Member # 2758) on February 14, 2015, 12:27 PM:

Is it feasible to replace the spring Barry?

Posted by Barry Fritz (Member # 1865) on February 14, 2015, 01:39 PM:

It could be replaced if I could find one that was same or similar. I'll see if my ace hardware has a drawer full. The shaft itself does move in and out a bit and maybe it is not supposed to. That may be the problem.

Posted by Janice Glesser (Member # 2758) on February 14, 2015, 02:33 PM:

I wonder if the Sanyko 1000 has the same spring? If so I could pull it off my parts only machine and send it to you.

Posted by Barry Fritz (Member # 1865) on February 14, 2015, 02:49 PM:

Thanks Janice. I don't know if the spring is the same as on the 1000. Frank would likely know. I went to the hardware store and they don't have any springs that are even close to working. I put a third washer behind the spring and that made the gear engage, but was to much as it would not disengage in reverse. That combo was with two thicker washers I have and the thinner one that was on the machine. I will next try just the two thicker ones. It is so close! Off to the daughter's house to baby sit while they go out for Val Day dinner.

Posted by Janice Glesser (Member # 2758) on February 14, 2015, 07:02 PM:

I checked on the spring in my 1000. The entire roller assembly appears much different than the 2000H. The spring is shorter... only 13 twists and I count 21 on yours. You are welcome to have it though.

I found this video of a guy who makes his own springs...very interesting. https://www.youtube.com/watch?v=XQBbGF4-t4s

Posted by frank arnstein (Member # 330) on February 15, 2015, 12:07 AM:

Barry,

......where you said above "I put a third washer behind the spring and that made the gear engage, but was to much as it would not disengage in reverse."

How did you determine that it would not disengage in reverse? Did you try to stop the rotation of the rubber drive wheel with your fingers when running it in reverse? It should be easy to stop it from turning as it disengages drive to the rubber wheel. When put back to forward project, the nylon clutch halves will automatically lock together and drive to the rubber wheel will resume.

dogtor ![[Wink]](wink.gif)

[ February 15, 2015, 01:17 AM: Message edited by: frank arnstein ]

Posted by Barry Fritz (Member # 1865) on February 15, 2015, 09:48 AM:

Frank,

Yes, I did try to stop the roller with my fingers. I thought that would surely make the gears disengage because of the way they are designed to mesh. Didn't work.

The shaft that the gear and spring are on has some in/out play in it. Is it supposed to have that play?

Posted by Barry Fritz (Member # 1865) on February 15, 2015, 06:27 PM:

I think I have solved the problem. I stretched the heck out of the spring, used the original and one thicker washer as before, and now it is working. Engages nicely and disengages in reverse. Hopefully it will continue to work. Thanks Janice and Frank for you assistance.

Posted by frank arnstein (Member # 330) on February 15, 2015, 07:08 PM:

You are a star Barry... well done.

Assisted very ably by Janice with her constant encouragement.

Have you tried it out reverse projecting with film yet?

Has it stopped pulling the top loop flat when in reverse project?

dogtor ![[Smile]](smile.gif)

Posted by Barry Fritz (Member # 1865) on February 15, 2015, 08:11 PM:

Thanks Frank. This forum is a wonderful place with advice and encouragement on all matter of topics.

Yes, I tried film in Reverse and all is good. With roller not grabbing film, there are no jitters. Thanks again.

Barry

Posted by Janice Glesser (Member # 2758) on February 16, 2015, 11:19 AM:

Yippeeee! All is good. I admire your diligence Barry....AND it's always great to hear your expert advice Frank ![[Smile]](smile.gif)

Posted by Barry Fritz (Member # 1865) on February 16, 2015, 12:18 PM:

Thanks Janice. What is odd to me is that the motor had enough power to cause this problem to begin with. It must have happened as Frank described. However, that nylon gear with the flat spot on the sleeve to match the flat spot on the shaft would require a heck of a lot of torque to turn it askew on that shaft.

Posted by James Wilson (Member # 4620) on February 18, 2016, 12:20 PM:

Thanks Barry, Dogtor & Janice,

Just what I needed, I`d never have found this on my own.

This place is really great.

Posted by Barry Fritz (Member # 1865) on February 18, 2016, 02:43 PM:

You're welcome James. Let us know, in your original thread about this problem, if you are able to free up that roller.

Posted by Pasquale DAlessio (Member # 2052) on February 18, 2016, 03:22 PM:

Hi Jan

That spring video is amazing. Something new for me to try.

PatD

Posted by Janice Glesser (Member # 2758) on February 18, 2016, 10:21 PM:

Pat...I can see you trying something like that ![[Smile]](smile.gif) Let us know how it turns out. The guy made it look easy...but I'm sure he's had lots of practice.

Let us know how it turns out. The guy made it look easy...but I'm sure he's had lots of practice.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif) Let us know how it turns out. The guy made it look easy...but I'm sure he's had lots of practice.

Let us know how it turns out. The guy made it look easy...but I'm sure he's had lots of practice.