This is topic BEAULIEU 708 EL ST .........back to life in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=010468

Posted by Phil Murat (Member # 5148) on January 30, 2016, 04:22 PM:

I had a very hard time when I woke a 708 EL SEREO which was sleeping for many years and suffered improper storage.

At first power up, the machine was making low frequency noises and once loaded no sound was available . Moreover, the red LED was steady light on, as it is supposed to do during recording something.

Upon Andrew advices, I warm the big transformer with a “Hair Gun” and the 50hz noise disepears.

That was a very good point.

Considering the main failure (No sound) it was important to find the source as to repair as well.

I am not an electronic specialist at all and my knowledges are very limited.

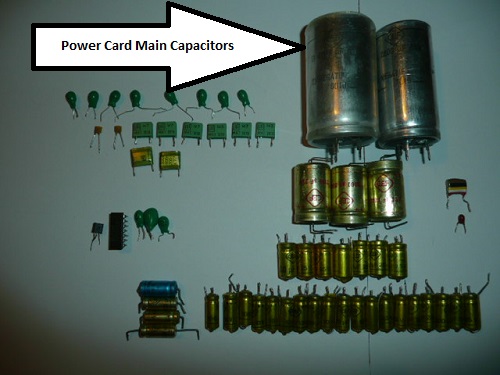

So , through different exchanges with some friends, I decided to renew ALL Electrolytic Capacitors first.....

These capacitors are "Time Limited" and lost performances beyond 10 years. Also Power Capacitors failure is not a rare phenomenon for 708 projector family.

The power capacitors are very important as they filter (Soften) the current deliverered to the machine.

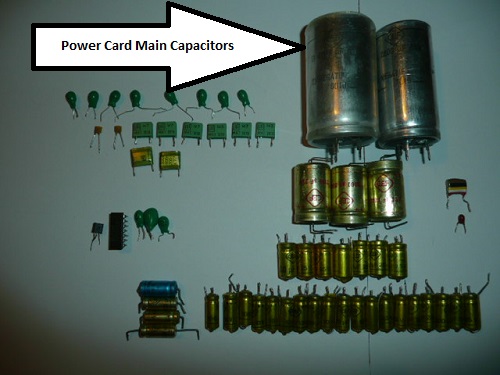

Here are the capacitors and other components replaced :

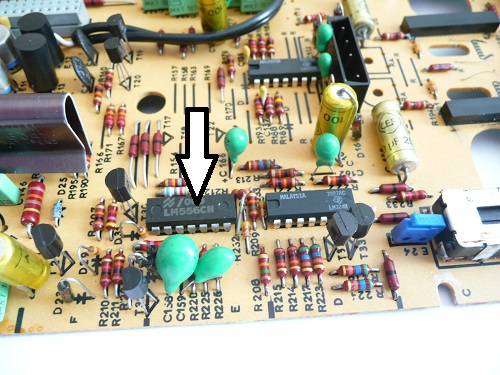

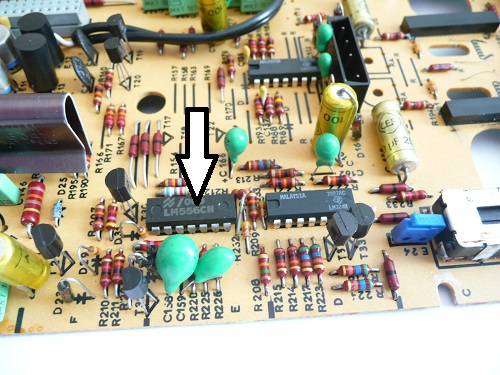

LM556N is a dual timer which is supposed to Control the Recording Functions. There is a high probability it suffered from Voltage peaks and once shorted, blocked sound entering Preamp.

A new LM556N has been fitted on a DIL support and surrounding capicitors replaced too.

You can observe that many “Tentalum” small capacitors ("Green Drops") where installed by Beaulieu:

Right now , it's not justify anymore, as improve technology offer equivalent Electrolytic capacitors just cheaper…

Here is the LM556N before replacement:

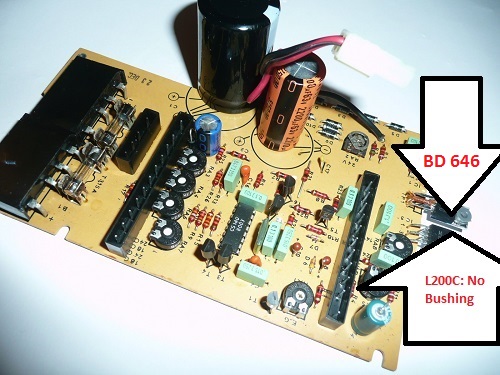

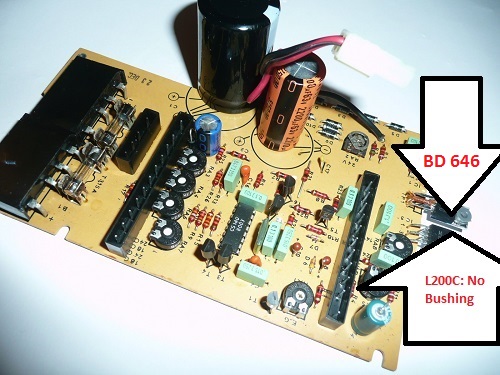

Concerning the Power Card :

- If the Claw Motor run "Full Speed" and/or associated fuse fails out , that means that TP1 (BD646) is shorted. You can replace it by BD648 or BD650, NOT easy to find and offering more performance.

- TP1 has to be perfectly insulated from case (Bushing + Micas shim), otherwise it deads immediately.

- IC1 and IC3 have both to be grounded to the case (NO BUSHINGS!!), otherwise you experience unwanted funny "low noises" in Preamp, overlapping the signal comming from heads.

- During operation, put a finger on the TP1 / IC1 / IC3 shell : if you feel heat above 30 °c , check component installation again….

It is very important to renew Thermal Grease compound for TP1 / IC1 / IC3 / STK441 (Power Amplifier Module) as it dries many years after.

Avoid at any cost Thermal Silicons which dry like a glue. They are less performant and complicate futur disssemblies.

Here is a spare STK441:

Now the machine is running pretty good, offering a very good sound, efficient and dynamic. Motors regulation works properly, no stalls observed.....

Champagne!!!!

[ February 23, 2016, 12:29 PM: Message edited by: Phil Murat ]

Posted by Alan Rik (Member # 73) on January 30, 2016, 05:44 PM:

Great work! You deserve a night out PLUS Champagne for that work! Great to hear that another machine has been revived and is still with us. ![[Smile]](smile.gif)

Posted by Paul Suchy (Member # 80) on January 30, 2016, 06:59 PM:

Phil, this is amazing; for a person claiming no technical expertise, you put me to shame! Congratulations on your achievement.

Posted by Andrew Woodcock (Member # 3260) on January 31, 2016, 02:02 AM:

Phil,I will take some time out later to study with the manual the parts you have changed out and will hopefully be able to understand the work on TP 1 etc?

I'm pleased you managed to salvage the main transformer despite being left in damp conditions for many years.

It is a pity you do not own a Megger as you really could do with testing the IR on the transformer windings now you have dried them out satisfactorily using a heat gun.

Personally,I'd have opted for the oven at fairly low temperature in preference from the two options I suggested, but nevertheless a result is a result and I am very pleased it worked out ok for you!

Well done indeed in restoring much life to what otherwise would have been a once very expensive lump of scrap metal.

How has your lens faired in all of this damp storage Phil?

Is it still clear and without any fungus?

Also Phil, It may very well now be a good idea to get your now fully operational machine P.A.T. tested just to ensure the transformer and I.E.C. power supply socket and Voltage Regulator etc are all electrically safe.

Posted by Phil Murat (Member # 5148) on January 31, 2016, 02:49 AM:

High Alan, Paul, Andrew

Thanks for encouraging message!!

I spent many time also at phone with friend(s) crossing the different ideas..

I download from the Web many Datasheets, trying to understand how Beaulieu used this components.

3 days Job, 1 month for research....

Then , I learned a lot at the end , and this is very positive too.

Many "Beads of sweat" were necessary to do that. The more difficult was to work with a magnifying glass (x3 is good) and paying attention to the tinies PCB copper tracks.....

To do that I used :

- A small Soldering Iron (Pencil Tip), 20W

- A desoldering Pump and Copper mesh for small soldered points.

- A good quality stain with cleaning flux included

- Multimeter

(Observe also, that , if necessary you could use a computer as oscilloscope through the Sound Card and a special soft.

I have not experienced this as it was not necessary to analyse signals in my case.)

In an other way , it is quite difficult to find a serious professional technician to do it, and then he probably charges me a lot!!

Through this post, my idea is to bring all tools as necessary to motivate owners who love their machine to do it themselves even they were never been educated to this specialty.

An other point is that some components are no longer supplied.

some of them are not offering equivalent:

- TDK441 (Power Stereo Amplifier) : No Equivalent, can be find in sleeping stock, approx 20 Euros.

- LM556N : Common (Texas Instrument), Available anywhere, Approx 6 Euros

- TAA761A & TAA2761A : Siemens Audio Component, not easy to find, unfortunately price fluctuate from 3,5 E to 12 Euros.

Equivalent TAA765A & TAA2765A is much better (Higher T° strengh)

- TDA4290 : Audio component for Tone , Trebble, Volume Control.

No Equivalent found , price fluctuating from 4,5 Euros and...?

Concerning Capacitors again, I think to sistematically renew them on Power Supply Card is the minimum required , even your machine seems to operate properly, as the other components (Stereo & Regulation) like to take a good quality current.

This is cheap money , involving one / two hours manhours for the job, 100% benefit at the end !!

I encourage projectors owners to do it.....without thinking twice, do not wait they fail Shorted (This is the worse situation)

CAPACITORS:

Concerning the Capacitors range and value , never take a Voltage limit below the indications. Higher is not a problem, just the component size is increasing.

Concerning the Capicity itself , stay closed to the value, never below. For a Power Supply, a too much higher value could stress Diodes associated.

Different Classes are available:

Standard is +/- 20%

Some of them installed on the Sound Card comes under Class "J" which means +/- 5% . They are making the references for TDA4290 for exemple.

Tighter is the Class, higher is the price.....

Phil

*****************************************************************

Andrew , just reading your message:

Yes I took up some fungus back to the front Lens.Fortunately Front Lens is easy to remove. Just to unscrew front ring.

There are probabilities that Transformer "Low noise" come back , one day or an other. If necessary I remove transformer and dry it out under "reasonnable Temp" in an Oven.

Taking out Transformer needs the Sound Card to be removed once more.....

Andrew, I think there is a problem in the Beaulieu Repair Manuals available from different sources.

The Last "Regulation Card" generation do not appear and it can lead to confusion with former one.

Tell me what you can find from your side

[ January 31, 2016, 06:27 AM: Message edited by: Phil Murat ]

Posted by Andrew Woodcock (Member # 3260) on January 31, 2016, 10:55 AM:

What about P.A.T. testing Phil?

You really do need to know that the transformer winding insulation is still sound my friend!!

Please test as soon as possible.

I am confused somewhat Phil regarding the terminology used for the various printed circuit boards to be able to completely understand what you are missing.

Is for example what you are referring to a,"sound card" Is it really just the Stereo Amplifier P.C.B.?

[ January 31, 2016, 12:52 PM: Message edited by: Andrew Woodcock ]

Posted by Phil Murat (Member # 5148) on February 01, 2016, 01:22 AM:

High Andrew,

-What is P.A.T meaning?

- Sound Card is just to make the difference between the Main PCB and the Stereo Amplifier (STK441) fitted alone on a small PCB.

- At this time I am not in position to perform special tests (Insulations for different configurations) for the Transformer (Medger looks like to be Pro Tools for specialist).

I can only make standard measures with Multimeter.

- I just need the "New Schematic"; Power & Regulation Card showing IC1/IC3/TP1.

Unfortunately, I am afraid that Beaulieu missed to update Repair Manual in the past , as HTI schematic is missing too......

Thanks in advance

Posted by Andrew Woodcock (Member # 3260) on February 01, 2016, 01:39 AM:

Thanks Phil, yes I see now why you would make a separation between the STK 441 board and the main p.c.b in your description sorry.

P.A.T. testing is just a service carried out to check electrical items for safety and conformity here in the UK.

I am sure there must be an equivalent service in France in this era.

It would carry out an insulation resistance test as standard on your machine as well test for earth leakage current etc.

P.A.T. testing here in the UK simply means portable appliance testing and is mandatory for any appliance used in a public building or in a public place nowadays here.

For example: factories, office buildings, libraries etc etc.

Btw; my service manual also does not contain the items you are seeking 're HTI etc.

Posted by Phil Murat (Member # 5148) on February 23, 2016, 12:57 PM:

Hello,

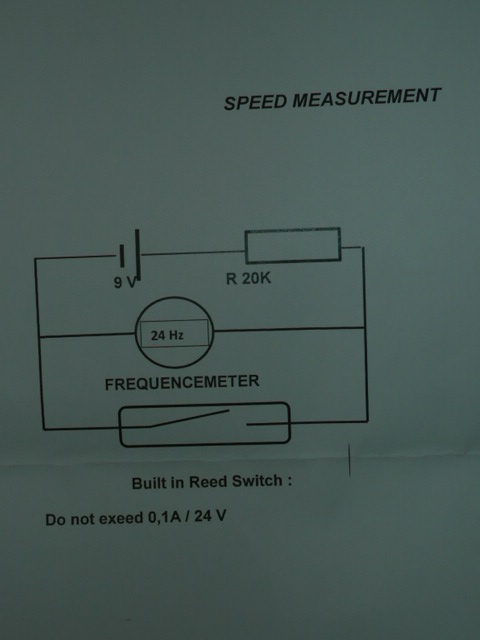

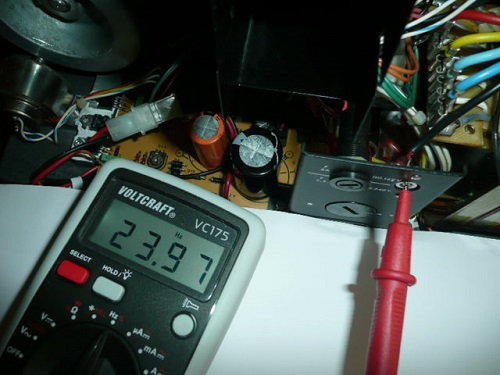

Here is a method to Check Projector Speed during Speed adjustment procedure:

- To allow an acurate post synchro.

- To allow an easy Video Transfer

- To have an idea of Components Health

A) The Principe:

B) An Exemple of Installation :

C) The Result !!!

(Only Positive Probe is plugged, Not Negative Plugging,....... to avoid Signal polution by the Transformer proximity):

N.B :

I had to abandon TIP42C and to return to BD646 installation as it was impossible to get full power with this component.

As it is difficult to find BD646 (BD648 OR 650) , I assume that BDW94B or BDX54CG are possible Equivalents (But there is no warantie for the result, I mean , reaching full power and confortable speed adjustment margin.)

Right Now,in Original configuration, the speed can be adjusted from 22 to 28 fps and without any loss of speed during friction adjustment.

The Multimeter Frequencemeter is just 40 Euros........

Posted by Andrew Woodcock (Member # 3260) on February 23, 2016, 01:47 PM:

It'd be nice to have that idea modified into a permanent installation on the projector by having a small built in frequency meter just below the counter. A little LCD display would fit very well here.

Good work there Phil.

Posted by Phil Murat (Member # 5148) on February 24, 2016, 10:17 AM:

High Andrew,

Yes, this is a nice chalenge to built in this device!!!

Also, there is room enough inside projector to add funny things...

Moreover , such device can be incorporated in any projector you need to control speed (providing there is room enough too).

Observe it can be done with an incremental wheel associated to an optical switch (Ex : Computer Mouse).

If somebody is interested to experience an exiting improvement, it can be achieved using an "ARDUINO Card" for few money and featuring incredible possibilities as Dual motors Control and LCD display. The ARDUINO Card is fully flexible and can be programed through a Computer connected to ARDUINO Card USB port !!!

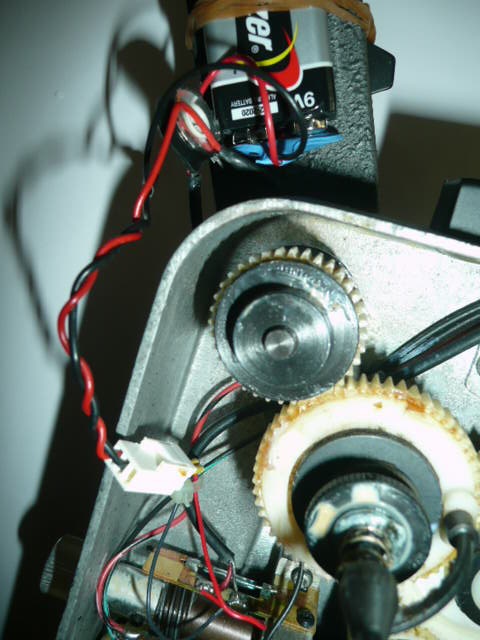

Here is a small improvement for BEAULIEU Main Motor installation.

As I was replacing the fixture Grommets, I observed that Beaulieu miss to install small sleeves inside to avoid grommets extruding when screws are normally tightened.

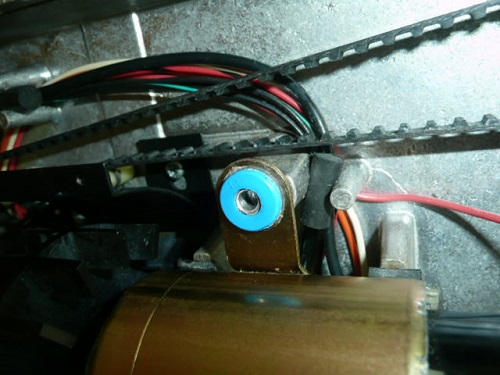

A)New Grommet (Blue) with small sleeve installed:

B)Srew / Washer fitted and normaly tightened under standard torque:

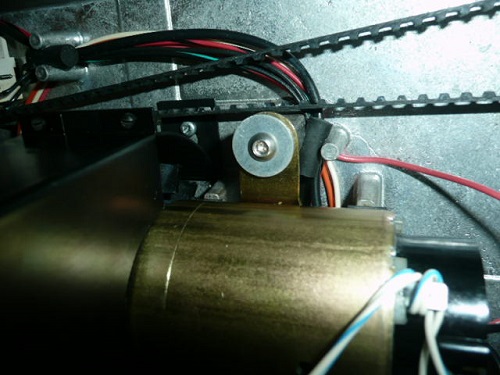

MAIN MOTOR Alternate Supply for BEAULIEU :

Here is a motor bought brand new for 20 Euros !!!

This is a "LENCO" usually installed on BAUER / NORIS machines Electronicaly regulated.....

It has been "BEAULIEU" converted (Shaft thouroughly shortened to BEAULIEU size requirements).

Otherwise, this MOTOR is EXACTLY the same and works perfectly!!!.........

........Just for a price 10 x Below !

Posted by Andrew Woodcock (Member # 3260) on February 24, 2016, 11:28 AM:

You have to transfer the old rubber cushioning gromits from the original motor into the new Phil. I had to do this on my recent motor changeout.

If you want a new motor though Phil, as expensive as they are, Beaulieu official stock carried by Wittners is the only way I can find to obtain the right one now, brand new and boxed.

I couldn't find a stockist of Lenco motors anymore when I looked.

Which Bauer machine do you think this was fitted to BTW Phil? Certainly not the Studio range?

You did well there though my friend. 20 euros is still a bargain price now for any that works, let alone a new one! ![[Wink]](wink.gif)

[ February 25, 2016, 07:39 AM: Message edited by: Andrew Woodcock ]

Posted by Phil Murat (Member # 5148) on February 24, 2016, 11:44 AM:

These Blue Grommets are used on Hard Drive Computers and fit properly on the Beaulieu Motor , also they look more long-lasting.

.Beaulieu Motor come under ref BK6901-51

.Alternate Item (BAUER / NORIS) come under ref BK6901-36, at this price I took 2 items !! ![[Wink]](wink.gif)

Also looks to be used on NORISOUND 410.......

Posted by Andrew Woodcock (Member # 3260) on February 24, 2016, 12:30 PM:

do you know which Bauer model these motors are supposed to fit Phil?

The marginal difference in product codes, I suppose just takes into account the difference in shaft lengths between the two motors.

The rubber inserts are widely available Phil from any good Engineering merchant or Electrical supplier like RS etc.

[ February 25, 2016, 03:44 AM: Message edited by: Andrew Woodcock ]

Posted by Phil Murat (Member # 5148) on February 25, 2016, 03:37 AM:

Not found yet Andrew , I assume these are Bauer Projectors produced around year 1977......

Still Under insvestigation ![[Wink]](wink.gif)

Posted by Andrew Woodcock (Member # 3260) on February 25, 2016, 03:42 AM:

Yeah quite possibly Phil, but I have no idea which one unless it was the 430/ 450 stereo models. (Not a studio model).

I cannot imagine how they would have utilized the tachometer??

It's not a method they used on the 525/610 etc.it's just not their style of working from what I've seen

These have a separate serrated wheel and optical sensor to the motor to feedback the speed reference and count the frames in essence.

See if your powers of observation Phil can find us both some cheap spare new capstan drive motors from somewhere. ![[Wink]](wink.gif)

[ February 25, 2016, 05:13 AM: Message edited by: Andrew Woodcock ]

Posted by Phil Murat (Member # 5148) on February 25, 2016, 06:28 AM:

Do you have any details (Manufacturer, model, ref, etc....) concerning the small Capstan Motor ?

I do not remember to have observe a label on the motor shell.

Then it is also regulated with a tacho.

May be it is a Lenco too.

Posted by Andrew Woodcock (Member # 3260) on February 25, 2016, 07:07 AM:

I don't think I have seen any nameplate details on this one Phil.

It does have something of a tacho on it though you're right.

The photograph on Wittner's beaulieu.de website, very cleverly obscures any of the actual nameplate details and just shows you the Beaulieu logo at the top of the nameplate.

Here is a link to the ones Phil refers to above for anyone adept with using a hacksaw and file!

http://www.ebay.co.uk/itm/111766152860?_trksid=p2055119.m1438.l2649&ssPageNam e=STRK%3AMEBIDX%3AIT

Posted by Phil Murat (Member # 5148) on March 03, 2016, 12:18 PM:

Concerning Capstan Motor :

I don't Know if that can Help, here is the P/N reported on a label , hiden behind the rubber around the motor shell :

9904 120 01809

W02 - 924

And now, this is the Web answer.......

http://fr.farnell.com/allied-motion-premotec/9904-120-18105/servo-motor-12vdc-3840rpm/dp/147875

But unfortunately, NO TACHO included with ...........Hummmmm

Posted by Andrew Woodcock (Member # 3260) on March 03, 2016, 12:25 PM:

Hmmmm. Interesting Phil. Maybe the tachometer is an add on separate part by Beaulieu to control the motor??

I just downloaded the datasheet here Phil, and one of the options featured in the listing which includes encoder, planetary gear head etc etc ...is a built in tachometer! ![[Smile]](smile.gif)

Perhaps it's just something you have to specify and select when placing an order?

Now to find a stockists somewhere here in the UK if possible. ![[Wink]](wink.gif)

They appear to be based in Holland, so that's not too bad. I think RS stock some of these but haven't found this particular one yet.

Posted by Phil Murat (Member # 5148) on March 03, 2016, 12:57 PM:

I am afraid the Beaulieu Capstan Motor is a special manufactured item ordered by Beaulieu in the past......

.......And what about using a small DC motor (or not DC, just a small motor with permanent magnet rotor for exemple): In a reverse mode use, it becomes a basic Generator ![[Roll Eyes]](rolleyes.gif) ?????

?????

The best should be to find a Brushless Item

Also, to anyone who is reading this tip......... Do not scrap your former PC printer, as you can find many interesting things inside (opto couplers, small motors, and so, and so..) ![[Razz]](tongue.gif)

![[Razz]](tongue.gif)

Posted by Andrew Woodcock (Member # 3260) on March 03, 2016, 01:02 PM:

These are permanent magnet motors Phil?

Posted by Phil Murat (Member # 5148) on March 03, 2016, 01:04 PM:

I don' t know at this time.....

What I feel is this motor is very closed to capstan motors used on former 80'S tape recorders......

TEAC, TECHNIC, PIONNEER, etc....

Posted by Andrew Woodcock (Member # 3260) on March 03, 2016, 01:35 PM:

Sorry Phil, the above was a statement not a question. I only used a ? Because I was confused by your statement.

Anyhow, they are permanent magnet D.C. motors and there is an option here for purchasing with a built in tachometer, just like the ones we would want!

I think the tacho gen is a.c. btw.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Wink]](wink.gif)

![[Wink]](wink.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Roll Eyes]](rolleyes.gif) ?????

?????![[Razz]](tongue.gif)

![[Razz]](tongue.gif)