This is topic Eumig 900 series repairs and tips in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=011200

Posted by Paul Adsett (Member # 25) on January 08, 2017, 01:44 PM:

Anyone who owns a Eumig 938 stereo projector, or any of the non-coaxial reel design 900ís, knows that the automatic threading system works flawlessly 99% of the time. So when my 938 refused to thread any of my films, despite re-trimming and straightening the leaders, I knew something had gone seriously wrong. It didínt take long to track down the problem.

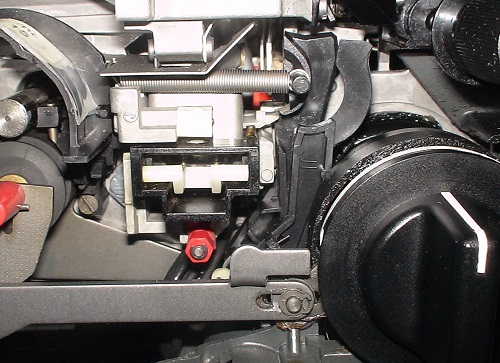

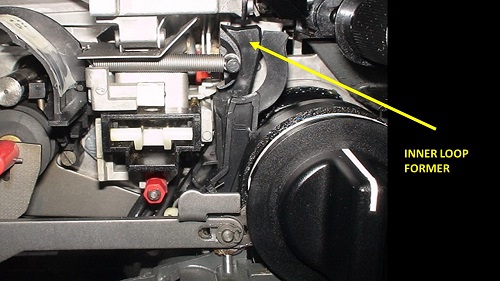

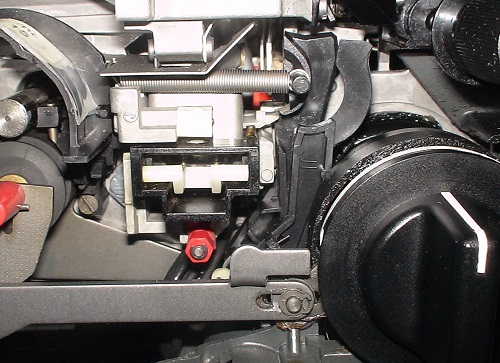

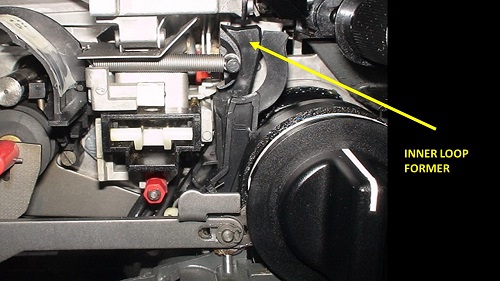

The automatic loop forming on the 900ís is all mechanical, controlled by a complex system of cams on the control knob, and cam followers integrated into the loop formers. The problem with my machine was that the plastic cam follower, which is part of the inner bottom loop former, had simply snapped off. And itís no wonder, the plastic arm which engages the cam is a thin plastic beam only 2mm thick! Exactly the same happened on one of my Eumig 926 GLís, so I believe this is a part that is likely to have failed on many of the 900 series machines. Eumig were incredibly brilliant designers, but unlike the very solid build of the 800 series machines, the 900 series machines (although much better performers) featured many flimsy plastic components.

I thought my 938 was done for, since there is no way to manually thread these machines ,and the prospect of dismantling and reassembling that complex cam system is extremely daunting to say the least.

Since the threading problem was due to the rear side of the bottom loop former now being way too forward for the film to enter into the guide, I fitted a rubber band around the knob of the loop former and stretched it back over to the knob on the sound capstan shaft. This pulled the loop former back to its correct position for threading. Low and behold, I found it worked like a charm, and faultless threading was restored. Not liking rubber bands, I then decided to fit something more elegant, and found a tension spring which does the job perfectly. The spring hooks over the knob on the loop former and lies over the top off the sound head block, hooking over back edge of the metal plate.

One annoyance of the 900 machines is the need to use a screwdriver to remove the cover every time you want to clean the gate. Why Eumig did not use a knob instead of a screwdriver slot is beyond me, but here is a simple fix. I found that a standard automobile tire valve cover can be pressed over the head of the screw, and can be epoxied in place. You may have to file the plastic head of the sleeve on the bolt very slightly to get it to fit. Now , I can spin off both the cover screws on the 938 in a couple of seconds, with no searching for a screwdriver. It really is a much better way to do it.

One thing I like better on the 926 GL than the 938, is the cover. The GL cover is very attractive with the gold and black 2-tone finish and the embossed Eumig decal. It also seems to be a much more solid cover. Well, the 926 cover fits perfectly on the 938, and I think it makes the machine look great:

Posted by Edwin van Eck (Member # 4690) on January 10, 2017, 06:21 AM:

Hi Paul,

The Eumig 9-series is in our range of projectors, where we try to make all spare parts for, to keep this series up and running as long as possible. It are fine machines.

Currently we have these spare parts available:

http://www.van-eck.net/itable.php?lang=nl&size=0&cat=film&merk=57&type=S932%20Supersound

Are there any other parts you would buy, if we develop these?

Posted by Paul Adsett (Member # 25) on January 10, 2017, 11:16 AM:

Hi Edwin, yes I certainly agree that the Eumig 938 is a fine machine, and the sound quality is amazing.

As I said, I suspect that there are a lot of 900 series machines around, all with broken plastic arms on the lower loop former, and therefore unable to thread any film. Both my 926GL and 938 stereo have this problem. The spring I added is the best kind of reasonably successful fix that I have come up with, but a new manufactured part, possibly using some strengthening filler, would be a much better way to go.

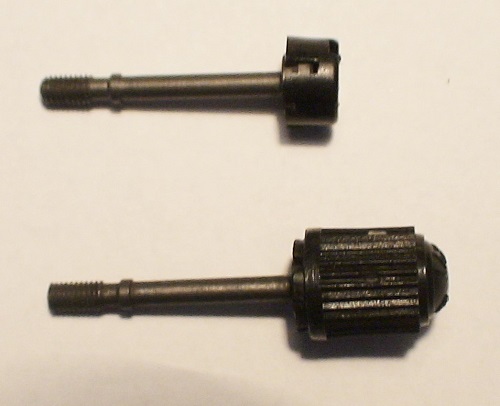

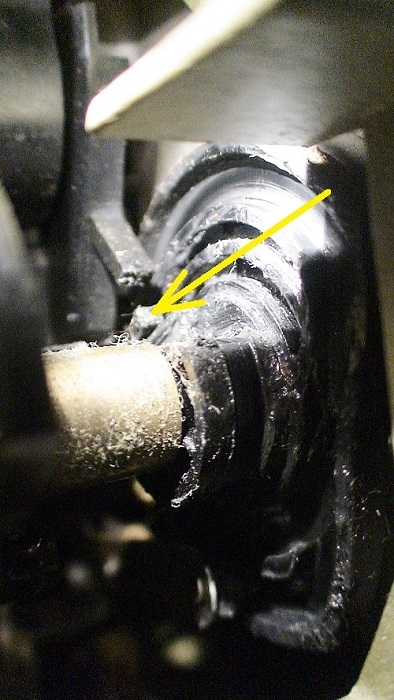

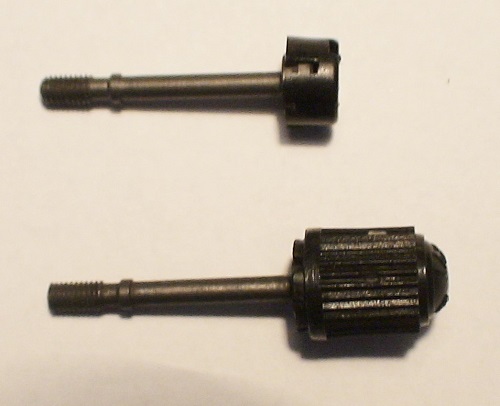

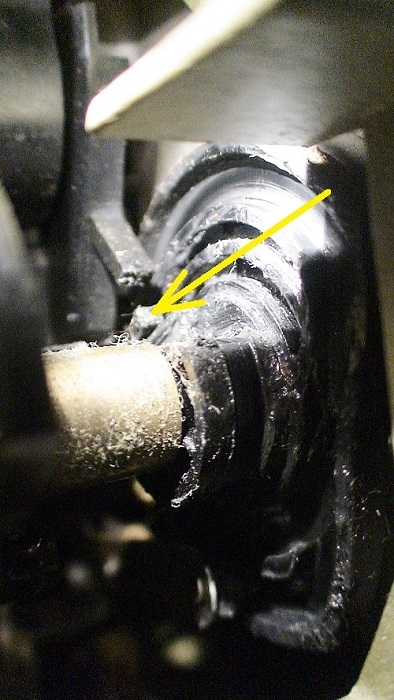

Here is a photo showing the breakage point of the plastic arm, which is a feature of the lower inner loop former part (labelled in the photo above):

And here is the piece that broke off:

This arm is only 2mm square section, and the back has a small cylindrical feature 2.5 mm dia and 1mm high, which projects out from the surface to engage into the slot in the rotary cam. I suspect it broke while I was pushing down on the loop restorer knob, while running a film ( yes this little beam section has to bend when you depress the loop former!

Another part that seems to consistently fail on these 900 machines is the main switch. I have had three 900 machines where the switch has frozen up and burned out. I have not been able to find any replacements and had to resort to mounting a rocker switch on the rear of the machine:

While I have your attention Edwin, I see that you manufacture replacement worm gears for these 900 machines. The worm gear on my 926 recently broke up, how difficult a job is it to replace it? :

[ January 10, 2017, 12:26 PM: Message edited by: Paul Adsett ]

Posted by Maurizio Di Cintio (Member # 144) on January 11, 2017, 04:13 AM:

Paul, what you wrote is awesome!!! Also because years ago I had the same problem with the same part of the loop former. AND I came up with a similar solution: a spring taken from a pen, which I bolted to one of the screws which hold in place the film gate.

I like your idea of using the front cover of the 926 for the 938: we should find a way to correct the name engraved on it though.

Fortunately I've never had any issues with the main switch. But should I have, I'll certainly use your solution.

Yet I still think the most delicate and wear-prone part is the sound head on these fine machines. I had found a company here in Italy which is able to build magnetic heads for card readers and use also sendust alloy. I thought to myself: "It would be great if these guys could re-manufacture a Eumig head with sendust alloy". So since I was in contact with the Eumig museum in Wien and I met Herr Vockenuber's daughter, I tried asking them about the original blueprints and specs of this head but unfortunately they were all sold to Bauer/Silma in the Turin-based factory (along with the machine to produce them) when Eumig went bankrupt, so they lost trace of it. Eventually all this stuff was scraped off when Silma ceased operations too. That's very sad, but I was wondering if some of the brilliant engineers here might figure out the specs using an original/used head. If we can have all the necessary information, perhaps we could start a short-run production... I estimate a relatively high number of S/8 collectors might be interested in this head... Any suggestions??

Posted by Andrew Woodcock (Member # 3260) on January 11, 2017, 11:47 AM:

Maurizio, i can do nothing to solve or help with the 900 series soft magnetic head situation, however when i'm home again i may be able to decipher how many turns of wire, thickness of wire with a micrometer and resistance of both coils were originally used on the Wolke mag heads.

This would certainly help for the manufacture of certain heads for certain machines.

I could also provide dimensions for the yoke etc if this helps?

If any manufacturer would be prepared to manufacture new sendust alloy yokes, we may then be able to produce some new heads so long as we had old ones to salvage the outer shell body parts from?

[ January 11, 2017, 04:31 PM: Message edited by: Andrew Woodcock ]

Posted by Edwin van Eck (Member # 4690) on January 11, 2017, 12:06 PM:

Thanks all for the good tips on parts which are needed. We will dive into this to make these parts available again!

If someone else has requirements / wishes, let me know.

BTW: we have released today an instruction video how to replace the worm gear for these projectors: https://www.youtube.com/watch?v=8HGUY2mnSRA&feature=youtu.be

Also I encountered some broken/missing filmguides on top of the projector. So we will also make these:

[ January 11, 2017, 02:57 PM: Message edited by: Edwin van Eck ]

Posted by Paul Adsett (Member # 25) on January 11, 2017, 07:08 PM:

Excellent video Edwin! I had no idea what would be the best way to undertake this repair, but having seen the video I now feel that I can do the job. So, I will soon be ordering up a new worm gear from you for my 926GL.

One question, do you recommend greasing this gear, or not?

Andrew,

I wonder if an X-RAY of the head would be helpful in re-engineering it?

Posted by Edwin van Eck (Member # 4690) on January 12, 2017, 02:33 AM:

Yes, always grease the moving parts!

We use for this Molykote G-4500, see: http://shop.van-eck.net/?_globalsearch=molykote

Posted by Mark Todd (Member # 96) on January 13, 2017, 09:31 AM:

Hi Edwin have you got any of my emails about the set I wanted to return please.

Thought I had better wait until I hear from you before I post them.

You can message me on here if there is an email issue.

Best Mark. Thanks.

Posted by Edwin van Eck (Member # 4690) on January 13, 2017, 09:57 AM:

Hi Mark,

I just have sent a PM.

Posted by Andrew Woodcock (Member # 3260) on January 13, 2017, 06:30 PM:

I am sure you're right Paul regarding the re engineering of the head, though admittedly, it's something I'd never for one second, ever considered previously. ![[Smile]](smile.gif)

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Smile]](smile.gif)