This is topic Chinon SS1200 Rewind Problem-I'm stumped in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=011315

Posted by Alan Rik (Member # 73) on March 03, 2017, 11:27 PM:

There was a previous thread on this machine with the same situation. I started a new thread because that one was pretty old and there was no conclusion.

So this is the problem:

Plays beautifully, rock steady, nice image, booming sound, but...the rewind at the start of a reel is nice and strong but every time it gets near the end of the reel it starts to slow down and stop.

I have the service manual and I increased the torque to the motor but it didn't help. I adjusted the belt tensioner to rule that out.

But from what I can see and feel, when the film is in rewind mode the front arm motor is strong. I can barely stop the spinning empty hub. Even if I put a 1200 ft reel the motor is strong. However when it rewinds an actual reel I can feel there is drag on the take up reel. Like there is resistance. If I go and take the reel off of the machine and hold it by hand the motor flies and the film is rewound. So..any ideas?

If I had another SS1200 I could see how the machine is supposed to be but I don't.

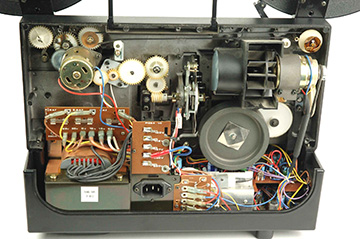

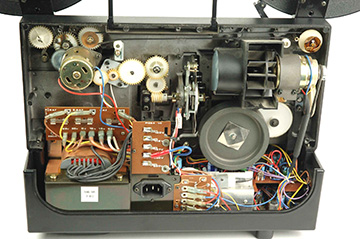

Here is a pic of the back of the machine via Van Eck. (thanks Edwin!)

I'm stumped! Its so much easier to work on a GS1200 believe it or not-

And a better pic here:

http://www.van-eck.net/img/itable/images/film_139_Lux%20sound%2080%20stereo_14426 56357737.jpg

Posted by Paul Browning (Member # 2715) on March 04, 2017, 04:50 AM:

Hi Alan, I have a brand new one of these, if its any help at all I will get it out and have a look to see the action on this rewind. As this is unused it will give us the best understanding of how this suppose to be, all I ask is if you have a copy of the service manual on pdf send one over please. I do like this machine, doesn't get as much coverage as some the other projectors, but a good performer from what I read.

Posted by Alan Rik (Member # 73) on March 04, 2017, 07:59 AM:

Hi Paul, I don't have it as a PDF yet but I will scan the manual later today and get it to you.

I have to eat my previous words for my hate of Chinons this time! I had a Chinon 4100, my first projector, and it ate many of my films. It had a terrible rewind which would jam, etc.

But this is the 1st Chinon I have used that is gentle on film.

Pretty nice machine.

Let me know once you take a look at the rewind mechanism. I hate being stumped!

PM sent-I'll need your email address for the manual.

Posted by Andrew Woodcock (Member # 3260) on March 04, 2017, 08:28 AM:

Toothed drive belt as it transpires, therefore all previously written, is irrelevant.

[ March 06, 2017, 04:42 PM: Message edited by: Andrew Woodcock ]

Posted by Paul Browning (Member # 2715) on March 04, 2017, 09:21 AM:

Hello Alan, your in box is full so can't reply to your request. I also have a scrap one of these courtesy of Derann,from Derek one after noon at the shop, it was on his counter looking sorry for itself, when asked he said it would stop or slowdown when rewinding !!!!!, but your upload jogged my memory on this, and I think I know what the problem is, I will need to dig out the scrapper Alan. The new one will provide us with some important data on this machine, and specifically this problem on the machine.

Posted by Alan Rik (Member # 73) on March 04, 2017, 12:22 PM:

Ok! Mail all cleared out. ![[Smile]](smile.gif) Lets get this baby going again!

Lets get this baby going again!

Posted by Paul Browning (Member # 2715) on March 04, 2017, 12:50 PM:

A lot less going on in there than the GS for sure. PM now sent over to you Alan. Once I get the scrapper out, I'll check to see if this still works and does still slow down with the big reel on, perhaps it could be salvaged, everything else seems to work, heads are warn down though. We have come some way since I had this donated, the technology can help us now, such things did not exist then.

Posted by Alan Rik (Member # 73) on March 04, 2017, 10:38 PM:

Manual sent to you via Google Drive.

Posted by Paul Browning (Member # 2715) on March 05, 2017, 05:14 PM:

Thanks Rik, manual now downloaded. Ok, on the new machine, I checked the voltage across the connections when in rewind mode with no reel on, this was 5.0v give or take. I loaded a elmo 12ft reel full to the brim, and placed an empty one on the front again an elmo. I then placed in into rewind and checked the voltage, 13v to start with, gradually reducing back down as the reel got more empty, about half way it was at 10v or so, and slowing down quite a lot. By the time it finished the voltage was back to just about the starting voltage of 5.0v. Now this is on the brand new machine, not the scrapper. So even on the new machine this slows down a lot more than I was expecting, the scrapper voltage 4.0v to start with and about 10 v max under the same conditions, belt tension about the same, turning the hubs without reels on, to me about the resistance. The scrapper could not complete the rewind and just stopped about 300ft or so from the end, it would go again with a bit of help from me. The motor looks like the same one that's on the elmo. I'm looking at the manual to see if there is a measurement like on the elmo for tension or torque setting for clutches, it looks just too simple for any of this stuff though, will check on the scrapper.

Posted by Alan Rik (Member # 73) on March 05, 2017, 11:43 PM:

HI Paul,

So I measured the voltage in rewind with no reels on it and mine read 13.97 volts.

How did you get the voltage of 5? I measured the voltage from the leads coming off the motor to where it ended, the small board to the right of the power cord input.

There is a torque adjustment you can make. Its on page 8 of the manual. I feel like the torque on mine is strong its just baffling why it can't complete an entire reel. Strange is that it will do about 360 ft of a 400fter. But if I put on a 1200ft reel it will do almost 900 and then quit. So its not the size/weight thats the problem but the load as it nears the end?

I hope there is a solution. It plays movies great.

If you try to turn the reel holder by hand on the take up arm, is it difficult to move? Mine is. Makes it seem like that is the cause of the tension. Like there is too much gunk on there or something. I just don't know. If you take the back off the machine and watch as it rewinds - does the big toothed belt move?

So the tension of the main toothed belt on both machines seem the same?

I'll send a video of the machine in a day or two with the back off and you can tell me if its like yours.

Posted by Paul Browning (Member # 2715) on March 06, 2017, 01:35 AM:

Hi Alan, I used the same reference point to measure, interesting the difference of start voltage , I will recheck mine. The scrapper does not have the two coil springs in the rear arm I noticed, not checked the new one but I will now. These must act as some kind of tensioning for the film take up.my point is that the motor is almost at it limit from new to do these jobs asked , and I note the GS has two of these motors, I'm sure its the same one. There is gear trains in both arms these do take some turning when no grease is present, no belts in here.

Posted by Alan Rik (Member # 73) on March 06, 2017, 02:43 PM:

Here's another question for you: When you have the machine on rewind without a take up reel is the machine fairly quiet? Or does it make a bit of noise? Mine is noisy when you rewind without a reel but if you put on a reel its becomes quiet.

My take up arm only has the gears and not the 2 springs like the forward take up arm as shown in the manual.

Posted by Paul Browning (Member # 2715) on March 06, 2017, 03:34 PM:

Hi Alan, The 5.0 volts are measured when in the forward position. Its no more noisy than any other projector really, the front gear train are straight cut gears and these tend to be more noisy than the helical cut gears. The toothed belt does not turn at all in rewind position. When in the rewind position the front set of three gears are moved forward by inertia, and cannot connect to the forward gear which is part of the hub that moves the toothed belt. How did you measure the front take up reel when setting the rewind torque?.

Posted by Alan Rik (Member # 73) on March 06, 2017, 04:08 PM:

Ah...ok. This is different. When my machine goes into rewind the toothed belt turns. That is the drag that is causing the motor to come to a crawl I think. Can you send me a video link of what happens when you go into rewind? I will send you one when I get back. I'll upload it to Youtube.

So if you have the machine in standby position, not forward or reverse, and you turn the take up hub by hand, does the toothed gear turn? The way my machine is, the take up reel hub is connected to the set of gears in the arm, connected to the main gear closest to the machine. This in turn will turn the toothed gear that you can see from the back of the machine when the back cover is off. So then the toothed belt will turn the gear near the front of the machine. So no matter what, the toothed belt always moves if you turn the gear either in rewind or by hand.

I just went and turned the Torque Potentiometer till it seemed stronger. Yes..very scientific I know-

Posted by Paul Browning (Member # 2715) on March 06, 2017, 04:52 PM:

The motor is turning in different directions in the these two position settings. Looking from the back with the back cover removed, in the forward position green button engaged both motor and rear hub spins in an anti-clockwise direction and engages just the one gear attached to the wheel and toothed belt. In the rewind position both the front hub and motor will turn in a clockwise direction as viewed from the back. It cannot reach the gear in this position to turn the toothed belt because the gear train has moved forward to engage the single gear on the base of the front arm. The centre gear swings from side to side as the motor changes direction and the inertia throws it either way. Just one screw hold this plate in place and should not be locked down on this swing plate. Sorry Alan I have no facility for any video upload. But if you can show me what yours is doing I can tell you what I think is going on.

Posted by Alan Rik (Member # 73) on March 06, 2017, 06:56 PM:

I was mistaken. The toothed belt doesn't move unless there is a take up reel that is being rewound. Then it will move. I measured the voltage. A strong 13.9 volts than about halfway it goes to 10v, and then I see it rapidly go to 8, 7, 6, zero. Stop.

And the reel that is being rewound is very tight. So that is probably due to the tension that is on the rear take up reel when being rewound.

Here is the video link.

So..what do you think? https://youtu.be/HIC6IKIIrTo

Posted by Paul Browning (Member # 2715) on March 07, 2017, 03:54 PM:

Hi Alan, Ok in rewind position with reels on the front and back hubs with film ready to rewind. The rear hub will turn because its connected only by the fact that the film is joining the two reels together, and this is making the thing turn not anything in the front gear train. As mentioned in my previous comments the gear cannot connect to both front and rear gears its just not big enough, and it would trash the gears in the process.

Next thing I did, this is with the scrapper, connected a separate power supply to the motor, and set this to our 13.9v, with a empty reel on the front hub, and a full one on the back hub, into rewind, connected a multi meter at the connection points to monitor voltage drop. No voltage drop, current draw was 500 milliamps to start with and 3 times this at the end, it did not stop once, just slowed down towards the end, but could have done a bigger reel I feel. Now this is a scrapper and I have not adjusted the torque resistor either. One other thing I should mention here is that the gear on the motor actually moved out of position, outward, I did wonder if this was the initial culprit and slipping on the shaft, I think I will try to glue this in position and see if this helps. I could not turn this by hand, but the torque at some point may be able too. I would add that the noise you can hear is the one gear that connects the motor to the two gears, this wears on the shaft because this has no bearing so is moving slightly side to side as it rotates, if you grab the gear you can move it, the new one is quieter because of this.

Posted by Alan Rik (Member # 73) on March 07, 2017, 04:40 PM:

So it sounds like our machines are moving properly. Maybe I'll take the rear clutch apart to see if there is a slipping gear in there? This seems like such a common problem with this machine it would be great to have a solution to this finally. On doing a search for this I found a few threads on this with no solution. The Service manual is pretty basic in a bad way. Let me know what happens with your experiment. Thanks!

Posted by Phil Murat (Member # 5148) on March 08, 2017, 11:23 AM:

Hi Rik,

Check your Email and let me know about test results.

Phil

Posted by Paul Browning (Member # 2715) on March 08, 2017, 05:55 PM:

Perhaps you could share the results on this thread Alan, because for whatever reason phil doesn't want to share it on the forum with me or any other chinon ss1200 owner, odd stance to take.

Posted by Alan Rik (Member # 73) on March 09, 2017, 12:24 AM:

Hi Paul- no it's not that. Phil is helping me with a Beaulieu problem right now. I seem to have a stable of broken machines. I sent him an email about this since I didn't want to clog up the thread till I had something more concrete. I am very appreciative of all the help on this one guys! And hopefully collectively we can figure this all too common but unresolved Chinon issue !

Posted by Paul Browning (Member # 2715) on March 09, 2017, 01:29 AM:

Thank's Alan for clarifying that, apologies to phil then. That's why I thought it was odd of him, he has the energy and verve to sort out the beaulieu for sure. Good luck with it, i'll push on with chinon gear gluing and then test it, perhaps look at the power circuit that does the rewind, something not right there.

Posted by Phil Murat (Member # 5148) on March 09, 2017, 03:15 AM:

Hi Paul,

Thanks, no problem.

Once,this "Rewinding" issue fixed, it is up to Rik to bring there something sumarizing the T/S approach.

Morever it is very interesting we focused on the same way concerning the "Electronical Control" for the concerned motor.

I have suggested Rik to bring me a picture for this card as a 50K Resistor Trimmer is somewhere to adjust efficiency for what I call an "Overload Protection" (or Also Autoshutdown as well)

Posted by Paul Browning (Member # 2715) on March 09, 2017, 07:12 AM:

The motor does not like being put under a load, but on a separate power supply, although the amps go up 3 fold it proves it can do the job, like you say maybe a safety feature of the circuit but it struggles, with the volts going off the cliff and the motor then stalling. I thought it was on some kind of timer circuit. Odd one for sure.

Posted by Alessandro Pavoni (Member # 1739) on August 15, 2017, 03:42 AM:

Alan, did you solve the problem ??

Please let me know, I have the same on my Chinon SS1200.

thanks

Posted by Alan Rik (Member # 73) on August 15, 2017, 05:56 PM:

Unfortunately I threw the towel in on this one. It was NOT designed to be worked on as the electronics were buried..buried..buried in the machine. I had to take apart the entire thing and still there were more to remove. When it became apparent that I would have to get it down to the bare bones to work on it I decided against it. Life is too short! ![[Smile]](smile.gif)

Good luck! It really is a nice machine and if you can get that sorted that would be great.

Posted by Andrew Woodcock (Member # 3260) on August 15, 2017, 06:16 PM:

Can't say I blame you Alan in any way regarding this one. ![[Wink]](wink.gif)

Posted by frank arnstein (Member # 330) on August 21, 2017, 07:43 AM:

Greetings to the forum members who followed this interesting thread,

It seems this problem effects nearly every Chinon 1200 in the world.

After some careful study I have arrived at the root cause of this conundrum and will happily share the fix with anyone that asks me.

Dogtor Frankarnstein.

[ September 10, 2017, 06:31 AM: Message edited by: frank arnstein ]

Posted by Andrew Woodcock (Member # 3260) on August 21, 2017, 08:25 AM:

Yet another great addition to add to the "Index of Technical Topics" here.

Well done Frank for sharing and well done too for discovering the root cause in the first instance! ![[Smile]](smile.gif)

Posted by Paul Browning (Member # 2715) on August 21, 2017, 12:42 PM:

Thanks Frank, i'll check this out. I have a new machine and this is also present on this, but not as bad as some, like Alan Riks machine, but perhaps in my case it could be solidified grease in there. I do know the gear trains are greased up, but I will renew this now, to reduce friction between the gears. Thanks again for some great information.

Posted by Mark L Barton (Member # 1512) on June 24, 2018, 06:19 AM:

I have a Chinon S1200 Stereo with exactly the same issue, in rewind, and down to the last 300 odd foot the rewind goes from powerful to sluggish to stop, I love this projector and in all other respects its superb ( I have several ST1200s and GS1200's, but always reach for the Chinon for a quick play of a new title) So, did any one find a cure, was it too much hardened grease, or electronic issues (if its that I wont even go there)

Thank you

Posted by frank arnstein (Member # 330) on June 27, 2018, 07:27 AM:

Hi Mark,

The actual cause is the sticking pawl of a rewind Sprag clutch. This clutch is inside the big plastic gear which the toothed belt drives. It's behind the big plastic washer on the take-up drive shaft.

This small mechanical clutch ratchet/pawl is now stuck in one position due to hardened old grease. It won’t allow the free-wheeling in one direction needed for fast easy rewinding. Instead it drives the toothed belt and gear unnecessarily. This causes a lot of unwanted load and extra noise which forces the rewind to slow and then end prematurely.

To free up this "Sprag Clutch" I would spray Isopropyl alcohol or some other evaporative spray onto the sticking clutch parts to dissolve and wash away the old grease and dirt.

You may need to partially dismantle behind the washer to get to the little ratchet parts. Watch out you don't loose any tiny springs or other bits there.

When working properly, it must allow slip of the shaft when rewinding film and lock up when projecting film. Observe the clutch working then reassemble and test again by hand, rotating the take-up spindle in both directions by hand, to test the lock and release of the ratchet pawl.

If you are successful, the normal fast rewind ability of your machine will return and it will be quieter in rewind as well. Lubing the gear train axles in both arms will reduce friction even further. Dry plastic is noisy and drags.

So see how you go and let us know.

Dogtor Frankarnstein

![[Wink]](wink.gif)

![[Razz]](tongue.gif)

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Smile]](smile.gif) Lets get this baby going again!

Lets get this baby going again!

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Razz]](tongue.gif)