This is topic GS1200 Green guides in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=011772

Posted by Graham Ritchie (Member # 559) on October 02, 2017, 03:10 PM:

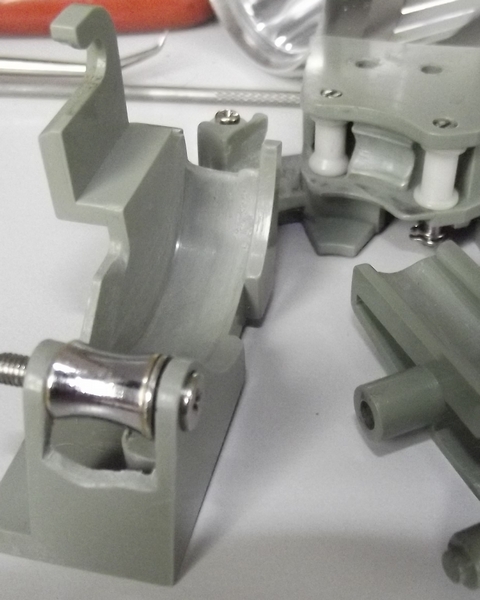

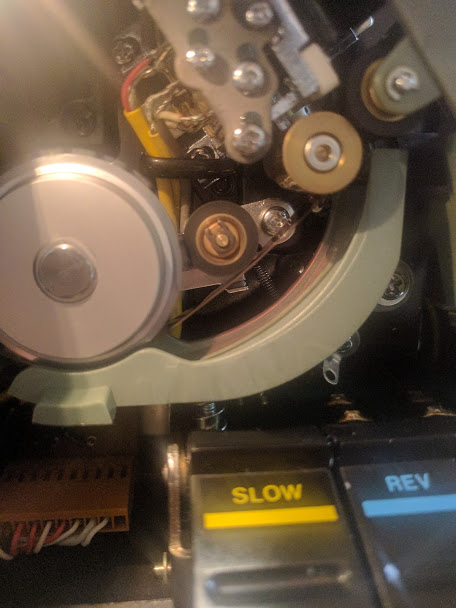

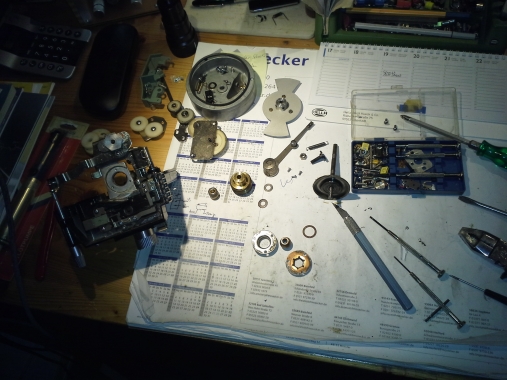

As we all know they wear over time, so of late I decided have a go once and for all to improve things, here are some photos of what I have been up to.

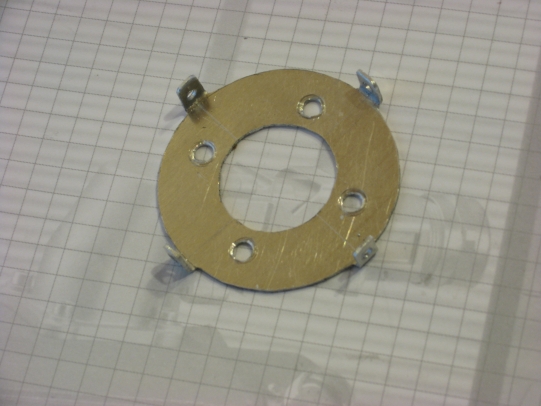

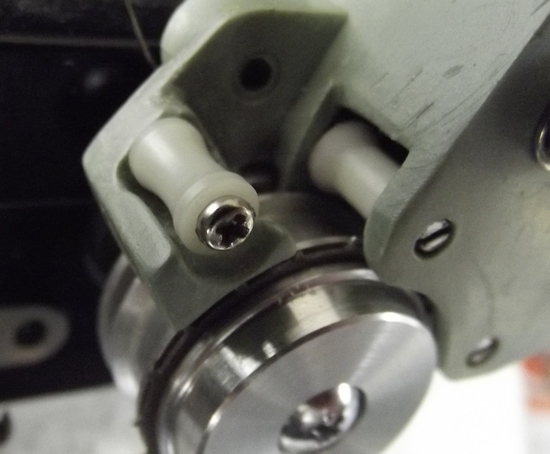

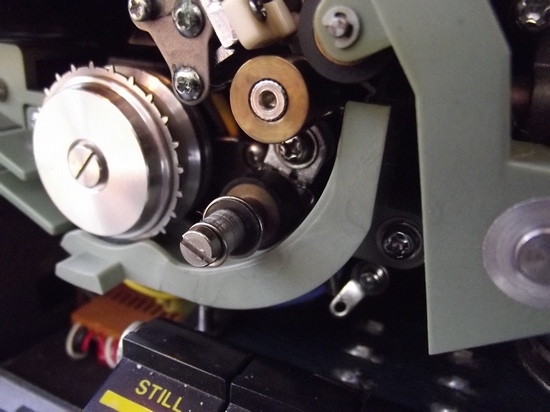

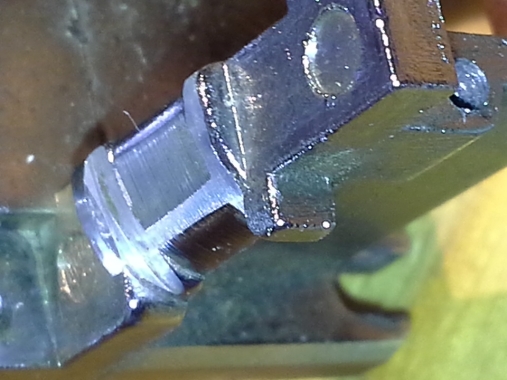

I filled up the inside of the guide with metal set, drilled a small threaded hole for a old roller and its shaft, taken from a Raynox projector. The idea was not to have any hard contact when the film does the sharp upward turn onto the sprocket, instead to have a roller that will turn on contact.

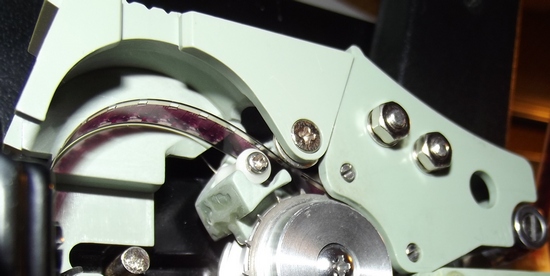

The next thing was to fit an extra roller on the centre top sprocket guide, plus grind out a deeper groove.

Plus fit another small turning roller again from an a old Raynox to the fwd part of that centre guide.

Also fitted a chrome rotating roller on the threading button.

It took quite a while to do all this work, but feel that the end result was worth it.

Posted by Graham Ritchie (Member # 559) on October 02, 2017, 06:16 PM:

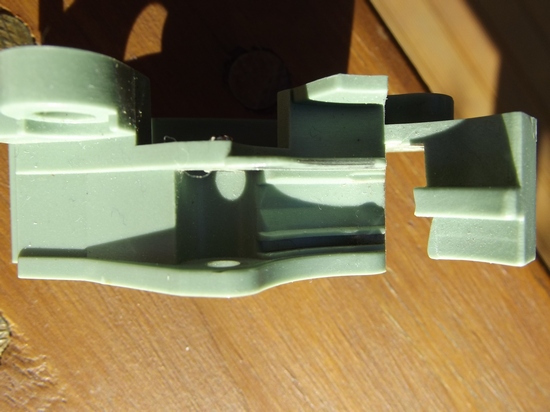

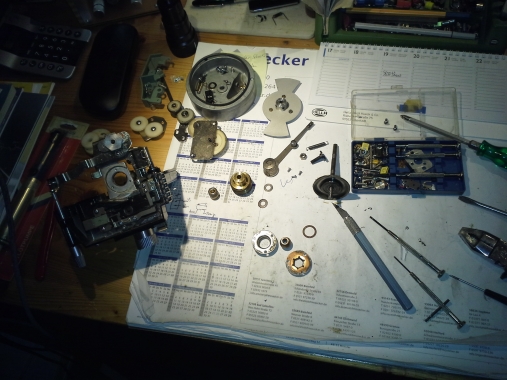

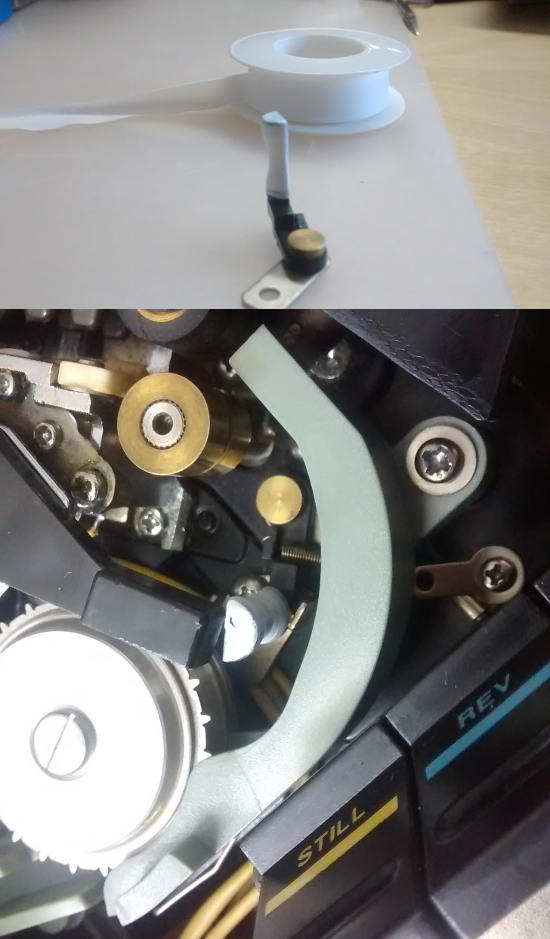

Here are a couple of before photo's, plus the last one with everything completed...well hopefully ![[Wink]](wink.gif)

The top sprocket bottom feed guide...note the wear point. It can get a lot worse than this, and will scratch film.

The top sprocket centre guide...also note the wear point. Once again if its left, it will wear "flat" and scratch film. This is where fitting a extra roller is important.

The all done photo ![[Cool]](cool.gif)

[ October 05, 2017, 03:08 AM: Message edited by: Graham Ritchie ]

Posted by Maurizio Di Cintio (Member # 144) on October 03, 2017, 04:12 AM:

To the best of my knowledge and relying ONLY on my own experiences, the other points that are prone to scratch film are the lower black tensioner, the lower sprocket guide, the sound head pressers and the loop former on later machines (those in which the lower loop faces backwards): on these machines, film can hit the loop former when running in reverse and IF the loop former is dirty, it can scratch. I hope I won't upset anybody with this disclosure - it's just out of my experience.

Posted by Paul Browning (Member # 2715) on October 03, 2017, 07:00 AM:

Well done Graham, not a girls guide, but boys guide to improving these, and a picture perfect guide. I always thought the first guide could be made in 3 parts, front, back and the centre guide, which could be replaced when warn, or updated as now, as these are bolted to the frame of the machine through the front to back plates.

Posted by Steven J Kirk (Member # 1135) on October 03, 2017, 11:51 AM:

That lower black tensioner... the problem there is in the back with the 'kick start' little wheel on the flywheel. If all works properly the film runs like a third loop and doesn't touch the lower tensioner.

Posted by Graham Ritchie (Member # 559) on October 03, 2017, 09:07 PM:

Thanks everyone ![[Smile]](smile.gif)

Posted by Mark Mander (Member # 340) on October 04, 2017, 01:54 AM:

Great job Graham,Nice pictures too,Mark

Posted by Tom Photiou (Member # 130) on October 04, 2017, 02:15 PM:

Must add my own 1200HD is one such example, its had a lot of work done over the years etc but like many it is now around 35/40 years old and has had an awful lot of use over the years, i mean a lot!! ![[Wink]](wink.gif)

Of course i guarantee like many, if it hadn't have been serviced & repaired professionally over the years it would either be scratching every film i put through it or more likely be in the tip by now with many many others. ![[Wink]](wink.gif)

Posted by Mark Mander (Member # 340) on October 04, 2017, 03:07 PM:

But parts on all machines wear out eventually and will mark films,Ricky stated that his Beaulieu marked a film due to a worn part,I don't know how you can say otherwise as it's there on this topic from someone who experienced it,Eumigs can scratch and I've known a Fumeo Mark a film all down to many hours of use,if they had replaced the parts before the extent of the wear showed on the film it wouldn't have happened,applies to all machines,redirecting the film path is a way of preserving the original items but if you replaced the parts with new then the machine would perform scratch free too,Mark

Posted by Tom Photiou (Member # 130) on October 04, 2017, 03:50 PM:

On that front guide on the GS1200s, i must try and find the old film for the collector magazine that had an article where someone had an all metal one made with the rollers also being replaced with small chrome/metal rollers in order to stop the known scratching,i cant recall if it was a company or a private individual who may have had it made for a one off. I definatly remember this though ![[Wink]](wink.gif)

Posted by Paul Adsett (Member # 25) on October 04, 2017, 04:09 PM:

I have never understood why Elmo designed the film path with the film going over the top sprocket instead of under as in just about every other projector. Going under is so much simpler and far kinder on the film.

Posted by Paul Browning (Member # 2715) on October 04, 2017, 04:41 PM:

I believe even the metal guide wear's in the same place as the original green guide, where the new roller is located, they are stationary while the film travels at speed across one point, its going to wear. Grahams original upload was inspired, helpful and to be applauded by many owners of the mighty GS.....

Posted by Graham Ritchie (Member # 559) on October 04, 2017, 08:01 PM:

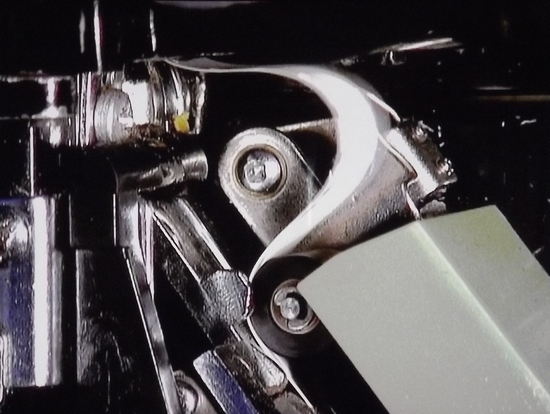

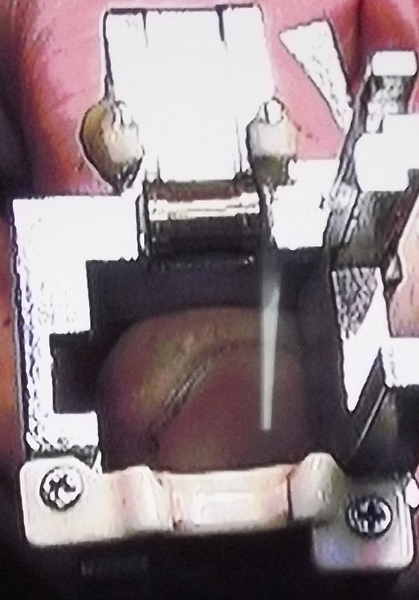

Last night I watched Keith Wilton excellent Armchair Odeons Reel One Two-Disc Special Edition dvd bought through Derann years ago..saw Paul Adsett wonderfull home cinema ![[Cool]](cool.gif) very nice Paul. Also on disc two, David Locke discuss the GS1200 scratching, and what he did to fix things. Apart from those top sprocket guides, he also talks about the early GS1200 forward facing bottom loop. I do hope Keith and David dont mind me mentioning them, plus using a couple of screen shots from there wonderfull dvd to describe what David did.

very nice Paul. Also on disc two, David Locke discuss the GS1200 scratching, and what he did to fix things. Apart from those top sprocket guides, he also talks about the early GS1200 forward facing bottom loop. I do hope Keith and David dont mind me mentioning them, plus using a couple of screen shots from there wonderfull dvd to describe what David did.

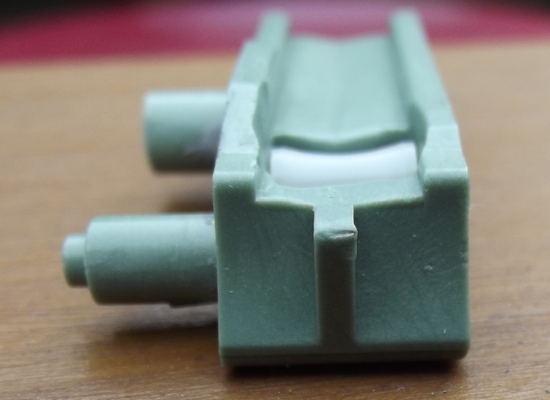

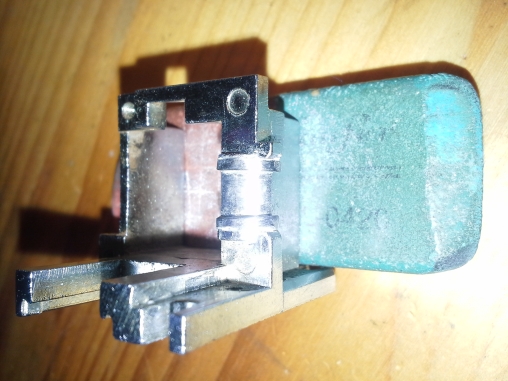

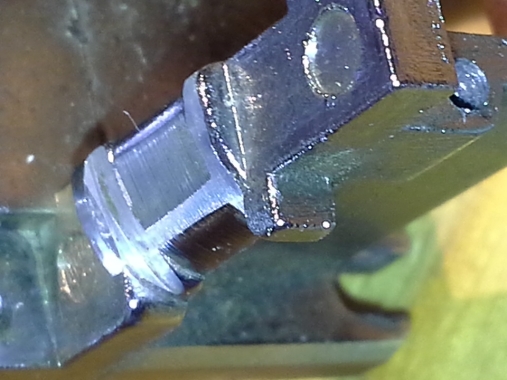

The first photo shows the film path and the rubber roller that pushes the film down, its at that point where the stripe rubs hard on that chrome looking casting wearing to a flat surface.

David goes on to descibe, how he fitted a small brass roller and using the same ceramic material, as shown in the bottom film guide. He also uses some of that material as a replacement for those two posts that guide the film onto the new brass roller from its loop. David does say that this ceramic material is so hard it will never wear out....or words to that effect...the photo is not very good, but you can see the brass roller and those upright two posts...Hope this is of help for those that have a forward facing bottom loop GS1200.

[ October 05, 2017, 03:20 AM: Message edited by: Graham Ritchie ]

Posted by Jason Smith (Member # 5055) on October 04, 2017, 08:44 PM:

Thanks Graham for sharing your photos and the work you did on your GS-1200. I've been able to make a few of the same mods on my machine after using this forum and others as a resource.

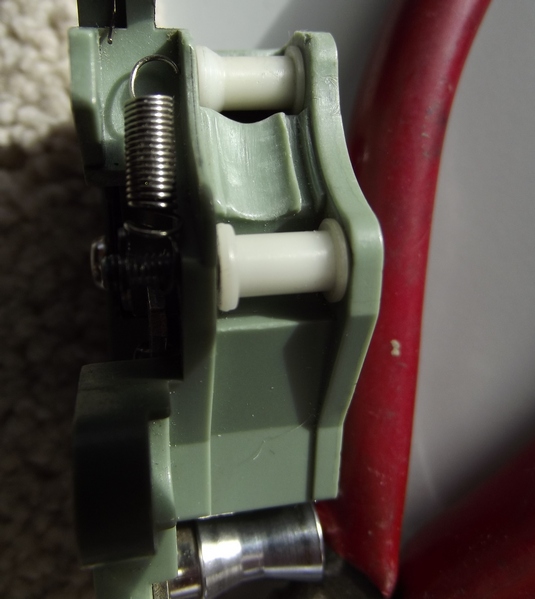

Here is a picture of the lower tensioner mod in my GS-1200. After hearing about this mod on another forum, I replaced the black plastic lower tensioner with the rubber wheel tensioner from a ST-1200 HD parts machine.

[ October 05, 2017, 04:26 AM: Message edited by: Jason Smith ]

Posted by Douglas Meltzer (Member # 28) on October 04, 2017, 11:35 PM:

You may notice that this thread is quite a bit shorter now and certain references are made that are not explained in the reading. I have removed a number of posts, most of them from a single source and also those that replied to those posts.

I realize that a bit of good information has been lost in the process and I apologize for that, however the combative tones in certain replies needed to go away.

Now please, let's stay on topic.

Doug

[ October 05, 2017, 12:36 AM: Message edited by: Douglas Meltzer ]

Posted by Mark Todd (Member # 96) on October 05, 2017, 03:28 AM:

Nicely done Doug.

I wonder if Edwin would be prepared to sell the small white/black rollers he makes for his fittings.

Be especially handy for 160, 180 and 600`s where you don`t want to spend a high amount of money but they also need these bits done.

https://shop.van-eck.net/PP-0098.html

Beswt Mark.

Posted by Graham Ritchie (Member # 559) on October 05, 2017, 03:33 AM:

Thanks Doug

I have edited mine as well.. tidied things up bit.

Jason that's a brilliant idea, I will have to do something similar and look through my junk box. I ran "Airplane" tonight and I am not to sure if its my imagination or poor hearing ![[Roll Eyes]](rolleyes.gif) but the projector seems to be running quieter. The film itself ran very smoothly through the rollers, with a nice rock steady image

but the projector seems to be running quieter. The film itself ran very smoothly through the rollers, with a nice rock steady image ![[Cool]](cool.gif) it looked good

it looked good ![[Smile]](smile.gif)

Posted by Bill Phelps (Member # 1431) on October 05, 2017, 03:38 AM:

Nice job Graham.......success!

Posted by Paul Browning (Member # 2715) on October 05, 2017, 03:55 AM:

I wonder what ceramic was used for the guides. I work with these materials every day, and if I had a choice it would be cubic zirconia. All need to be ground with diamond wheels, but are harder than most materials they would come in contact with. Alumina is used for the lamp base, but it must be in its green state, not fired. It is resistant to heat and a very good insulator, especially high voltage, and is very stable too.

Posted by Tom Photiou (Member # 130) on October 05, 2017, 06:22 AM:

I have been well informed that the little ceramic white guide very rarly wears if at all. Again, i bought one of these and so far have never used it,

It would be great if someone could re-manufacture all the white rollers and the rubber rollers on the 1200 series models including the old ST1200, GS1200 and the 1200HD with the extra lower rollers. ![[Wink]](wink.gif)

Posted by Mark Mander (Member # 340) on October 05, 2017, 07:25 AM:

Glad it all ran smoothly Graham,definitely going to check all my ST's and GS's and try some mods,Mark

Posted by Mathew James (Member # 4581) on October 05, 2017, 08:12 AM:

Doug, Thanx a Million!!!!

Graham, I wanted to post before just how wonderful this is. Great documentation and pics. Thanx for sharing with us Elmo fans!

Posted by Renzo Dal Bo (Member # 5688) on October 05, 2017, 11:35 AM:

Thank you all for usefull advice about GS1200.

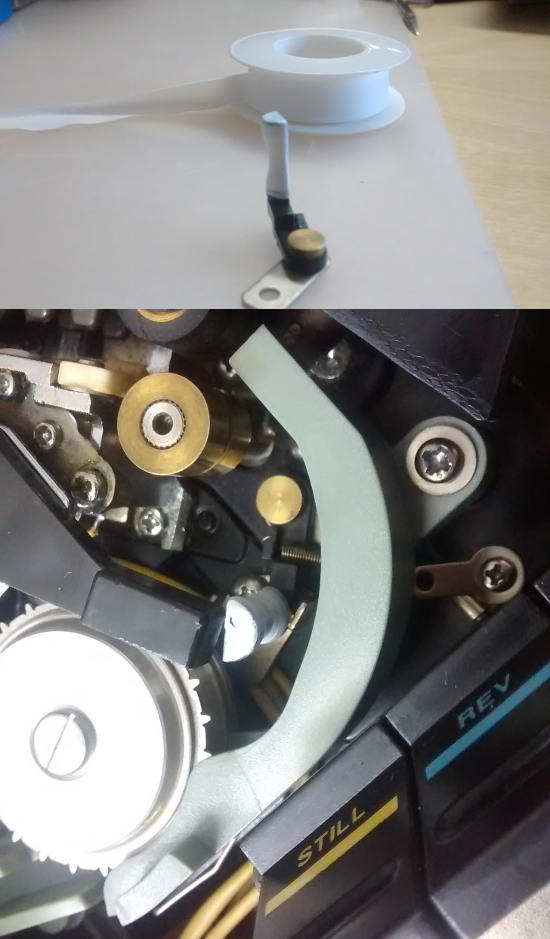

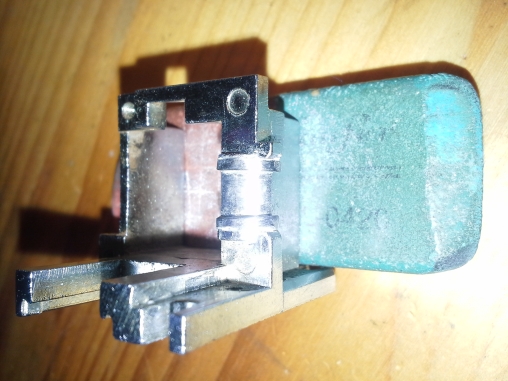

For those who haven't a ST1200HD to cannibalize the roller, as Jason suggests, I tried another quick way to solve the problem of the lower scratching tensioner on my GS, with good results.

I simply wrapped the tensioner with a teflon tape, a low friction material that easily adapts itself without bonding it.

Another advantage is its white color. When you see the black plastic appears again, it's time to substitute it.

Renzo

[ October 05, 2017, 04:45 PM: Message edited by: Renzo Dal Bo ]

Posted by Graham Ritchie (Member # 559) on October 05, 2017, 04:04 PM:

Another brilliant idea with the teflon Renzo ![[Cool]](cool.gif)

Thanks everyone ![[Smile]](smile.gif) what I enjoy reading is what other ideas people come up with, its that sharing and enjoying the hobby of film projection no matter what guage or projector you have

what I enjoy reading is what other ideas people come up with, its that sharing and enjoying the hobby of film projection no matter what guage or projector you have ![[Smile]](smile.gif)

Posted by Jason Smith (Member # 5055) on October 05, 2017, 08:58 PM:

quote:

I simply wrapped the tensioner with a teflon tape, a low friction material that easily adapts itself without bonding it.

I really like that idea. I heard of using aluminum adhesive tape to cover the parts that wear on the GS-1200 on another forum. I always wanted to try it out but was a little afraid to. I heard that the aluminum tape wears but at a slow rate. I would like to try your idea Renzo.

I have tried a lot of different solutions for that lower tensioner. As suggested on another forum, I reshaped the lower tensioner where it had worn with a soldering iron back to its original shape. After using my GS-1200 for a year and a half though, I noticed where the lower tensioner was starting to wear again.

I hear that Leon Norris also sells a lower tensioner roller mod for the GS-1200. That might be a solution for anyone who wants a more permanent solution.

Posted by Graham Ritchie (Member # 559) on October 08, 2017, 01:28 AM:

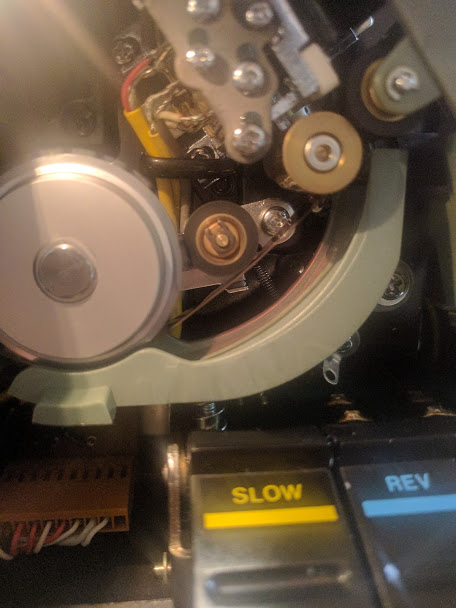

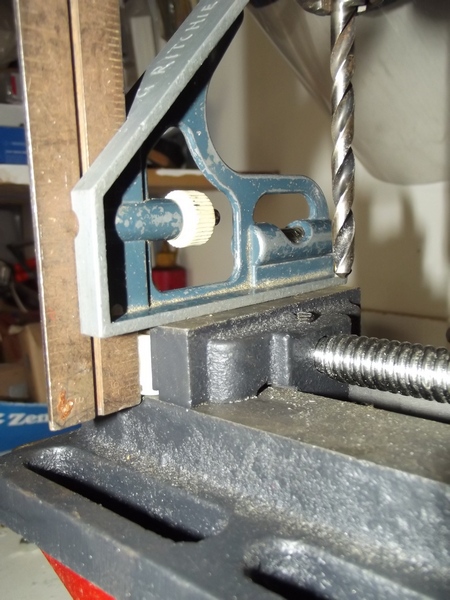

Well I made an effort to do something about that tensioner.

I think what Jason has done is the way I want to go, I do like the roller idea.

Anyway I had a look through my junk box, but could only find this old roller, that got me thinking, why not drill it out and slip it over the tensioner as its length is spot on. The problem came up against was fitting it, in that on start up for the first few seconds it was just touching the sprocket. In the end , not giving up and unable to move the tensioner to the right, I ground the white roller down, used a small amount of Arladite only the top surface of the black tensioner to the white roller, or what was left of it. Thinking that someday I want to get to the original black guide I was carefull with the Arlidite...just a we bit not to much.

Well its a temporary fix that should last for a while, until I can come up with Jason roller idea which is much better, however the tensioner worked well, kept position nice and steady..

After running my favorite film through a few times, I am happy...

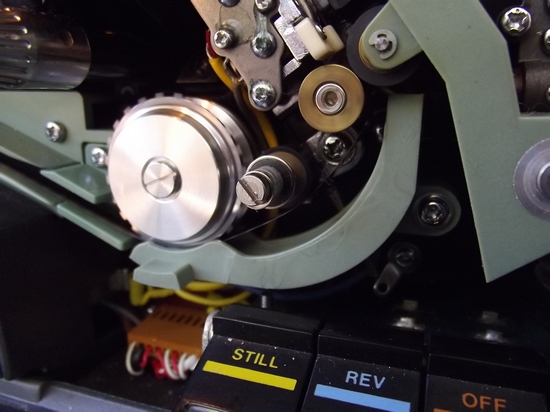

Posted by Graham Ritchie (Member # 559) on October 23, 2017, 10:50 PM:

Well I have been a busy little bee on this GS1200 ![[Roll Eyes]](rolleyes.gif) although what I did to the black tensioner worked fine, I still felt I could do better, so removed it and fitted a rotating rubber roller I found from an old ST1200.

although what I did to the black tensioner worked fine, I still felt I could do better, so removed it and fitted a rotating rubber roller I found from an old ST1200.

It took a while to change things over, but the end result and after a lot of testing.. threading.. stopping and starting it seems to work fine. After a couple of seconds on start up the roller finds its own position and stays in the one spot happily turning away. I think thats all the mods I need to do on this machine, better get back to watching films ![[Smile]](smile.gif)

I fitted shims to either side of the roller and altered them in or out just a we bit to get the roller in the right spot running on the film..

I could trim the lenght of shaft back, but its fine and does not get in the way of the projector side cover... I might just leave it ![[Smile]](smile.gif)

Posted by Thomas Knappstein (Member # 6134) on October 26, 2017, 11:20 AM:

Hello Graham!

Very Very good Work youve done on your GS. I had put in this second little Roller in the green Guide over the Sprocket over 25 Years ago when i started with collecting full feature Films in 1991. The Machine makes no Scratches on every Print in my Collection. The lover tensider Roller from an old ST 1200 HD I have in my Machines to. Interesting is the fixing of this worn out Sound head Part. I have repaired this Part for a machine with the backwards Loop. Next Time I will upload some Picture here. Do you have long Arms and Focus remute on your Machine?

Posted by Graham Ritchie (Member # 559) on October 26, 2017, 03:00 PM:

Thanks Thomas ![[Smile]](smile.gif)

I dont have long arms or focus remote, although years ago I did make a long play unit and large reels that clamped onto the GS handle that could easily take 2-3hrs of film non-stop.

Look forward to seeing your photos...your focus remote sounds very interesting. ![[Cool]](cool.gif)

Graham. ![[Smile]](smile.gif)

Posted by Steven J Kirk (Member # 1135) on October 26, 2017, 03:23 PM:

But surely if the 'kick-start' on the flywheel is set properly the film doesn't touch the lower tensioner but runs like a 3rd loop. You can only see this when the machine is running. Where the film is when stopped isn't an indication of if the tensioner is touching.

Posted by Paul Adsett (Member # 25) on October 26, 2017, 05:01 PM:

On both my GS1200'S the tensioner is pulled up by the film, so the film is always in contact with the tensioner during forward projection. The tensioner should be steady and not float up and down, which can produce WOW on these machines. It really is a complex film path compared with, say, Eumig's, and I sometimes wonder if that sprung tensioner was a 'fix' of some kind. I still don't understand how the GS'S set the 18 frames picture to sound separation during auto threading.

Posted by Thomas Knappstein (Member # 6134) on October 27, 2017, 11:54 AM:

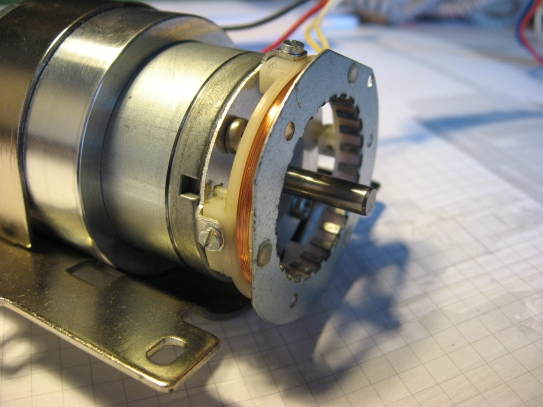

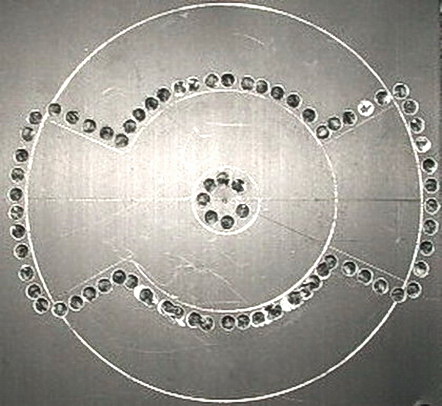

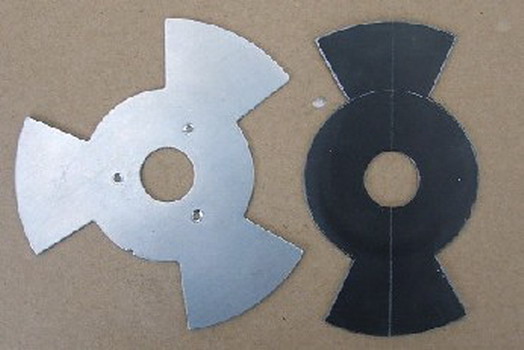

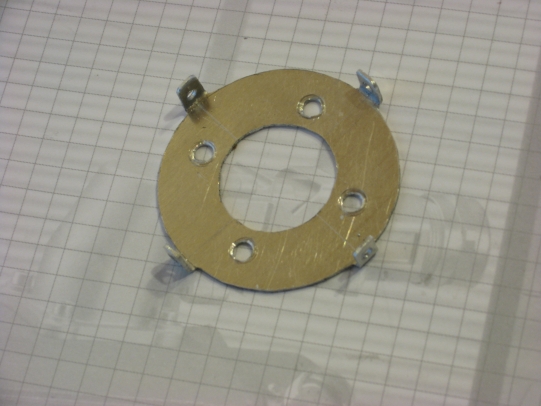

Here is one Picture of my focus remute Motor.

It is a Stepper Motor with a Worm Gear for präcise focusing.

And one pic from my Machine with 3200ft Reels on.

Posted by Thomas Knappstein (Member # 6134) on October 28, 2017, 12:29 AM:

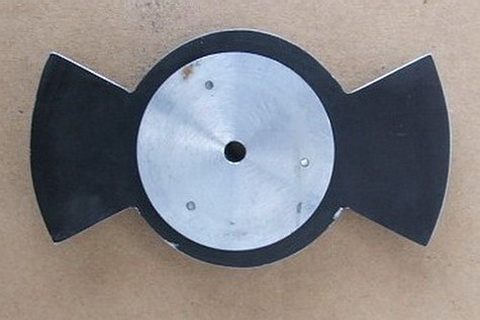

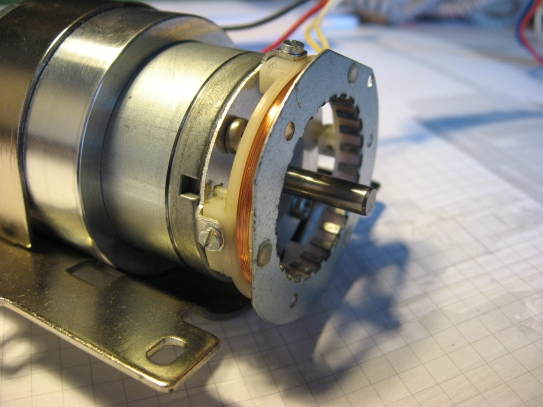

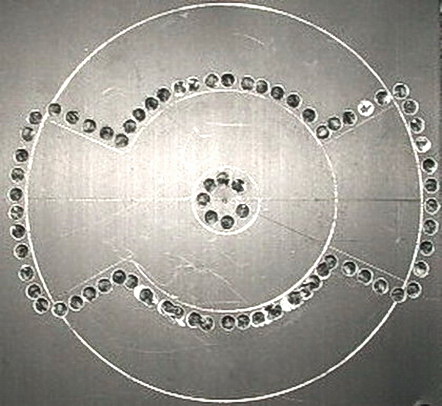

Here are some other Pictures from

repaired and modificated Parts of the GS1200

The last Picture shows an alternate Main Motor wich comes from Dunkermotoren. A Factory in Germany. The Speed control Tachometer I have changed by a wheel ith 24 Holes in and an optical IR Light Sensor.

Posted by Graham Ritchie (Member # 559) on October 28, 2017, 12:49 PM:

Thomas those are amazing mods you have done to the GS1200 ![[Cool]](cool.gif)

In particular the main motor...can you still vary the speed from 24fps to 18fps? ![[Smile]](smile.gif)

Posted by Thomas Knappstein (Member # 6134) on October 28, 2017, 12:58 PM:

Hi Graham!

Yes the Speed can be switched from 18 to 24 and variable.

But ll my GS have two blade shutters so there is flickering on 18 frames per second. My 18 frames own made films I played on a ST 1200. I have one Pic. from repairing the Calw Mechanic of a GS 1200 . There you can see the two blade shutter. Your little rollers on the upper Sprocket guide are very good. I dont have a machine to make those Parts.

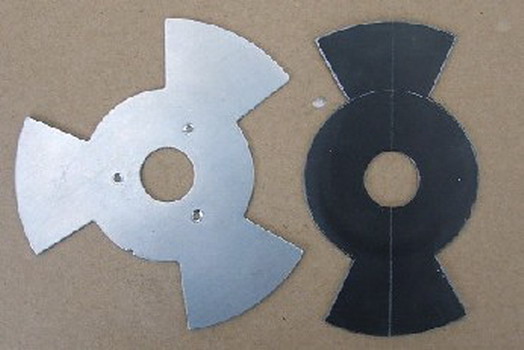

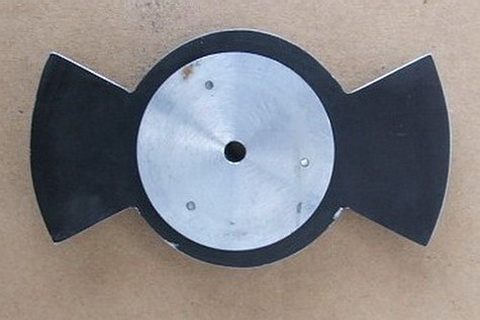

Posted by Graham Ritchie (Member # 559) on October 29, 2017, 03:08 AM:

Thanks Thomas ![[Smile]](smile.gif)

I also fitted a two blade shutter to this particular GS1200 and use other Elmo three bladed projectors for the 18fps. ![[Cool]](cool.gif)

I made my own two bladed from a old B/H 16mm a few years ago..

Posted by Thomas Knappstein (Member # 6134) on October 29, 2017, 05:23 AM:

Very nice work. Its much brighter with the two blade shutter and the Elmo 1:1,0 Zoom Lens.

What do you say about my focus remute?

Posted by Graham Ritchie (Member # 559) on October 29, 2017, 12:50 PM:

Your focus remote is really something ![[Cool]](cool.gif) does it clamp onto the focus knob? The great thing about your remote is that you can sit and watch the film without getting up to adjust things even slightly.

does it clamp onto the focus knob? The great thing about your remote is that you can sit and watch the film without getting up to adjust things even slightly.

Thomas you need to make a short video one day showing all this working ![[Cool]](cool.gif)

![[Smile]](smile.gif)

Posted by Janice Glesser (Member # 2758) on October 29, 2017, 02:15 PM:

Graham...very nice DIY two blade shutter ![[Smile]](smile.gif)

Posted by Phil Murat (Member # 5148) on October 30, 2017, 12:53 AM:

Hello Thomas,

Very interesting modification that you introduce for main motor.

Could you tell me more for alternate motor parameters (means : Maxi Voltage, I max, Power max, speed max.....as possible).

Also, Speed Control conversion (From Tacho to Infra Red) is the future when a motor fails now, as it is more and more difficult to find a small motor with "Tacho Generator" integrated.

(I have this improvement "on left" for my Beaulieu's machines)

Moreover, using a brushless motor should be a nice improvement too.

So, before former motor replacement done, did you record tacho frequency in the aim to determine holes pattern for Infra Red Disk ?

Is aleternate Motor used is brushless or not ?

Posted by Thomas Knappstein (Member # 6134) on October 30, 2017, 01:30 AM:

Hello Graham! I dont know how I can upload a video here.

Please check your private Messages on Facebook. Ihave send two Pics about my Projection Booth.

Hello Phil! The Infrared Tachometer you only need if there is no original Motor avalaible. If you have the old original Elmo Motor you can cut it of and take the original Tacho out. Than mount it on the new Dunker Motor. My English is not so good tho explain every Detail. So look at he folowing Pictures. I must take some Photos of the IR Version. The Wheel must have 24 Holes in it. And you must get 6V from the Pulse conector of the Elmo. And than Pulse Rec is out of Funktion. I take a look into the Service Manuel of the GS 1200. There you can read that this Tachometer gives 24 Pulses per Round. Also I drilled 24 Holes in my Disc and check the Waves on an Oszilloscope. They are nearly the same as the original Tacho gives out. With a few resistors you can manage this.

Posted by Phil Murat (Member # 5148) on October 30, 2017, 12:38 PM:

Hi Thomas,

Thanks for the pictures.

I found this for this Motor family :

ALTERNATE MOTOR

Moreover, It includes a front Ball Bearing, this is much better than original ELMO motor.

I assume Infra Red solution is also much better due to the "Square Signal" generated (instead of a classical waves generated by Tacho).

BEAULIEU"s Tacho Main motor generates around 800 Hz (24 fps Mode).

So, I assume a 15 Holes disk will work.

Infra Red modules I use are supposed to work under 5V.

Posted by Thomas Knappstein (Member # 6134) on October 30, 2017, 12:59 PM:

Hi Phil!

The Motor I use has Ball bearing on both sides. This Motor runs in all of my GS machines over 10 Years now without any Problem.

Posted by Paul Browning (Member # 2715) on October 30, 2017, 01:34 PM:

You are certainly a breath of fresh air Thomas, with your innovative ideas and add on's for the GS. I see you have the long play arms on your GS projectors, how are the motor holding up, or have you found an alternative motor for this too.....

Posted by Paul Adsett (Member # 25) on October 30, 2017, 08:01 PM:

That's a very ingenious focusing system that Thomas has come up with, but I wonder just how well it works, as the 'backlash' in the GS1200 focusing knob is pretty significant.

Posted by Thomas Knappstein (Member # 6134) on October 31, 2017, 01:45 AM:

Hi Paul!

You can turn the Focus remute Poti (special one) and the Motor gives it 1:1 on the Focus Knob on the Elmo. So you have the same feeling as you turn the Knob itself. I have one Poti nearly to the Screen. So I can turn the Sharpness very exactly.

Paul Browning!

The take up and rewinding Motors are still the original ones. They did a good Job over 25 Years now. Bu I dont rewind My Films on the GS. I have a seperate Motor Rewinder.

Posted by Paul Browning (Member # 2715) on October 31, 2017, 01:58 PM:

Fair comment Thomas, perhaps someone will find a new motor for the GS that can do both, the long play arms don't look out of place on the machine, and 25 years of use not bad, and a simple design that works, no complicated clutches and ratchets that no one understands.....

Posted by Burton Sundquist (Member # 5813) on August 24, 2019, 01:10 AM:

I have read the thread and realize that these mods are essential. Let's face it. The Top of the line Super 8 projector WILL scratch film. I previously blamed the Van eck guide. This was wrong. His roller did not cause a green emulsion scratch.

GS related issue I WILL deal with.

Posted by Leon Norris (Member # 3151) on August 24, 2019, 09:12 AM:

Just remember I have plenty of new green guides in stock! For the GS1200 projector! Always check those guides!

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Wink]](wink.gif)

![[Cool]](cool.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Wink]](wink.gif)

![[Wink]](wink.gif)

![[Cool]](cool.gif) very nice Paul. Also on disc two, David Locke discuss the GS1200 scratching, and what he did to fix things. Apart from those top sprocket guides, he also talks about the early GS1200 forward facing bottom loop. I do hope Keith and David dont mind me mentioning them, plus using a couple of screen shots from there wonderfull dvd to describe what David did.

very nice Paul. Also on disc two, David Locke discuss the GS1200 scratching, and what he did to fix things. Apart from those top sprocket guides, he also talks about the early GS1200 forward facing bottom loop. I do hope Keith and David dont mind me mentioning them, plus using a couple of screen shots from there wonderfull dvd to describe what David did.

![[Roll Eyes]](rolleyes.gif) but the projector seems to be running quieter. The film itself ran very smoothly through the rollers, with a nice rock steady image

but the projector seems to be running quieter. The film itself ran very smoothly through the rollers, with a nice rock steady image ![[Cool]](cool.gif) it looked good

it looked good ![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Cool]](cool.gif)

![[Smile]](smile.gif) what I enjoy reading is what other ideas people come up with, its that sharing and enjoying the hobby of film projection no matter what guage or projector you have

what I enjoy reading is what other ideas people come up with, its that sharing and enjoying the hobby of film projection no matter what guage or projector you have ![[Smile]](smile.gif)

![[Roll Eyes]](rolleyes.gif) although what I did to the black tensioner worked fine, I still felt I could do better, so removed it and fitted a rotating rubber roller I found from an old ST1200.

although what I did to the black tensioner worked fine, I still felt I could do better, so removed it and fitted a rotating rubber roller I found from an old ST1200. ![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Cool]](cool.gif)

![[Smile]](smile.gif)

![[Cool]](cool.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Cool]](cool.gif)

![[Cool]](cool.gif) does it clamp onto the focus knob? The great thing about your remote is that you can sit and watch the film without getting up to adjust things even slightly.

does it clamp onto the focus knob? The great thing about your remote is that you can sit and watch the film without getting up to adjust things even slightly.![[Cool]](cool.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)