This is topic Perplexing Problem in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=012161

Posted by Barry Fritz (Member # 1865) on March 16, 2018, 10:30 AM:

Projector is a Chinon DS 300. It feeds and runs fine in forward, but in reverse, it stops feeding. It seems as though the problem is in the reel arm because if I take the reel off the arm, it feeds the film fine. This indicates it is not a problem with the sprockets or elsewhere in the film path. However, with the reel of and in reverse, if I try to grasp the spindle to stop it, I cannot. This tells me there is plenty of torque there. The gears are operating as they should. A video of the issue can be viewed here: Reverse Problem

Posted by Steve Klare (Member # 12) on March 16, 2018, 10:44 AM:

Hi Barry,

It sounds to me like the clutch in the supply arm is locked up.

The clutches are there because the speed of the spindles has to change continuously as the diameter of the film piled on the reel changes but the inches per second of film through the gate stays constant.

I think what's happening to you is the film speed that the reel is demanding and the film speed that the sprockets in the film path are trying to set are different and this is causing the motor to stall.

The reason you are OK in forward projection is the supply spindle is freewheeling then.

I'm also pretty sure you should be able to grab an empty spindle and stall it while the motor keeps running: this is another sign something is stuck.

(Verstehst du?)

Posted by Barry Fritz (Member # 1865) on March 16, 2018, 10:56 AM:

Since we are talking about it in Reverse, do you mean the clutch on the rear arm? If that is the case, why does the film feed and the spindles turn when the reel is not on the spindle?

Posted by Steve Klare (Member # 12) on March 16, 2018, 10:59 AM:

In reverse, your rear spindle freewheels and the film tension on its own pulls the rear reel around. (In forward it is powered.)

Since you can't push on a string, in reverse projection and rewind the front spindle has to be powered to pull the film onto the supply reel, so then the front clutch is active.

I think what's happening to you is something like this:

In rear projection, your machine is shooting film out the front at 4 Inches per second. At the rate the front reel can turn, the film would go on the reel at let's say 8 inches per second. If the clutch was OK it would slip and allow for this difference.

-but it's locked, so the film is very tight going onto the supply reel and that's stalling the reel and the motor that's now hard-geared to it.

When you take the reel off the spindle, it is free to turn, so the motor un-stalls.

Now, you should be able to rewind just fine. What's the difference?

-There is no film inside the film path, so no speed conflict and binding.

Try this: Without film put it in reverse and (briefly) grab the front spindle (put an empty reel on for emphasis if you need it).

If the clutch is OK you should be able to stop the spindle while motor stays turning.

If the clutch is locked, the motor will stall (do this for as short a time as you can: it's not good for the machine!)

Posted by Mathew James (Member # 4581) on March 16, 2018, 12:10 PM:

Hi Barry,

I agree with Steve here. I have had a similar issue with clutches on the elmo and if the chinon is made similar, then this was also my thought. My clutches are made of cork. It will be interesting to see what the chinon clutches are like.

Posted by Barry Fritz (Member # 1865) on March 16, 2018, 04:01 PM:

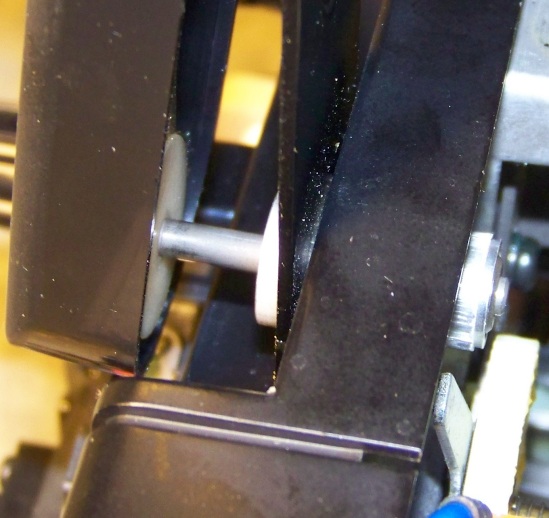

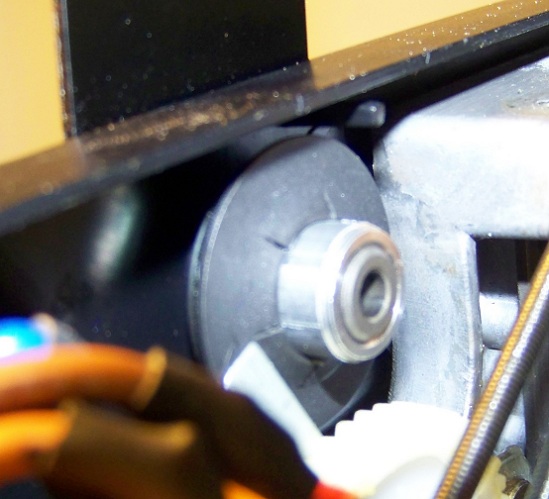

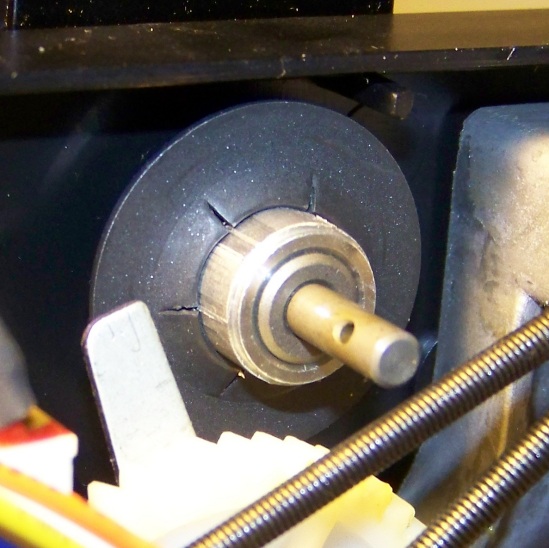

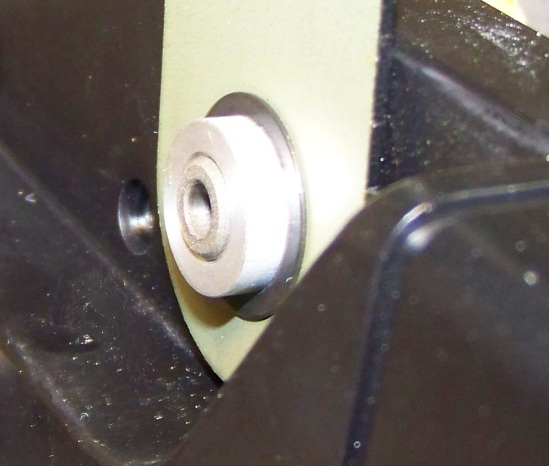

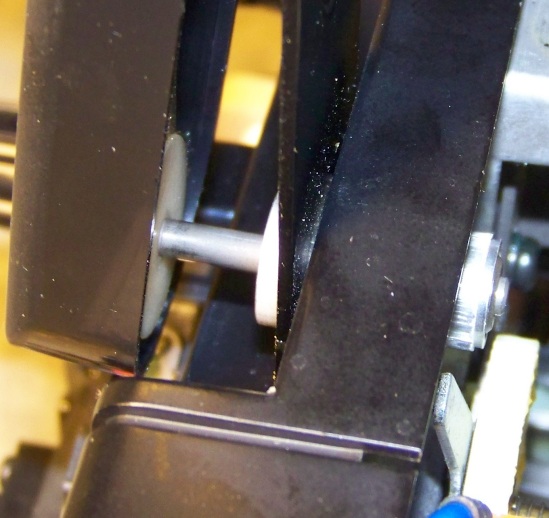

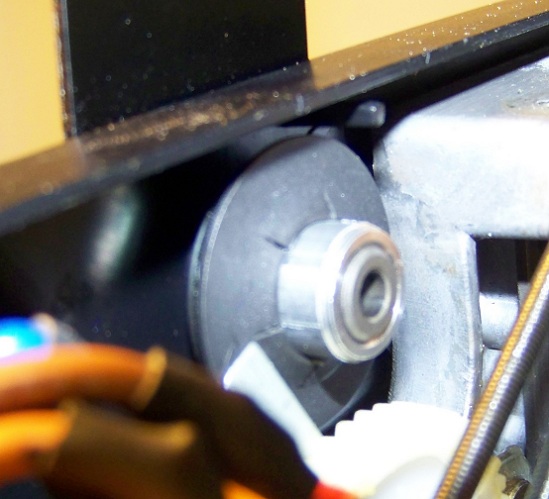

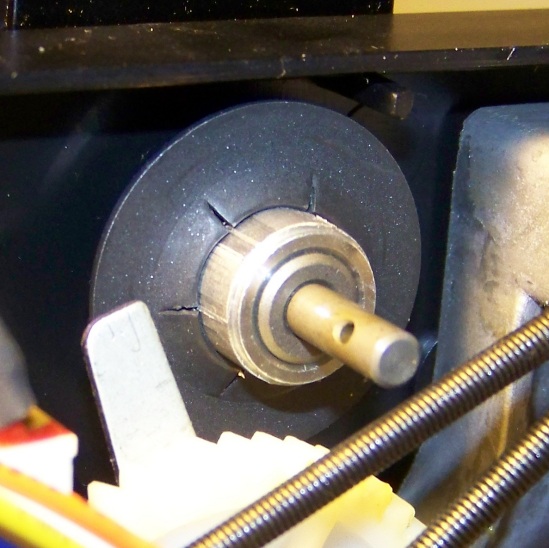

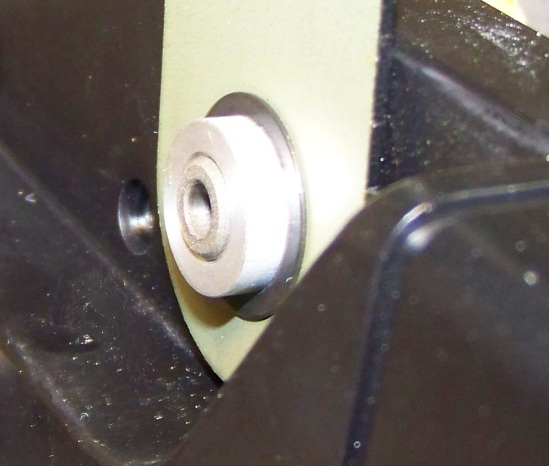

I removed the gear from the shaft of the the reel arm and disassembled it. I do not see a clutch mechanism here.

the pulley and shaft go through the center of the object that holds the reel arm onto the body of the projector. It is held in place by a large push washer. On the rear reel shaft, there is what appears to be a friction pad pressing against the pulley by a spring. If I grab the front spindle tightly while it is spinning, I can stop it. This stops all the gears that move the sprockets and the pulley to the motor. The motor does not stop, the rubber drive belt just slips.

While I had the reel arm apart, I noticed that the pulleys and the metal spring belt were covered in grease. I cleaned them up before reassembly. Could it be that they were supposed to be greased so that they would slip and act sort of like a clutch? Seems pretty lame to me.

[ March 16, 2018, 05:56 PM: Message edited by: Barry Fritz ]

Posted by Steve Klare (Member # 12) on March 16, 2018, 07:06 PM:

I'd think there would have to be some real clutch mechanism on the front like you found on the back. For the reasons we covered before, it's an essential.

It's something that needs to be fine tune-able as well: enough friction to rewind a full reel at high speed without stalling, yet enough slippage to wind film projected backwards gently.

This is starting to sound like a job for Doctor Janice!

I'm not too sure I've even been in the same room as a Chinon projector, let alone take one apart!

Posted by Barry Fritz (Member # 1865) on March 16, 2018, 07:45 PM:

I'd think so also. I have had a number of different Super 8 projectors and I believe all of them had some sort of clutch there. Usually a pad of some material that had a spring against it for pressure adjustment.

I have the User Manual for this but sure would like to get a Service Manual.

Posted by Douglas Warren (Member # 1047) on March 17, 2018, 01:40 AM:

Barry:

PM sent regarding the service manual.

Douglas

Posted by Janice Glesser (Member # 2758) on March 17, 2018, 01:51 AM:

Hi Barry...Steve asked me to jump in with this problem. However I'm not sure there is much I can suggest. I have a Chinon SP330MV which from the front looks almost identical to your DS300...but the gears and pulleys are setup very differently.

Just an observation... In watching your video I noticed when you removed the reel the gear moved slightly as if releasing. There is a lever that moves up to the upper gear when you put it in reverse. Is that lever pushing up against the back of the gear and jamming it. I replaced the belt in my arm...It's possible that the belt is jamming the lower pulley when you push on the reel...but then releases when you pull the reel off. See if replacing the belt helps.

I'm guessing the problem lies in that region of the supply arm. There's lots of plastic in the arm assembly and parts get easily cracked which can cause things to get misaligned. The supply arm on mine won't stay up on its own due to a broken component where the bottom pulley attaches to the inside gear assembly. Trying to find that part would be near impossible...so I use a strip of Velcro to hold the arm in place and other than that the projector runs great.

Just keep looking....you'll solve the mystery ![[Smile]](smile.gif)

Posted by Barry Fritz (Member # 1865) on March 17, 2018, 09:20 AM:

Doug: I have not received your PM.

Janice: That lever does not interfere with anything, and I do not see anything that is cracked or damaged anywhere.

Posted by frank arnstein (Member # 330) on March 18, 2018, 11:57 PM:

Barry wrote....

"I noticed that the pulleys and the metal spring belt were covered in grease. I cleaned them up before reassembly. Could it be that they were supposed to be greased so that they would slip and act sort of like a clutch?"

I believe the answer to that question is "Yes".

Not all Chinon models are built exactly the same mechanically but they all seem to use a lot of steel wire belts.

The grease is put there to allow the spring steel belts to slip when required. Both wire arm belts and the forward drive wire belt need to be able to stretch a bit and then slip using the grease.

This weird Chinon technique prevents things from locking up in certain operations without the use of expensive and complex clutches.

So lube up the wire belts then try again Barry and let us know.

Dogtor Frankarnstein

![[Smile]](smile.gif)

![[Wink]](wink.gif)

Posted by Barry Fritz (Member # 1865) on March 19, 2018, 11:34 AM:

Hi Frank: Glad to hear from you again. I cleaned the lube off, so I will go down to the shop and relube and try again. I did notice that the other longer spring belt that runs back to the rear take-up pulley is greased also. That is a weird set-up. I will let you know if it works.

UPDATE!! SUCCESS!! I Super Lubed the pulleys and the spring belt inside the reel arm and ran some film. On Reverse, it worked perfectly! Thanks Dogtor Frank and others who responded and to Doug.

Posted by Mathew James (Member # 4581) on March 19, 2018, 01:52 PM:

Great to hear it is working Barry!

Also happy to see the dogtor around... has helped me fix some tough ones...

Posted by Steve Klare (Member # 12) on March 19, 2018, 02:31 PM:

This is one for the books!

It goes to show how creative the people that designed these machines really were: they found a way of squeezing the action of a clutch out of a drive belt!

It's as if they dispensed with the clutch in a car by very skillfully greasing the tires on the drive wheels!

Posted by Douglas Warren (Member # 1047) on March 19, 2018, 03:13 PM:

That's great news Barry! Very pleased to hear it's working now.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif)