This is topic Elmo GS 1200 lower tensioner in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=012354

Posted by Steven J Kirk (Member # 1135) on June 15, 2018, 05:19 PM:

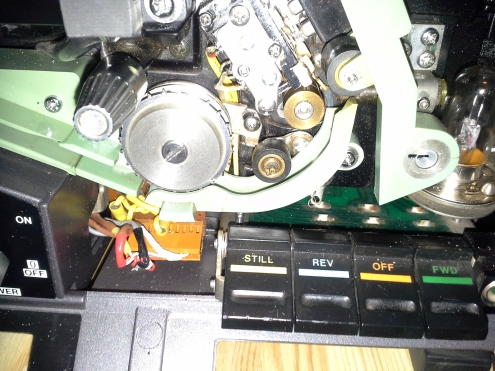

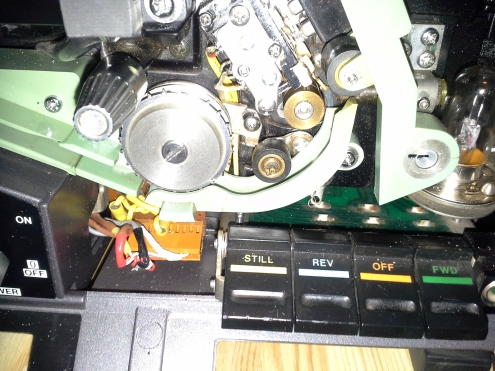

So both my machines now run with the film hard against the lower tensioner creating a fear of scratching although otherwise they are fine and project well. But they didn't do this in the past. The GS surely should run with a 'third loop' and the film not touch the dreaded lower tensioner. I believed a factor in this happening was the idler wheel on the flywheel in the back of the machine but I have now spent the evening cleaning the flywheel and idler on both machines with alcohol and even adjusted the position of the mounting on one - because the idler mounting is clearly designed so that you can change the position of the idler wheel against the flywheel - to no effect.

One thing I do wonder about is that the 'idler on' position clearly turns the flywheel slower than when the idler is 'off' and the flywheel is 'driven' by the film between the capstan and roller in the film path. Is this right? Should the idler be driving the flywheel faster and is there some slippage I am missing... Anyone who has tackled this is welcome to respond.

Posted by Chip Gelmini (Member # 44) on June 15, 2018, 08:37 PM:

Is this with magnetic or optical sound? There are two different ways to adjust tension depending on the format of the film. You should test this to make sure if you have not done so already. I believe tension has something to do with it unless of course the idle roller in the gear box has gone soft.

I do not have this issue keep in mind this is guess work trying to help you.

Posted by Bill Brandenstein (Member # 892) on June 16, 2018, 01:03 PM:

Chip, with your recently serviced machines, do you see slack around the tensioner with normal mag-track films?

I'm seeing the same as Steven. If I'm understanding this correctly, then something wears out, the tensioner becomes worn, and then the tensioner begins scratching film.

Can anyone post a photo of what the normal "third loop" should look like?

Posted by Chip Gelmini (Member # 44) on June 16, 2018, 05:22 PM:

Wouldn’t loose or bad tension produce “wow & flutter?” Or a pitch in the sound that varies.

My machines are good.

Posted by Graham Ritchie (Member # 559) on June 16, 2018, 06:02 PM:

There is only two loops on the GS1200 top/bottom of the gate. The black tensioner is in constant contact with the film, or should be all the time to smooth things out.

Over the years that contact will wear and scratches can occur. What you can do is carefully remove it and file the wear marks out, so only the edge of the film is in contact.

Other than that you could modify it with a roller, as described in previous posts regarding the GS1200 scratching films.

Posted by Bill Brandenstein (Member # 892) on June 16, 2018, 06:38 PM:

OK, so that means Steven's question is incorrect (sorry, friend) and my original fears and understanding of eventual replacement/modification are valid.

Interesting, because the feed inlet on the machine I'm using is ready for replacement but the tensioner has some life left to it.

Posted by Chip Gelmini (Member # 44) on June 16, 2018, 07:07 PM:

One other thought is which version of the GS is it forward bottom loop or backwards bottom loop the design change could make a difference?

Posted by Steven J Kirk (Member # 1135) on June 16, 2018, 10:16 PM:

I may well be wrong, quite possibly. In reverse projection there definitely is a 'third loop' however. Also I am sure that my xenon machine worked that way originally and the film was not in permanent contact with the tensioner. I have worked on the rubber tire on the idler and roughed up the flywheel in the area where they meet. This has improved the grip of the wheel but has not changed where the film sits in the path. To my mind the loop under the gate is also too big as if the film was perhaps only two frames less on that side of the capstan and two more on the other that would make a 'third loop' and a smaller 2nd loop that would not be in danger of touching the recessed threading guide... any suggestions welcome and don't worry about saying I am wrong, no offence taken.

Both machines are the later type with backwards formed 2nd loop and one is the xenon version.

Posted by Thomas Knappstein (Member # 6134) on June 17, 2018, 03:00 AM:

Hello!

Change the lower Tensioner to the Tensioner Wheel of the late ST 1200 Machine with the two Tensioner Wheels. Then you never have any Problems ith this.

Posted by Joe Taffis (Member # 4) on June 17, 2018, 10:37 AM:

My view is that as long as the rounded bottom of the plastic tensioner is smooth, it won't scratch the film. Anyway that's what I've been told concerning the GS1200, so I check it often...

The thing that concerns me about replacing it with the rubber roller, is the sound problem it caused that I believe Paul Adsett wrote about in a previous post. Is that no longer a concern?

Posted by Chip Gelmini (Member # 44) on June 17, 2018, 10:43 AM:

When the film is going through the sound head remember it is the soundtrack side rubbing against the tension idler not the emulsion side So even though the film can still get scratched the color layers are safe unless they rub against the other green part directly above the reverse/still buttons.

Posted by Graham Ritchie (Member # 559) on June 17, 2018, 02:19 PM:

Steven

When you put the projector into reverse you will loose your bottom loop, as its the claw which is pulling the film up over the soundheads, although the bottom sprocket is feeding the film into those bottom guides, the film is still being subjected to quite a bit of strain due to loosing that bottom loop just below the gate. I would only use reverse, if the leader fails to get things right when threading, other than that I would avoid using reverse.

Because of the friction of the stripe rubbing along that black tensioner, it will wear away in time causing flats, which can scratch your film.

Regarding sound I have not had any problems after fitting a DIY roller, it runs fine. ![[Smile]](smile.gif)

Posted by Paul Adsett (Member # 25) on June 18, 2018, 07:25 PM:

If everything is working as it should, the film should always be in contact with the lower black tensioner, the tensioner should be pulled about half way up from the totally free position and the maximum pull up position, and the tensioner position should be stable.

If the tensioner oscillates up and down during projection, it is an indication of film slippage at the capstan/pinch roller and/or uneven take up reel torque. Film slippage may be a result of over lubrication of the film and/or too low a pinch roller pressure. Both of these conditions can cause WOW on the sound track.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Smile]](smile.gif)