This is topic REVIEW: Van Eck Eumig 900 Series Wormwheel in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=012839

Posted by Paul Adsett (Member # 25) on March 11, 2019, 11:11 AM:

My Eumig 938 has been making more noise than usual of late, and I suspect that the main plastic wormwheel on the drive shaft may be the culprit. I have a similar situation on my old 926G Stereo, which really makes a racket. So I decided to purchase one of Edwin Van Eck's replacement worm wheel's manufactured by the additive 3D printing process. I decided to do a 'trial run' on the 926GL before attempting the illustrious 938.

I ordered the part from Edwin in late December, but by the end of February it had not arrived. I emailed Edwin and they immediately sent another part via Deutche post, which arrived within 10 days.

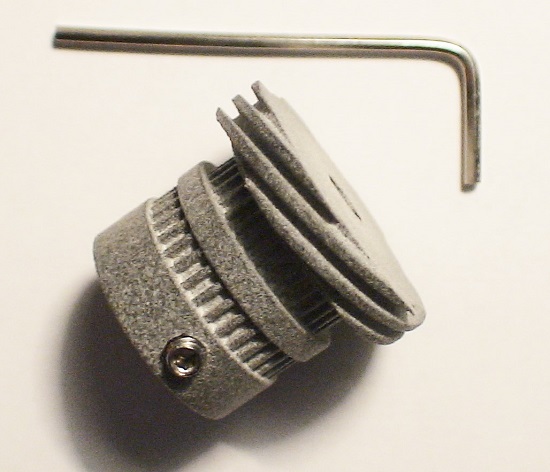

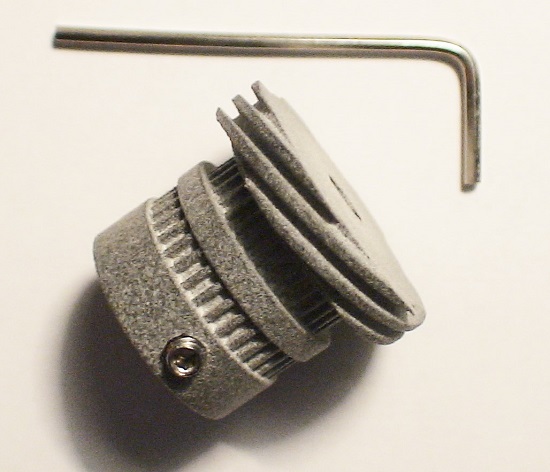

So here is the kit as received, which includes the 3D printed worm gear and the hex socket wrench for the set screws on the part.

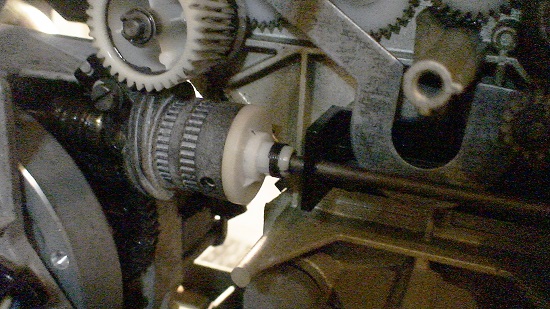

A close look reveals the surface finish of the part which, like all 3D printed parts, cannot attain the smooth polished surface finish of injection molded plastic parts. The part seems to have some filling fibers in the printing material, no doubt for additional structural strength.

Inherent in Eumig's original design of this worm gear is the very thin feathered section of the gear thread at the transition points to the outer faces of the hub. In fact some of the thread actually broke away when I pushed on it. This is not a show stopper, all I had to do was file off a bit of the threads and round it off to eliminate the extremely thin cross section at the hub interface. Maybe Edwin can modify his CAD model to eliminate this issue on any future parts. Lets face it, this is another example of Eumig's poor engineering of plastic parts which are usually way too thin in cross section, and are designed more like metal components.

For the replacement operation I followed Edwin's excellent YouTube video:

https://www.youtube.com/watch?v=8HGUY2mnSRA

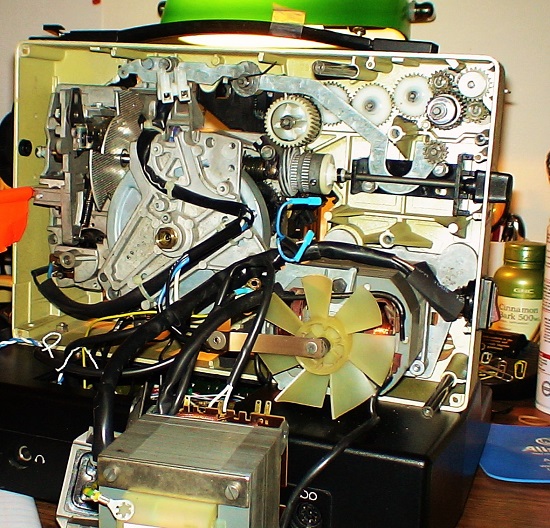

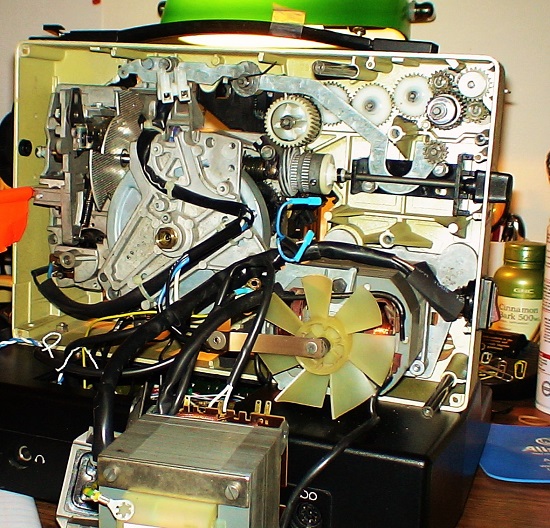

I found this video invaluable, although I did not find it necessary to remove the flywheel housing and the flywheel, so the exact procedure might be slightly different between the various 900 series projectors. In order to remove the worm gear it is first necessary to remove the transformer, the idler pulley system, and the spring loaded inching knob:

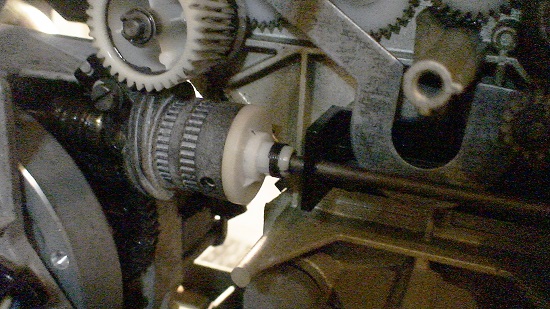

Here is the condition of the original worm gear as removed from the 926.As you can see it has pretty well disintegrated:

Here is the new worm gear installed into the 926GL:

Everything went well until I somehow managed to snap the drive belt when reinstalling it so I will have to get a replacement before I know how quiet the machine now is, although looking at the condition of the original wormwheel I think the new part will work well. Right now, turning the shaft by hand is smooth and quiet.

Let me conclude by thanking Edwin for making this, and many other parts, available for restoring our beloved projectors.

Posted by Leon Norris (Member # 3151) on March 11, 2019, 01:05 PM:

Paul, that part does go! I have one in stock! From van Eck! I repaired two 900 series Eumigs! That was a good move from van eck! I had the machine fixed in minutes!

Posted by Martin Dew (Member # 5748) on March 11, 2019, 02:00 PM:

Great post, Paul, thanks. Just took two 938s to Mr White today, mainly because they sounded a little noisy. Hope they don't have worm issues, but I'm sure John will find the source quickly.

Posted by Janice Glesser (Member # 2758) on March 11, 2019, 02:28 PM:

Thank you Paul for a great post. We can never have enough "How-to" threads. I don't have one of these projectors...but owners will definitely benefit from your experience and the information you have shared.

Posted by Jim Schrader (Member # 9) on March 11, 2019, 07:03 PM:

Now if the 16mm b&h’s were this easy

Posted by Edwin van Eck (Member # 4690) on March 12, 2019, 01:48 AM:

Hi,

Good to hear our efforts to supply new parts to keep slide and film projectors up and running as long as possible are well appreciated!

Quote from the original post:

"Inherent in Eumig's original design of this worm gear is the very thin feathered section of the gear thread at the transition points to the outer faces of the hub. In fact some of the thread actually broke away when I pushed on it. This is not a show stopper, all I had to do was file off a bit of the threads and round it off to eliminate the extremely thin cross section at the hub interface. Maybe Edwin can modify his CAD model to eliminate this issue on any future parts. Lets face it, this is another example of Eumig's poor engineering of plastic parts which are usually way too thin in cross section, and are designed more like metal components."

I will ask the CAD drawer for this model to update the design.

Also if you encounter parts which frequently break down, please check out our spare part finder: https://van-eck.net/itable.php?lang=en&size=0&cat=all&merk=none&type=none

If you can't find the part you are looking for, please let us know.

Greetings from the Netherlands,

Edwin van Eck

Van Eck Video Services

Posted by Paul Adsett (Member # 25) on March 28, 2019, 12:44 PM:

Yesterday I received a new drive belt for my Eumig 926GL Stereo from Van Eck, so I was able to install it and finally able to test out the now replaced Van Eck wormwheel. I am pleased to report that the 3D printed wormwheel works just fine and the projector is now fully functional and projecting a rock steady picture, While I had the machine apart I also replaced the sound head with another one with less head wear. And I replaced the lamp socket and also added a tension spring to the auto threader lower guide. The machine now performs great, with belting sound.

I must say it is very satisfying to re-furb a projector back to full working order.

Posted by Leon Norris (Member # 3151) on March 28, 2019, 03:59 PM:

Paul, your becoming a real pro! It pays to learn and know your machine!

Posted by Paul Adsett (Member # 25) on March 28, 2019, 06:22 PM:

Thanks Leon! This particular Eumig was a clunker parts machine until I was able to get the necessary replacement parts from Edwin Van Eck. It is now a projector that can come to life again! ![[Smile]](smile.gif)

The Eumig 926GL is a great performing stereo machine with rock steady picture and superb quality sound, but the coaxial reels are a real pain, so it will never be a favored projector for me. The main problem with the 900 series Eumigs (not the 800's) is the really flimsy design of many of its plastic parts, many of which should have been metal That wormwheel should never have been plastic to start with, it should have been brass.

I now have both my GS1200'S performing well, and I really love the robust build quality and modular layout of the GS. I know many people have commented to the effect that the GS is the Ferrari of super 8 projectors, and they are right. I also love my Eumig S938 Stereo, but I have to limit its useage because the heads wear out fast. No such concern with the GS heads, they seem to last forever.

Posted by Leon Norris (Member # 3151) on March 29, 2019, 10:17 AM:

Your right Paul, the sound heads in the GS1200 do last a long time! I hardly replaced these heads! And remember the same head fits the ST1200 HD Models also! If you keep this up I will be sending you some repair work ? Enjoy!

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Smile]](smile.gif)