|

Author

|

Topic: BEAULIEU 708 EL ST .........back to life

|

Phil Murat

Jedi Master Film Handler

Posts: 671

From: Villeneuve St Georges, France

Registered: Dec 2015

|

posted January 30, 2016 04:22 PM

posted January 30, 2016 04:22 PM

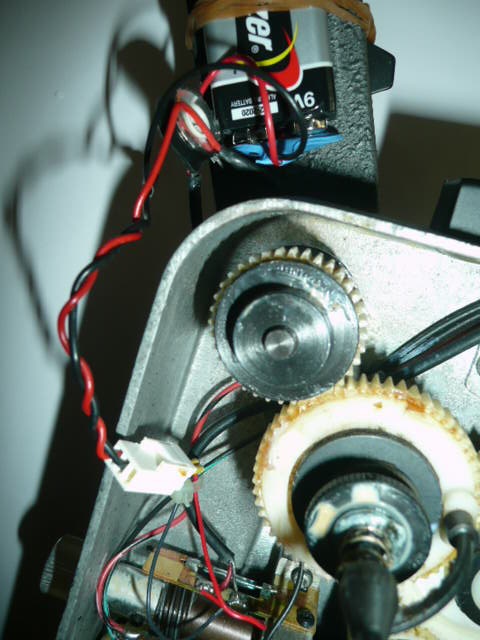

I had a very hard time when I woke a 708 EL SEREO which was sleeping for many years and suffered improper storage.

At first power up, the machine was making low frequency noises and once loaded no sound was available . Moreover, the red LED was steady light on, as it is supposed to do during recording something.

Upon Andrew advices, I warm the big transformer with a “Hair Gun” and the 50hz noise disepears.

That was a very good point.

Considering the main failure (No sound) it was important to find the source as to repair as well.

I am not an electronic specialist at all and my knowledges are very limited.

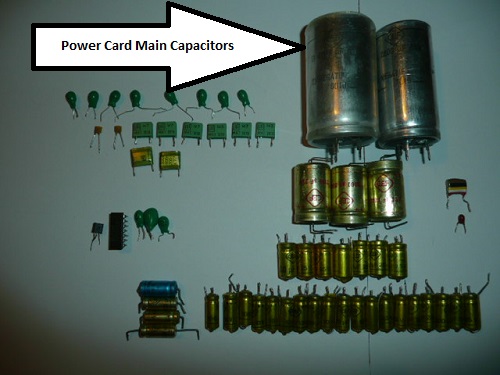

So , through different exchanges with some friends, I decided to renew ALL Electrolytic Capacitors first.....

These capacitors are "Time Limited" and lost performances beyond 10 years. Also Power Capacitors failure is not a rare phenomenon for 708 projector family.

The power capacitors are very important as they filter (Soften) the current deliverered to the machine.

Here are the capacitors and other components replaced :

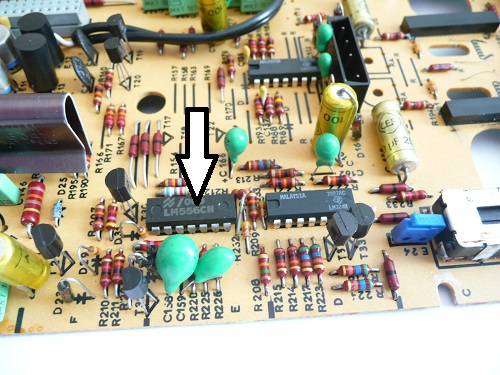

LM556N is a dual timer which is supposed to Control the Recording Functions. There is a high probability it suffered from Voltage peaks and once shorted, blocked sound entering Preamp.

A new LM556N has been fitted on a DIL support and surrounding capicitors replaced too.

You can observe that many “Tentalum” small capacitors ("Green Drops") where installed by Beaulieu:

Right now , it's not justify anymore, as improve technology offer equivalent Electrolytic capacitors just cheaper…

Here is the LM556N before replacement:

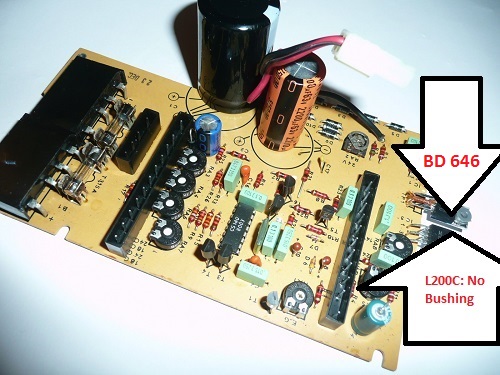

Concerning the Power Card :

- If the Claw Motor run "Full Speed" and/or associated fuse fails out , that means that TP1 (BD646) is shorted. You can replace it by BD648 or BD650, NOT easy to find and offering more performance.

- TP1 has to be perfectly insulated from case (Bushing + Micas shim), otherwise it deads immediately.

- IC1 and IC3 have both to be grounded to the case (NO BUSHINGS!!), otherwise you experience unwanted funny "low noises" in Preamp, overlapping the signal comming from heads.

- During operation, put a finger on the TP1 / IC1 / IC3 shell : if you feel heat above 30 °c , check component installation again….

It is very important to renew Thermal Grease compound for TP1 / IC1 / IC3 / STK441 (Power Amplifier Module) as it dries many years after.

Avoid at any cost Thermal Silicons which dry like a glue. They are less performant and complicate futur disssemblies.

Here is a spare STK441:

Now the machine is running pretty good, offering a very good sound, efficient and dynamic. Motors regulation works properly, no stalls observed.....

Champagne!!!!

[ February 23, 2016, 12:29 PM: Message edited by: Phil Murat ]

| IP: Logged

|

|

|

|

|

|

|

|

Phil Murat

Jedi Master Film Handler

Posts: 671

From: Villeneuve St Georges, France

Registered: Dec 2015

|

posted January 31, 2016 02:49 AM

posted January 31, 2016 02:49 AM

High Alan, Paul, Andrew

Thanks for encouraging message!!

I spent many time also at phone with friend(s) crossing the different ideas..

I download from the Web many Datasheets, trying to understand how Beaulieu used this components.

3 days Job, 1 month for research....

Then , I learned a lot at the end , and this is very positive too.

Many "Beads of sweat" were necessary to do that. The more difficult was to work with a magnifying glass (x3 is good) and paying attention to the tinies PCB copper tracks.....

To do that I used :

- A small Soldering Iron (Pencil Tip), 20W

- A desoldering Pump and Copper mesh for small soldered points.

- A good quality stain with cleaning flux included

- Multimeter

(Observe also, that , if necessary you could use a computer as oscilloscope through the Sound Card and a special soft.

I have not experienced this as it was not necessary to analyse signals in my case.)

In an other way , it is quite difficult to find a serious professional technician to do it, and then he probably charges me a lot!!

Through this post, my idea is to bring all tools as necessary to motivate owners who love their machine to do it themselves even they were never been educated to this specialty.

An other point is that some components are no longer supplied.

some of them are not offering equivalent:

- TDK441 (Power Stereo Amplifier) : No Equivalent, can be find in sleeping stock, approx 20 Euros.

- LM556N : Common (Texas Instrument), Available anywhere, Approx 6 Euros

- TAA761A & TAA2761A : Siemens Audio Component, not easy to find, unfortunately price fluctuate from 3,5 E to 12 Euros.

Equivalent TAA765A & TAA2765A is much better (Higher T° strengh)

- TDA4290 : Audio component for Tone , Trebble, Volume Control.

No Equivalent found , price fluctuating from 4,5 Euros and...?

Concerning Capacitors again, I think to sistematically renew them on Power Supply Card is the minimum required , even your machine seems to operate properly, as the other components (Stereo & Regulation) like to take a good quality current.

This is cheap money , involving one / two hours manhours for the job, 100% benefit at the end !!

I encourage projectors owners to do it.....without thinking twice, do not wait they fail Shorted (This is the worse situation)

CAPACITORS:

Concerning the Capacitors range and value , never take a Voltage limit below the indications. Higher is not a problem, just the component size is increasing.

Concerning the Capicity itself , stay closed to the value, never below. For a Power Supply, a too much higher value could stress Diodes associated.

Different Classes are available:

Standard is +/- 20%

Some of them installed on the Sound Card comes under Class "J" which means +/- 5% . They are making the references for TDA4290 for exemple.

Tighter is the Class, higher is the price.....

Phil

*****************************************************************

Andrew , just reading your message:

Yes I took up some fungus back to the front Lens.Fortunately Front Lens is easy to remove. Just to unscrew front ring.

There are probabilities that Transformer "Low noise" come back , one day or an other. If necessary I remove transformer and dry it out under "reasonnable Temp" in an Oven.

Taking out Transformer needs the Sound Card to be removed once more.....

Andrew, I think there is a problem in the Beaulieu Repair Manuals available from different sources.

The Last "Regulation Card" generation do not appear and it can lead to confusion with former one.

Tell me what you can find from your side

[ January 31, 2016, 06:27 AM: Message edited by: Phil Murat ]

| IP: Logged

|

|

|

|

|

|

|

|

Phil Murat

Jedi Master Film Handler

Posts: 671

From: Villeneuve St Georges, France

Registered: Dec 2015

|

posted February 23, 2016 12:57 PM

posted February 23, 2016 12:57 PM

Hello,

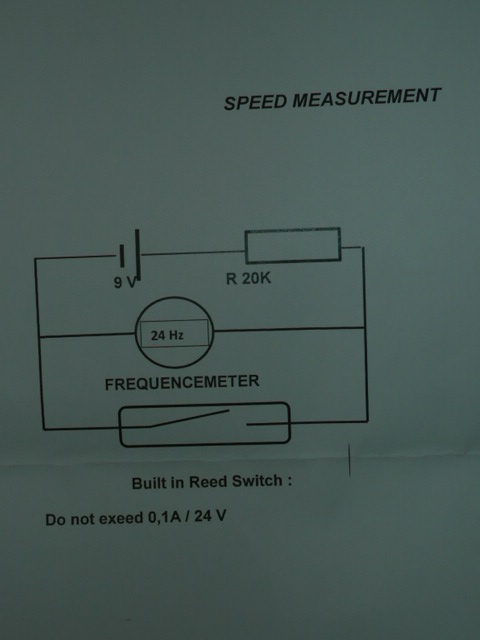

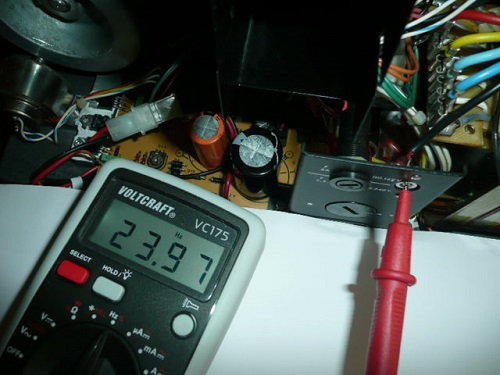

Here is a method to Check Projector Speed during Speed adjustment procedure:

- To allow an acurate post synchro.

- To allow an easy Video Transfer

- To have an idea of Components Health

A) The Principe:

B) An Exemple of Installation :

C) The Result !!!

(Only Positive Probe is plugged, Not Negative Plugging,....... to avoid Signal polution by the Transformer proximity):

N.B :

I had to abandon TIP42C and to return to BD646 installation as it was impossible to get full power with this component.

As it is difficult to find BD646 (BD648 OR 650) , I assume that BDW94B or BDX54CG are possible Equivalents (But there is no warantie for the result, I mean , reaching full power and confortable speed adjustment margin.)

Right Now,in Original configuration, the speed can be adjusted from 22 to 28 fps and without any loss of speed during friction adjustment.

The Multimeter Frequencemeter is just 40 Euros........

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UBBFriend: Email this page to someone!

UBBFriend: Email this page to someone!

Printer-friendly view of this topic

Printer-friendly view of this topic

UBBFriend: Email this page to someone!

UBBFriend: Email this page to someone!

Printer-friendly view of this topic

Printer-friendly view of this topic