This is topic The Eumig 'inactivity problem' in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=013150

Posted by Adrian Winchester (Member # 248) on October 21, 2019, 02:50 PM:

I've heard it said more than once that Eumigs - and this might particularly apply to 800 series projectors and earlier - benefit from being used on a reasonably regular basis. I'm inclined to think there must be some basis to this, as one I've only used for roughly around three hours after a service about 7-8 years ago, didn't immediately get up to speed on the last two or three occasions when I used it, and following another interval it has almost ground to a complete halt. And I remember another Eumig I used to own seriously slowing down in similar circumstances, despite it also being used very little after a service.

I wondered, therefore, if anyone has a broad idea with regard to why regular use is particularly desirable in relation to these Eumigs? If there's something that's particularly prone to seizing up after periods of inactivity, might there be a reasonably easy fix when users come across this problem? Any insights appreciated.

[ October 22, 2019, 06:41 PM: Message edited by: Adrian Winchester ]

Posted by Paul Adsett (Member # 25) on October 21, 2019, 03:46 PM:

I think it may all come down to that metal ball/ rubber disc drive system. As long as the rubber (bonded to the metal disc) is not too hard and dried out the friction coefficient to the metal ball is sufficiently high to avoid slippage. But if the disc dries out and hardens up then problems will arise. The rubber disc MUST deform a little under the pressure of the ball in order to get some kind of surface area contact, otherwise there is just a point contact which is no good for transferring anykind of torque to the disc. Regular running probably keeps the rubber disc reasonably supple and also keeps the grease in the mechanism from hardening up. Various treatments of the rubber disc, such as brake fluid, automobile belt dressing, alcohol etc have been suggested on this forum.

Posted by Will Trenfield (Member # 5321) on October 21, 2019, 04:41 PM:

I tend to agree with Paul. I've used brake fluid to make the rubber disks supple again. I now use a product called Platenclene intended for the rubber rollers on printers. You spray it onto a cloth and wipe the rubber disks. The surplus is then wiped off with another cloth. It needs to be used with care as the label makes clear.

Posted by Adrian Winchester (Member # 248) on October 22, 2019, 07:00 AM:

Paul & Will - many thanks for the replies; your insight into this is very helpful. I see Platenclene is reasonably economical and readily available from (e.g.) ebay sources. It looks an inspired idea so I'll get some. Perhaps it will also be good for rubber 16mm projector feet that have become hard and smooth, and I might even use it on my printer!

Posted by Mike Spice (Member # 5957) on October 22, 2019, 09:16 AM:

Like anything mechanical, it needs to be run, like a car left standing or driven every day.

A projector or a tape recorder or record player needs a run once a fortnight, once a month.

Eumig's particularly with that awful rubber wheel affair is the death of a machine if it is not regularly run and warmed up.

My Eumig 902 GL really suffered and only managed around 15fps instead of 18fps because of that ridiculous design....

Posted by Leonard Goss (Member # 3172) on October 22, 2019, 04:39 PM:

Never thought of using brake fluid, must give that a try!

Posted by Janice Glesser (Member # 2758) on October 22, 2019, 06:09 PM:

This thread has me pulling my Eumigs off the shelf. I'm going to be running them tonight. I might have to pick up some brake fluid too just in case ![[Smile]](smile.gif)

Posted by Will Trenfield (Member # 5321) on October 23, 2019, 03:51 AM:

This is what I posted about using brake fluid a good while back. Take care using it. "This is how I treated the disks on a couple of mine from the 700 series. After cleaning the disks, as you've done, I stood the projector on its front and applied brake fluid (glycol-ether based not mineral) to the rubber on the front disk with a small paintbrush. It's best to put some paper or an old cloth under it to soak up any drips. I left it to soak in for 24 hours before wiping off any surplus. I then stood the projector on its back and repeated the process". My Eumig can be sluggish when first started but gets up to speed if I run it without film for a short while.

Posted by Mike Spice (Member # 5957) on October 23, 2019, 01:19 PM:

I now have an image in my head of Janice taking out 8 Eumig projectors, all pointing in different directions at the wallpaper, sitting on the floor in the lounge, showing different empty gates on the wall. No film, just squares of light, and a lot of shutter noise!

All plugged in to one extension lead ![[Smile]](smile.gif)

![[Big Grin]](biggrin.gif)

Posted by Janice Glesser (Member # 2758) on October 23, 2019, 07:10 PM:

LOL Mike! Thank goodness I only have 3 Eumigs...otherwise your vision may not have been too far off. I'm not known for my cable management ![[Smile]](smile.gif)

Posted by Graham Ritchie (Member # 559) on October 23, 2019, 10:09 PM:

I have fixed this problem on a few projectors now...check previous post. "Eumig Drive Motor" Its just wear and tear and as a result it goes out of adjustment, what I did is how they set these up in the factory on assembly.

Posted by Paul Adsett (Member # 25) on October 23, 2019, 11:15 PM:

Here is the link to Graham's and others postings on the Eumig Motor Drive:

http://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=012525

Posted by Martin Dew (Member # 5748) on November 01, 2019, 04:41 PM:

Eumig actually recommends application of alcohol on the drive discs in each of the operation manuals. I clean both the ball and discs with a Q-tip and RS Pro Isopropyl Alcohol. I find that two separate applications on consecutive days usually does the trick, and I've managed to get quite a few abandoned Eumigs running now. Then, as Mike Spice says, it's just a question of using the machine regularly.

Posted by John Armer (Member # 4655) on November 02, 2019, 05:00 AM:

Graham's tip of adjusting the levers that move the motor has actually worked well for me. I have a well-used 810 that used to take a bit of time to get up to speed and with a minor adjustment it now runs full speed immediately. I have also used Platenclene to good effect too.

Posted by Graham Ritchie (Member # 559) on November 02, 2019, 12:36 PM:

That's great news John ![[Smile]](smile.gif)

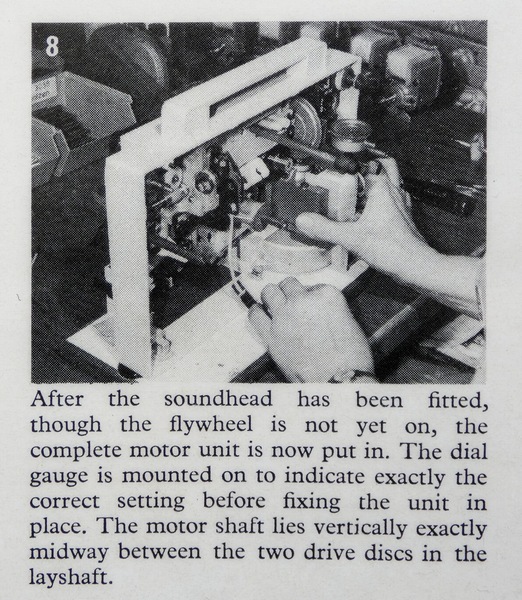

I was reading an article just lately and came across this one particular photo taken in the Eumig factory, note the comments about the dial gauge and the importance of adjusting the motor to be in the exact center, If you don't have a dial gauge then just use feeler gauges, anything at all, as long as its set exactly in the center.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Big Grin]](biggrin.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)