This is topic Eumig Mark S speed problems out of the ordinary stuff. in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=011152

Posted by Niels Peter Buch (Member # 3757) on December 12, 2016, 02:06 PM:

My Eumig cannot obtain speed ( 15 fps / 21 fps )

Disc drive sanded and cleaned with alcohol.

Still it wont to obtain right speed.

Driveshaft driven by hand seems normal !

Motorspindel can be stopped in action, when I lighty press the motor( spindle ) against the discdrive!

Where is my problem ?

Weak/faulty motor and can I "clean " this motor ?

If anyone out there can help, I would be very pleased.

Kind regards

Posted by Niels Peter Buch (Member # 3757) on December 17, 2016, 10:21 AM:

Problem solved to an ok performance :

Motor consol on fanhouse : 2 screws unthigtend.

Motor lifted as high as possible in

oval slots.

Thightend screws

Speed now : 17 / 23 fps.

Posted by Andrew Woodcock (Member # 3260) on December 17, 2016, 10:38 AM:

Well played Niels! ![[Wink]](wink.gif)

Posted by Niels Peter Buch (Member # 3757) on December 17, 2016, 10:49 AM:

Thanks Andrew ![[Smile]](smile.gif)

This was new to me.

It seems to me, that theese models from the early 60 s.

Has a slightly weaker motor or just plain " tired" due to age.

This can hopefully help other members in this great forum.

Merry Christmas ![[Smile]](smile.gif)

Posted by Andrew Woodcock (Member # 3260) on December 17, 2016, 10:50 AM:

That's the idea Niels with these type of posts, I agree.

Congratulations once again my friend on your accomplishment. ![[Wink]](wink.gif)

Posted by Paul Adsett (Member # 25) on December 17, 2016, 06:54 PM:

I have found that wiping the rubber drive discs with a little automobile belt dressing applied to a Q-tip, seems to renew the rubber and restore the running speed.

Posted by David Hardy (Member # 4628) on December 18, 2016, 05:24 AM:

The main problem with older rubber disc driven Eumigs

is that over time a groove is formed in the disc and this

leads to speed problems.

Its a shame there is no simple solution such as spraying some form of rubber solution into the groove.

Posted by Maurice Leakey (Member # 916) on December 18, 2016, 05:41 AM:

We must not forget that Niels' Eumig Mark S could now be over fifty years old as this model was marketed in 1965.

It's great that it now appears to be running satisfactorily.

Posted by David Hardy (Member # 4628) on December 18, 2016, 05:47 AM:

Yes Maurice my own Marks S is still chugging away.

It has speed problems too but gets up to speed when warmed

up. I let it run for a few minutes when I get it started before

threading up. It is so old it needs a "hand crank" to get it going.

A bit like a vintage motor car. Still its amazing it still

works and has sound. I still love it !

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

Posted by Andrew Woodcock (Member # 3260) on December 18, 2016, 05:57 AM:

Not so much in these early years, but certainly on all of their later models, its such a pity that Eumig being the experts in the field that they undoubtedly were, did not move away from this archaic friction wheel driven design that they stuck with right until the very end.

Had they had gone down the dc electronic driven route, their fabulous on board sound capabilities and recording facilities could have been fully realized as well as playback irregularities such as these,would have been completely eliminated.

Posted by Paul Adsett (Member # 25) on December 18, 2016, 11:19 AM:

I have to agree with you there Andrew. I think if Eumig had set their sites on producing a projector like the GS1200 or Beaulieu, it would have been a stunning machine.

Posted by Andrew Woodcock (Member # 3260) on December 18, 2016, 01:38 PM:

It would certainly have been far better than the ones they did make,that's for sure!

Even then though, it'd be far cry from being like a Beaulieu Paul, in any respect.

Even the drive belt configuration on the later Eumigs is an absolute nightmare,just as in the same sense, so is the Bauer layout.

Both great machines, but when you look at the logical layout and build quality of a Beaulieu including components used...

No comparison I'm afraid.

Electronically maybe, mechanically...no where even close.

Posted by Will Trenfield (Member # 5321) on December 18, 2016, 03:05 PM:

I've a couple of projectors which had this problem when I bought them. I wouldn't sand the rubber disks. I cleaned mine with 100% Isopropyl Alcohol. Then I stood the projector on its front and brushed brake fluid onto the front disk. This was left overnight to soak in. The next day, I wiped off the surplus, stood the machine on its back and repeated the process. Worked well and I haven't needed to do anything to them since.

Posted by David Hardy (Member # 4628) on December 18, 2016, 03:13 PM:

A great tip there Will. Thanks ! ![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

Posted by Will Trenfield (Member # 5321) on December 18, 2016, 05:03 PM:

It's not my original idea, David, but one I saw suggested on another site when searching for advice. The brake fluid could be causing the rubber to expand. The braking system on a car has loads of rubber seals and washers so the fluid shouldn't do any harm to the rubber disks. Use plenty of kitchen paper towel under the disks when brushing the brake fluid on though in case it drips, as it can be corrosive to paint and copper apparently.

Posted by Andrew Woodcock (Member # 3260) on December 18, 2016, 05:15 PM:

I'd make sure if you are placing brake fluid on rubber friction linings, that it is the Glycol-Ether type and not the silicone or Mineral Oil based ones!

I'd imagine any solvent would do a job here of rejuvenating the surface of the rubber.

At the end of the day, all you are requiring, is to remove any shiny hardened glaze or lubricant from the surface to reinstate the frictional properties of the rubber again.

That is why using wet & dry or fine emery cloth does a great job also.

Posted by Steve Klare (Member # 12) on December 18, 2016, 05:44 PM:

I seem to recall this conversation before, but it was "brake cleaner" and not "brake fluid".

I'm kind of lucky along these lines: I've been bracing for a slipped disk on my own Eumig for 14 years now and I haven't had the "pleasure" so far.

-great machine: I've had all sorts of more modern stuff I've bought brand new since I got it which died a long time ago!

Posted by Will Trenfield (Member # 5321) on December 18, 2016, 06:22 PM:

Whilst using Wet & Dry or fine emery paper would reduce surface glaze, there is the danger that over-zealous use with too hard a grade could remove some of the rubber coating which is the last thing you want. What grades would you suggest using if you were to go down this route?

Posted by Andrew Woodcock (Member # 3260) on December 19, 2016, 10:46 AM:

The finest Will.

You'd be rubbing away from now until next Christmas before you'd significantly wear the rubber away using wet and dry.

That sounds a bit more like it btw Steve!

I personally, cannot imagine why anyone would wish to place hydraulic oil on a friction lining?

Posted by David Hardy (Member # 4628) on December 20, 2016, 01:39 PM:

I read someone somewhere can replace the worn rubber disc.

Does anyone know who it is and how much it costs ?

Posted by Simon Wyss (Member # 1569) on December 21, 2016, 12:38 PM:

The driven discs may not be the main problem.

There are more things to observe. One is that the motor has plain bearings which obviously run dry. If one feels resistance on twisting the motor spindle (unplug projector from the mains), the bearings are up. Itís not possible to lubricate them from outside. The motor must be disassembled. Machining for ball bearings is strongly advised.

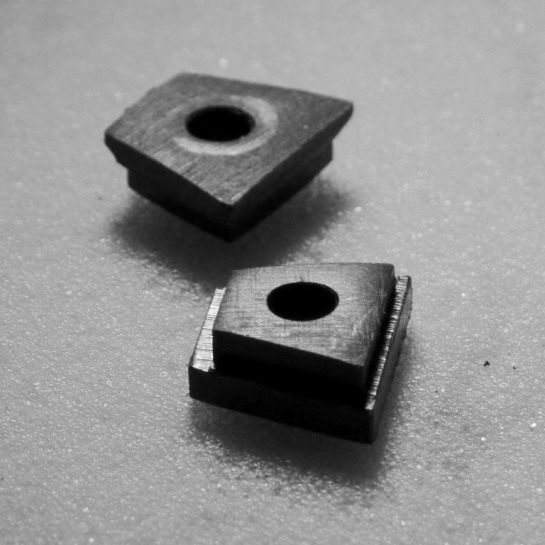

Two, the motor is rocked in two directions, two studs of it are held in plastic parts that can disintegrate. If thatís the case, the drive is gone altogether. Hereís a pair of replacement holders a mechanic once made for me of POM. These can be slipped right into the cast metal frame and the motor put back between them.

In case of interest I can have more rhomboids made and send them out. One would look at probably $40 for a pair plus shipping.

Again, the motor bearings represent the bigger problem, so Iíd switch to an other projector for Regular-Eight film. With 8-S the choice of sound projectors appears to be smaller but I think the investments are well worth it to a heavy user.

Posted by David Hardy (Member # 4628) on December 21, 2016, 03:24 PM:

Thanks for that further information Simon.

Very helpful indeed. ![[Smile]](smile.gif)

Posted by Andrew Woodcock (Member # 3260) on December 21, 2016, 03:26 PM:

Indeed!

Great work there Simon, thanks for sharing it here. ![[Smile]](smile.gif)

![[Wink]](wink.gif)

Posted by Will Trenfield (Member # 5321) on December 21, 2016, 04:19 PM:

Replacement motor mounts are also available from Van Eck Video Services. See http://shop.van-eck.net/PP-0138.html. The plastic which holds the mounts just falls apart with age like the feet.

Posted by Niels Peter Buch (Member # 3757) on December 21, 2016, 04:57 PM:

This thread seems to develop .... great.

Im all " ears ".

Thank you very much !

Posted by Terry Sills (Member # 3309) on December 21, 2016, 05:51 PM:

Simon is correct here. It is not so much that the disc drive is the problem but rather the mountings of the motor which deteriorate over time and affect the precision of the contact between the spinning rubber disc and the metal drive wheel. I have encountered this problem quite a few times over the years and when the mountings are replaced the problem is solved. It is possible to make your own replacement mountings with resin and so long as the original mounts are not too badly deteriorated you can use them as proformers to make replacements. It means removing the motor, which is not so much a problem, but the internal (rearmost mount) can be fiddly to remove and replace, but not impossible by any means. well worth doing because they are a great machine and so well engineered.

Posted by Simon Wyss (Member # 1569) on December 22, 2016, 04:53 AM:

Hello, Terry and everyone

One can say that the Eumig Mark S projector is well engineered. Four bores in the roof leading to the main shaft bearings plus felt lines would complete the refurbishment.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Smile]](smile.gif)

![[Wink]](wink.gif)