This is topic Building 8mm film Cleaning System - Are you interested? in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=011275

Posted by Dennis Bennett (Member # 5789) on February 07, 2017, 06:12 PM:

I have spent hours on the web looking for a film cleaning system much like the old ECCO 360 that is no longer in production or available as a used item on eBay.

So.... I had a former student of mine, now an engineer, build me one. We are considering producing several if there is enough interest.

Please provide feedback and what you would be willing to pay for this machine.

YouTube Presentation link below image.

I can be reached at: savethosephotos@gmail.com

YouTube - First Step Film Prep presentation

Posted by Winbert Hutahaean (Member # 58) on February 07, 2017, 07:08 PM:

Dennis, it is always a good situation if we have alternative product. This can make the price down or better machine. Have you read this previous article:

Product Review: Film-O-Clean

I believe there are always big interests for a simple film cleaning machine.

cheers,

Posted by Dennis Bennett (Member # 5789) on February 07, 2017, 07:18 PM:

After looking at the article, it seems I may have seen this in the past, but for some reason it did not register with me as a film cleaner. Thanks for making me aware of this product.

Posted by Paul Adsett (Member # 25) on February 07, 2017, 07:29 PM:

Doug gave a great review of the Film-O-Clean. Why is it no longer available?

Posted by Andrew Woodcock (Member # 3260) on February 07, 2017, 07:29 PM:

Roy Neils Product is superb but at the end of the day, run any film through a cloth of FilmGuard just before a screening on a high torque slow speed unit, you get exactly the same result.

Zero base scratches, no dirty specks anywhere ( believe me I have received film full of animal hair before now!), but ultimately..

It, like anything else, can do nothing at all if your film has Green Emulsion Scratches, Two Green Dots Or Green Smiley Mouths etc etc

It ain't crude projector proof, nor a remedy for one!

Posted by Dennis Bennett (Member # 5789) on February 07, 2017, 07:45 PM:

The reason I had the First Step Film Prep built, was I quickly became frustrated with re-wetting the cleaning cloth. I wanted something that would keep it moist while advancing the film. This machine meets that goal.

Posted by Andrew Woodcock (Member # 3260) on February 07, 2017, 07:48 PM:

It doesn't bother me Dennis to run a film through my LPU before screening.

1/4 hr tops ![[Wink]](wink.gif)

Posted by Douglas Meltzer (Member # 28) on February 07, 2017, 07:48 PM:

Roy had to stop production for a while, however when I last spoke with him he was hoping to start up again soon.

Dennis' ECCO type machine looks really interesting. Dennis, I like the presentation. I'd love to see a short video of your prototype in action.

Doug

Posted by Dennis Bennett (Member # 5789) on February 07, 2017, 08:02 PM:

Doug,

I will try to put a short video together tomorrow.

Dennis

Posted by Andrew Woodcock (Member # 3260) on February 07, 2017, 08:07 PM:

Go for it Dennis! ![[Wink]](wink.gif)

Posted by Larry Arpin (Member # 744) on February 08, 2017, 12:55 AM:

Is it wide enough for 35mm? How much is the approximate cost? Ballpark would be good enough.

Posted by Dennis Bennett (Member # 5789) on February 08, 2017, 12:17 PM:

The cleaning strip is 2 inches wide.

Don't have a price yet - the person building them is checking on what costs are for ordering the materials in bulk. So it will be cost of materials and his time to build. I will keep you informed. Hope to post to a link to a video of the machine cleaning film sometime today.

Posted by Dennis Bennett (Member # 5789) on February 08, 2017, 05:23 PM:

Doug,

As promised - here is a link to a very short video of the First Step Film Prep system cleaning film.

First Step - Film Prep cleaning 8mm film

This machine is a prototype and we are taking suggestions for improvements.

Thank you for your interest.

Dennis

Posted by Andrew Woodcock (Member # 3260) on February 08, 2017, 05:38 PM:

Looks like a nice professionally built machine Dennis, I'd just like to see two Vee profiled rollers where the nylon rollers come into contact with the film frame, rather than flat profiled rollers if I were buying one of these.

Just so there is no chance whatsoever of contact with the films frames themselves from any surface that may perhaps be slightly abrasive once in use.

Other than that, it looks a fine device Dennis! ![[Wink]](wink.gif)

Posted by Dennis Bennett (Member # 5789) on February 08, 2017, 06:23 PM:

Ok, will look into making a modification.

Is it important to you for the cloth to advance automatically, or are you fine with advancing it yourself.

Dennis

Posted by Andrew Woodcock (Member # 3260) on February 08, 2017, 06:26 PM:

As said Dennis, i don't use a Roy Neil cleaner, but if I did, I would want to offer the option of both if possible.

One automated by a ratcheting system, then the facility to turn this by switch to manual.

Covers all options that way.. one for the lazy projectionist, one for the perfectionist projectionist! ![[Wink]](wink.gif)

the vee profiled nylon rollers would require a fairly steep angle on them over that width to cater for all gauges of film.

Either that or interchangeable rollers.

Posted by Barry Fritz (Member # 1865) on February 08, 2017, 06:33 PM:

If "V" type rollers are used, you would need to have them specific for each size of film. As it is now, the machine can be used for any size film.i

Posted by Andrew Woodcock (Member # 3260) on February 08, 2017, 06:38 PM:

Why?

Posted by Barry Fritz (Member # 1865) on February 08, 2017, 07:16 PM:

Andrew, you explain the issue with the V roller. You must have been posting about the same time I was as I did not see that post then. Anyway, you explain the problem with the V roller. One large roller would seem ungainly, in my view. The inter changeable roller would be better, I think, but would complicate the design a bit and add to the cost.

[ February 08, 2017, 08:48 PM: Message edited by: Barry Fritz ]

Posted by Andrew Woodcock (Member # 3260) on February 09, 2017, 01:54 AM:

I would simply keep the universally sized tapered rollers that would cover all sizes from 8mm to 35mm, but then add two simple input guides that are adjustable and lockable to keep whatever sized film is being run through, centred within the unit. two plain M6 steel rods would do it made from cheap round bar with a series of pre drilled correctly spaced holes in a lower bedplate.

The taper doesn't need to be huge, just large enough to create a gap in the middle for even the small format film, so only the edges of the film are ever in contact.

Posted by Kevin Clark (Member # 211) on February 09, 2017, 04:26 AM:

I had one of Larry Urbanski's Ecco cleaners like this years ago and it never marked any film frames despite the flat profile shaped entrance and exit rollers.

Those rollers always turn because the low profile of the cleaning unit means the film is always tight against them when directed down from the rewinds.

I regret selling mine and would defintely buy one of these if the price is right and it is wide enough for 35mm films.

Kevin

Posted by Andrew Woodcock (Member # 3260) on February 09, 2017, 05:49 AM:

I was simply thinking there may be a possibility Kevin, especially after use where debris from an unraveling, uncleaned film, may fall onto the Roller prior to cleaning.

Like Dog hair for example!! ![[Mad]](mad.gif)

Relieve the roller, there is no possibility to speak of if not directly in contact with the films frames.

Posted by Kevin Clark (Member # 211) on February 09, 2017, 11:14 AM:

You are right Andrew especially as Dennis has asked for any re-design suggestions - how about adding a couple of slanted profile movable collars over the current flat guide rollers that could be moved in or out to provide edge only contact to the film whichever guage is being cleaned?

Kevin

Posted by Andrew Woodcock (Member # 3260) on February 09, 2017, 11:20 AM:

Better still mate! ![[Wink]](wink.gif)

Posted by Eric Bowen (Member # 5791) on February 09, 2017, 03:54 PM:

I'm new at this and so I don't have any idea of what a fair price for this cleaning equipment would be, but if I am able to afford it I would definitely be interested.

Posted by Dennis Bennett (Member # 5789) on February 11, 2017, 12:10 AM:

Wow, I appreciate all of the discussion. Intelligent discussion leads to improved product design.

We are looking into interchangeable rollers, however, I don't have experience with the original ECCO machine, so I do appreciate comments from experience users. In other words, no need to fix a design if it isn't broken. I've also encouraged the engineer who designed the "First Step - Film Prep" to join this forum and the 16mm forum. This should help us in making design improvements.

Posted by Ali Hipperson (Member # 5643) on February 21, 2017, 05:42 AM:

Hi Dennis.

I am very impressed with what I have seen and read in this thread already - and, depending on the cost, would certainly be interested in purchasing a unit.

Well done on bringing a very welcome and useful piece of 'kit' back into the hobby/past-time! ![[Smile]](smile.gif)

Ali.

Posted by David Ollerearnshaw (Member # 3296) on February 22, 2017, 03:34 AM:

I use the ECCO that I bought on holiday in LA. It works great, I used the Spondon long play unit with it. The only problem I have is the plastic pipe that takes the fluid from bottle to pads became brittle and had to be changed a number of times.

The rollers have never been a problem. Your version does look more professional.

Posted by Dennis Bennett (Member # 5789) on February 23, 2017, 09:59 AM:

Thank you for the latest information especially concerning the rollers. Just to let you know that we are going forward with this project. We are currently researching a source for v-shaped rollers. If you have any sources, please share.

It is also possible that cad views showing improvements will be posted in the future seeking your input.

Posted by Sean Calvert (Member # 5800) on February 27, 2017, 08:37 AM:

Hello all,

I am the designer working with Dennis on this system. Thanks for the great suggestions. I've found a tapered roller supplier so I'll make that change to the design. This will allow 8mm up to 35mm width film. I am still looking into a ratcheting advancement mechanism for the cleaning cloth, but I think I'll build the simple version first to get it into peoples' hands and will work on an upgrade for advancing the cloth afterward. If you think of other items you would like to see improved or added, please let me know! Thanks!

Posted by Sean Calvert (Member # 5800) on March 05, 2017, 06:46 PM:

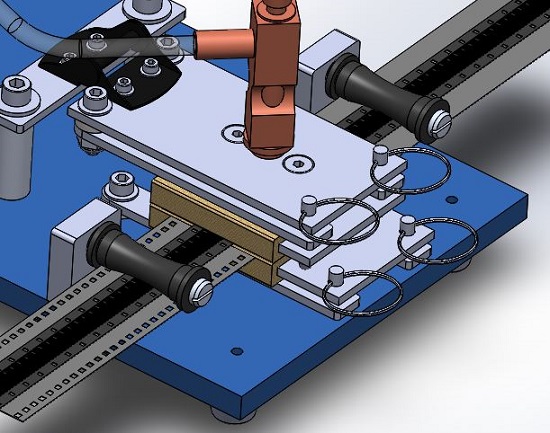

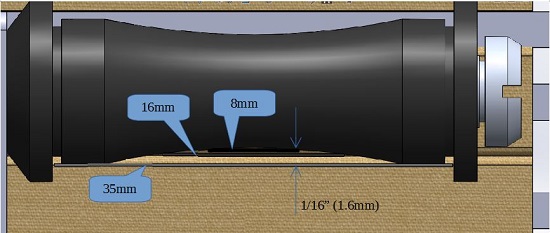

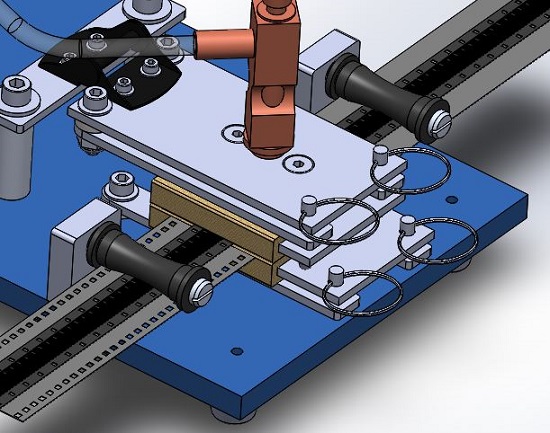

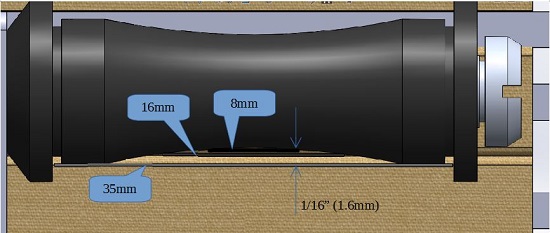

I've added tapered rollers to the design and as they are sized for 35mm film, it looks like all three sizes should work with a common set of rollers. In the attached pictures you'll see 8mm, 16mm, and 35mm film. Each is in contact on the edges of the film with a gap in the center. It is difficult to see with the 8mm, but there is a gap between the contact points.

I'm using 1/8" thick felt so there is 1/4" (about 6mm) of padding between the metal structure. The most the film would need to flex between the roller and the center of the two felt pads is about 1/32" (just under 1mm).

I'd love some feedback. It sounds like we have some interest so I'd like to move ahead with my manufacturing drawings to get some of these built and into your hands. Thanks!

Posted by Paul Adsett (Member # 25) on March 05, 2017, 08:30 PM:

Sean, nice 3D model. What CAD program are you using?

Posted by Sean Calvert (Member # 5800) on March 24, 2017, 06:41 PM:

Thanks, Paul!

I use SolidWorks 2017. It's a great design package.

Posted by Sean Calvert (Member # 5800) on March 28, 2017, 10:20 PM:

Hello, all!

Thank you for your interest in this machine! I've received quotes for the parts and will be able to sell these for $380. Please let me know, either here or via private message, if you are interested and I'll work on getting an ordering method set up so we can get parts moving.

Thanks!

Posted by Dennis Bennett (Member # 5789) on July 07, 2017, 05:17 PM:

The day has arrived!

The "First Step Film Prep machine is now available for purchase.

The first machines will be built when 7 orders have been submitted.

Here is the link for ordering.

https://dbennettech.wixsite.com/first-step-film-prep

Thank you for your patience and spread the word.

Posted by Dennis Bennett (Member # 5789) on December 07, 2017, 09:29 AM:

I know it has been awhile, but Sean is willing to build some machines.

Initially, he was waiting for a minimum number to get starter.

However, he is now willing to start production.

Would you please send a message to Sean or myself to update your interest in purchasing one of these machines.

Dennis Bennett - dbennettech@gmail.com

Sean Calvert - seangcalvert@gmail.com

Here is the link to a website for ordering.

https://dbennettech.wixsite.com/first-step-film-prep

Thank you for your patience and spread the word.

Posted by Chip Gelmini (Member # 44) on December 07, 2017, 07:07 PM:

https://m.youtube.com/watch?v=SozepDnuSSw

My cleaner in operation cotton rolls are soaked with lubricant upon motion everything moves nothing gets scratched.

(This post amended Dec 8th. Please watch the entire video. The camera starts in the theater, then goes in the booth. A light comes on, and the cleaner is above the scope lens.)

The machine under construction is a very good idea. Kudos to those of you who are interested in making it a reality!

[ December 08, 2017, 02:02 PM: Message edited by: Chip Gelmini ]

Posted by Brian Fretwell (Member # 4302) on December 08, 2017, 06:51 AM:

That link goes to an extract from Star Wars Super8 and shots of the projector when I try it - not your film cleaner.

Posted by Chip Gelmini (Member # 44) on December 08, 2017, 10:12 AM:

Please visit that link again watch the part of the extract the camera will go into the booth a light will come on and the cleaner will be shown I am sorry I did not make that clear the first post

(Dec 8th original comment now edited)

[ December 08, 2017, 02:03 PM: Message edited by: Chip Gelmini ]

Posted by Sean Calvert (Member # 5800) on December 08, 2017, 02:55 PM:

Thank you again for your interest. I’d like to collect orders until next Friday, December 15th. At that point, I’ll compile the list of materials to purchase for those machines and will start building.

Posted by Sean Calvert (Member # 5800) on December 26, 2017, 09:52 AM:

It looks like we have 5 people interested. I will be sending emails directly to them this morning. If you are interested and do not receive a message from me, please email me at seangcalvert@gmail.com. I'll try to remember to post a few pictures of production when I get rolling.

Merry Christmas, everyone!

Posted by Brad Miller (Member # 2) on December 27, 2017, 12:46 AM:

Not trying to hijack this thread, but Chip's use of the defacto cinema-standard film cleaner made by Kelmar (older versions were branded Christie) is a much better way to go. I've used the Ecco before and it doesn't do anywhere near as good of a job as the Kelmar.

The Ecco's design uses stationary cleaning pads that must be manually moved to prevent scratching. The Kelmar design advances on its own as the film spins the main drive wheel. You just design some sort of method of mounting like Chip did, thread your film through it and go enjoy the show! No need to stand there and obsess over it on the rewinds.

The Kelmar cleaners are available used on ebay and near-effortlessly converted to run 16mm or 8mm gauge with a couple of bolts and some washers. This is the very machine FilmGuard is recommended to be applied with and it works fine with other solutions as well. The only thing it doesn't have is the constant drip onto the pads, but that just isn't needed with a slow-drying solution.

Talk to Chip and others who have used the Kelmar OR the miniaturized version of the Kelmar that Roy Neil produces called the Film-O-Clean. Its really no comparison.

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Wink]](wink.gif)

![[Wink]](wink.gif)

![[Wink]](wink.gif)

![[Wink]](wink.gif)

![[Mad]](mad.gif)

![[Wink]](wink.gif)

![[Smile]](smile.gif)