This is topic Beaulieu 708EL take-up slipping. in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=011607

Posted by Alan Gouger (Member # 31) on July 17, 2017, 09:22 PM:

My 708 has always worked great until recently when the take up stopped midway through a movie.

I removed the projectors back cover and take take up arm cover and all belts seam fine. The main belt that runs the length of the projector and drives the take-up clutch is operating perfectly. It seams what ever the cause starts in the clutch or somewhere after. I tightened the clutch a half turn but that did not solve the issue.

What is strange is I can run the projector with no film and I cannot stop the take up shaft by hand yet when I add a film reel it seams to stop at some point a few minutes into a movie as if there is no belt connected internally. At that point manually turning the reel does not reengage it I have to turn off the projector and on again sometimes more then once for it to grab again.

I thought for sure tightening the clutch would resolve the issue but that did not seam to help. I just cant seam to find any evidence that would be causing this.

Thanks for listening!

Posted by Phil Murat (Member # 5148) on July 18, 2017, 01:14 AM:

Hi Alan,

I understand problem is on Rear Arm.

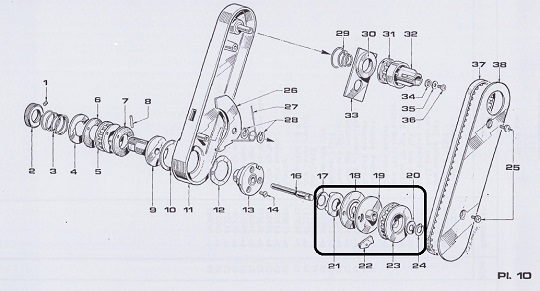

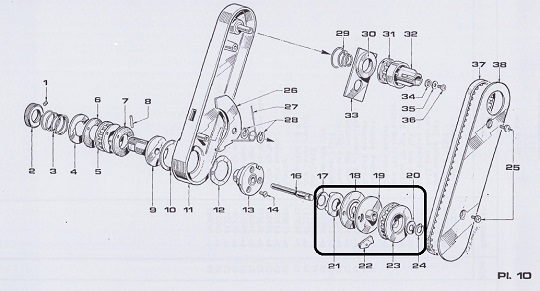

If Friction Clutch (inside)is in good condition , check (outside) ratchet assembly inside arm (Detailed Figure P22/30 , Beaulieu Service Manual).

Ratchet assy is made of items 18/19/22/23.

There is no spring inside this assembly, so that it can jam easily.....

Before disassembling it , spray thin oil (with a pipe) behind pulley and test.

If OK, no more dismantling is necessary.

Do not overtighten slipping clutch. Overtorque leads to parts extra wear (inside), main motor can suffer too.

Normal Friction Torque values are 600 to 800 centinewton/centimeter.

Posted by Alan Gouger (Member # 31) on July 19, 2017, 09:44 AM:

Hello Phil after removing the take-up arm cover would the Ratchet assembly be the bottom gear.

Thank you for reaching out.

Posted by Andrew Woodcock (Member # 3260) on July 19, 2017, 10:01 AM:

Alan, you are correct in your assumption there above and please see the following video footage I have recently uploaded for you.

There is nothing in it you won't already be familiar with or indeed nothing you won't already know, but in order for me to explain proceedings properly and before moving on to the detailed drawing of the assembly, it is most important you fully familiarize yourself with this part of the mechanism first.

https://vimeo.com/226160263

This video shows both of the take up and rewind reel arm clutches with the front cover plates removed for both arms.

Notice that at all times the internal drive from the motor, drives completely through all of the internal mechanism of the drive chain through to the hubs in these clutches in both forwards and reverse projection modes.

In other words, both clutch hubs turn constantly in both directions.

The only part of the clutch assemblies that do not drive constantly in either direction are the outer gear hub portion on the clutches.

In forwards projection mode, the rear take up clutch hub and the silver gear hub are both rotating.

The rewind clutch hub also rotates but the silver coloured gear hub directly above does not rotate.

In reverse projection mode, the rewind (front) take up clutch hub and the silver gear hub are both rotating.

The take up (rear) clutch hub also rotates but the silver coloured gear hub directly above it does not rotate.

It is these clutch mechanisms which likely hold the key to your problems I believe, just as Phil earlier has kindly pointed out.

What I suggest you should initially do, is remove both cover plates on your machine and inspect the mechanism several times over in both forwards and reverse projection modes.

It should work CONTINUALLY as the mechanism works in the above video.

If you watch it carefully, you will notice that when switching from forwards to reverse projection mode, there can be seen a slight delay before engaging the outer gear hub into drive mode on some occasions. This is quite normal.

What isn't normal however, is if you observe the drive stalling under any load at times. This is an indication all is not quite how it should be internally with these clutch arrangements.

for you to discover whether or not this is the case with your own machine, you may have to leave the cover plates for the reel arms removed while projecting a few films to simulate what is happening here.

Try to restrict your loaded films to the minimum size you can get away with to experience and recreate the problem so you are able to fully observe the clutch gear hub stalling momentarily with a little luck.

If both centre hubs of these clutches are moving freely in forwards and reverse as I suspect they are, I would advise you to immediately return to the rear clutch tension setting by unscrewing the adjuster collar by the same margin you increased the tension by, by turning in the opposite direction as before.

Take these first steps then please report back your findings.

Once the problem is pinpointed exactly to source of origin, I can post you the drawings here of whichever sub assembly is required to rectify the issue hopefully, if you feel confident you can both dismantle and reassemble the relevant sub assembly correctly with the necessary detailed care and attention these machines require.

Posted by Phil Murat (Member # 5148) on July 19, 2017, 11:55 AM:

Hello Andrew, Alan,

Reviewing Beaulieu Documentation, I found something strange :

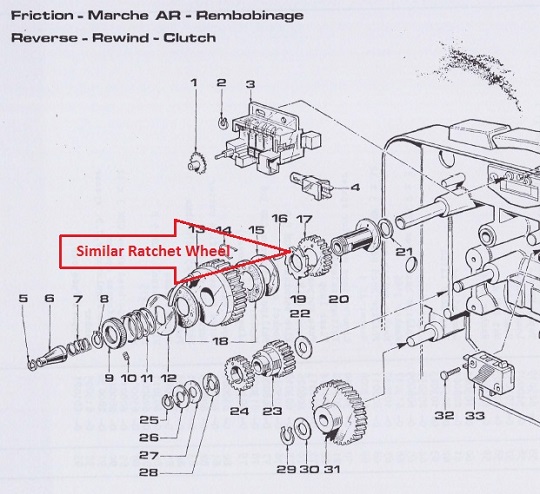

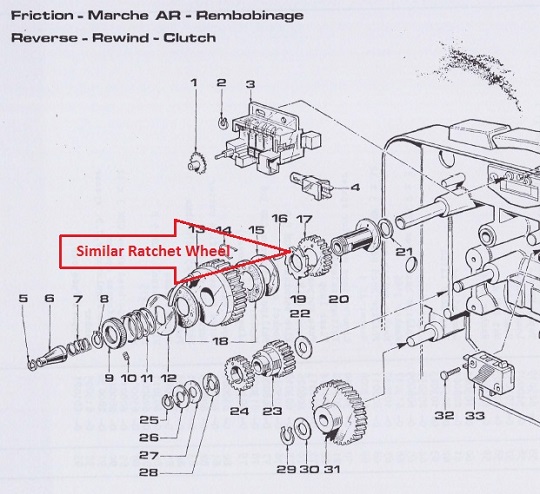

The Ratchet Wheel do not appear. The ratchet Wheel is steel material and secured on white nylon pulley.

This Ratchet Wheel shape is very closed to the one which can be found in Page 6 (Figure Reverse-Rewind Clutch), Item 19.

May be early projectors were showing "one piece" nylon ratchet-pulley......

Normaly the ratchet steel wheel is very strong and do not wear easyly

The Ratchet Wheel looks like that :

Posted by Alan Gouger (Member # 31) on July 21, 2017, 09:13 PM:

Andrew and Phil I will have time this weekend to give this another look based on your advice. Thank you for the help.

Posted by Andrew Woodcock (Member # 3260) on July 22, 2017, 05:10 AM:

No problem Alan and let us both know how you get along in order to pinpoint exactly where the problem exists.

To Phil,

Sorry but from my own limited experience of examining the clutch assemblies on my machines, I see nothing incorrect regarding the drawings against the components on my own machines.

Having said all of that, like I have already said to Alan, I have no experience of actually dismantling any of these clutch assemblies so far as none on my own have ever posed any kind of a problem to date.

I am sure this is something that will change over time, but for now, I am sure Phil or someone like Rob Young and others, would offer far greater experience based advise, than I presently can.

Posted by Rob Young. (Member # 131) on July 25, 2017, 06:59 AM:

Alan,

Don't know if any of this will help but I went through a full repair a couple of years ago;

http://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=009823# 000000

Also my post regarding this, which may be of interest;

http://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=011039# 000022

[ July 26, 2017, 01:35 PM: Message edited by: Rob Young. ]

Posted by Phil Murat (Member # 5148) on July 26, 2017, 09:53 AM:

Hi Rob,

Thanks for your comments ! ![[Smile]](smile.gif)

We do our possible to help Beaulieu's owners(cause I like to work on it as my favourite "field game") to maintain their machine and to enjoy it as long as possible.

As you can imagine it's hard to find a "repair station" more driven by quality of result than the invoice.

I have some funny exemple from my side .

So bringing some DIY proper "keys" offers 3 beneficial effects :

- Saving lot of time

- Saving a lot of Money

- Learning a lot

many people on the wed are sharing their experience in different domains. I found great informations for my cars and computers and save a lot of time and money.

However , I am away some days with no web available.

[ July 27, 2017, 01:35 AM: Message edited by: Phil Murat ]

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Smile]](smile.gif)