This is topic Braun 1000 - remove cogwheel help in forum 8mm Forum at 8mm Forum.

To visit this topic, use this URL:

https://8mmforum.film-tech.com/cgi-bin/ubb/ultimatebb.cgi?ubb=get_topic;f=1;t=011611

Posted by Stuart Reid (Member # 1460) on July 20, 2017, 07:15 AM:

I'm trying to replace the fractured cogwheel on my Visacustic 1000. I've removed the grub screw that holds it in place but the cogwheel won't budge. Do I need to force it off as it's been there for nearly forty years or am I missing something else I need to do?

Posted by Josef Grassmann (Member # 378) on July 20, 2017, 09:03 AM:

Hello,

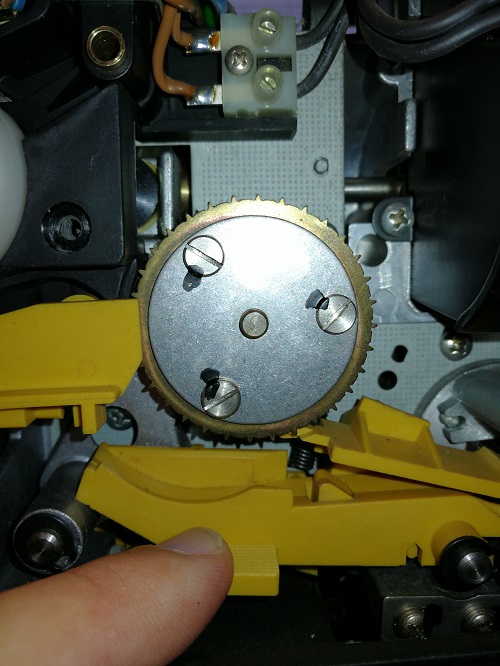

there are min. two screws, a short time they had been manufactured with 3 screws (120°).

Please search for further screw(s).

Josef

Posted by Renzo Dal Bo (Member # 5688) on July 20, 2017, 09:13 AM:

Hi Stuart, nice to find here other Braun Visacustic entusiasts.

It's very harder to pull off the cogwheel than to push out its axis towards the other side. You have only to remove some parts to free the lower sprocket that is fixed on the same axis. It is very simple and takes you a little time. You have to remove: 1) the main switch lever; 2) the three screws of the black plastic cover of the main switch; 3) the plastic cover of the main switch; 4) and now, lowering the yellow guides in front of the lower sprocket, with the help of a small hammer and a needle you can give some small shots to the axis up to free the cogwheel. At the moment I am not at home, but if you want tomorrow I will post here some pics.

[ July 22, 2017, 12:56 PM: Message edited by: Renzo Dal Bo ]

Posted by Stuart Reid (Member # 1460) on July 22, 2017, 07:49 AM:

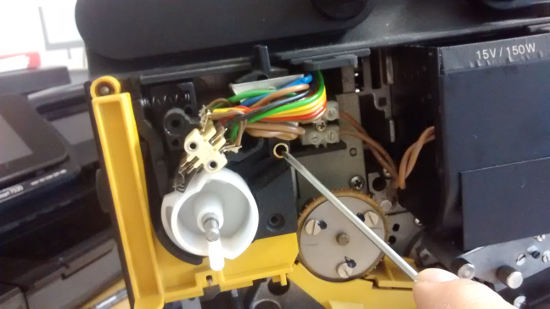

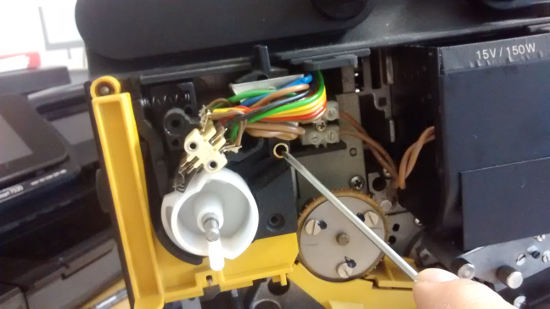

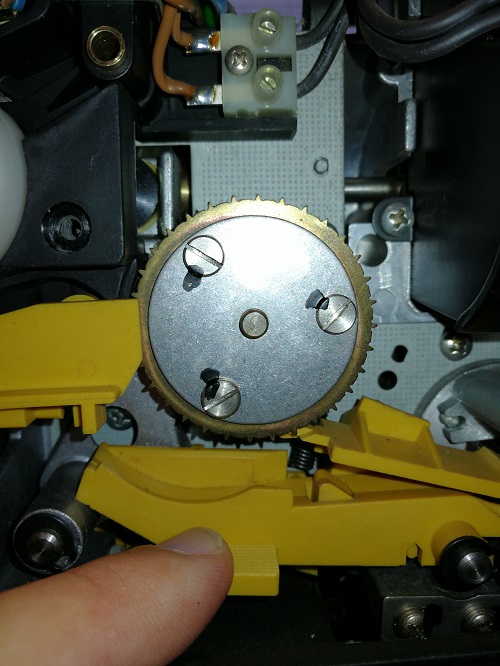

Renzo, thanks for your help. I've followed your instructions, but I'm not sure where I need to guide the pin for the hammer? Here's where I'm at:

Hope you can help further!

Posted by Phil Murat (Member # 5148) on July 22, 2017, 10:49 AM:

Hi Stuart,

Hope it's for you, Uprated Gear, Brass material, discount !!!!

VISACUSTIC COGWHEEL

Posted by Renzo Dal Bo (Member # 5688) on July 22, 2017, 11:21 AM:

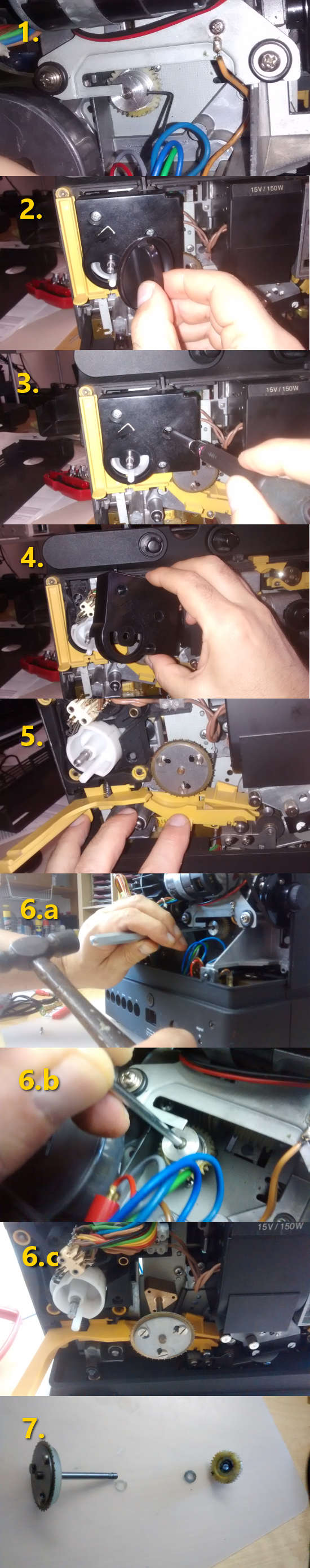

Hi Stuart, sorry for my bad English, maybe the words I used made my instructions confused. Please feel free to correct me if I go wrong.

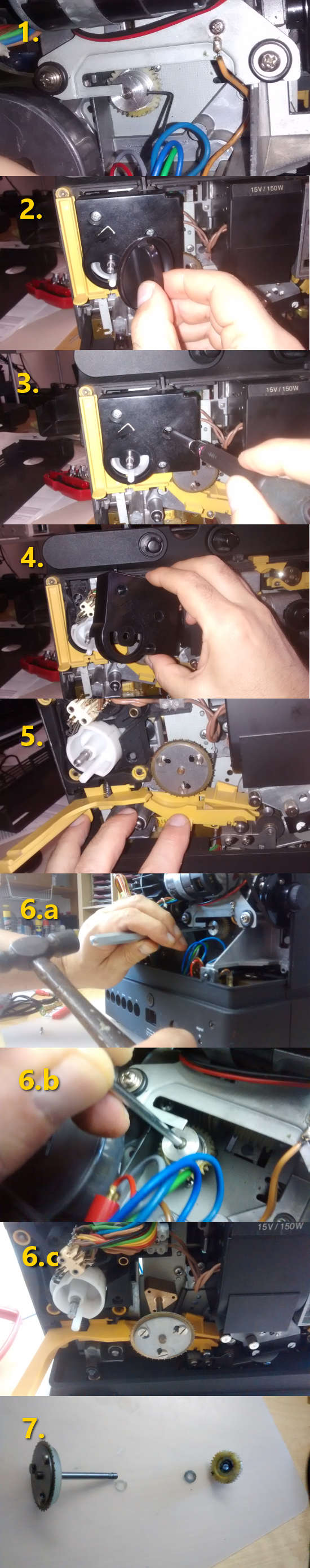

Here are all the photos of the whole sequence, you already partially executed.

1. Unscrew the grub screw of the cogwheel.

2. Remove the main switch lever.

3. Uscrew the three screws of the main switch plastic cover.

4. Remove the main switch cover.

5. Open both the yellow guides, they must stay in the lowest open position.

6.a-b-c With a small hammer and a spine give some light hits to the center of the axis until it moves backwards.

7. Remove the cogwheel and its washer from back side and slip off the lower sprocket with its axis and washer from the front side.

Warning! Sometimes, if the grub screw of the cogwheel was previously very hard tight, it could have left a dent on the axis. In order to avoid to scratch the bushing, before to slip off the axis, grind the dent with some sand paper or a diamond file.

This also makes easier to mount the new cogwheel, above all if it is a metal cogwheel.

In this way of removing the cogwheel, it is also possible to clean the old lube from the axis and renew it.

Renzo

[ July 22, 2017, 02:33 PM: Message edited by: Renzo Dal Bo ]

Posted by Stuart Reid (Member # 1460) on July 23, 2017, 10:33 AM:

Thanks Renzo, I changed the cogwheel but that hasn't fixed my problem. I still have a speed problem where the projector drops speed every second. It runs fine then every second it slows down a bit, but then immediately goes back to full speed. It does the same thing when rewinding. Here's a Youtube link explaining. web page

Posted by Renzo Dal Bo (Member # 5688) on July 23, 2017, 11:00 AM:

Stuart, look closely at the lower sprocket meanwhile it is in motion. Stare one point of it and hear if the frequency of the noise matches every revolution of the sprocket. This happens every speeds you select.

What kind of cogwheel did you buy? Metal or Plastic?

I suspect it is plastic ...

[ July 24, 2017, 01:24 AM: Message edited by: Renzo Dal Bo ]

Posted by Steve Klare (Member # 12) on July 23, 2017, 02:03 PM:

Stuart,

I had something similar a couple of years back. One of my machines would experience a drop in pitch every couple of seconds and then recover. It turned out to be contamination of the lube on the worm gear:

Lubricating Projectors

I can't guarantee a fix, but it is cheap and easy, so it's worth a try. I do this on all my machines as regular maintenance. I just had the back off one of my machines for something else and re-did this while I was at it. Maybe it added a minute onto the job.

[ July 23, 2017, 03:22 PM: Message edited by: Steve Klare ]

Posted by Stuart Reid (Member # 1460) on July 25, 2017, 05:38 AM:

Renzo, yes it's plastic. HOWEVER, taking this and Steve's thoughts into account, I've realised that BEFORE replacing the cogwheel and AFTER replacing it, I've heard the same noise repeating when the machine slows down, it's a slight scraping noise which I am convinced is coming from the lower sprocket. I think it's either poor lubrication or possibly a missing washer behind the lower sprocket. However, in the process of using a hammer and pin to knock the lower sprocket/cogwheel out, I've dislodged a piece of brass tubing from the front side of the machine. Please take a look and let me know if you can think where it belongs. I've looked very closely at the rollers etc but cannot see an obvious place.

Thanks

Stu

Posted by Phil Murat (Member # 5148) on July 25, 2017, 08:17 AM:

Hi Stu,

Reviewing video you posted here, there is a high probalibility the "shout of mouse" noise has nothing to see with Cogwheel rotating parts.

The frequency of this noise is very slow.....

That looks like a film-edges rubbing on some plastic parts.....

Posted by Renzo Dal Bo (Member # 5688) on July 25, 2017, 08:34 AM:

Hi Stuart,

believe me, you really can solve this issue.

I owned seven Visacustic projectors (3x2000 & 4x1000) and I had the same problem to substitute the original cogwheel.

I always bought metal cogwheels, but, some time ago, I tried a pair of plastic cogwheel. They both had more or less the same problem and at the end I understood why. The bore of the plastic cogwheel is a bit out of tolerance, larger than the original and the plastic is a material more deformable than brass. When you tighten the grub screws the cogwheel doesn't turn in center with its axis. So when it engages the worm gear, every turn it goes in contrast with it and slows down the projector for a moment.

You can realize about that with a close video of the cogwheel.

Looking at its edge, you can see it moves slightly back and forth. My Visacustic had the same symptoms than yours. Fortunately I removed a metal cogwheel from another Visacustic projector and by magic the issue was solved.

I warned the seller about that. He was very kind and refunded me after returning of the wrong cogwheels. He also told me his engeneers were working to a new version of the cogwheel. He also told me he wanted to send me a new one for free as soon as they had built it. I never received it, so I am still thinking the problem has not completely solved.

I am so sure that the problem is the plastic cogwheel that really if you post me private your address I am willing to lend you one of my metal cogwheels for a try.

About the brass tube, you have to insert it on the hole of the longest screw of the main switch cover, according to the photo. Probably it came off with the screw, I can't imagine you have hit so hard with your hammer! ![[Smile]](smile.gif)

Renzo

[ July 25, 2017, 11:10 AM: Message edited by: Renzo Dal Bo ]

Posted by Stuart Reid (Member # 1460) on July 25, 2017, 11:19 AM:

Phil: yes it does sound like the squeak you get with film rubbing on plastic, however I also experience this noise with no film in the projector.

Renzo: thanks so much for your kind offer. I'll investigate further, as I'm wondering why the noise was there before I swapped out the cogwheel? If I have no luck I will certainly take you up on your offer of a cogwheel. This forum is amazing, both in knowledge, but just as importantly, generosity!

Posted by Renzo Dal Bo (Member # 5688) on July 25, 2017, 12:42 PM:

Stuart, the two causes are different but both lead to a slight periodic motion slowdown of the lower sprocket. In the original cogwheel the crack on the plastic between two next teeth increases the gap between them. So when they encouter the wormgear there is a small lack in motion. About the motion slowdown of the plastic cogwheel we have already discussed.

The beauty I found in our hobby and above all in repairing our "babies" makes me feel as a small Sherlock Holmes and stimulates my mind in problem solving.

I always look forward to see "them" coming back to life, even if sometimes my joy has to wait for a long time.

[ July 25, 2017, 03:09 PM: Message edited by: Renzo Dal Bo ]

Visit www.film-tech.com for free equipment manual downloads. Copyright 2003-2019 Film-Tech Cinema Systems LLC

UBB.classicTM

6.3.1.2

![[Smile]](smile.gif)