|

Author

|

Topic: Beaulieu 708EL New Spool Spindles

|

|

|

|

|

|

|

|

|

Andrew Woodcock

Film God

Posts: 7477

From: Manchester Uk

Registered: Aug 2012

|

posted July 07, 2017 04:46 AM

posted July 07, 2017 04:46 AM

Here is what has been previously posted Maurice,..

Mon Jun 05, 2017 11:10 pm

Collected and fitted the first of my new spindle hubs today. Works very well and I am pleased with the results.

I will have a matching pair by Wednesday with a little luck.

Then Alan kindly wrote back "Looks Great!"

Then,..

Wed Jun 07, 2017 9:35 am

I am just about to go to the workshop now to see the guy who created the stainless spindle hub and tab.

He wants this first one back to verify and reference all dimensions while making the second one.

This one I have asked for a smaller pin on. I got my figures wrong to begin with by requesting that the pin diameter should be 2mm.

2mm works out fine for Elmo "Jewel" reels and the large Beaulieu /Posso reels, which is what I based my dimensions on, however some other plastic reels require only a 1.5mm Dowel pin to act as a key to insert into their slots.

So this dowel is being removed and then replaced with a 1.5mm SS type that will then fit all spools.

All else worked out absolutely fine though I am pleased to say and that includes the manner in which the reels lock on all of the ones I have been able to fit so far.

I instructed the engineer to make the centre point of the diagonal keyway slot in the tab to be point where it touches on the reel. This way it allows smaller thinner reels still to be able to lock securely while also having around 50% of the slot free to allow the reels to be released easily.

This part I am really pleased with as a first off, as it worked out exactly how I wished it to.

The second hub is going to take longer now while I wait for M1.5x 8mm Stainless Steel dowels to arrive with me as I had to order these online In the end as they are not an easy size to pick up from Engineering Merchants.

I still should have the finished first pair back with me in around a week's time with any luck.

The most critical aspect in all of this, so far as a successful working hub is concerned, is ensuring the 6.5mm counterbored hole is just to a critical depth.

0.5mm too long and the spindle has endfloat in it and will not lock to the original shaft without axial movement, 0.5mm too short and the new spindle hub simply locks up when tightening the internal shaft retaining screw. He left this purposefully short and i then finished drilled it to the exact critical depth to suit the shaft length at home, so he can then replicate it on the next one.

We now have an exact precise dimension for this to allow all subsequent ones to be made without trial in future.

Then we received a series of questions from Edwin Van Eck..

"Hi,

I had just a meetings with my engineers about replacing the sinter bronze bearings with ball bearings.

There are possibilities here.

But first we need to know:

- has this modification been done?

- what is the difference between PP-0012 (2 sinter bronze bearings) compared to ball bearings?

- are two ball bearings being used, or one ball bearing and one sinter bronze bearing? (I have an original reel holder which comprises of one ball bearing and one sinter bronze bearing)."

--------------------

Edwin van Eck

Van Eck Video Services

To which i replied...

First question...

"Has this modification been done?"

Not quite sure what is meant by that question Edwin sorry, so I will have to answer that one by asking another question in return...

Has what modification been done?

Second question.

"What are the differences between the two sintered bronze bearing design and the ball bearing design ?

Originally Beaulieu issued all mono and early twin track duoplay projectors with nylon hubs containing one singular sleeve bronze bearing of around 10mm in length.

These work very well up to a point and customers were complaining of premature motor failure due to excessive loads being placed on them by trying to drive the larger reels using these bronze sleeve bearings.

The rewinding of full 2200ft reels of film proved particularly detrimental to the well being of the motor windings long term health.

Beaulieu then modified their existing Nylon hubs by removing the bronze sleeve bearing and moulding a larger cavity within the rear section of the hub to then place two back to back slim fitting self contained ball bearing units inside the cavity.

This proved very successful and gave far greater velocity and far less drag or friction on the hub bearing and drive motor, once this modification was completed and was then subsequently implemented to every machine that was built thereafter.

This was around the time the Stereo model was first released.

Early examples of these hubs show signs of where the previous bronze bearing design had been fitted but then retrospectively a cavity was bored to the outer section within the nylon to accommodate the two ball bearings.

Later nylon spindle hubs and indeed the ones which can be ordered still from Wittners, omitted the bronze bearing insert altogether and simply added the moulded cavity into the nylon hub with no insert of any kind.

There is no benefit whatsoever by having the bronze bearing even in part form, alongside the two ball bearings in their own cavity or chamber.

If you have an original Beaulieu hub Edwin, with some of the old bronze bearing insert in tact plus the cavity or chamber with only one ball bearing fitted, it is because one has become misplaced somewhere along the way.

All have both the space and necessity to require two ball bearings per hub to be fitted to allow the assembly to both fit correctly as well as work correctly.

The spindle hubs I am replicating above, came much later and were fitted only to a few select models, namely the HTI 250w models, some fade computer models and then all of the later 93 Stereo Studio models.

Contrary to what you may hear Edwin, my advice, always based on my own extensive experiences and extended research with these things,would be to simply discontinue the original sintered bronze sleeve bearing design that you replicated from the original Beaulieu nylon hubs and do as they did, and supersede your design using the twin ball bearing arrangement as these in practice are far superior in use than the early design and subsequently, do not cause any issues with premature motor failure or indeed excessive overloading / overheating.

then,..

Thu Jun 15, 2017 12:48 am

Just returned from visiting the workshop to collect my second piece. I now have two completed pieces ready to fit on the first machine. Will test extensively throughout the day using various different reel sizes and types.

There shouldn't be any issues however as the pin diameter is now 1.5mm and luckily, the Stainless Steel ones arrived in time for the Engineer to fit those prefered kind thankfully.

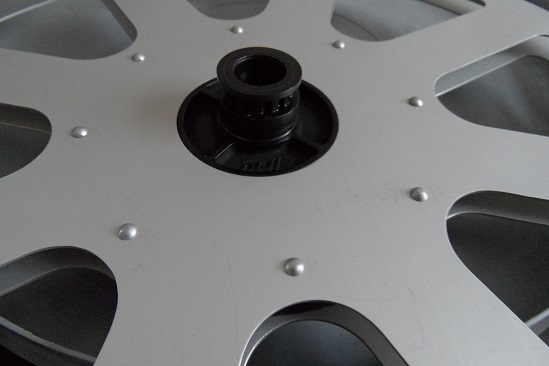

These photos also show some of the tooling and stock engineering parts required to make this venture into a reality.

There may be a chance future ones of these may be entirely made from one piece stainless or aluminium round bar (except for the locking tab of course), as he has now invested in a dividing head for milling small gears accurately.

It makes no real difference to the end product except to say these would then become readily available to anyone whether they have the later Beaulieu nylon hubs with the dual ball bearings fitted or not, as the case may be.

There is more to conclude, but i'd need a reply first before I may post more photographs on the conclusion once these were fitted.

--------------------

"C'mon Baggy..Get with the beat"

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

Andrew Woodcock

Film God

Posts: 7477

From: Manchester Uk

Registered: Aug 2012

|

posted July 09, 2017 08:25 AM

posted July 09, 2017 08:25 AM

It would mean that these would be even higher in cost to produce Phil.

It would also mean these replica "Studio" hubs would then be made from one piece stainless steel minus the rear washer and retaining clip of course.

Furthermore, what this would facilitate until such time as Edwin produces his new improved nylon hubs with the two ball bearings fitted, is an ability for any Beaulieu owner to obtain a set of these with or without the later original hubs already to hand to act as a donor for these.

In reality, I see no difference in the standard of manufacture between using a full stainless steel hub including the gear section or alternatively, doing as Beaulieu did and utilizing the rear nylon gear and bearing section of the nylon hubs and then incorporating the stainless section by integrating it through the machining processes.

They both would work in exactly the same manner and to the very same standards, I would predict.

Just that the all Stainless Steel arrangement would cost far more to produce.

I have never had any issues with nylon gear section of the hubs with these and cannot envisage how anyone ever would to be honest, as there is really nothing to wear out on these.

Reading you post differently Phil, if you are implying that gearwheels or other such components other than those associated directly with the spindle hubs could possibly be manufactured by this same engineer by using the new dividing head machinery, then yes, of course this may now be a possibility in the future for any round metal component that isn't a cast component in it's original form. ![[Smile]](smile.gif)

--------------------

"C'mon Baggy..Get with the beat"

| IP: Logged

|

|

|

|

|

|

|

UBBFriend: Email this page to someone!

UBBFriend: Email this page to someone!

Printer-friendly view of this topic

Printer-friendly view of this topic

![[Smile]](smile.gif) )

)