|

Author

|

Topic: Eumig Drive Motor

|

Graham Ritchie

Film God

Posts: 4001

From: New Zealand

Registered: Feb 2006

|

posted September 27, 2018 03:15 AM

posted September 27, 2018 03:15 AM

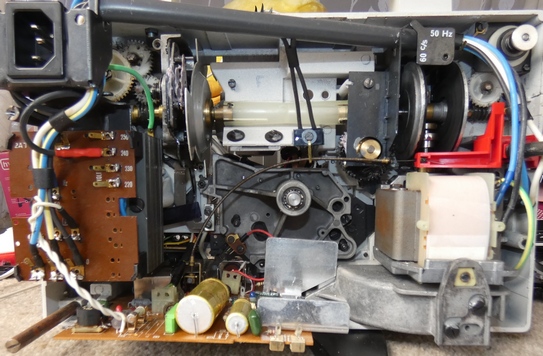

I am going through some old Eumig projectors at the moment, in a attempt to bring some of them back to life. I already have got one 810D fixed up a while ago and its going great.

Another 810D I was just going to use for spares, as the projector speed was very slow, even at times almost stopped. I did try adjusting things but nothing was working out.

Then I hit on the idea lets have a look at the motor mounts, well, everything was fine, in fact I cant see how they could ever wear out, as all they are doing is tilting the motor onto the drive disks. Anyway I did put a little grease onto the shafts that the motor pivots on.

It made no difference as far as the slow drive was concerned, so the next thing was to unscrew the 4 screws you see in the below photo. With the switch in the off position I held the motor shaft in the "center" of the two drive discs. holding it there I adjusted the "two levers" so they just made contact with the motor casting then tighten up the 4 screws.

Bingo as soon as I switched the projector on, and then switched to either fwd or rev, it went like a little rocket. After a good workout, I then cleaned the discs with IPA plus a lube of light oil on the main shaft bearing, and a touch of grease for the cam the claw runs on.

The conclusion I came to is this, if you are having trouble with speed then do those adjustments, you must remember things wear with age and as such get out of adjustment, by doing this has worked a treat and no matter 18 or 24fps the projector gets up to the correct speed in a instant...just like new ![[Smile]](smile.gif)

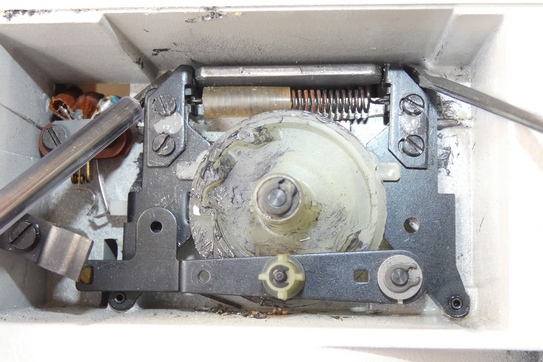

Just got to refit the flywheel. I have to admit I have never been much of a fan for Eumig projectors, but the more I muck around with them the more I like them.

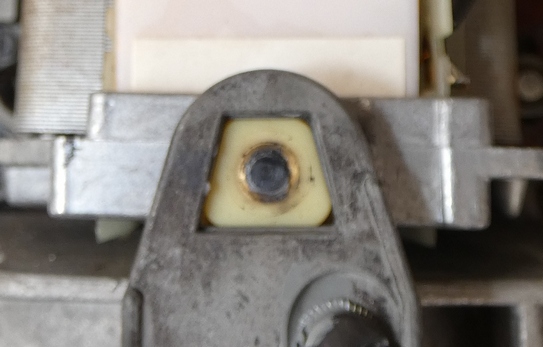

The motor tilts on two mounts, this is one of them, I had just refitted the motor...never wear out.

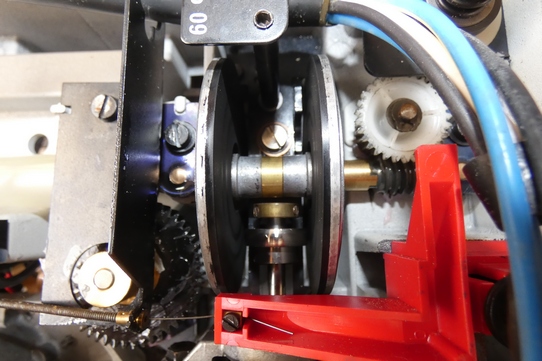

Right to the adjusting....with those 4 screws loose, hold or some how, lock the motor shaft exactly in the center of those two drive discs..

Then move those two little levers so they make contact with the motor casing then simple tighten them..

Don't forget the projector selector switch is still in the off position....those are the 4 screws and two levers.

I would bet that most of the problems people have with speed or should I say the lack of it, is down mostly to adjustment.

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Paul Adsett

Film God

Posts: 5003

From: USA

Registered: Jun 2003

|

posted September 30, 2018 09:26 AM

posted September 30, 2018 09:26 AM

I don't understand why Frank is being so secretive of his Eumig fix. This speed problem has been an almost constant discussion on this forum ever since I can remember. Other members, myself included (automobile belt dressing), have offered what they feel are helpful remedies to the problem, so there is no lack of interest in any advice put forward. Graham has generously given us all the benefit of his hard work, so I fail to see why Frank is so guarded about providing his own "real actual cure". Let's hear it, the suspense is unbearable! ![[Big Grin]](biggrin.gif)

[ September 30, 2018, 11:11 AM: Message edited by: Paul Adsett ]

--------------------

The best of all worlds- 8mm, super 8mm, 9.5mm, and HD Digital Projection,

Elmo GS1200 f1.0 2-blade

Eumig S938 Stereo f1.0 Ektar

Panasonic PT-AE4000U digital pj

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Paul Browning

Phenomenal Film Handler

Posts: 1006

From: West Midlands United Kingdom

Registered: Aug 2011

|

posted October 01, 2018 04:00 PM

posted October 01, 2018 04:00 PM

Just something I came across while trying to fix my GS 1200, when the auto lace lever would not latch down. The tiny spring that holds it down would not do its job, after several attempts at adjusting with the service manual, I found a spare I'd bought off ebay with this spring still in place, so I compared the two side by side, the only thing I could see is that the wire it was made from was just that bit thinner, and having checked this with a micrometer, it was a tiny amount probably a .002 " at the most. So I fitted it any way, and it worked first time, and still does. I guess due to cost this spring could be thinner so not as strong, or not correctly tempered and gone weak over time, either one or both could be true. frank arnstein well spotted, and graham well done to you, with an alternative that works as well, great work for the guys who have these machines, and maybe not so confident to try grahams method, but could try franks method ....

| IP: Logged

|

|

|

|

|

|

|

UBBFriend: Email this page to someone!

UBBFriend: Email this page to someone!

Printer-friendly view of this topic

Printer-friendly view of this topic

![[Smile]](smile.gif)

![[Roll Eyes]](rolleyes.gif) but will leave that to someone else

but will leave that to someone else ![[Big Grin]](biggrin.gif)

![[Wink]](wink.gif)

![[Razz]](tongue.gif)