|

Author

|

Topic: Beaulieu 708EL New Spool Spindles

|

|

|

|

|

|

|

Maurice Leakey

Film God

Posts: 5895

From: Bristol. United Kingdom

Registered: Oct 2007

|

posted March 23, 2017 06:54 AM

posted March 23, 2017 06:54 AM

Mark

The original spindles were designed by Beaulieu to be reasonably tight to ensure that their 2200ft spools did not "wobble" as they rotated.

Unfortunately, many spools from different manufacturers would not go on due to being too tight. Owners were not aware of this and tried hard to push them onto the spindles thus wearing, and eventually breaking off one, or more of the poorly made "springy" clips which hold the spools on.

In earlier days, Wittner had replacement spindles (as used on the later xenon models) which had a turn-over clip. These were great replacements, but unfortunately Wittner's stocks have long gone.

The later introduction of the stereo model incorporated ball-bearings in the spindles to ensure even running, but the "springy" clips still remained the same.

Whilst the new spindles from Van Eck have a metal bore, they do not have any ball-bearings. However, as I said, provided these are lubricated now and again there seems to be no problems on this front.

The new spindles from Van Eck are made from what seems to be a stronger material and the "springy" clips have been redesigned and as the overall diameter of the spindles is slighter less than the originals they appear to be a much better replacement.

I have both the mono and the stereo models which are OK at the moment but I have the new spindles "in reserve".

--------------------

Maurice

| IP: Logged

|

|

|

|

Andrew Woodcock

Film God

Posts: 7477

From: Manchester Uk

Registered: Aug 2012

|

posted May 08, 2017 05:29 AM

posted May 08, 2017 05:29 AM

To prolong your existing reel holders from Wittners Maurice, and also to gain better support with your larger reels fitted, I have found that by adding a few simple end caps to the ends of the reel holders, this offers by far greater support, to the springy clips that are only attached and supported at one end of the reel holders originally.

By fitting these, the nylon springy lugs are supported at both ends of the reel holders.

I don't fit these onto the reel holders though until a reel is fitted onto them as this may prematurely wear the retaining lugs on the nylon spring prongs.

This simply acts as an extra securing "locking" mechanism and forces the lugs to sit upright retaining the reels at all times.

It is almost impossible to remove a reel with these in place on a healthy reel holder.

The End Caps themselves are readily available online etc, only cost a few pence each and fit just right so they can easily be fitted and removed before and after screening.

The size that I have found fits best is 8mm End Caps.

There is no doubt by fitting these on occasions, the reel holders themselves should remain fully functional for a very long time and they should also stop them from ever flexing beyond the point they no longer serve to retain the reel fitted correctly.

The very same disciplines regarding reel types has to still be observed however and these won't allow reels that don't fit well on these machines to fair any better.

Stick with the usual line up of Posso, Elmo, Schneider, Gepe, Bonum etc to maintain the lugs on the spring clips without excessive wear to them.

[ May 08, 2017, 07:33 AM: Message edited by: Andrew Woodcock ]

--------------------

"C'mon Baggy..Get with the beat"

| IP: Logged

|

|

|

|

|

|

Andrew Woodcock

Film God

Posts: 7477

From: Manchester Uk

Registered: Aug 2012

|

posted May 09, 2017 10:18 AM

posted May 09, 2017 10:18 AM

Finally, another very often overlooked issue with these original and copied spindle hubs is that when they first arrive they have a moulded abutment face on them that is incorrect as a datum face.

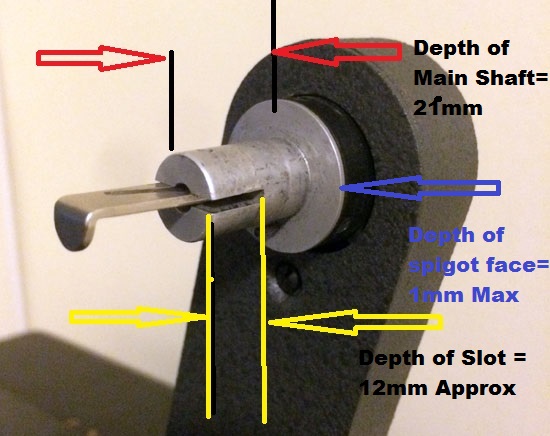

Observe the following photographs..

The above photograph is a stock photograph of how these appear from Wittners when you first receive them.

The arrows point to to moulded abutment lugs that form the datum face for the spool to sit flat against at the rear.

The problem with these abutment lugs, is they allow all correct sized spools to sit too far forward onto the spindles and as a result the fitted correct type spools do not click into position over the spring splines and their lugs correctly.

The reels never travel far back enough to make it successfully over the back of the retaining lugs. As a result, even with brand new reel holders, you can find the reel is tempted to force it's way off from the reel holder.

Also you will find that the alignment of the film running along the initial floating roller is not central. The film wants always to ride over the outer edge of the floating roller.

The solution is to do what had already been carried out to my own machine when I got it.

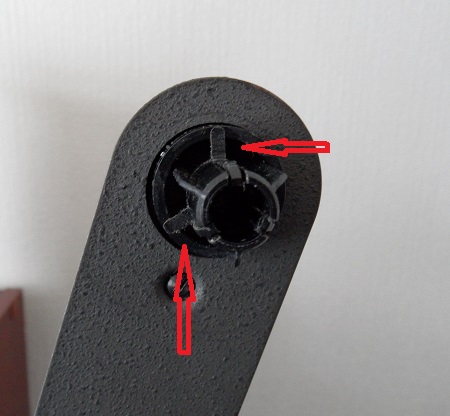

See photograph below...

This was the front reel holder I removed from my own machine when I first got it.

The yellow short stubby arrow indicates to an area of wear on the reel holder through attempting to fit ill fitting spools of incorrect size, to the machine over a number of previous years.

The Red long thin arrow indicates the flat abutment face brought about by the previous owner "engineering" the holder correctly to allow the spools to sit right up to the rear face of the holder.

When I first received my new reel holder from Wittners, knowing this information above, I first filed off each of the Abutment Face Lugs to allow the spools fitted onto it, to sit always in the correct and centrally aligned position on the new reel holder.

This also enabled the reassuring "clunk" as the spool passes over the back of the retaining lugs to be heard on each occasion.

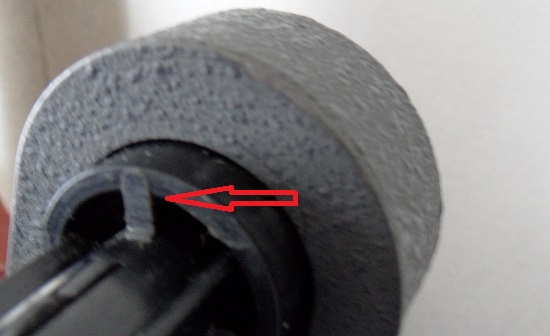

This is how my present front reel holder now appears.

The red arrows in the photographs above show now that the abutment face is almost as far back on the reel holders as is possible given the restrictions to file a perfectly flat face onto this shaped piece.

By the time this has been carried out, the distance between the red arrowed face and the very end of the lugs on top of the spring splines, is the correct depth of a standard reel such as an Elmo 1200ft Jewel reel or a Posso 2200ft spool for example.

Finally to close, here we see the significant difference between the original Beaulieu reel holders as supplied by Wittners and those supplied by E.V.E.

The uppermost photograph illustrates the original later Beaulieu designed reel holder incorporating two ball bearings per reel holder while the lower photograph illustrates the alternative brass bush fitted each, to act as a sleeve bearing for the ones currently supplied by Van Eck Video Services.

[ May 09, 2017, 11:43 AM: Message edited by: Andrew Woodcock ]

--------------------

"C'mon Baggy..Get with the beat"

| IP: Logged

|

|

|

|

|

|

Andrew Woodcock

Film God

Posts: 7477

From: Manchester Uk

Registered: Aug 2012

|

posted May 25, 2017 11:52 AM

posted May 25, 2017 11:52 AM

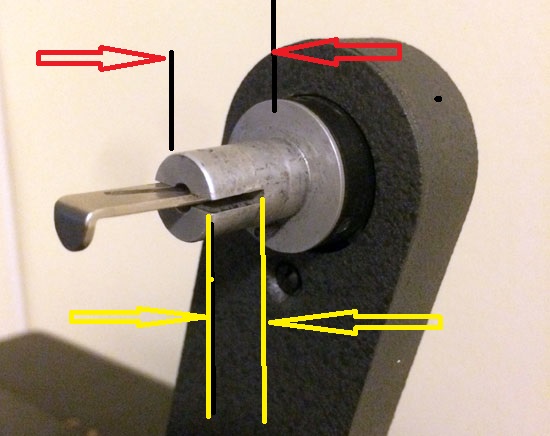

As an update to this thread, I have this afternoon been speaking with a small batch engineering shop local to myself.

They have agreed to manufacture the metal parts contained in the uprated Studio / HTI reel holders that still include the much improved two ball bearing system.

I am looking to have the first pair manufactured on Tuesday of next week.

They ain't going to be cheap, but as we know, neither are the Nylon alternatives from Wittners!

I will update on here by the end of next week and report my findings from this initial batch.

If it proves a success, which i have no reason to believe it won't based on our talks and my own submitted data with this one, then I will be in a position hopefully to offer more of these to any other user who has the later dual bearing style nylon existing spindle hubs already.

In the end, after talks and submitted proposals, it was jointly decided to keep the design as original as anything further was making the over all cost uneconomically viable for myself and no doubt other potential customers.

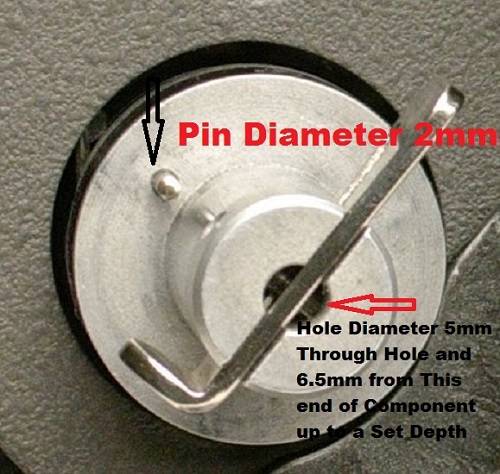

I would be most grateful if an existing user of these type of spindle hubs could provide me with two dimensions, this would help me guarantee uniformity over the originals and while this can be reasonably accurately calculated, precise measurements would be extremely useful for us with this one please.

I will illustrate the two critical dimensions in picture form this evening thanks.

Any help would be most gratefully received.

I would urge anyone with two ball broken nylon spindle holders to keep hold of them. They will be required in addition to the new parts to successfully recreate the old improved original HTI ones. ![[Smile]](smile.gif)

--------------------

"C'mon Baggy..Get with the beat"

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UBBFriend: Email this page to someone!

UBBFriend: Email this page to someone!

Printer-friendly view of this topic

Printer-friendly view of this topic

![[Wink]](wink.gif)

![[Smile]](smile.gif)

![[Big Grin]](biggrin.gif)