|

Author

|

Topic: Beaulieu: Fast & Easy Speed Setting Procedure

|

Phil Murat

Jedi Master Film Handler

Posts: 671

From: Villeneuve St Georges, France

Registered: Dec 2015

|

posted June 11, 2017 07:24 AM

posted June 11, 2017 07:24 AM

Here is a very fast and simple procedure to pré-trim speeds for Beaulieu projector.

To do it no film is loaded.

However, as prerequisites, insure you that mechanic systems are perfectly free and smooth ! (Lub bearings as necessary with penetrant thin oil), belts are serviceable. Pinch Roller has to be free and perfectly clean,its Rubber has to be in perfect condition for surface and Roundness. If these conditions are not met you can experience speed(s) fluctuation (WOW / Flutter) which can make final adjustment hard to achieve.

Moreover, this small procedure allows to quickly check "Capstan Motor" health and Electronic drive quality.

It is very important to watch a perfect Capstan Motor speed stability as Capstan Speed is considered as the REFERENCE for the Electronic Dual Drive Stucture.

Tools :

- Multimeter with Frequencemeter capability included and allowing measures within +/- 1% (You can find it for 60 Euros approx)

- White Tape (5mm X 15mm)

- Black Fine Marker

- Flat screw driver , narrow tip, extra long

A) First Step

1) After removing Back cover, Once Multimeter is set on “Frequencemeter” position , put each probe tip on soldiers (White / Blue) Wires , Tacho Terminals:

2) 24fps is 2160Hz measured from Tacho

3) 18fps is 1625Hz

4) Observe these values have to be perfectly stable , doesn’t matter if values are different at this time

5) If values unstabilities are observed and if wire contacts are in good condition , replace the “Time Factor” capacitor (C4) by a new one 5% Class minimum.(15nf.J.100v)

6) 2160Hz is set by RA3 , 1625Hz is set by RA4.

7) To be note if Multimeter accuracy is +/- 1%, final result precision is much higher what you can expect (Final speed for capstan Shaft is divided with a good ratio)

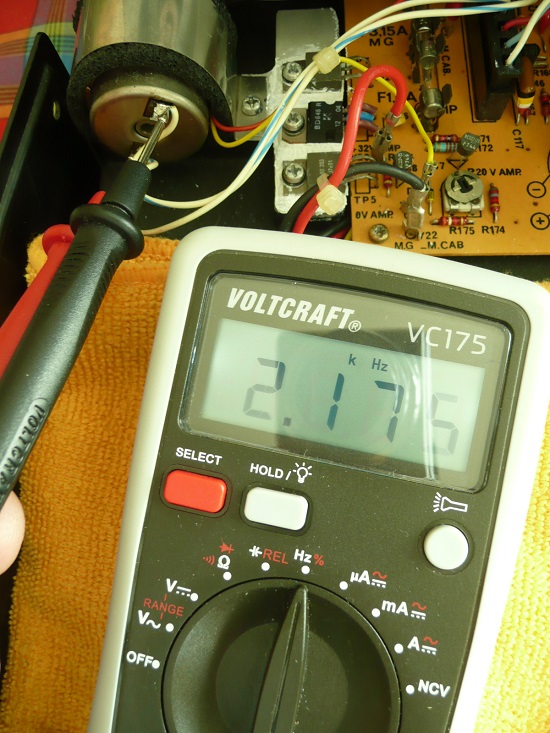

Exemple of Tacho Frequency measure (Here, a BEAULIEU 708EL MONO):

2,175Khz or 2175 Hz.

B) Second Step

Once “reference” well setted, the idea is to adjust “Claw Main Motor” to "mid range" when playing in Sound mode.

So, Turn off the machine.

1) Set main knob in sound position.

2) Stick on the white strip behind “Buckle Black Sensor” and to the case.

3) Facing the machine, Push Sensor to the left up to the 1St step but do not overpass it. With black fine marker report position on the tape.

4) Release sensor and report its new stop position on tape.

5) Then put a mark on white tape at mid range between Left and right stops reported before.

6) "Power On" the machine, Set main knob on "Sound" mode , and Block sensor with a soft material on "Mid Range" position reported on white tape.

7) With Multimeter, check Frequency from Main Motor Tacho terminals .

8) Observe value is around 500Hz. As necessary set RA6 to reach this value.

Additionnal Info :

RA1 (Also Labelised "E.G") is supposed to adjust Sensor efficiency (more or less Voltage to the tiny bulb located inside "Mask").

That means "Fast" or "Slow" sensor response.

Generally RA1 is set at Mid-Range position, which also increase tiny bulb life and allows a smooth operating.

This is what I did on my projectors. If properly done this “pré-set” procedure works much better than BEAULIEU procedure described in Shop Manual and an oscilloscop is not required.

This procedure takes around 15mn to set the machine

[ August 14, 2017, 10:26 AM: Message edited by: Phil Murat ]

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Phil Murat

Jedi Master Film Handler

Posts: 671

From: Villeneuve St Georges, France

Registered: Dec 2015

|

posted August 15, 2017 09:30 AM

posted August 15, 2017 09:30 AM

Hi Andrew,

Not sure to understand exactly, but at this time , I have not checked all the points, means all the speed range.

But , logically , Capstan Motor Speed has to be proportionate to frequency and can be drawn as a straight line.

Of course, to confirm, I need at least more than 3 points.

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UBBFriend: Email this page to someone!

UBBFriend: Email this page to someone!

Printer-friendly view of this topic

Printer-friendly view of this topic

![[Wink]](wink.gif)

![[Cool]](cool.gif)

![[Smile]](smile.gif)

![[Roll Eyes]](rolleyes.gif)

![[Big Grin]](biggrin.gif)

![[Razz]](tongue.gif)